Abstract

Kraft lignin was oligomerised using a bulk laccase solution in varying amounts of buffer and ethanol solvents. The activity of laccase and kinetic parameters was analysed by adjusting the buffer pH and ethanol:buffer ratio. The qualitative weighted average molecular weight (Mw) distribution showed significant variation when ethanol (40:60) solvent was used. GPC analysis confirmed the presence of fractions with higher molecular weight, where the Mw after 30 min was 7859, compared to 90 min in the buffer medium, where Mw was only 1779. These condensed units exhibited lower antioxidant values, characteristic of a polymerisation reaction. Py-GC/MS analysis demonstrated that the sample with the highest molecular weight displayed increased G-type lignin units and higher levels of polysaccharides residue compared to the original kraft lignin. The addition of ethanol as a green solvent, mixed with buffer, resulted in a 4.4-fold increase in Mw compared to buffer alone. These findings highlight the advantageous role of ethanol as a medium to obtain lignin units with high molecular weight.

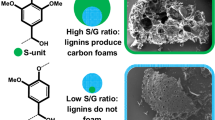

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available upon request.

References

Agustin MB, Carvalho DM, Lahtinen MH et al (2021) Laccase as a tool in building advanced lignin-based materials. ChemSusChem. 14:4615–4635. https://doi.org/10.1002/cssc.202101169

Ai M-Q, Wang F-F, Huang F (2015) Purification and characterization of a thermostable laccase from Trametes trogii and its ability in modification of kraft lignin. J Microbiol Biotechnol. 25:1361–1370. https://doi.org/10.4014/jmb.1502.02022

Asgher M, Noreen S, Bilal M (2017) Enhancement of catalytic, reusability, and long-term stability features of Trametes versicolor IBL-04 laccase immobilized on different polymers. Int J Biol Macromol. 95:54–62. https://doi.org/10.1016/j.ijbiomac.2016.11.012

Bissaro B, Várnai A, Røhr ÅK, Eijsink VGH (2018) Oxidoreductases and reactive oxygen species in conversion of lignocellulosic biomass. Microbiol Mol Biol Rev. 82. https://doi.org/10.1128/MMBR.00029-18

Bolaño C, Palanti S, Benni L, Moldes D (2021) Enhancement of wood biological resistance and fire retardant properties after laccase assisted enzymatic grafting. Forests 12:1102. https://doi.org/10.3390/f12081102

Bourbonnais R, Paice MG, Reid ID et al (1995) Lignin oxidation by laccase isozymes from Trametes versicolor and role of the mediator 2,2’-azinobis(3-ethylbenzthiazoline-6-sulfonate) in kraft lignin depolymerization. Appl Environ Microbiol. 61:1876–1880. https://doi.org/10.1128/aem.61.5.1876-1880.1995

Bourque H, Laurin I, Pézolet M et al (2001) Investigation of the poly( <scp>l</scp> -lactide)/poly( <scp>d</scp> -lactide) stereocomplex at the air−water interface by polarization modulation infrared reflection absorption spectroscopy †. Langmuir 17:5842–5849. https://doi.org/10.1021/la0009792

Camarero S, Galletti GC, Martínez AT (1997) Demonstration of in situ oxidative degradation of lignin side chains by two white-rot fungi using analytical pyrolysis of methylated wheat straw. Rapid Commun Mass Spectrom. 11:331–334. https://doi.org/10.1002/(SICI)1097-0231(19970228)11:4<331::AID-RCM844>3.0.CO;2-H

Cheng H-H, Whang L-M (2022) Resource recovery from lignocellulosic wastes via biological technologies: advancements and prospects. Bioresour Technol. 343:126097. https://doi.org/10.1016/j.biortech.2021.126097

Cheon M, Chang I, Mohanty S et al (2007) Structural reorganisation and potential toxicity of oligomeric species formed during the assembly of amyloid fibrils. PLoS Comput Biol. 3:e173. https://doi.org/10.1371/journal.pcbi.0030173

Crestini C, Argyropoulos DS (1998) The early oxidative biodegradation steps of residual kraft lignin models with laccase. Bioorg Med Chem. 6:2161–2169. https://doi.org/10.1016/S0968-0896(98)00173-4

de Haro JC, Tatsi E, Fagiolari L et al (2021) Lignin-based polymer electrolyte membranes for sustainable aqueous dye-sensitized solar cells. ACS Sustain Chem Eng. 9:8550–8560. https://doi.org/10.1021/acssuschemeng.1c01882

del Río JC, Gutiérrez A, Hernando M et al (2005) Determining the influence of eucalypt lignin composition in paper pulp yield using Py-GC/MS. J Anal Appl Pyrolysis. 74:110–115. https://doi.org/10.1016/j.jaap.2004.10.010

Domínguez G, Blánquez A, Borrero-López AM et al (2021) Eco-friendly oleogels from functionalized kraft lignin with laccase SilA from Streptomyces ipomoeae : an opportunity to replace commercial lubricants. ACS Sustain Chem Eng. 9:4611–4616. https://doi.org/10.1021/acssuschemeng.1c00113

Du X, Li J, Gellerstedt G et al (2013) Understanding pulp delignification by laccase–mediator systems through isolation and characterization of lignin–carbohydrate complexes. Biomacromolecules 14:3073–3080. https://doi.org/10.1021/bm4006936

Fiţigău IF, Peter F, Boeriu CG (2013) Oxidative polymerization of lignins by laccase in water-acetone mixture. Acta Biochim Pol. 60:817–822

García A, Toledano A, Serrano L et al (2009) Characterization of lignins obtained by selective precipitation. Sep Purif Technol. 68:193–198. https://doi.org/10.1016/j.seppur.2009.05.001

Gouveia S, Fernández-Costas C, Sanromán MA, Moldes D (2012) Enzymatic polymerisation and effect of fractionation of dissolved lignin from Eucalyptus globulus Kraft liquor. Bioresour Technol. 121:131–138. https://doi.org/10.1016/j.biortech.2012.05.144

Gouveia S, Fernández-Costas C, Sanromán MA, Moldes D (2013) Polymerisation of kraft lignin from black liquors by laccase from Myceliophthora thermophila: effect of operational conditions and black liquor origin. Bioresour Technol. 131:288–294. https://doi.org/10.1016/j.biortech.2012.12.155

Huber D, Ortner A, Daxbacher A et al (2016) Influence of oxygen and mediators on laccase-catalyzed polymerization of lignosulfonate. ACS Sustain Chem Eng. 4:5303–5310. https://doi.org/10.1021/acssuschemeng.6b00692

Ibrahim V, Mamo G, Gustafsson P-J, Hatti-Kaul R (2013) Production and properties of adhesives formulated from laccase modified kraft lignin. Ind Crops Prod. 45:343–348. https://doi.org/10.1016/j.indcrop.2012.12.051

Ibrahim V, Mendoza L, Mamo G, Hatti-Kaul R (2011) Blue laccase from Galerina sp.: Properties and potential for kraft lignin demethylation. Process Biochem. 46:379–384. https://doi.org/10.1016/j.procbio.2010.07.013

Kline LM, Hayes DG, Womac AR, Labbé N (2010) Simplified determination of lignin content in hard and soft woods via UV-spectrophotometric analysis of biomass dissolved in ionic liquids. BioResources 5:1366–1383

Lai Y-Y, Huang V-H, Lee H-T, Yang H-R (2018) Stacking principles on π- and lamellar stacking for organic semiconductors evaluated by energy decomposition analysis. ACS Omega. 3:18656–18662. https://doi.org/10.1021/acsomega.8b02713

Laurichesse S, Avérous L (2014) Chemical modification of lignins: towards biobased polymers. Prog Polym Sci. 39:1266–1290. https://doi.org/10.1016/j.progpolymsci.2013.11.004

Lim HY, Yusup S, Loy ACM et al (2021) Review on conversion of lignin waste into value-added resources in tropical countries. Waste Biomass Valori. 12:5285–5302. https://doi.org/10.1007/s12649-020-01307-8

Lim J, Sana B, Krishnan R et al (2018) Laccase-catalyzed synthesis of low-molecular-weight lignin-like oligomers and their application as UV-blocking materials. Chem – An Asian J. 13:284–291. https://doi.org/10.1002/asia.201701573

Lourençon TV, de Lima GG, Ribeiro CSP et al (2021) Antioxidant, antibacterial and antitumoural activities of kraft lignin from hardwood fractionated by acid precipitation. Int J Biol Macromol. 166:1535–1542. https://doi.org/10.1016/j.ijbiomac.2020.11.033

Lourençon TV, Hansel FA, Da Silva TA et al (2015) Hardwood and softwood kraft lignins fractionation by simple sequential acid precipitation. Sep Purif Technol. 154. https://doi.org/10.1016/j.seppur.2015.09.015

Lu Y, Lu Y-C, Hu H-Q et al (2017) Structural characterization of lignin and its degradation products with spectroscopic methods. J Spectrosc 2017:1–15. https://doi.org/10.1155/2017/8951658

Lund M, Ragauskas AJ (2001) Enzymatic modification of kraft lignin through oxidative coupling with water-soluble phenols. Appl Microbiol Biotechnol. 55:699–703. https://doi.org/10.1007/s002530000561

Matos M, Claro FC, Lima TAM et al (2021) Acetone:water fractionation of pyrolytic lignin improves its antioxidant and antibacterial activity. J Anal Appl Pyrolysis. 156:105175. https://doi.org/10.1016/j.jaap.2021.105175

Mattinen M-L, Suortti T, Gosselink RJA et al (2008) Polymerization of different lignins by laccase. BioResources 3:549–565

Mattonai M, Tamburini D, Colombini MP, Ribechini E (2016) Timing in analytical pyrolysis: Py(HMDS)-GC/MS of glucose and cellulose using online micro reaction sampler. Anal Chem. 88:9318–9325. https://doi.org/10.1021/acs.analchem.6b02910

Melo TO, Tomasi JDC, Pires OAB et al (2018) Simultaneous pyrolysis and trimethylsilylation with N-methyl-(trimethylsilyl) trifluoroacetamide for the characterisation of lignocellulosic materials from kraft pulping. Holzforschung 72:851–862. https://doi.org/10.1515/hf-2017-0193

Mikkilä J, Trogen M, Koivu KAY et al (2020) Fungal treatment modifies kraft lignin for lignin- and cellulose-based carbon fiber precursors. ACS Omega. 5:6130–6140. https://doi.org/10.1021/acsomega.0c00142

Monyoncho EA, Zamlynny V, Woo TK, Baranova EA (2018) The utility of polarization modulation infrared reflection absorption spectroscopy (PM-IRRAS) in surface and in situ studies: new data processing and presentation approach. Analyst 143:2563–2573. https://doi.org/10.1039/C8AN00572A

Munk L, Sitarz AK, Kalyani DC et al (2015) Can laccases catalyze bond cleavage in lignin? Biotechnol Adv. 33:13–24. https://doi.org/10.1016/j.biotechadv.2014.12.008

Pastorova I, Botto RE, Arisz PW, Boon JJ (1994) Cellulose char structure: a combined analytical Py-GC-MS, FTIR, and NMR study. Carbohydr Res. 262:27–47. https://doi.org/10.1016/0008-6215(94)84003-2

Rashid T, Kait CF, Murugesan T (2016) A “Fourier transformed infrared” compound study of lignin recovered from a formic acid process. Procedia Eng. 148:1312–1319. https://doi.org/10.1016/j.proeng.2016.06.547

Re R, Pellegrini N, Proteggente A et al (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med. 26:1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Rico A, Rencoret J, del Río JC et al (2014) Pretreatment with laccase and a phenolic mediator degrades lignin and enhances saccharification of Eucalyptus feedstock. Biotechnol Biofuels. 7:6. https://doi.org/10.1186/1754-6834-7-6

Salvachúa D, Katahira R, Cleveland NS et al (2016) Lignin depolymerization by fungal secretomes and a microbial sink. Green Chem. 18:6046–6062. https://doi.org/10.1039/C6GC01531J

Sana B, Chia KHB, Raghavan SS et al (2017) Development of a genetically programed vanillin-sensing bacterium for high-throughput screening of lignin-degrading enzyme libraries. Biotechnol Biofuels. 10:32. https://doi.org/10.1186/s13068-017-0720-5

Savikhin V, Toney MF (2019) Organic thin-film microstructure characterization. In: Handbook of organic materials for electronic and photonic devices. Elsevier, pp 489–528

Schuerch C (1952) The solvent properties of liquids and their relation to the solubility, swelling, isolation and fractionation of lignin. J Am Chem Soc. 74:5061–5067. https://doi.org/10.1021/ja01140a020

Shi Y, Chai L, Tang C et al (2013) Biochemical investigation of kraft lignin degradation by Pandoraea sp. B-6 isolated from bamboo slips. Bioprocess Biosyst Eng. 36:1957–1965. https://doi.org/10.1007/s00449-013-0972-9

Singh G, Arya SK (2019) Utility of laccase in pulp and paper industry: a progressive step towards the green technology. Int J Biol Macromol. 134:1070–1084. https://doi.org/10.1016/j.ijbiomac.2019.05.168

Singh G, Arya SK (2021) A review on management of rice straw by use of cleaner technologies: abundant opportunities and expectations for Indian farming. J Clean Prod. 291:125278. https://doi.org/10.1016/j.jclepro.2020.125278

Srebotnik E, Hammel KE (2000) Degradation of nonphenolic lignin by the laccase/1-hydroxybenzotriazole system. J Biotechnol. 81:179–188. https://doi.org/10.1016/S0168-1656(00)00303-5

Tavares APM, Silva CG, Dražić G et al (2015) Laccase immobilization over multi-walled carbon nanotubes: kinetic, thermodynamic and stability studies. J Colloid Interface Sci. 454:52–60. https://doi.org/10.1016/j.jcis.2015.04.054

Tejado A, Peña C, Labidi J et al (2007) Physico-chemical characterization of lignins from different sources for use in phenol–formaldehyde resin synthesis. Bioresour Technol. 98:1655–1663. https://doi.org/10.1016/j.biortech.2006.05.042

Thá EL, Matos M, Avelino F et al (2021) Safety aspects of kraft lignin fractions: discussions on the in chemico antioxidant activity and the induction of oxidative stress on a cell-based in vitro model. Int J Biol Macromol. 182:977–986. https://doi.org/10.1016/j.ijbiomac.2021.04.103

Vural D, Smith JC, Petridis L (2018) Dynamics of the lignin glass transition. Phys Chem Chem Phys. 20:20504–20512. https://doi.org/10.1039/C8CP03144D

Wang L, Tan L, Hu L et al (2021) On laccase-catalyzed polymerization of biorefinery lignin fractions and alignment of lignin nanoparticles on the nanocellulose surface via one-pot water-phase synthesis. ACS Sustain Chem Eng. 9:8770–8782. https://doi.org/10.1021/acssuschemeng.1c01576

Wexler AS (1964) Characterization of lignosulfonates by ultraviolet spectrometry. Anal Chem. 36:213–221

Zhou M, Fakayode OA, Ren M et al (2023) Laccase-catalyzed lignin depolymerization in deep eutectic solvents: challenges and prospects. Bioresour Bioprocess. 10:21. https://doi.org/10.1186/s40643-023-00640-9

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001.

Author information

Authors and Affiliations

Contributions

Conceptualisation: Claro, F.C., Magalhães, W. L. E.; methodology: Claro, F.C., de Lima, G. G.; validation: Claro, F.C., Matos, M.; formal analysis: de Lima, G. G.; investigation: Claro, F.C., de Lima, T.A.M., Matos M., Avelino, F.; resources: Magalhães W.L.E., Lomonaco D.; data curation: Claro, F.C., de Lima G. G.; writing: Claro F.C., de Lima G. G.; visualisation: de Lima G. G.; supervision and funding acquisition: Magalhães, W.L.E.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOCX 27 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Claro, F.C., de Lima, G.G., de Lima, T.A.M. et al. Characterisation of laccase-mediated lignin polymerisation: implications for molecular weight, thermal stability, and electrical properties. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05040-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05040-9