Abstract

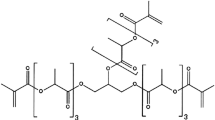

Industrial appliances exploiting biocomposites reinforced with natural fibers have considerably improved in current decades suitable to the advantages of natural fiber durability and environmental friendliness in addition to the advantages of desirable composite characteristics. The current effort uses composites that have up to 20 weight percent (wt%) of fabric derived from coir, a pretty well-known natural fiber from India. Two sets of bio-composites were fabricated using compression molding and two sets of coir fibers with equal lengths of 10 and 20 mm and varied wt% of vinyl ester resin via 0, 5, 10, 15, and 20%. According to experimental findings, bio-composites containing up to 15 wt% have greater tensile, flexural, and impact strength than plain vinyl ester. However, above 15 wt% fiber reinforcement, the mechanical strength has diminished. The biocomposite material with a 20-mm length and 20 wt% coir has a maximum thermal conductivity of 0.3164 W/m K; additionally, water absorption test carried out for all laminated composites.

Similar content being viewed by others

References

Bhoopathi R, Ramesh M, Deepa C (2014) Fabrication and property evaluation of banana-hemp-glass fiber reinforced composites. Procedia Eng 97:2032–2041

Suresh S, Sudhakara D, Vinod B (2019) Investigation of bio-waste natural fiber–reinforced polymer hybrid composite: effect on mechanical and tribological characteristics of biodegradable composites. Mech Soft Mater 1(1):12

Das G, Biswas S (2016) Effect of fiber parameters on physical, mechanical and water absorption behaviour of coir fiber–epoxy composites. J Reinf Plast Compos 35(8):628–637

Wang B, Sain M, Oksman K (2007) Study of structural morphology of hemp fiber from the micro to the nanoscale. Appl Compos Mater 14:89–103

Avella M, Casale L, Dell’erba R, Focher B, Martuscelli E, Marzetti A (1998) Broom fibers as reinforcing materials for polypropylene-based composites. J Appl Polym Sci 68(7):1077–1089

Duigou AL, Davies P, Baley C (2011) Replacement of glass/unsaturated polyester composites by flax/PLLA biocomposites: is it justified? J Biobased Mater Bioenergy 5(4):466–482

Marsavina L, Sadowski T (2007) Stress intensity factors for an interface kinked crack in a bi-material plate loaded normal to the interface. Int J Fract 145(3):237–243

Marsavina L, Linul E, Voiconi T, Sadowski T (2013) A comparison between dynamic and static fracture toughness of polyurethane foams. Polym Test 32(4):673–680

Lebrun G, Couture A, Laperrière L (2013) Tensile and impregnation behavior of unidirectional hemp/paper/epoxy and flax/paper/epoxy composites. Compos Struct 103:151–160

Sapuan SM, Leenie A, Harimi M, Beng YK (2006) Mechanical properties of woven banana fibre reinforced epoxy composites. Mater Des 27(8):689–693

Irawan AP, Sukania IW (2015) Tensile strength of banana fiber reinforced epoxy composites materials. Appl Mech Mater 776:260–263

Wong KJ, Yousif BF, Low KO (2010) The effects of alkali treatment on the interfacial adhesion of bamboo fibres. Proc Inst Mech Eng L: J Mater: Des Appl 224(3):139–148

Parre A, Karthikeyan B, Balaji A, Udhayasankar R (2020) Investigation of chemical, thermal and morphological properties of untreated and NaOH treated banana fiber. Mater Today: Proc 22:347–352

Munshi MR, Alam SS, Haque MM, Shufian A, Rejaul Haque M, Gafur MA, Rahman F, Hasan M (2022) An experimental study of physical, mechanical, and thermal properties of rattan-bamboo fiber reinforced hybrid polyester laminated composite. J Nat Fiber 19(7):2501–2515

Jayabal S, Ramprasath R, Prithivirajan R, Sathiyamurthy S, Christal K (2016) Mechanical performance of bio particulated natural green husk coir fiber-vinyl ester composites. Cellulose 28(35.7):31–33

Udaya Kumar PA, Ramalingaiah S, B., Rajini, N. and Satyanarayana, K.G. (2018) Effect of treated coir fiber/coconut shell powder and aramid fiber on mechanical properties of vinyl ester. Polym Compos 39(12):4542–4550

Anbarasan R, Kalaignan GP, Vasudevan T, Gopalan A (1999) Characterization of chemical grafting of polyaniline onto wool fiber. Int J Polym Anal Charact 5(3):247–256

Balaji A, Sivaramakrishnan K, Karthikeyan B, Purushothaman R, Swaminathan J, Kannan S, Udhayasankar R, Haja Madieen A (2019) Study on mechanical and morphological properties of sisal/banana/coir fiber-reinforced hybrid polymer composites. J Braz Soc Mech Sci Eng 41:1–10

Udhayasankar R, Karthikeyan B, Balaji A (2020) Comparative mechanical, thermal properties and morphological study of untreated and NaOH-treated coconut shell-reinforced cardanol environmental friendly green composites. J Adhes Sci Technol 34(16):1720–1740

Vishal K, Rajkumar K, Sabarinathan P, Arun A (2023) Mechanical and thermal characteristics of steam-exploded silane grafted Kigelia Pinnata fruit (KPF) fiber reinforced vinyl ester polymer composites. Polym Compos 1(1):1–17

Jacob M, Thomas S, Varughese KT (2004) Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos Sci Technol 64(7-8):955–965

Udhayasankar R, Karthikeyan B (2019) Processing of cardanol resin with CSP using compression molding technique. Mater Manuf Process 34(4):397–406

Haque MR, Sajib KH, Haque MM, Zahura FT, Hasan MA, Ahmed SSU, Alam MF, Hasan M, Gafur MA (2023) Mechanical characterization of banana-nylon fibre reinforced Vinyl ester composites. Adv Mater Process Technol 9(3):1–20

ASTM D638, Standard test method for tensile strength of reinforced plastic materials

ASTM D790, Standard test method for flexural strength of reinforced plastic materials

ASTM D256, Standard test method for impact strength of reinforced plastic materials

ASTM D570, Standard test method for water absorption of reinforced plastic materials

Vishal K, Rajkumar K, Nitin MS, Sabarinathan P (2022) Kigelia africana fruit biofibre polysaccharide extraction and biofibre development by silane chemical treatment. Int J Biol Macromol 209:1248–1259

Sabarinathan P, Rajkumar K, Annamalai VE, Vishal K (2020) Characterization on chemical and mechanical properties of silane treated fish tail palm fibres. Int J Biol Macromol 163:2457–2464

Arthanarieswaran VP, Kumaravel A, Kathirselvam M (2014) Evaluation of mechanical properties of banana and sisal fiber reinforced epoxy composites: Influence of glass fiber hybridization. Mater Des 64:194–202

Lin JC, Chang LC, Nien MH, Ho HL (2006) Mechanical behavior of various nanoparticle filled composites at low-velocity impact. Compos Struct 74(1):30–36

Khan SH, Rahman MZ, Haque MR, Hoque ME (2023) Characterization and comparative evaluation of structural, chemical, thermal, mechanical, and morphological properties of plant fibers. In: Annual Plant: Sources of Fibres, Nanocellulose and Cellulosic Derivatives: Processing, Properties and Applications. Singapore, Springer Nature Singapore, pp 1–45

Agunsoye JO, Aigbodion VS (2013) Bagasse filled recycled polyethylene bio-composites: Morphological and mechanical properties study. Results in Physics 3:187–194

Ramprasath R, Jayabal S, Sundaram SK, Bharathiraja G, Munde YS (2016) Investigation on impact behavior of rice husk impregnated coir-vinyl ester composites. Macromol Symp 361(1):123–128

Balaji A, Karthikeyan B, Swaminathan J, Raj CS (2018) Effect of filler content of chemically treated short bagasse fiber-reinforced cardanol polymer composites. J Nat Fiber 16(4):613–627

Reis PNB, Ferreira JAM, Antunes FV, Costa JDM (2007) Flexural behaviour of hybrid laminated composites. Compos A: Appl Sci Manuf 38(6):1612–1620

Gopinath A, Kumar MS, Elayaperumal AJPE (2014) Experimental investigations on mechanical properties of jute fiber reinforced composites with polyester and epoxy resin matrices. Procedia Eng 97:2052–2063

Aggarwal PK, Raghu N, Karmarkar A, Chuahan S (2013) Jute–polypropylene composites using m-TMI-grafted-polypropylene as a coupling agent. Mater Des 43:112–117

Gu Y, Tan X, Yang Z, Zhang Z (2014) Hot compaction and mechanical properties of ramie fabric/epoxy composite fabricated using vacuum assisted resin infusion molding. Mater Des 56:852–861

Sakib S, Haque MR, Haque MM, Faruqi F, Ahmed SSU, Hasan M, Gafur MA (2023) Effect of fibre orientation and stacking sequence on properties of hybrid composites. Mater Sci Technol 39(13):1627–1639

Yan ZL, Wang H, Lau KT, Pather S, Zhang JC, Lin G, Ding Y (2013) Reinforcement of polypropylene with hemp fibres. Compos Part B 46:221–226

Balaji A, Karthikeyan B, Swaminathan J, Sundar Raj C (2018) Thermal behavior of cardanol resin reinforced 20 mm long untreated bagasse fiber composites. Int J Polym Anal Charact 23(1):70–77

Barreto ACH, Rosa DS, Fechine PBA, Mazzetto SE (2011) Properties of sisal fibers treated by alkali solution and their application into cardanol-based biocomposites. Compos A: Appl Sci Manuf 42(5):492–500

Berger H, Kari S, Gabbert U, Rodriguez Ramos R, Bravo Castillero J, Guinovart Diaz R (2007) Evaluation of effective material properties of randomly distributed short cylindrical fiber composites using a numerical homogenization technique. J Mech Mater Struct 2(8):1561–1570

Karkri M (2017) Thermal conductivity of biocomposite materials. Biopolymer Composites in Electronics 129–153

Jawaid M, Khalil HA, Bakar AA, Khanam PN (2011) Chemical resistance, void content and tensile properties of oil palm/jute fibre reinforced polymer hybrid composites. Mater Des 32(2):1014–1019

Shibata S, Cao Y, Fukumoto I (2005) Effect of bagasse fiber on the flexural properties of biodegradable composites. Polym Compos 26(5):689–694

Acknowledgements

We are grateful to the management of Kalaignar Karunanidhi Institute of Technology for acknowledging our research work and encouraging the submission of this paper.

Author information

Authors and Affiliations

Contributions

P.Prabhu - conceptualization, methodology, data curation, writing - original draft.

V. Chokkalingam - supervision, review & editing, validation.

S. Arunkumar – investigation, formal analysis, visualization.

Prakash Perumal – project administration, demonstration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prabhu, P., Chokkalingam, V., Arunkumar, S. et al. The investigation on mechanical, thermal conductivity and water absorption characteristics of coir fiber-reinforced vinyl ester biocomposites. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05273-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05273-2