Abstract

Isatis indigotica Fort. root (Ban-lan-gen, IIR), a traditional Chinese medicine (TCM), has an ancient and well-documented history for its medicinal properties. Aside from epigoitrin, indole alkaloids, and their corresponding derivatives as medicinal ingredients, it also contains lots of biomass such as starch. Herein, a new starch was isolated from IIR and the physicochemical properties such as amylose content, moisture content, ash content, morphology, thermal properties, and crystallography were characterized systematically. The amylose content of IIR starch was 19.84 ± 0.85%, and the size and shape of starch granules is ellipsoidal shape with sizes from 2 to 10 μm. IIR starch exhibited a C-type pattern and had 25.92% crystallinity (higher than that of corn starch). The gelatinization temperature of IIR starch was 58.68–75.41 °C, and its gelatinization enthalpy was ΔHgel = 4.33 J/g. After decocting, the IIR’s residues can be used to prepare anhydro-sugars in a polar aprotic solvent. The total carbon yield of levoglucosan (LG), levoglucosenone (LGO), 5-hydroxymethylfurfural (HMF), and furfural (FF) could reach 69.81% from IIR’s decoction residues in 1,4-dioxane with 15 mM H2SO4 as the catalyst. Further, the residues after dehydration were prepared into biochar by thermochemical conversion and the BET surface area of biochar was 1749.46 m2/g which has good application prospect in soil improvement and alleviates obstacles of IIR continuous cropping.

Similar content being viewed by others

1 Introduction

Isatis indigotica Fort., a member of the Cruciferous family, is native to China, and its dried roots are named Ban-lan-gen [1]. Numerous pharmacological studies have reported that the extracts or isolated compounds of I. indigotica Fort. root (IIR) have anti-inflammatory and antiviral activities and can be further processed into Ban-lan-gen granule which is used in China for the treatment of eruptive epidemic diseases such as hepatitis B [2], pneumonia [3], influenza [4, 5], and so on. IIR is one of the drugs recommended by the Chinese government for the prevention and control of severe acute respiratory syndrome (SARS) in 2003 [6]. During the COVID-19 pandemic, the screening of antiviral Chinese medicines showed that IIR had an obvious inhibitory effect on the new coronavirus [7]. To this date, I. indigotica is widely cultivated in China, and the output of IIR reached 50,000 tons in 2020. According to the standard of China National Medical Products Administration (YBZ-PFKL-2021008), the extraction rate of Ban-lan-gen granules from IIR is only 25 ~ 38%; thus, lots of extracted residues are discarded as waste.

As the storage organ of I. indigotica Fort., IIR contains lots of nutrients such as starch or protein except medicinal ingredients. There were reports in some literature about the lignocellulose contents of IIR, but these data are very different from each other. For example, Li et al. [8] reported that the starch content of IIR was 26.88–43.89%, and Jia et al. [9] found that the contents of starch, reducing sugar, and crude fiber in IIR were 2.36%, 1.30%, and 25.72%, respectively. Although the main reason for this confusion was the inconsistency of determination methods, it showed that IIR and its decoction residues contain a large amount of starch components.

Based on the fact that IIR contains high content biomass, the researchers explored some preliminary IIR utilizations. For instance, Qin et al. [10] used IIR’s decoction residues to prepare organic fertilizer, which can ameliorate the soil microenvironment and improve the disease resistance of Trichosanthes kirilowii Maxim; Li [11] found that the chicken feed prepared from I. indigotica or IIR’s decoction residues can increase the weight of chickens and prevent avian influenza; Wei et al. [12] and Yuan et al. [13] pyrolyzed IIR’s decoction residues to biochars which were used to treat the wastewater containing heavy metal lead ions or restrain soil CO2 emission. Although these preliminary utilizations can consume lots of IIR, the value of these products is cheap and, thus, cannot evoke the enthusiasm of disposal enterprises. Some researchers prepared fermentable sugars from traditional Chinese herb residues and then utilized them to produce high-value products, such as fuel ethanol [14], succinic acid [15], lactic acid [16], polysaccharide [17], xylitol [18], cellulase [19], gellan gum [20], and so on. However, the existence of some bioactive substances and medicine residues in these fermentable sugars is a limiting factor for further application.

Recently, anhydro-sugars derived from biomass combustion or pyrolysis have received extensive attention as a source of fermentable sugars [21], chiral pools, and platform compounds [22]. Among the anhydro-sugars, levoglucosan (1,6-anhydro-β-d-glucopyranose, LG) and levoglucosenone (1,6-anhydro-3,4-dideoxy-β-d-glycero-hex-3-enopyranos-2-ulose, LGO) are more attractive. LG has a huge reserve and can form glucose 6-phosphate to involve the glycolytic pathway by expressing LG kinase (LGK) or obtain glucose by hydrolysis of LG for further fermentation [23,24,25], and LGO comprises a cyclic acetal, chiral carbon, and α,β-unsaturated ketone motif and is suitable for the synthesis of C6 monomer (hexan-1,6-diol), green solvent (cyrene), natural products (such as tetrodotoxin), chiral auxiliaries, and bioactive compounds [26, 27]. At present, the preparation of anhydro-sugars using agricultural wastes such as peanut husk [28], bagasse [29], barley straw [30], and rice husk [31] as raw materials has been studied. For the starch-rich IIR, the preparation of high-value anhydro-sugars is also a worth exploring direction.

Biomass carbonization technology is an important link for comprehensive utilization of biomass waste chain such as agricultural waste [32,33,34], kitchen waste [35], forest-based waste [36], industry-generated waste [37, 38], and poultry waste [39, 40]. Converting residue into biochar at the end of biomass comprehensive utilization can not only avoid secondary environmental hazards, but also realize the complete consumption of waste. Meanwhile, the resulting biochar is a solid carbonaceous material with high aromatization, good stability, large specific surface area, rich pore structure, and strong adsorption capacity. It is widely used to improve soil fertility [41, 42] and overcome obstacles for continuous cropping [43, 44], and as a cost-effective adsorbent for sewage treatment [45, 46].

In this study, a new starch was isolated from IIR scraps through the dry or wet method, and then its physicochemical properties such as amylose content, ash content, morphology, thermal properties, and crystallography were systematically compared with those of corn starch. Simultaneously, anhydro-sugars were prepared from the IIR’s decoction residues in 1,4-dioxane using H2SO4 as the catalyst, and the dehydration residues were further transformed into biochar. The whole utilization process of IIR scraps and IIR’s decoction residues not only avoided the environmental damage caused by traditional Chinese medicine (TCM) residue–disordered treatment but also provided an example of TCM wastes to high-value products.

2 Materials and methods

2.1 Materials

IIR was provided by Hainan Huluwa Pharmaceutical Group Co., Ltd. Corn starch, amylose, 1,4-dioxane (Diox), acetone (Act), 2-butanone (methyl ethyl ketone, MEK), dimethyl carbonate (DMC), tetrahydrofuran (THF), N-methyl pyrrolidone (NMP), methanesulfonic acid (MSA), p-toluenesulfonic acid (TsOH), H2SO4, and KOH were purchased from Aladdin Reagent Co., Ltd. Furfural (FF), 5-hydroxymethylfurfural (HMF), alpha-amylase (EC 3.2.1.1), and glucoamylase (EC 3.2.1.3) were obtained from Sigma-Aldrich. LGO and LG were purchased from Suzhou Carbosynth Co., Ltd. Other chemical reagents were acquired from Tianjin Hengxing Chemical Preparation Co., Ltd.

2.2 Determination of lignocellulose components in IIR scraps or IIR’s decoction residues

The lignocellulosic components (cellulose, hemicellulose, and lignin) in IIR were determined by following the National Renewable Energy Laboratory (NREL)’s analytical procedures [47], and the determination results of each sample were expressed as the average of three replicates. However, it should be noted that this method is biased and inaccurate in the determination of samples containing both cellulose and starch, because IIR mostly comes from the energy storage part of plants. Although the NREL recently presented a new laboratory analytical procedure (LAP) for simultaneous determination of starch and cellulose content, the accuracy of hemicellulose and lignin was sacrificed. To solve this problem, we first determined the total glucose content by two-stage acid hydrolysis as NREL method, which is named glucan, and then determined the starch content by enzymatic hydrolysis shown in the next section. Therefore, in this paper, the given lignocellulosic component mainly includes the content of glucan (cellulose and starch), hemicellulose, and lignin and is calculated according to the equation of the NREL method.

2.3 Determination of the starch and gelatinized starch content

According to the starch liquefaction and saccharification process [48], α-amylase (EC 3.2.1.1) and glucoamylase (EC 3.2.1.3) were sequentially used to degrade the starch components in IIR scraps and gelatinized starch components in its decoction residues.

The dried IIR scraps were weighed, and water (solid–liquid ratio of 1:15) was added; then, the pH value was adjusted to 6.0 with H2SO4, and the samples were gelatinized for 30 min at 110 °C. After cooling to 65 °C, α-amylase (40 U/g IIR scraps) was added and liquefaction was conducted in the water bath at 65 °C for 8 h. During the process of liquefaction, samples were taken and an iodine color reaction was used to verify whether the starch in IIR scrap was completely liquefied. After cooling, the pH value of the liquid was adjusted to 5.0 by H2SO4, and glucoamylase (200 U/g IIR scraps) was added for saccharification at 60 °C for 20 h. After saccharification, an iodine color reaction was also used to detect whether the saccharification was complete.

The liquid samples were vacuum filtered through a quartz fiber filter. The undiluted filtrate can then be analyzed for glucose and other carbohydrates by high-performance liquid chromatography (HPLC). The solid residues were washed with cold water three times and transferred to a 40 °C vacuum oven for drying overnight. The residue masses were obtained by weighing.

The determination method of gelatinized starch content in IIR’s decoction residues was the same as above.

The starch content in IIR scraps and the gelatinized starch content in IIR’s decoction residues were calculated with the following equation:

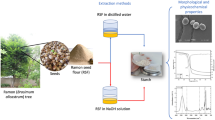

2.4 IIR starch extraction

According to the method of Wei et al. [49], Jiang et al. [50], and Maniglia and Tapia-Blácido [51], with IIR scraps as raw material, starch was extracted by the dry and wet methods (shown in Scheme 1). For the dry method, the IIR scraps were crushed and the powder was directly sieved through 220 meshes. Then, ethanol was added with a ratio of 1:5 (weight). After stirring, alcohol-soluble impurities were removed by centrifugation. The precipitate was then suspended in 0.1% NaOH solution with a ratio of 1:10 (weight). After acid neutralization, the solution was centrifuged, and the middle layer was dried by a spray dryer. For the wet method, IIR scraps were first crushed in water, and then sieved through 220 meshes. The filtrate was centrifuged and precipitated. After drying, ethanol was added at the ratio of 1:5 (weight). The next steps are the same as those of the dry method. The starch yield was calculated as follows (see Scheme 1 for the extraction process):

2.5 Preparation of anhydro-sugars from IIR’s decoction residues

Based on Cao et al.’s [21, 22] report, the preparation of anhydro-sugars from IIR’s decoction residues was performed in a 100-mL EasyChem (E100) reactor (Beijing Century Senlong experimental apparatus, series GB150-2011). The IIR’s decoction residues and Diox (or other solvents) were quantitatively added to the reaction vessel at the solid–liquid ratio of 1:100, and then 40 μL H2SO4 was added to the reaction vessel. The reaction was conducted for 2 h at 190 °C with 7 MPa N2. During dehydration, samples were taken out multiple times from the system. The product carbon yields were calculated from the gas chromatograph (GC) and HPLC detection.

Calculation method of product yield:

2.6 Preparation of biochar from anhydro-sugar residues

After dehydration, the anhydro-sugar residues were filtered and washed three times with deionized water. According to methods of Lin et al. [52] and Cui et al. [53], the dry anhydro-sugar residues was mixed with KOH in a mass ratio of 1:2, dissolved in 25 mL deionized water, thoroughly stirred, and dried. Then, the mixture was pyrolyzed in a tubular furnace at 800 °C for 4 h with a heating rate of 10 °C/min. After pyrolyzing, the product was washed with deionized water until the filtrate pH value was neutral, and was dried in a 105 °C oven.

2.7 Analysis methods

LGO, HMF, and furfural were analyzed using a GC (Shimadzu, GC-2010 Plus equipped with a flame ionization detector and a Restek RTX-VMS capillary column). The injection port and the detector were held at 240 °C. The column flow rate was 1 mL/min with a He carrier gas. The GC oven temperature was initially held at 40 °C for 5 min, ramped to 240 °C at 7.5 °C/min, and kept at 240 °C for 15 min. For each analysis, the injection volume was 1 μL.

LG, glucose, xylose, and arabinose were analyzed using HPLC (Shimadzu, LC-20) equipped with UV (UV–Vis; SPD-20AV) and RI (RID-10A) detectors. Separation was achieved using a Bio-Rad Aminex HPX-87H column at 35 °C with 5 mM H2SO4 as mobile phase, flowing at a rate of 0.6 mL/min. For each analysis, the injection volume was 10 μL.

2.8 Characterization methods

2.8.1 Elemental analysis (CHONS)

The contents of C/H/O/N/S elements were determined by the Vario EL Cube elemental analysis spectrometer.

2.8.2 Amylose content

The content of amylose in extracted starch was determined according to the method by Sharlina et al. [54]. Approximately 100 mg of starch, 1 mL of 95% ethanol, and 9 mL of 1 mol/L sodium hydroxide were added to a beaker. The beaker was then heated in boiling water for 10 min, cooled, and transferred to a 100-mL volumetric flask (A). Then, deionized water was added until the volume reached 100 mL (starch suspension A). Starch suspension A (5 mL) was pipetted into another volumetric flask (B). Then, 1 mL of 1 mol/L acetic acid, 2 mL of 2.6% w/v potassium iodide solution, and deionized water were added to volumetric flask B until the volume reached 100 mL. Solution B was sonicated for 20 min and transferred to a cuvette; then, the amylose content was determined at 720 nm using the Shimadzu UV-1800 UV Spectrophotometer (Japan). A series of starch solutions containing 0%, 10%, 20%, 25%, 30%, and 35% standard potato amylose were prepared using the abovementioned steps. A standard graph was plotted using the absorbance reading at 720 nm versus percentages of standard potato amylose. The amylose content of starch samples was determined from a standard graph and expressed as the percentage.

2.8.3 Proximate analysis

Moisture, biomass soluble in ethanol, and ash contents were analyzed according to the method described in AOAC [55].

2.8.4 Scanning electron microscopy

The samples were placed on carbon adhesive tape attached to the stub and sputter coated with 20 nm of gold (SCD 050 Sputter Coater, Balzers). The morphology of starch granules was observed in an S-4800 SEM at 5 kV or 15 kV acceleration.

2.8.5 Fourier transform infrared spectroscopy

Fourier transform infrared (FT-IR) spectroscopy was carried out on the samples using the model Spectrum One Fourier transform infrared spectroscope (Thermo Scientific Nicolet iS5) equipped with an attenuator for total reflectance (ATR). The analyses were carried out in the region from 4000 to 400 cm−1, with a resolution of 4 cm−1 and 32 scans.

2.8.6 X-ray

The crystalline structures of the films were examined using an X-ray diffractometer (Bruker D8 ADVANCE, Germany). The instrument employed nickel-filtered Cu Kα radiation (λ = 0.15406 nm) and worked at a voltage of 40 kV and a current of 30 mA. The 2θ range from 5° to 90° in steps of 2°/min was used. The samples were cut into pieces using a laboratory grinder, and their crystallinity was determined by the method of Nara and Komiya [56].

where Dc is the crystallinity, Ac is the X-ray diffraction diagram crystalline region area, and Aa is the amorphous region of the X-ray diffraction diagram.

2.8.7 Differential scanning calorimetry (DSC)

The thermal properties of IIR starch were measured using a differential scanning calorimeter (Netzsch DSC 200F3), which had previously been calibrated with indium. The samples were weighed directly into aluminum differential scanning calorimetry (DSC) pans, to which 7 mL of deionized water was added. After sealing, the pans were left to equilibrate for 1 h at room temperature before the analysis was performed. A sample was subjected to a heating ramp of 30–120 °C and at a heating rate of 10 °C/min. An empty aluminum pan was used as a reference. The onset (To), peak (Tp), and conclusion (Tc) temperatures and gelatinization enthalpy (ΔH) were estimated directly by the instrument software.

2.8.8 Physical adsorption of N2

Adsorption–desorption of nitrogen measures was performed using Micromeritics equipment, model TriStar II 3020, at liquid nitrogen temperature (77.35 K). The textural parameters were determined from the obtained isotherms. From the nitrogen adsorption and isotherm of desorption curves, specific surface area (BET method) and the pore size distribution (BJH) were obtained, respectively.

3 Results and discussion

3.1 Starch extraction and characterization

By the NREL and enzymolysis method, the glucan content in IIR scraps was 55.32 ± 1.59%, and the starch content was 51.43 ± 2.33%. The glucan content in IIR’s decoction residues was 60.30 ± 2.69%, and the gelatinized starch content was 57.66 ± 2.29%. Both IIR scraps and IIR’s decoction residues contain a large amount of available starch components. These starches can be hydrolyzed into fermentable sugars for fermentation, but it is still necessary to consider whether there are residual bioactive components, such as epigoitrin [57].

The IIR starch yield and its elemental analysis and ash and amylose contents are shown in Table 1. From IIR scraps, the starch extraction yields 53.53 ± 2.38% and 71.65 ± 1.72% through the dry and wet methods, respectively. The C, H, and O contents of IIR starch prepared by the wet method were 41.54%, 6.49%, and 51.05%, respectively, which were more similar to the C, H, and O (42.13%, 5.92%, and 51.75%, respectively) contents in corn starch. In addition, the ash content of IIR starch produced by the wet method was only 0.9 ± 0.19%, which was also lower than that by the dry method. The amylose content in the W-IIR starch was 19.84 ± 0.85%. This data was lower than the amylose content in corn starch (30.56 ± 2.79%) and other starch-rich TCMs, such as Pinellia ternata (27.86 ± 0.24%) [58], Yam (19.47 ~ 22.17%) [59], and Fritillaria (21.7 ~ 30.2%) [60]. Amylose content affects some properties of starch. The lower the amylose content, the better its adhesion.

IIR starch granules were roughly elliptical with the smooth surface, and the average particle size was 2–10 μm (shown in Fig. 1). IIR starch has a similar shape to Yam [61] or Fritillaria [62], but its size is smaller than them (23.39–26.87 μm and 24.9–33.1 μm, respectively). The variation in size and shape of starch granules may be due to biological origin, and the physicochemical properties such as light transmittance, expansibility, and water binding ability are significantly related to the average size of starch granules isolated from different plants [61].

The infrared spectrum of IIR starch is presented in Fig. 2A. The peaks of IIR starch were completely consistent with those of corn starch. The absorptions at 1160 cm−1, 1080 cm−1, and 930 cm−1 were referred to C–O tensile vibration in starch. The peaks at 1650 cm−1 and 1350 cm−1 were represented by C = O and C–O–C groups, respectively. The band at 2930 cm−1 was associated with C–H stretching. The peaks between 3300 and 3400 cm−1 were related to O–H bond stretching.

Native starches from plant tissues are usually divided into A, B, or C type due to different crystallinities. The A-type starch has strong diffraction peaks at 15° and 23° and double peaks at 18° and mainly exists in cereal endosperm, such as wheat [63] and rice [64]. The B-type starch exists mainly in some tubers or roots, such as potato [64] and yam [65], and has a strong diffraction peak at 17°, a small diffraction peak at 23°, and a most characteristic peak at 5°. The C-type starch has both A- and B-type crystallinities and is found in some legume seeds and rhizomes, such as bean [66]. XRD patterns of corn starch and IIR starch are shown in Fig. 2B. Corn starch presents typical A-type starch characteristics which were evidenced by the presence of strong diffraction peaks at 15.2° and 23°, a connected double peak at 17.2° and 18.0°, and a weak diffraction peak at about 20°. For IIR starch, it is a C-type starch that has strong diffraction peaks at 15.3°, 17.2°, and 23.2°, but a weak diffraction peak at 5.6°. Additionally, the crystallinity degree of IIR starch was 25.92%, and that of corn starch was 14.84%, which was negatively correlated with their respective amylose content.

Gelatinization is the basic characteristic of most starch. Thermodynamic analysis reveals that the gelatinization process can be regarded as the melting process of starch crystallization [67]. Table 2 shows the gelatinization temperature (To, Tp, Tc), gelatinization temperature range (ΔT), and gelatinization enthalpy (ΔHgel) of IIR starch and corn starch. The initial gelatinization temperature, gelatinization peak temperature, and gelatinization termination temperature of IIR starch were 58.68 °C, 68.31 °C, and 75.41 °C, respectively. These data were lower than those of corn starch (65.68 °C, 70.43 °C, and 79.54 °C, respectively). The gelatinization enthalpy (ΔH) of IIR starch and corn starch was 4.33 J/g and 10.08 J/g, respectively. This indicated that corn starch needed more energy to disorder starch granules’ crystalline structure.

In summary, a new IIR starch that has smaller particle size, lower amylose content, higher crystallinity, and easier gelatinization was obtained. This IIR starch exhibits some unique properties that can compete with or complement other commercial starches in some potential applications.

3.2 Preparation condition optimization of anhydro-sugars from IIR’s decoction residues

Compared with IIR scraps, the IIR’s decoction residues have more enormous amount. This part of the waste residue needs to find a more valuable utilization direction except for hydrolyzing them into fermentable sugar. Table 3 shows the determination results of biomass components in IIR’s decoction residues. After decoction of IIR, the starch component in the waste residue is converted into gelatinized starch and its content was 57.66 ± 2.29% (shown in Table 3). According to Cao et al.’s [21, 22] report, starch is more easily degraded to anhydro-sugars than cellulose. This provides a new application direction for the gelatinized starch in IIR’s decoction residues. Herein, we optimized conditions such as solvent and catalyst, dosage of catalysts, temperature, and substrate concentration in the preparation of anhydro-sugars which used IIR’s decoction residues as raw material.

Six kinds of polar aprotic solvents including Diox, Act, MEK, DMC, THF, and NMP were chosen as the candidate. In Fig. 3, among all candidate solvents, anhydro-sugars can be obtained from IIR’s decoction residues. The highest yields of LG, LGO, and total carbon were obtained in Diox, and they were 28.04%, 41.44%, and 63.46%, respectively. Our previous report revealed that these acids with pKa between − 3 and − 2 had better catalytic efficiency for preparation of anhydro-sugars [22, 68]. For the three catalysts (H2SO4 (pKa = − 2.0), MSA (pKa = 12.6), and TsOH (pKa = − 2.8)), they showed similar catalytic effect on IIR’s decoction residues. Even changing the number of catalysts (H2SO4 as an example) has little effect on the yields of LG, LGO, and total carbon (shown in Fig. 4).

The influence of different catalysts and concentrations on LG, LGO, total carbon yield. (1) Experimental conditions: 1 g of IIR residues, 190 °C, 2 h, 40 μL of 15 mM catalyst (TsOH, MSA, H2SO4), and 100 mL Diox. (2) Experimental conditions: 1 g of IIR residues, 190 °C, 2 h, 40 μL of H2SO4 concentrations (10 mM, 15 mM, 25 mM, 30 mM), and 100 mL Diox. Note: \({\left[\mathrm{Yield}\right]}_{\mathrm{Total carbon}} \left(\mathrm{\%}\right)\)=\({\left[\mathrm{Yield}\right]}_{\mathrm{HMF}} \left(\mathrm{\%}\right)+{\left[\mathrm{ Yield}\right]}_{\mathrm{FF}} \left(\mathrm{\%}\right)+{\left[\mathrm{ Yield}\right]}_{\mathrm{LG}} \left(\mathrm{\%}\right)+{\left[\mathrm{ Yield}\right]}_{\mathrm{LGO}} \left(\mathrm{\%}\right)\), and these yields were the highest yield

Raising the reaction temperature has different effects on the yields of anhydro-sugars (shown in Fig. 5). With the increase of temperature, the time when the LG’s yield reaches the peak value was advancing, but the value tends to increase first and then decrease; for LGO, its highest yield seems to have little effect on the investigated temperature range, but the decomposition of LGO was increasing with the extension of time at high temperature; for the total carbon yield, the highest value (69.81%) was obtained at 190 °C. Decreasing the substrate concentration can improve the stability of LGO (final yield 44.78%) as well as the total carbon yield (reached 69.81% in Fig. 5). This result is not lower than that reported in the literatures, such as the following: Cao et al. [22] reported that LGO yield was up to 51% from cellulose in THF under mild reaction conditions (170 ~ 230 °C, 5 ~ 20 mM H2SO4), He et al. [68] produced LGO and HMF from cellulose with a total carbon yield up to 65% in a THF and water mixture, and Lusi et al. [69] used high-voltage alternating current as plasma source to achieve complete liquefaction of cellulose, and LGO yield was 43%. Therefore, it indicated that the IIR’s decoction residues have a promising prospect as a raw material for preparing anhydro-sugars.

The influence of different reaction temperatures (black square, red circle, blue triangle) and substrate concentrations (red circle, green diamond) on LG, LGO, and total carbon yield. Experimental conditions (black square, red circle, blue triangle): 1 g of IIR residues; reaction temperature of 180 °C, 190 °C, and 200 °C; 2 h; 40 µL of 15 mM H2SO4; and 100 mL Diox. Experimental conditions (red circle, green diamond): 0.8 g and 1 g of IIR residues, 190 °C, 2 h, 40 μL of 15 mM H2SO4, 100 mL Diox

3.3 Biochar from anhydro-sugar residues

As a medical waste, IIR’s decoction residues were dehydrated into anhydro-sugars in polar aprotic solvent to improve their value. However, after the degradation of IIR’s decoction residues, 10–20% of black solid waste will often be remained, which will bring an extra burden to the environment if they are not properly disposed of. The characterization of this black solid residue found that its carbon content (61.42%) was higher than that of the IIR’s decoction residues (41.97%), and its oxygen content (26.42%) was lower than that of IIR’s decoction residues (39.36%). From the FTIR spectrum, the peaks of oxygen-containing groups such as hydroxyl and carbonyl groups could be distinguished. So, we speculated that these black residues should be the product of incomplete dehydration. After filtration and drying, this black residue was reused to prepare anhydro-sugars, but the yield was lower than 5%. Some studies have not proposed the disposal of biomass residue after the preparation of anhydro-sugars [70, 71].

However, the black residue from anhydro-sugar preparation of IIR’s decoction residues also belongs to biomass waste, and it can be carbonized into biochar. Therefore, we followed the common method (as Sect. 2.6 described: in the tubular furnace at 800 °C for 4 h with a heating rate of 10 °C/min) to prepare biochar from this residue, and the characterizations of biochar are presented in Table 4 and Fig. 6.

Table 4 compares the elemental composition of the original residue and the prepared biochar. Elemental analysis showed that the carbon content increased from 61.42 to 92.00% after carbonization. The decrease of H/C, O/C, and (N + O)/C indicated that this biochar had high aromatic properties, low hydrophilicity, and reduced surface functional groups. The loss of H and O elements in the carbonization process was mainly attributed to the dehydration of raw materials and the fracture of weak bonds. After carbonization, the N content decreased significantly, which was due to the release of NOX and NH3 during the pyrolysis process [72]. The BET surface area, pore volume, and pore diameter of biochar reflected the physical changes caused by the carbonization process. The BET surface area, pore volume, and pore diameter of the original residue was 5.65 m2/g, 0.02 cm3/g, and 1.61 nm, respectively. After carbonization at 800 °C for 4 h, they increased to 1749.46 m2/g, 0.48 cm3/g, and 16.39 nm, respectively. This transformation led our prepared biochar to have the potential to be applied in the fields of pollutant removal, soil improvement, energy production, and carbon sequestration.

Figure 6 compares the scanning electron microscopy (SEM), IR, and XRD patterns of the residue before pyrolysis and the biochar after pyrolysis. From Fig. 6, the surface of the residue before pyrolysis was filled with many shallow pores and their average pore size was 0.5–2 μm (Fig. 6A). After pyrolysis, biochar exhibited more sunken pores with the average pore size of 1–5 μm on the surface (Fig. 6B). This is consistent with the increasing result of the BET surface area, pore volume, and pore diameter. As shown in Fig. 6C, almost all the peaks that are presented in the anhydro-sugars’ preparation residues disappeared in the biochar FT-IR spectrum except for only O–H stretching vibration at 3436 cm−1 and few C–H stretching vibrations observed at 2920 cm−1, because lots of dehydration and decarboxylation took place at high temperature during pyrolysis. In the XRD pattern of the anhydro-sugar residues (Fig. 6D), we can still find two sharp diffraction peaks (26° and 31.5°) that are completely different from those of C-type starch (characteristic peaks at 15°, 17°, and 23°). However, in biochar, the corresponding peaks completely disappeared, and only a broad and slow amorphous diffraction peak at 43° was left. This indicated that the biomass components in the anhydro-sugar residues were completely degraded during pyrolysis. Recently, biochar, as a good soil conditioner, has exhibited its advantages in improving soil rhizosphere microecological environment, promoting plant growth and development, and alleviating obstacles of continuous cropping [73]. For instance, Yang et al. [44] reported that biochar has a high adsorption capacity for autotoxic ginsenosides of Sanqi (Panax notoginseng), and steam sterilization plus biochar could effectively eliminate negative plant-soil feedback (NPSF) to Sanqi. The same results were also exhibited in the improvement of continuous cropping to Pinellia ternata, Dendrobium officinale, and Andrographis paniculata [74,75,76].

4 Conclusion

As a kind of special waste-contained biomass, TCM residues were generated with the prosperous development of TCM and brought major problems of environmental pollution and sustainable development. Hence, the disposal of TCM residues attracted more attention. In this study, we presented a completely comprehensive utilization of IIR wastes into special starch, anhydro-sugars, and biochar. A new starch was isolated from IIR scraps by the wet method with 71.65 ± 1.72% yield and has the characteristics of smooth surface, small particle size, and easy gelatinization. This IIR starch can become a unique resource for application in food processing. For the IIR’s decoction residues, the degradation to anhydrous sugar in dioxane using H2SO4 as the catalyst was explored. Under optimized conditions, the yields of LG and LGO from IIR’s decoction residues as feedstock were similar to the yield of microcrystalline cellulose or corn starch. Additionally, we used the anhydro-sugars’ preparation residues to form biochar through biomass hydrothermal carbonization. Its BET surface area was up to 1749.46 m2/g. This macro-porous biochar may play a certain role in wastewater treatment, soil improvement, and overcoming continuous cropping obstacles of Isatis indigotica. Further, techno-economic assessment and expansion of this model to other starch-rich TCM wastes will be the next focus.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Atukuri D, Rashmi M, Chandrashekhar M, Afreen T, Mujavar PH (2021) Recent update on the pharmacological significance of Isatis tinctoria L. (Brassicaceae) extracts. Polycycl Aromat Compd 2021:1–19. https://doi.org/10.1080/10406638.2021.1886126

Wang T, Wang X, Zhuo Y, Si C, Yang L, Meng L, Zhu B (2020) Antiviral activity of a polysaccharide from Radix isatidis (Isatis indigotica Fortune) against hepatitis B virus (HBV) in vitro via activation of JAK/STAT signal pathway. J Ethnopharmacol 257:112782

Du Z, Liu H, Zhang Z, Li P (2013) Antioxidant and anti-inflammatory activities of Radix isatidis polysaccharide in murine alveolar macrophages. Int J Biol Macromol 58:329–335

Li Z, Li L, Zhou H, Zeng L, Chen T, Chen Q, Zhou B, Wang Y, Chen Q, Hu P, Yang Z (2017) Radix isatidis polysaccharides inhibit influenza A virus and influenza A virus-induced inflammation via suppression of host TLR3 signaling in vitro. Molecules 22:116

Yang Z, Wang Y, Zheng Z, Zhao S, Zhao J, Lin Q, Li C, Zhu Q, Zhong N (2013) Antiviral activity of Isatis indigotica root-derived clemastanin B against human and avian influenza A and B viruses in vitro. Int J Mol Med 31:867–873

Lin CW, Tsai FJ, Tsai CH, Lai CC, Wan L, Ho TY, Hsieh CC, Chao PDL (2005) Anti-SARS coronavirus 3C-like protease effects of Isatis indigotica root and plant-derived phenolic compounds. Antiviral Res 68:36–42

Yu B, Lin F, Ning H, Ling B (2021) Network pharmacology study on the mechanism of the Chinese medicine Radix isatidis (Banlangen) for COVID-19. Medicine 100:32

Li X, Wei W, Zhang J, Li L, Niu L (2020) Study on the correlation between starch content and active ingredients medicinal component content in Isatidis Radix. Hua Xue Gong Cheng Shi 34:24–26

Jia W, Qin K, Liu L (2010) Research on the components determination of Isatia indigotica Fort Draff and its application. Tai Shan Yi Xue Yuan Xue Bao 31:520–521

Qin M, Duan X, He P, Zhang Y, Pei L (2021) Effects of biological organic fertilizer from Isatidis Radix residue on yield and fruit quality of Trichosanthes kirilowii Maxim. Bei Fang Yuan Yi 05:109–114

Li G (2008) Fement value and utilization of indigowoad leaf, Isatis indigotica residues. Ying Yang Yu Ri Liang https://doi.org/10.19567/j.cnki.1008-0414.2008.02.007

Wei P, Wei D, Mo D (2003) Biosorption of lead by Isatis indigotica Fort Draff. Li Zi Jiao Huan Yu Xi Fu 19:351–356

Yuan H, Lu T, Wang Y, Huang H, Chen Y (2014) Influence of pyrolysis temperature and holding time on properties of biochar derived from medicinal herb (Radix isatidis) residue and its effect on soil CO2 emission. J Anal Appl Pyrolysis 110:277–284

Ma H, Li H, Zhang F, Wang Q, Tu M (2019) Effects of nitrogen substitute and Hypericum perforatum extract on the ethanol fermentation of traditional Chinese medicine dregs. Ind Crops Prod 128:385–390

Wang C, Su X, Sun W, Zhou S, Zheng J, Zhang M, Sun M, Xue J, Liu X, Xing J, Chen S (2018) Efficient production of succinic acid from herbal extraction residue hydrolysate. Bioresour Technol 265:443–449

Nguyen CM, Nguyen TN, Choi GJ, Choi YH, Jang KS, Park YJ, Kim JC (2014) Acid hydrolysis of Curcuma longa residue for ethanol and lactic acid fermentation. Bioresour Technol 151:227–235

Zheng YX, Xiao FX, Lin L, Chen K, Wang ZH, Tian J, Song JP, Wang Q (2015) Optimization of extraction process for total polysaccharides from Artemisiae annuae herb residue by response surface methodology and evaluation of its antioxidant activity. Chin J Exp Tradit Med Formulae 21:8–11

Wu CX (2008) Study on citrus fruit peels hemicellulosic hydrolysate for production of xylitol by fermentation. Southwest University

Zhang S, Chang S, Xiao P, Qiu S, Ye Y, Li L, Yan H, Guo S, Duan J (2019) Enzymatic in situ saccharification of herbal extraction residue by a medicinal herbal-tolerant cellulase. Bioresour Technol 287:121417

Wu Y, Huang TY, Li ZX, Huang ZY, Lu YQ, Gao J, Hu Y, Huang C (2021) In-situ fermentation with gellan gum adding to produce bacterial cellulose from traditional Chinese medicinal herb residues hydrolysate. Carbohydr Polym 270:118350

Cao Q, Ye T, Li W, Chen J, Lu Y, Gan H, Wu H, Cao F, Wei P, Ouyang P (2020) Dehydration of saccharides to anhydro-sugars in dioxane: effect of reactants, acidic strength and water removal in situ. Cellulose 27:9825–9838

Cao F, Schwartz TJ, Mcclelland DJ, Krishna SH, Dumesic JA, Huber GW (2015) Dehydration of cellulose to levoglucosenone using polar aprotic solvents. Energy Environ Sci 8:1808–1815

Ermolenko MS (2013) Convenient and efficient synthesis of 2,4-dideoxy-levoglucosan. Synth Commun 43:2841–2845

Wang JQ, Zheng JL, Wang JT, Lu ZM (2018) A separation and quantification method of levoglucosan in biomass pyrolysis. Ind Crops Prod 113:266–273

Das O, Sarmah AK (2015) Value added liquid products from waste biomass pyrolysis using pretreatments. Sci Total Environ 538:145–151

Davydova AN, Pershin AA, Sharipov BT, Valeev FA (2015) Synthesis of chiral 2,3-cis-fused butan-4-olides from levoglucosenone-1,3-diene diels-alder adducts. Mendeleev Commun 25:271–272

Samet AV, Lutov DN, Firgang SI, Lyssenko KA, Semenov VV (2011) A concise approach to chiral chromenes based on levoglucosenone. Tetrahedron Lett 52:3026–3028

Junior EGS, Silva NRF, Perez VH, David GF, Olivares FL, Fernandes SA, Justo OR, Simionatt E (2021) Fast pyrolysis of peanut husk agroindustrial waste: intensification of anhydro sugar (levoglucosan) production. Waste Biomass Valori 12:5573–5585

David GF, Justo OR, Perez VH, Perez MG (2018) Thermochemical conversion of sugarcane bagasse by fast pyrolysis: high yield of levoglucosan production. J Anal Appl Pyrolysis 133:246–253

Bouxin FP, Clark JH, Fan J, Budarin V (2019) Combining steam distillation with microwaveassisted pyrolysis to maximise direct production of levoglucosenone from agricultural wastes. Green Chem 21:1282–1291

Téllez JF, Silva MP, Simister R, Gomez LD, Fuertes VC, Paoli JMD, Moyano EL (2021) Fast pyrolysis of rice husk under vacuum conditions to produce levoglucosan. J Anal Appl Pyrolysis 156:105105

Nguyen BT, Dinh GD, Dong HP, Le LB (2022) Sodium adsorption isotherm and characterization of biochars produced from various agricultural biomass wastes. J Clean Prod 346:131250

Gheorghe-Bulmau C, Volceanov A, Stanciulescu I, Ionescu G, Marculescu C, Radoiu M (2022) Production and properties assessment of biochars from rapeseed and poplar waste biomass for environmental applications in Romania. Environ Geochem Health 44:1683–1696

Nguyen TTV, Phan AN, Nguyen TA, Nguyen TK, Nguyen ST, Pugazhendhi A, Phuong HHK (2022) Valorization of agriculture waste biomass as biochar: as first-rate biosorbent for remediation of contaminated soil. Chemosphere 307:135834

Elkhalifa S, Al-Ansari T, Mackey HR, McKay G (2019) Food waste to biochars through pyrolysis: a review. Resour Conserv Recycl 144:310–320

Saletnik B, Bajcar M, Saletnik A, Zaguła G, Puchalski C (2021) Effect of the pyrolysis process applied to waste branches biomass from fruit trees on the calorific value of the biochar and dust explosivity. Energies 14:4898

Sellaoui L, Silva LFO, Badawi M, Ali J, Favarin N, Dotto GL, Erto A, Chen Z (2021) Adsorption of ketoprofen and 2- nitrophenol on activated carbon prepared from winery wastes: a combined experimental and theoretical study. J Mol Liq 333:115906

Zhu X, Luo Z, Guo W, Cai W, Zhu X (2022) Reutilization of biomass pyrolysis waste: tailoring dual-doped biochar from refining residue of bio-oil through one-step self-assembly. J Clean Prod 343:131046

Li C, Xie S, Wang Y, Jiang R, Wang X, Lv N, Pan X, Cai G, Yu G, Wang Y (2021) Multi-functional biochar preparation and heavy metal immobilization by co-pyrolysis of livestock feces and biomass waste. Waste Manag 134:241–250

Sutton DR, Vierrether OM, Anderson KE, Wisner CA (2017) Biochar from alpaca manure, the basics. Microsc Microanal 23:1138–1139

Wang J, Pan X, Liu Y, Zhang X, Xiong Z (2012) Effects of biochar amendment in two soils on greenhouse gas emissions and crop production. Plant Soil 360:287–298

Wang Z, Zheng H, Luo Y, Deng X, Herbert S, Xing B (2012) Characterization and influence of biochars on nitrous oxide emission from agricultural soil. Environ Pollut 174:289–296

Wu D, Zhang W, Xiu L, Sun Y, Gu W, Wang Y, Zhang H, Chen W (2022) Soybean yield response of biochar-regulated soil properties and root growth strategy. Agronomy 12:1412

Yang M, Yuan Y, Huang H, Ye C, Guo C, Xu Y, Wang W, He X, Liu Y, Zhu S (2019) Steaming combined with biochar application eliminates negative plant-soil feedback for sanqi cultivation. Soil Tillage Res 189:198–198

Pan X, Gu Z, Chen W, Li Q (2021) Preparation of biochar and biochar composites and their application in a Fenton-like process for wastewater decontamination: a review. Sci Total Environ 754:142104

Ahmad M, Rajapaksha AU, Lim JE, Zhang M, Bolan N, Mohan D, Vithanage M, Lee SS, Ok YS (2014) Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere 99:19–33

Sluiter AD, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker DP (2008) Determination of structural carbohydrates and lignin in biomass: laboratory analytical procedure. https://api.semanticscholar.org/CorpusID:100361490. Accessed 2021-10-12

Permanasari AR, Yulistiani F, Purnama RW, Widjaja T, Gunawan S (2018) The effect of substrate and enzyme concentration on the glucose syrup production from red sorghum starch by enzymatic hydrolysis. Earth Environ Sci 160:012002

Wei C, Qin F, Zhu L, Zhou W, Chen Y, Wang Y, Gu M, Liu Q (2010) Microstructure and ultrastructure of high-amylose rice resistant starch granules modified by antisense RNA inhibition of starch branching enzyme. J Agric Food Chem 58:1224–1232

Jiang Q, Gao W, Li X, Zhang J (2011) Characteristics of native and enzymatically hydrolyzed Zea mays L., Fritillaria ussuriensis Maxim. and Dioscorea opposita Thunb. starches. Food Hydrocoll 25:521–528

Maniglia BC, Tapia-Blácido DR (2016) Isolation and characterization of starch from babassu mesocarp. Food Hydrocoll 55:47–55

Lin W, Zhou J, Sun S, Yang F, Ye Z (2022) Optimization of preparation of KOH‑modified sludge biochar via response surface method and its enhanced Cd (II) removal from wastewater. Biomass Convers Biorefin https://doi.org/10.1007/s13399-022-03486-x

Cui S, Zhao Y, Liu Y, Huang R, Pan J (2021) Preparation of straw porous biochars by microwave-assisted KOH activation for removal of gaseous H2S. Energy Fuels 35:18592–18603

Sharlina MSE, Yaacob WA, Lazim AM, Fazry S, Lim SJ, Abdullah S, Noordin A, Kumaran M (2017) Physicochemical properties of starch from Dioscorea pyrifolia tubers. Food Chem 220:225–232

AOAC. Official Methods of Analysis of AOAC International. 18th Ed. USA. https://doi.org/10.1016/0924-2244(95)90022-5

Nara S, Komiya T (1983) Studies on the relationship between water-satured state and crystallinity by the diffraction method for moistened potato starch. Starke 35:407–410

Luo Z, Liu LF, Wang XH, Li W, Jie C, Chen H, Wei FQ, Lu DH, Yan CY, Liu B, Kurihara H, Li YF, He RR (2019) Epigoitrin, an alkaloid from Isatis indigotica, reduces H1N1 infection in stress-induced susceptible model in vivo and in vitro. Front Pharmacol 10:78

Li X, Zhang X, Yang W, Guo L, Huang L, Li X, Gao W (2021) Preparation and characterization of native and autoclaving-cooling treated Pinellia ternate starch and its impact on gut microbiota. Int J Biol Macromol 182:1351–1361

Wang Y, Zhang L, Li X, Gao W (2011) Physicochemical properties of starches from two different yam (Dioscorea opposita Thunb.) residues. Braz Arch Biol Technol 54:243–251

Wang S, Yu J, Gao W, Pang J, Yu J, Xiao P (2007) Characterization of starch isolated from Fritillaria traditional Chinese medicine (TCM). J Food Eng 80:727–734

Wang S, Liu H, Gao W, Chen H, Yu J, Xiao P (2006) Characterization of new starches separated from different Chinese yam (Dioscorea opposita Thunb.) cultivars. Food Chem 99:30–37

Li X, Gao W, Jiang Q, Hao J, Guo X, Huang L (2012) Physicochemical, morphological, structural, and thermal characteristics of starches separated from Bulbus fritillaria of different cultivars. Starke 64:572–580

Li C, Zhou D, Fan T, Wang M, Zhu M, Ding J, Zhu X, Guo W, Shi YC (2020) Structure and physicochemical properties of two waxy wheat starches. Food Chem 318:126492

Wong KT, Poh GYY, Goh KKT, Wee MSM, Henry CJ (2021) Comparison of physicochemical properties of jackfruit seed starch with potato and rice starches. Int J Food Prop 24:364–379

Oliveira AR, Ribeiro AEC, Gondim ÍC, Santos EAD, Oliveira ÉRD, Coutinho GSM, Júnior MSS, Caliari M (2021) Isolation and characterization of yam (Dioscorea alata L.) starch from Brazil. LWT 149:111843

Ren Y, Yuan TZ, Chigwedere CM, Ai Y (2021) A current review of structure, functional properties, and industrial applications of pulse starches for value-added utilization. Compr Rev Food Sci Food Saf 20:3061–3092

Obadi M, Qi Y, Xu B (2021) Highland barley starch (Qingke): structures, properties, modifications, and applications. Int J Biol Macromol 185:725–738

He J, Liu M, Huang K, Walker TW, Maravelias CT, Dumesic JA, Huber GW (2017) Production of levoglucosenone and 5-hydroxymethylfurfural from cellulose in polar aprotic solvent–water mixtures. Green Chem 19:3642–3653

Lusi A, Radhakrishnan H, Hu H, Hu H, Bai X (2020) Plasma electrolysis of cellulose in polar aprotic solvents for production of levoglucosenone. Green Chem 22:7871–7883

Wu K, Wu H, Zhang H, Zhang B, Wen C, Hu C, Liu C, Liu Q (2020) Enhancing levoglucosan production from waste biomass pyrolysis by Fenton pretreatment. Waste Manage 108:70–77

Teixeira MG, Pereira SPS, Fernandes SA, Silva MJ (2020) Enhancement of levoglucosan production via fast pyrolysis of sugarcane bagasse by pretreatment with Keggin heteropolyacids. Ind Crops Prod 154:112680

Gupta GK, Ram M, Bala R, Kapur M, Mondal MK (2018) Pyrolysis of chemically treated corncob for biochar production and its application in Cr(VI) removal. Environ Prog Sustain Energy 37:1606–1617

Yang XT, Ran ZF, Li R, Lin Y, Zhou J, Zhou LP (2021) Research progress on application of biochar in cultivation of agriculture and Chinese materia medica. Zhongguo Zhong Yao Za Zhi 46:2461–2466

Tang HM (2019) Effects of microbial fertilizer and biochar applications on the yield and quality of Pinellia ternata and soil microecology. Huazhong Agricultural University. https://doi.org/10.27158/d.cnki.ghznu.2019.000724

Chen QF (2015) Effects of biochar in culture media on quality and growth of Dendrobium officinale. Zhejiang Normal University. https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD201601&filename=1015646864.nh. Accessed 2021-05-07

Li Z, Chen YS, Chen RZ, Yang CM, Chen NB, Lu WD (2019) Effects of biochar on rhizospheric soil microbial community of continuous cropping Andrographis paniculata. Shang Rao Shi Fan Xue Yuan Xue Bao 39:50–55

Funding

This work was supported by the National Key Research and Development Program of China (2019YFC1906603), the National Natural Science Foundation of China (Grant No. 22078152), the Jiangsu Synergetic Innovation Center for Advanced Bio-Manufacture (XTD2211), and the Six Talent Peaks Project in Jiangsu Province (SWYY-118).

Author information

Authors and Affiliations

Contributions

Tingting Xu: methodology, investigation, data curation, and writing and preparation of original draft. Xin Gao and Yuanzhang Li: data curation, methodology, and investigation. Changqu Lin and Peipei Ma: investigation. Zhongzhong Bai and Jun Zhou: formal analysis and data curation. Hongli Wu: supervising, methodology, and funding acquisition. Fei Cao: supervising, funding acquisition, and writing including reviewing and editing. Ping Wei: conceptualization.

Corresponding authors

Ethics declarations

Ethical approval

It is not applicable for this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, T., Gao, X., Li, Y. et al. Characterization of isolated starch from Isatis indigotica Fort. root and anhydro-sugars preparation using its decoction residues. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03892-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03892-9