Abstract

Food packaging plays a significant role in the food industry and has an impact on a number of factors related to the food product and the consumer. Works on biodegradable polymers have been carried out in an effort to solve the issue of the environment being negatively impacted by the growing use of synthetic polymers. The objective of the present work is to compose bionanocomposites that can be used as packaging materials. Polylactic acid (PLA) loaded with (2% w/w) titanium dioxide nanoparticles (TiO2-NPs) nanoparticles (PLA/TiO2) bionanocomposite was successfully prepared. Then, CuO-TiO2 nanocomposite was prepared and added with different concentrations (1, 3, and 5% w.) to the PLA matrix to fabricate PLA/CuO-TiO2 bionanocomposites. Furthermore, the fashioned PLA/CuO-TiO2 bionanocomposites were evaluated via Fourier-transform infrared spectroscopy (FTIR), scanning electron microscope (SEM), transmission electron microscope (TEM), oxygen transmission rate (OTR), water vapor transmission rate (WVTR), and X-ray diffraction pattern (XRD). Moreover, the thermal, mechanical, and antimicrobial properties of the PLA bionanocomposites films were improved upon loading CuO-NPs (1.0, 3.0, and 5.0%) with the supported TiO2-NPs (2% w/w) compared by pure PLA. Moreover, the obtained result confirmed that the prepared PLA/CuO-TiO2 bionanocomposites were monitored seeking enhanced PLA bionanocomposites to be applied as packaging materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Plastic packaging materials are considered among the crucial categories as conserving and packaging products [1,2,3]. However, some complications may arise such as recycling these materials, their non-biodegradable behavior, and the dangerous residues they may leave in soil. The latter problem may generate significant threats for health and the surrounding environment. Hence, novel alternative packaging substrates are demanded with tailored features able to withstand the aforementioned problems. Polylactic acid (PLA) is aliphatic thermoplastic polyester. Also, PLA is biocompatible, biodegradable, and easily processed. It is a linear polymer having high mechanical properties. The latter ones are variable and can be adjustable according to the crystallinity of its nature [4,5,6]. Meanwhile, PLA is a suitable alternative polymer that can substitute undegradable ones in various environmental aspects. PLA can be regarded as an emerging eco-friendly biopolymer and affordable in a low cost. It is originated from natural sources through polymerizing lactic acid or lactide by means of fermenting sugars. The produced polymer varies in molecular weight according to the preparation conditions. Lactic acid possesses 2 stereoisomers. They are L-lactic acid and D-lactic acid. The resulting polymers are poly-L-lactic acid (PLLA) and poly-D-lactic acid (PDLA), respectively. PLA is favored in various implementations such as food packaging, drug delivery, tissue engineering, and biomedical applications. However, applying PLA in some applications may be limited. These obstacles can be correlated to the deficient antimicrobial efficiency of PLA, reduced toughness, and low thermal properties [7, 8]. Therefore, some approaches like blending, copolymerization, and insertion of inorganic fillers such as clays, alumina, carbon nanotubes, and titania into PLA can provide convenient solutions to improve the performance of PLA.

Recently, nanocomposites of PLA loaded with metal or metal oxide nanoparticles attracted the attention of researchers due to their environmental interests [9,10,11]. These concerns are boosted due to the reasonable physical, thermal, optical, and mechanical properties of these nanoparticles. They can be utilized in various applications such as drug delivery, wound healing, food packaging, and biosensors. The physico-chemical features of these nanoparticles are influenced by their high plasmon excitation activities with free surface electrons. Titanium dioxide nanoparticles (TiO2-NPs) with dimension less than 100 nm are among the emerging materials that exhibit hydrophilic, biocompatible, and photocatalytic behaviors. TiO2-NPs can prohibit utmost of the ultraviolet (UV) light. Hence, it retards the decomposition of the polymer and extends its durability upon being exposed to UV radiation [12, 13]. Furthermore, TiO2 is able to withstand the bacterial growth on the polymeric surfaces. It can generate the transfer of electron to the conductive band in the presence of light. So, it supports the oxidative strength of different substrates to create energetic moieties such as radicals. The later ones can stimulate the self-demolition process of bacteria.

Nowadays, these nanoparticles are applied as potential active packaging sheets. Some studies focused on enhancing the dissemination of nanoparticles inside the polymeric domain [14, 15], by means of in situ polymerization, melt, or solution mixing. PLA/TiO2 composites were prepared through mixing TiO2-NPs with PLA matrix [16]. These nanoparticles were chemically treated for a superior dispersion into the PLA matrix [17]. PLA/TiO2 bionanocomposites were investigated for estimating their antibacterial properties. The existence of titania did not change drastically the structure of the PLA matrix. Moreover, these nanoparticles altered the size of bacteria with reducing the extracellular polymeric substances. This antibacterial behavior succeeded to withstand the bacterial growth and the emergence of biofilm. Copper is a substantial metal in some foods where its salts or ions show noticeable antimicrobial effectiveness. It is capable of diminishing the fatal bacterial contagions [18]. Copper oxide (CuO-NPs) can be loaded into polymers to produce physically and chemically stable composites. They are recognized as antimicrobial agents for biopolymer-based films [19]. Thereafter, CuO-NPs are applied in cosmetics, food packaging, and pharmaceutical applications such as toothpastes, masks, and bandages.

In the present work, we attempt to prepare modified PLA films for packaging applications. The improvement of these films takes place via loading PLA with TiO2 nanoparticles followed by doping it with CuO nanoparticles for enhanced antimicrobial properties upon being used as a packaging material.

2 Materials and methods

2.1 Materials

Polylactic acid (PLA) Mw ~ 60,000 was obtained from Sigma Aldrich. Titanium dioxide nanoparticles (TiO2-NPs)—99.5% with particle size > 40 nm, copper nitrate (Cu (NO3)2), and sodium hydroxide (NaOH) were supplied from Sigma Aldrich, USA.

2.1.1 Microbial strains

The pathogenic strains used in the antimicrobial activity test are Staphylococcus aureus (ATCC 6538), Listeria monoytogenes (598), Bacillus cereus (B-3711), Escherichia coli (ATCC 8739), Salmonella typhimurium (14028s), and Aspergillus flavus (B-3357). All strains were obtained from Egypt’s National Research Centre’s Microbiological Lab.

2.2 Methods

2.2.1 Preparation of CuO-TiO2 nanocomposites

CuO-TiO2 nanocomposites were fabricated according to the following methods. Initially, TiO2-NPs were well dispersed in 50 mL of deionized water. Then, copper nitrate solution (0.1 M) as well as (0.1 M) sodium hydroxide (NaOH) solution were added gradually to TiO2-NPs suspension solution under strong stirring up to pH 14 where a black precipitate was formed. The precipitates of CuO-TiO2 nanocomposites were washed thoroughly with deionized water and absolute ethanol until pH 7 was acquired. The washed CuO-TiO2 nanocomposites were dried in an electric oven at 70 °C for 8 h and calcinated by heating at 450 °C for 3 h to assure the preparation of CuO-TiO2 nanocomposites.

2.2.2 Preparation of PLA/CuO-TiO2 bionanocomposites

PLA/CuO-TiO2 bionanocomposites were prepared using different concentrations (1.0, 3.0, and 5.0% w/w) of CuO-TiO2 nanocomposites. Firstly, 10 gm of PLA was dissolved in 100 mL dichloromethane, and then this solution was divided into 5 beakers, each one containing 20 mL of PLA solution. In addition, PLA solutions (10% w/v) were prepared separately as blank for comparison. Also, PLA/TiO2 bionanocomposite was fabricated by adding 0.2 gm of TiO2-NPs to the 10 mL of PLA solution. Thereafter, the CuO-TiO2 nanocomposites were added at the ratios of 1.0, 3.0, and 5.0% w/w to different aliquots of the prepared PLA solution. The PLA/TiO2 and PLA/CuO-TiO2 bionanocomposites were prepared by a steady addition of CuO-TiO2 nanocomposites suspension solutions to the PLA solution and sonicated for 15 min at room temperature, 500 W, frequency, 20 kHz, and amplitude 50% using ultrasonic homogenizer (Q500 Sonicator, Qsonica, USA). The solutions of PLA/CuO-TiO2 bionanocomposites were moved into a Teflon dish and left at room temperature for 24 h in order to vaporize the solvent and then produce PLA/CuO-TiO2 nanocomposite film.

2.2.3 Characterization of PLA/CuO-TiO2 bionanocomposites

Fourier transform infrared spectroscopy (FTIR, Model: Perkin Elmer) was used to investigate the functional groups expanded on the prepared solids’ surface. Samples disks were scanned over the wavenumber range between 400 and 4000 cm−1 at a resolution of 4 cm−1. X-ray diffraction (XRD) patterns of the prepared samples were analyzed by Brucker D8 Advance X-ray diffractometer. The voltage of Cu Kα is 40 kV and a current of 40 mA. Its 2θ ranged between 5 to 70°. The fractured surfaces of the tested bionanocomposites were investigated after being immersed in liquid nitrogen. The morphology of the samples was perceived by a scanning electron microscope (JEOL, JSM-6360LA, Japan). Thermogravimetric analyses (TGA) were carried out by means of Perkin Elmer TGA7. The samples were encapsulated in aluminum pans. They were heated in the range of 25 to 500 °C with a heating rate of 5 °C/min. The mechanical properties in terms of tensile stress and tensile strain at break for PLA/CuO-TiO2 nanocomposites containing different concentrations (1.0, 3.0, and 5.0% w/w) of CuO-TiO2 nanocomposites were evaluated by an Instron 34SC-5 universal tensile testing machine (UK) equipped with a load cell of 5 kN and a crosshead speed of 10 mm.min−1, according to ASTM D 882–18. The dumbbell specimens were die-cut from the casted films. Prior to testing, all specimens were conditioned at a temperature of 23 ± 2 °C and 50 ± 5% relative humidity for at least 24 h. The average of three parallel trails for each film was recorded.

The oxygen transmission rate (OTR) values of the composite films were measured using N530 B Gas Permeability Analyzer (China), as per the standards followed by ASTM D1434-82(2003). The film was fixed into the sample chamber. Thereafter, it passed through O2 to ensure complete removal of air, followed by testing. The results were averaged after being examined three times for each sample. The water vapor transmission rate (WVTR) was measured using the cup method utilizing the GBI W303 (B) Water Vapor Permeability Analyzer (China). The mass of water vapor that traveled over a unit area in a unit time at a controlled temperature (38 °C) and humidity (4%) was another factor used to compute WVTR (TAPPI Form 464).

2.2.4 The antimicrobial activity of PLA/CuO-TiO2 bionanocomposite plastic films

The antimicrobial activity of different PLA/CuO-TiO2 bionanocomposite plastic films was carried out by agar well diffusion method using nutrient agar medium according to [20]. The nutrient agar was transferred into the petri dishes and permitted to harden. A total of 0.1 mL of the activated tested microbes was feasted on the surface of the agar using a sterile swab individually. Plates were dried at 37 °C for 1 h, and discs of 0.5 cm diameter of each bionanocomposite plastic film were ready; then the plates were incubated at 37 °C for 24 h. The inhibition zone around each well was measured in millimeters.

3 Results and discussion

3.1 FTIR evaluations

FTIR spectra representing PLA, PLA/TiO2 bionanocomposite in the presence and absence of CuO nanoparticles are shown in Fig. 1. Characteristic peaks for neat PLA appear at 1745 cm−1 corresponding to C = O (stretching) and -CH3 symmetric and asymmetric at 2945 and 2998 cm−1, respectively. A stretching sharp peak arises at 1085 cm−1 of C-O. In addition, other bands can be noticed at 1359 and 1452 cm−1 for symmetric and asymmetric -CH3 groups. For TiO2 nanoparticles, the peak at 3426 cm−1 shows a characteristic band for the OH group of TiO2 nanoparticles.

3.2 XRD analysis of PLA-based films

Figure 2 illustrates the XRD patterns of PLA-based films. Characteristic peaks for PLA appear at 17° and 19.6°. They refer to 200/100 and 210 phase planes of PLA. Upon loading PLA with TiO2-NPs, no significant changes can be observed for PLA peaks. Meanwhile, a peak arises at 2Ɵ = 25.56°. It denotes to TiO2 nanoparticles. The latter peak coincides with rutile and anatase forms of titania [15]. The polymeric networks of PLA and its composites keep the amorphous structure. XRD peaks assert the presence of CuO after being doped into PLA/TiO2 nanocomposite. Distinctive maxima appear at 2Ɵ = 32.4°, 35.5°, 38.6°, and 48.7°. They determine different planes of CuO which are 110, 002, 200, and 202, respectively.

3.3 Morphological investigations

The morphology of the prepared PLA bionanocomposites samples was investigated through scanning electron microscopy (SEM). Figure 3 shows the morphology of the prepared PLA and its bionanocomposites. Pure PLA had a relatively flat and smooth surface (Fig. 3a). Surfaces of the PLA bionanocomposites were found to be substantially more coarse and irregular with the addition of 2% TiO2-NPs (Fig. 3b). SEM imaging was insufficient to distinguish the TiO2-NPs from the surface morphology due to the low concentration of the TiO2-NPs which added to the PLA matrix. In the PLA bionanocomposites, there was no phase separation that could be seen. Additionally, the polymer matrix showed aggregation when CuO-TiO2 nanocomposites were added at various concentrations. This aggregation was boosted by increasing the loading of CuO-TiO2 nanocomposites from 1 to 5% in the PLA matrix, as shown in Fig. 3c and d, respectively. In general, significant interfacial interaction between the inorganic and organic phases is achieved by chemically attaching polymer chains that cope the polymer matrix with inorganic nanoparticles [21, 22].

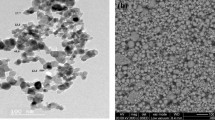

In Fig. 4, the transmission electron microscopy (TEM) images of TiO2, CuO-TiO2, and PLA/CuO-TiO2 are shown. In Fig. 4a, TiO2 nanoparticles can be easily recognized and well distributed, with an average size of 40 nm. They appear as tiny crystals with few agglomerations. Figure 4b demonstrates the TEM image for CuO-TiO2. The CuO-NPs were as spherical highly dispersed nanoparticles with the TiO2 nanoparticles, and their average diameters lie in the range of 10–15 nm. In Fig. 4c, TiO2 and CuO seem to be integrating together as spherical shapes referring to the original shapes of these nanoparticles inside the PLA matrix.

3.4 Mechanical properties of the prepared PLA/CuO-TiO2 bionanocomposites

The mechanical properties of the prepared PLA/CuO-TiO2 bionanocomposites films loaded with various concentrations of CuO-TiO2 nanocomposites and pure PLA are displayed in Table 1. Increased loading of CuO-TiO2 nanocomposites up to 5% greatly increased their tensile strength, and the aggregation of undispersed CuO-TiO2 nanocomposites is most likely responsible for the decrease in elongation (%) properties. Table 1 displays the tensile strength and elongation properties of the fabricated PLA/CuO-TiO2 bionanocomposites films containing 2% TiO2-NPs as well as different concentrations of CuO-TiO2 nanocomposites. The fabricated TiO2 bionanocomposite film displayed good mechanical properties compared with pure PLA where the tensile strength was increased from 45.34 MPa for pure PLA to 49.52 MPa for PLA/TiO2 bionanocomposite. Moreover, the elongation was reduced from 5.6% for pure PLA to 3.2% for PLA/TiO2 bionanocomposite. Correspondingly, the tensile strength was improved by increasing the CuO-TiO2 nanocomposites concentrations (0.0, 1.0, 3.0, and 5.0%) to be 45.34, 51.87, 60.54, and 65.23 MPa, respectively.

Moreover, the elongation at break decreased upon increasing the loadings of CuO-TiO2 nanocomposites to be 5.6, 2.8, 2.1, and 1.8%, respectively. This behavior might be due to the high CuO-TiO2 nanocomposite concentrations that result in nanoparticle aggregation according to the SEM observations. Furthermore, the tensile strength boosted, and elongation at break decreased. It could be ascribed to restricted polymer chain movement owing to CuO-TiO2 nanocomposites restraining the polymer chains. Commonly, the mechanical properties of PLA/CuO-TiO2 bionanocomposites are a function of the nanoparticle dispersion state in the polymer matrix as well as the degree of interactions between the bionanocomposites chains and nanoparticles. Therefore, the superior mechanical performances of PLA/CuO-TiO2 bionanocomposites can be due to the fact that the stress transmission at the interface between the matrix and nanofiller is more efficient with the CuO-TiO2 nanocomposites morphology than with the spherical shape alone. Accordingly, compared to a single nanoparticle, the developed PLA bionanocomposites with CuO-TiO2 nanocomposites established promising mechanical properties.

3.5 Thermal examination of PLA/CuO-TiO2 bionanocomposites

Determining the thermal stability through the decomposition temperatures of the samples was carried out by thermogravimetric analysis (TGA). Figure 5a represents the percentage of weight versus the heating temperature for PLA and its composites. The decomposition process of the investigated samples took place across a single stage. The primary weight loss is 52–103 °C referring to the release of moisture from the samples. A considerable loss in the weight can be noticed in the temperature range of 231–387 °C referring to PLA decomposition. The latter originated from intramolecular trans-esterification for cyclic oligomers in these polymeric chains [23]. At higher temperatures, complete degradation for the polymeric matrix is attained. The same thermal behavior is followed for PLA/TiO2 bionanocomposite, but the weight loss showed a sharper inclined slope than that of neat PLA. It implies a quicker release of volatile materials due to the presence of TiO2-NPs. The thermogram of the PLA/CuO-TiO2 bionanocomposites loaded with different contents of CuO-NPs is located at relatively higher temperatures than that of the pristine PLA.

Depositing CuO nanoparticles into the PLA matrix showed an enhancement in the thermal stability of the explored composites. The boosted thermal stability can be correlated to the surface catalytic effect of CuO-NPs. The latter reinforces the backbone of PLA through generating C = C double bonds. Meanwhile, alongside complex formation effect of CuO-NPs may arise. Copper ions participate in the complex formation with the OH groups of PLA [24]. In Fig. 5b, the derivative thermo-gravimetric (DTG) curves emphasize the results. They display a major weight loss peak due to decomposition in the range of 350–370 °C. This peak denotes to the thermal degradation of PLA. The accompanied shifts in the investigated samples vary according to various loadings of TiO2 and CuO-NPs into the PLA matrix. Sharper peaks appear upon adding TiO2-NPs when compared with pristine PLA. These nanoparticles retard the decomposition of PLA at lower temperatures but expedited the degradation at higher temperatures [25].

3.6 Barrier properties of the prepared PLA/CuO-TiO2 bionanocomposites

Figure 6a demonstrates the results of the WVTR showing the capability of penetration of water through PLA and its prepared composites. It is a substantial factor in determining the barrier properties of PLA upon being applied as a packaging material. The hydrophilicity and pore size influence WVTR values of the tested substrates expressing the highest barrier versus moisture permeability. Neat PLA shows a lower WVTR value than the other PLA/CuO-TiO2 bionanocomposites containing different concentrations (1.0, 3.0, and 5.0% w/w) of CuO-TiO2 nanocomposites. The presence of TiO2-NPs followed by doping with CuO-NPs permitted a more facile passage of water vapor. The WVTR values of the prepared PLA bionanocomposites were increased by the addition of TiO2-NPs and CuO-TiO2 nanocomposites increased compared with pure PLA films as revealed in Fig. 6a.

Correspondingly, the oxygen transmission rate (OTR) is a major guide to estimate the passage of oxygen through the packaging substrate. Subsequently, the lower the oxygen permits, the longer preservation time can be obtained for the packed product, for a better sealing and isolation from the external surrounding medium. Figure 6b shows OTR results for PLA-based composites after being subjected to a high pressure. Neat PLA showed the highest OTR value among the investigated samples. Introducing TiO2 to PLA led to a decrease in the magnitude of OTR when compared to that of pristine PLA. This stage was followed by gradual decrements in the OTR values upon increasing the content of CuO-TiO2 nanocomposites. Raising the concentration of nanoparticles either TiO2 or CuO inside the polymeric matrix led to impede the transmission of oxygen gradually from or into these films with a decrement in OTR values and denote to an enhancement in oxygen barrier capacity of the prepared PLA/CuO-TiO2 bionanocomposites. The latter property may be correlated to a relatively crystalline structure arising in the tested bionanocomposites. Moreover, the well-spread TiO2-NPs as well as CuO nanoparticles assisted in immobilizing the polymeric chains heading to a lower diffusion into the PLA network [26].

3.7 Assessment of the antibacterial activity

The antimicrobial effects of fabricated PLA/TiO2 bionanocomposite plastic films doped with (1, 3, and 5%) CuO-NPs against various pathogenic strains are shown in Table 2. The addition of different concentrations of CuO-NPs in the films significantly increased the diameter of zone inhibition. The PLA/CuO-TiO2 bionanocomposite films inhibited Gram-negative bacteria (L. monoctogenes, S. typhmirum, and E. coli) as well as Gram-positive bacteria (S. aureus and B. cereus) and mould (A. flavus). The zone of inhibition in PLA/TiO2 doped with 1% CuO-NPs bionanocomposites films ranged from 3 to 9 mm depending on the strain. This inhibition effect was significantly enhanced with 3% CuO-NPs films, with the zone of inhibition ranging from 7 to 13 mm, and increased with 5% CuO-NPs films, with the zone of inhibition ranging from 12 to 17 mm. This feature could be attributed to the presence of TiO2 and CuO nanoparticles [27, 28]. Moreover, the CuO-NPs possess an effective bactericidal action. This is consistent with the findings of [20, 29], who proposed that copper nanoparticles have a positive charge and may adhere to bacterial cell walls, resulting in an effective bactericidal action.

4 Conclusions

In the current study, PLA bionanocomposites were successfully fabricated using 2% w/w of TiO2 nanoparticles, and different contents of CuO-TiO2 nanocomposites were prepared through the casting method. The morphology of the prepared PLA bionanocomposites was examined using SEM and TEM techniques. The obtained results display that TiO2-NPs and CuO-TiO2 nanocomposites were well dispersed in the PLA matrix. TGA results demonstrate that the introduction of TiO2-NPs and CuO-TiO2 nanocomposites enhanced the thermal stability of the prepared bionanocomposites. The mechanical and permeability properties were improved upon loading the TiO2-NPs and CuO-TiO2 nanocomposites to the PLA matrix. These findings deliver novel PLA bionanocomposites which can lead to eco-friendly disposable polymer wastes when applied in food packaging applications.

Data availability

All data generated or analyzed during this study are included in this published article and are available from the corresponding author on reasonable request.

References

Stark NM, Matuana LM (2021) Trends in sustainable biobased packaging materials: a mini review. Mater Today Sustain 15:100084

Youssef AM, Abd El-Aziz EM, Morsi SMM (2022) Development and evaluation of antimicrobial LDPE/TiO2 nanocomposites for food packaging applications. Polym Bull 80:5417–5431

Saleh HM, Khalil AM (2022) Plastic films based on waste expanded polystyrene loaded with bagasse powder for packaging applications. Egypt J Chem 65(11):323–329

Moustafa H, El-Sayed SM, Youssef AM (2023) Synergistic impact of cumin essential oil on enhancing of UV-blocking and antibacterial activity of biodegradable poly (butylene adipate-co-terephthalate)/clay platelets nanocomposites. J Thermoplast Compos Mater 36(1):96–117

Fiore A, Park S, Volpe S, Torrieri E, Masi P (2021) Active packaging based on PLA and chitosan-caseinate enriched rosemary essential oil coating for fresh minced chicken breast application. Food Packag Shelf Life 29:100708

Rojas A, Velásquez E, Patiño Vidal C, Guarda A, Galotto MJ, López de Dicastillo C (2021) Active PLA packaging films: effect of processing and the addition of natural antimicrobials and antioxidants on physical properties, release kinetics, and compostability. Antioxidants 10(12):1976

DeStefano V, Khan S, Tabada A (2020) Applications of PLA in modern medicine. Eng Regen 1:76–87

Priyadarshini B, Rama M, Chetan, Vijayalakshmi U (2019) Bioactive coating as a surface modification technique for biocompatible metallic implants: a review. J Asian Ceram Soc 7(4):397–406

Mulla MZ, Rahman Md RT, Marcos B, Tiwari B, Pathania S (2021) Poly lactic acid (PLA) nanocomposites: effect of inorganic nanoparticles reinforcement on its performance and food packaging applications. Molecules 26(7):1967

Chong WJ, Shen S, Li Y, Trinchi A, Pejak D, Kyratzis IL, Sola A, Wen C (2022) Additive manufacturing of antibacterial PLA-ZnO nanocomposites: benefits, limitations and open challenges. J Mater Sci Technol 111:120–151

Loyo C, Moreno-Serna V, Fuentes J, Amigo N, Sepúlveda FA, Andrés Ortiz J, Rivas LM, Ulloa MT, Benavente R, Zapata PA (2022) PLA/CaO nanocomposites with antimicrobial and photodegradation properties. Polym Degrad Stab 197:109865

Zeljko M, Bulatović VO, Blažic R, Blagojević SL (2022) The development of eco-friendly UV-protective polyacrylate/rutile TiO2 coating. J Appl Polym Sci 139(25):e52393

Ait-Touchente Z, Khalil AM, Simsek S, Boufi S, Luis FV, Ferreira MR, Vilar RT, Chehimi MM (2020) Ultrasonic effect on the photocatalytic degradation of Rhodamine 6G (Rh6G) dye by cotton fabrics loaded with TiO2. Cellulose 27(2):1085–1097

De Falco G, Porta A, Petrone AM, Del Gaudio P, El Hassanin A, Commodo M, Minutolo P, Squillace A, D’Anna A (2017) Antimicrobial activity of flame-synthesized nano-TiO2 coatings. Environ Sci Nano 4:1095–1107

González S, Edwin A, Olmos D, Lorente MÁ, Vélaz I, González-Benito J (2018) Preparation and characterization of polymer composite materials based on PLA/TiO2 for antibacterial packaging. Polymers 10(12):1365

Raquez JM, Habibi Y, Murariu M, Doubois P (2013) Polylactide (PLA)-based nanocomposites. Prog Polym Sci 38:1504–1542

Kaseem M, Hamad K, Ur Rehman Z (2019) Review of recent advances in polylactic acid/TiO2 composites. Materials 12(22):3659

Esmailzadeh H et al (2021) CuO/LDPE nanocomposite for active food packaging application: a comparative study of its antibacterial activities with ZnO/LDPE nanocomposite. Polym Bull 78(3):1671–1682

Kalia A, Kaur M, Shami A, Jawandha SK, Alghuthaymi MA, Thakur A, Abd-Elsalam KA (2021) Nettle-Leaf extract derived ZnO/CuO nanoparticle-biopolymer-based antioxidant and antimicrobial nanocomposite packaging films and their impact on extending the post-harvest shelf life of guava fruit. Biomolecules 11(2):224

Youssef AM, Assem FM, El-Sayed HS, El-Sayed SM, Elaaser M, Abd El-salam MH (2020) Synthesis and evaluation of eco-friendly carboxymethyl cellulose/polyvinyl alcohol/CuO bionanocomposites and their use in coating processed cheese. RSC Adv 10(62):37857–37870

Li S, Meng Lin M, Toprak MS, Kim DK, Muhammed M (2010) Nanocomposites of polymer and inorganic nanoparticles for optical and magnetic applications. Nano Rev 1(1):5214

Bustamante-Torres M, Romero-Fierro D, Arcentales-Vera B, Pardo S, Bucio E (2021) Interaction between filler and polymeric matrix in nanocomposites: magnetic approach and applications. Polymers 13(17):2998

Kopinke F-D et al (1996) Thermal decomposition of biodegradable polyesters—II. Poly (lactic acid). Polym Degrad Stab 53(3):329–342

Gandhi S, Subramani R, Ramakrishnan T, Sivabalan A, Dhanalakshmi V, Nair MR, Anbarasan R (2010) Ultrasound assisted one pot synthesis of nano-sized CuO and its nanocomposite with poly (vinyl alcohol). J Mater Sci 45(6):1688–1694

Marra A, Silvestre C, Kujundziski AP, Chamovska D, Duraccio D (2017) Preparation and characterization of nanocomposites based on PLA and TiO2 nanoparticles functionalized with fluorocarbons. Polym Bull 74(8):3027–3041

Chi H et al (2018) Effect of high pressure treatment on poly (lactic acid)/Nano–TiO2 composite films. Molecules 23(10):2621

Youssef AM, El-Sayed SM (2018) Bionanocomposites materials for food packaging applications: concepts and future outlook. Carbohyd Polym 193:19–27

Youssef AM, El-Sayed HS, Islam EN, El-Sayed SM (2021) Preparation and characterization of novel bionanocomposites based on garlic extract for preserving fresh Nile tilapia fish fillets. RSC Adv 11(37):22571–22584

Harikumar PS, Aravind A (2016) Antibacterial activity of copper nanoparticles and copper nanocomposites against Escherichia coli bacteria. Int J Sci 5(2):83–90

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors wish to gratefully acknowledge the National Research Centre (NRC), Egypt, for supporting the current work through; Project No: 13020209.

Author information

Authors and Affiliations

Contributions

Ahmed M. Khalil, Samah M. El-Sayed, and Ahmed M. Youssef: conceptualization, formal analysis, investigation, methodology, resources, supervision, validation, writing—original draft, writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khalil, A.M., El-Sayed, S.M. & Youssef, A.M. Valorization of polylactic acid bionanocomposites enriched with CuO-TiO2 for packaging applications. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05152-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05152-2