Abstract

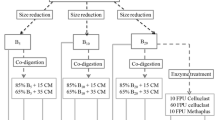

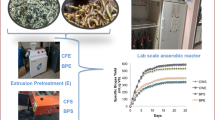

Anaerobic digestion of lignocellulosic biomass such as agricultural residues has gained interest due to its abundant presence in rural areas. However, anaerobic digestion of such biomass requires pretreatment to increase its digestibility. The effect of thermal, alkali, and extrusion pretreatments on the biomethane potential (BMP) of the lignocellulose-rich banana peduncle was studied with an automated methane potential test system (AMPTS II). The raw banana peduncle was characterized, and it was observed that the cellulose, hemicellulose, and lignin contents were 53.44, 19.83, and 14.25%, respectively. The BMP of the shredded banana peduncle was estimated using a AMPTS and found to be 184.32 mLN/g of volatile solid (VS) added. Further to increase the methane yield, the banana peduncle was subjected to bioextrusion, alkali, and thermal pretreatment. The thermally pretreated banana peduncle showed a maximum BMP of 377.60 mLN/g VS, compared to the BMP of alkali and extruded banana peduncle (298.9 and 248.02 mLN/g VS, respectively). Scanning electron microscopy (SEM) images showed the deconstructed cellulose structure of all the pretreated samples. As thermal pretreatment was effective, further optimization of pretreatment parameters was carried out using Response Surface Methodology (RSM) with temperature and time as independent variables and BMP as the response. Based on the experiments, thermal pretreatment of banana peduncle at 120 °C for 35 min yielded the maximum BMP of 532 mLN/g of VS added. First-order kinetic, modified Gompertz, and logistic models were used to study the methane potential kinetics. The modified Gompertz model was proved to be the most suitable model for modeling the methane production kinetics.

Similar content being viewed by others

Change history

27 November 2023

A Correction to this paper has been published: https://doi.org/10.1007/s13399-023-05132-6

Abbreviations

- S-BP:

-

Shredded banana peduncle

- E-BP:

-

Extruded banana peduncle

- A-BP:

-

Alkali-treated banana peduncle

- T-BP:

-

Thermally pretreated banana peduncle

- BMP:

-

Bio-methane potential

- AMPTS:

-

Automated methane potential test system

- AD:

-

Anaerobic digestion

- ADF:

-

Acid detergent fiber

- KWMC:

-

Koyambedu wholesale market complex

- NDF:

-

Neutral detergent fiber

- SEM:

-

Scanning electron microscope

- RSM:

-

Response surface methodology

- SMY:

-

Specific methane yield

References

Panwar NL, Kaushik SC, Kothari S (2011) Role of renewable energy sources in environmental protection: a review. Renew Sustain Energy Rev 15:1513–1524. https://doi.org/10.1016/J.RSER.2010.11.037

Kralova I, Sjöblom J (2010) Biofuels–renewable energy sources: a review. J Dispersion Sci Technol 31:409–425. https://doi.org/10.1080/01932690903119674

Ministry of New and Renewable Energy (MNRE) (2021) Retrieved from: https://mnre.gov.in/bio-energy/current-status Accessed 4 Nov 2021

Tursi A (2019) A review on biomass: importance, chemistry, classification, and conversion. Biofuel Res J 6:962–979. https://doi.org/10.18331/BRJ2019.6.2.3

Oliveira L, Cordeiro N, Evtuguin DV et al (2007) Chemical composition of different morphological parts from “Dwarf Cavendish” banana plant and their potential as a non-wood renewable source of natural products. Ind Crops Prod 26:163–172. https://doi.org/10.1016/j.indcrop.2007.03.002

Sheehan J, Aden A, Paustian K et al (2003) Energy and environmental aspects of using corn stover for fuel ethanol. J Ind Ecol 7:117–146. https://doi.org/10.1162/108819803323059433

Nigam JN (2001) Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J Biotechnol 87:17–27. https://doi.org/10.1016/S0168-1656(00)00385-0

Geddes C (2010) Simplifying the Lignocellulose to ethanol process through efficient pretreatment and improvement of biocatalyst. PhD Dissertation, University of Florida

Polematidis I (2007) Thermophilic, batch, high-solids bio gasification of sugar beet tailings [electronic resource]. Master thesis, Gainesville, University of Florida

Koppar A, Pullammanappallil P (2013) Anaerobic digestion of peel waste and wastewater for onsite energy generation in a citrus processing facility. Energy 60:62–68. https://doi.org/10.1016/J.ENERGY.2013.08.007

FAOSTAT (2020) Crops and livestock products. Retrieved from: https://www.fao.org/faostat/en/#data/QCL. Accessed 28 Nov 2021

Kamdem I, Tomekpe K, Thonart P (2011) Potential production of bioethanol, biomethane and pellets from lignocellulosic biomass waste from banana ( Musa spp.) in Cameroon, BASE [Online] 3:471-483. https://popups.uliege.be/1780-4507/index.php?id=7794

Wobiwo FA, Emaga TH, Fokou E et al (2017) Comparative biochemical methane potential of some varieties of residual banana biomass and renewable energy potential. Biomass Convers Biorefinery 7:167–177. https://doi.org/10.1007/s13399-016-0222-x

Chanakya HN, Sreesha M (2012) Anaerobic retting of banana and arecanut wastes in a plug flow digester for recovery of fiber, biogas and compost. Energy Sustain Dev 16:231–235. https://doi.org/10.1016/J.ESD.2012.01.003

Fagbemigun T, Fagbemi O, Buhari F et al (2016) Fibre Characteristics and Strength Properties of Nigerian Pineapple Leaf (Ananas cosmosus), Banana Peduncle and Banana Leaf (Musa sapientum) – Potential Green Resources for Pulp and Paper Production. J Sci Res Reports 12:1–13. https://doi.org/10.9734/jsrr/2016/29248

Pazmiño-Hernandez M, Moreira CM, Pullammanappallil P (2019) Feasibility assessment of waste banana peduncle as feedstock for biofuel production. Biofuels 10:473–484. https://doi.org/10.1080/17597269.2017.1323321

Tavanlar MA, Ramirez TJ, Sapin AB, Sedano SA (2012) Banana peduncle: to waste or not to waste. Banana peduncle: to waste or not to waste? https://agris.fao.org/agris-search/search.do?recordID=PH2014000240. Accessed 30 Mar 2022

Bueno CM, Sedano SA, Beltran ED, Sapin AB, Ramirez TJ, Tavanlar MA (2014) Chemical, cooking and sensory characteristics of burger patties with different levels of banana peduncle powder. Philipp J Vet Anim Sci 38:45–52

Venkiteshwaran K, Bocher B, Maki J, Zitomer D (2015) Relating anaerobic digestion microbial community and process function : supplementary issue: Water Microbiology. Microbiol Insights 8s2:37–44. https://doi.org/10.4137/mbi.s33593

Hagos K, Zong J, Li D, Liu C, Lu XH (2016) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sust Energ Rev 76:1485–1496. https://doi.org/10.1016/j.rser.2016.11.184

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev 45:540–555

Frigon JC, Guiot SR (2010) Biomethane production from starch and lignocellulosic crops: acomparative review. Biofuels Bioprod Bioresour 4:447–458. https://doi.org/10.1002/bbb.229

Mirmohamadsadeghi S, Karimi K, Azarbaijani R, Yeganeh LP, Angelidaki I, Nizami AS, Bhat R, Dashora K, Vijay VK, Aghbashlo M, Gupta VK (2021) Pretreatment of lignocelluloses for enhanced biogas production: a review on influencing mechanisms and the importance of microbial diversity. Renew Sustain Energy Rev 135:110173. https://doi.org/10.1016/j.rser.2020.110173

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW et al (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315:804–807. https://doi.org/10.1126/science.1137016

Dahunsi SO (2019) Mechanical pretreatment of lignocelluloses for enhanced biogas production: methane yield prediction from biomass structural components. Bioresour Technol 280:18–26

Sawatdeenarunat C, Nguyen D, Surendra KC, Shrestha S, Rajendran K, Oechsner H et al (2016) Anaerobic biorefinery: current status, challenges, and opportunities. Bioresour Technol 215:304–313. https://doi.org/10.1016/j.biortech.2016.03.074

Tian L, Zou D, Yuan H, Wang L, Zhang X, Li X (2015) Identifying proper agitation interval to prevent floating layers formation of corn stover and improve biogas production in anaerobic digestion. Bioresour Technol 186:1–7

Zhang C, Bi S, Zhao M, Chang S, Li Y, Pei P, Gao X (2016) Biogas production performance of different components from banana stems. Energ Fuel 30:6425–6429

Hosseini Koupaie E, Dahadha S, Bazyar Lakeh AA et al (2019) Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production-a review. J Environ Manage 233:774–784. https://doi.org/10.1016/J.JENVMAN.2018.09.106

Haldar D (2020) Purkait MK (2020) Thermochemical pretreatment enhanced bioconversion of elephant grass (Pennisetum purpureum): insight on the production of sugars and lignin. Biomass Convers Biorefinery 124(12):1125–1138. https://doi.org/10.1007/S13399-020-00689-Y

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318. https://doi.org/10.1016/J.BIORTECH.2018.04.099

Mozhiarasi V, Weichgrebe D, Srinivasan SV (2020) Enhancement of methane production from vegetable, fruit and flower market wastes using extrusion as pretreatment and kinetic modeling. Water Air Soil Pollut 231:1–21. https://doi.org/10.1007/s11270-020-04469-2

Mozhiarasi V, Speier CJ, Rose PMB et al (2021) Influence of pre-treatments and anaerobic co-digestion of slaughterhouse waste with vegetable, fruit and flower market wastes for enhanced methane production. Biomass Convers Biorefinery 8:1–8. https://doi.org/10.1007/s13399-021-01709-1

Liew LN, Shi J, Li Y (2011) Enhancing the solid-state anaerobic digestion of fallen leaves through simultaneous alkaline treatment. Bioresour Technol 102:8828–8834

Wahid R, Hjorth M, Kristensen S, Møller HB (2015) Extrusion as pretreatment for boosting methane production: effect of screw configurations. Energy Fuels 29:4030–4037

Kamdem I, Hiligsmann S, Vanderghem C, Jacquet N, Tiappi FM, Richel A, Jacques P, Thonart P (2018) Enhanced biogas production during anaerobic digestion of steam-pretreated lignocellulosic biomass from Williams Cavendish banana plants. Waste Biomass Valoriz 9:175–185

Pisutpaisal N, Boonyawanich S, Saowaluck H (2014) Feasibility of biomethane production from banana peel. Energy Procedia 50:782-788

Gunaseelan VN (2004) Biochemical methane potential of fruits and vegetable solid waste feedstocks. Biomass Bioenergy 26:389–399. https://doi.org/10.1016/j.biombioe.2003.08.006

Velmurugan B, Ramanujam RA (2011) Anaerobic digestion of vegetable wastes for biogas production in a fed-batch reactor. Int J Emerg Sci 1:478–486

Zhang C, Li J, Liu C, Liu X, Wang J, Li S, Fan G, Zhang L (2013) Alkaline pretreatment for enhancement of biogas production from banana stem and swine manure by anaerobic codigestion. Bioresour Technol 149:353–358. https://doi.org/10.1016/j.biortech.2013.09.070

Hjorth M, Gränitz K, Adamsen AP, Møller HB (2011) Extrusion as a pretreatment to increase biogas production. Bioresour Technol 102:4989–4994

Rigal L (1996) Twin-screw extrusion technology and the fractionation of vegetable matter. In Proceedings of the CLEXTRAL Conference, Firminy, France, 8–10 October

Baruah J, Nath BK, Sharma R, Kumar S, Deka RC, Baruah DC, Kalita E (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6:141

Tabatabaei M, Aghbashlo M, Valijanian E, Panahi HK, Nizami AS, Ghanavati H, Sulaiman A, Mirmohamadsadeghi S, Karimi KA (2020) Comprehensive review on recent biological innovations to improve biogas production, part 2: mainstream and downstream strategies. Renew Energy 146:1392–1407. https://doi.org/10.1016/j.renene.2019.07.047

Hansen J, Aanderud Z, Reid L, Bateman C, Hansen C, Rogers L, Hansen L (2021) Enhancing waste degradation and biogas production by pre-digestion with a hyperthermophilic anaerobic bacterium. Biofuel Res J 8:1433–1443. https://doi.org/10.18331/BRJ2021.8.3.3

Simioni T, Agustini CB, Dettmer A, Gutterres M (2022) Enhancement of biogas production by anaerobic co-digestion of leather waste with raw and pretreated wheat straw. Energy 28:124051. https://doi.org/10.1016/j.energy.2022.124051

Digman MF, Shinners KJ, Casler MD et al (2010) Optimizing on-farm pretreatment of perennial grasses for fuel ethanol production. Bioresour Technol 101:5305–5314. https://doi.org/10.1016/J.BIORTECH.2010.02.014

Shi Q, Li Y, Li Y et al (2019) Effects of steam explosion on lignocellulosic degradation of, and methane production from, corn stover by a co-cultured anaerobic fungus and methanogen. Bioresour Technol 290:121796. https://doi.org/10.1016/J.BIORTECH.2019.121796

Wang Y, Hou F, Xu H et al (2019) Integrated methane production improvement from sugarcane rind by microwave coupled calcium hydroxide pretreatment. Fuel 246:402–407. https://doi.org/10.1016/J.FUEL.2019.03.001

Srinivasan SV, Murthy DVS (2009) Statistical optimization for decolorization of textile dyes using Trametes versicolor. J Hazard Mater 165:909–914. https://doi.org/10.1016/j.jhazmat.2008.10.072

Hammond JB, Egg R, Diggins D, Coble CG (1996) Alcohol from bananas. Bioresour Technol 56:125–130. https://doi.org/10.1016/0960-8524(95)00177-8

Velásquez-Arredondo HI, Ruiz-Colorado AA, De Oliveira S (2010) Ethanol production process from banana fruit and its lignocellulosic residues: energy analysis. Energy 35:3081–3087. https://doi.org/10.1016/J.ENERGY.2010.03.052

Shah TA (2018) Effect of alkalis pretreatment on lignocellulosic waste biomass for biogas production. Int J Renew Energy Res 8:1318–1326. https://doi.org/10.20508/ijrer.v8i3.7725.g7431

Zheng Y, Zhao J, Xu F, Li Y (2014) Pre-treatment of lignocellulosic biomass for enhanced biogas production. Prog Energy Combust Sci 42:35–53. https://doi.org/10.1016/j.pecs.2014.01.001

Lamsal B, Yoo J, Brijwani K, Alavi S (2010) Extrusion as a thermo-mechanical pre-treatment for lignocellulosic ethanol. Biomass Bioenerg 34:1703–1710. https://doi.org/10.1016/j.biombioe.2010.06.009

Lehmann T (2009) Errichtung einer Biogas- u. Biobrennstofferzeugungsanlage- Demonstrationsvorhaben, Abschlussbericht K II b1 – 001333, Bundesministerium für Umwelt, Naturschutz und Reaktorsicherheit, Deutschland. (https://www.umweltinnovationsprogramm.de/sites/default/files/benutzer/36/dokumente/lehmann_maschinenbau_abschlussbericht_k_ii_b1_-_001333_141.pdf). Accessed 2 Feb 2022

VDI- Guideline 4630 (2006) Fermentation of organic materials. Characterization of substrate, sampling, collection of material data, fermentation tests, Beuth Verlag GmbH

Raposo F, Borja R, Martín MA, Martín A, De la Rubia MA, Rincón B (2009) Influence of inoculum–substrate ratio on the anaerobic digestion of sunflower oil cake in batch mode: process stability and kinetic evaluation. Chem Eng J 149(1–3):70–77

Teng Z, Changsong JH, Lu WX (2014) Design and optimization principles of biogas reactors in large scale applications. Reactor and process design in sustainable energy technology-chapter 4:99–134

Ware A, Power N (2017) Modeling methane production kinetics of complex poultry slaughterhouse wastes using sigmoidal growth functions. Renew Energy 104:50–59. https://doi.org/10.1016/j.renene.2016.11.045

Abudi ZN, Hu Z, Sun N, Xiao B, Rajaa N, Liu C, Guo D (2016) Batch anaerobic co-digestion of OFMSW (organic fraction of municipal solid waste), TWAS (thickened waste activated sludge) and RS (rice straw): influence of TWAS and RS pre-treatment and mixing ratio. Energy 107:131–140. https://doi.org/10.1016/j.energy.2016.03.141

Duan N, Ran X, Li R, Kougias P, Zhang Y, Lin C, Liu H (2018) Performance evaluation of mesophilic anaerobic digestion of chicken manure with algal digestate. Energies 11:1829. https://doi.org/10.3390/en11071829

Li P, Li W, Sun M, Xu X, Zhang B, Sun Y (2018) Evaluation of biochemical methane potential and kinetics on the anaerobic digestion of vegetable crop residues. Energies 12:26. https://doi.org/10.3390/en12010026

Esposito G, Frunzo L, Liotta F, Panico A, Pirozzi F (2012) Bio-methane potential tests to measure the biogas production from the digestion and co-digestion of complex organic substrates. The Open Environ Eng J 5:1–8

Gil MM, Miller FA, Brandão TRS, Silva CLM (2011) On the use of the gompertz model to predict microbial thermal inactivation under isothermal and non-isothermal conditions. Food Eng Rev 3:17–25. https://doi.org/10.1007/S12393-010-9032-2/FIGURES/3

Gibson AM, Bratchell N, Roberts TA (1987) The effect of sodium chloride and temperature on the rate and extent of growth of Clostridium botulinum type A in pasteurized pork slurry. J Appl Bacteriol 62:479–490. https://doi.org/10.1111/J.1365-2672.1987.TB02680.X

Deepanraj B, Sivasubramanian V, Jayaraj S (2017) Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int J Hydrogen Energy 42:26522–26528. https://doi.org/10.1016/J.IJHYDENE.2017.06.178

Ali MM, Bilai B, Dia N, Youm I, Ndongo M (2018) Modeling the kinetics of methane production from slaughterhouse waste and Salvinia Molesta: batch digester operating at ambient temperature. Energy and Power 8:61–70. https://doi.org/10.5923/j.ep.20180803.01

APHA (1998) Standard methods for the examination of water & wastewater. American Public Health Association, Washington DC

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugar S and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/acs.energyfuels.9b01089

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Morales-Polo C, Cledera-Castro M, Moratilla-Soria BY (2018) Reviewing the anaerobic digestion of food waste: from waste generation and anaerobic process to its perspectives. Appl Sci 810:1–35. https://doi.org/10.3390/app8101804

Rath J, Heuwinkel H, Herrmann A (2013) Specific biogas yield of maize can be predicted by the interaction of four biochemical constituents. Bioenergy Res 6:939–952. https://doi.org/10.1007/S12155-013-9318-3/FIGURES/2

Edström M, Nordberg Å, Thyselius L (2003) Anaerobic treatment of animal byproducts from slaughterhouses at laboratory and pilot scale. Appl Biochem Biotechnol 109:127–138. https://doi.org/10.1385/ABAB:109:1-3:127

Müller JA (2000) Pretreatment processes for the recycling and reuse of sewage sludge. Water Sci Technol 42:167–174. https://doi.org/10.2166/WST.2000.0197

Li Y, Jin Y, Li J, Nie Y (2016) Enhanced nitrogen distribution and biomethanation of kitchen waste by thermal pre-treatment. Renewable Energy 1(89):380–388

Kafle GK, Chen L (2016) Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag 48:492–502. https://doi.org/10.1016/J.WASMAN.2015.10.021

Manimaran P, Sanjay MR, Senthamaraikannan P et al (2018) Synthesis and characterization of cellulosic fiber from red banana peduncle as reinforcement for potential applications. J Nat Fibers 16:768–780. https://doi.org/10.1080/15440478.2018.1434851

Ray D, Sarkar BK (2001) Characterization of alkali-treated jute fibers for physical and mechanical properties. J Appl Polym Sci 80(7):1013–1020

Barua VB, Kalamdhad AS (2017) Effect of various types of thermal pretreatment techniques on the hydrolysis, compositional analysis and characterization of water hyacinth. Bioresour Technol 227:147–154. https://doi.org/10.1016/j.biortech.2016.12.036

Rafique R, Poulsen TG, Nizami AS, Asam ZZ et al (2010) Effect of thermal, chemical and thermo-chemical pre-treatments to enhance methane production. Energy 35:4556–4561. https://doi.org/10.1016/j.energy.2010.07.011

Ariunbaatar J, Panico A, Esposito G, Pirozzi F, Lens PNL (2014) Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl Energy 123:143–156. https://doi.org/10.1016/j.apenergy.2014.02.035

McVoitte WP, Clark OG (2019) The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon 5:e02140

Kamdem I, Hiligsmann S, Vanderghem C, Bilik I, Paquot M, Thonart P (2013) Comparative biochemical analysis during the anaerobic digestion of lignocellulosic biomass from six morphological parts of Williams Cavendish banana (Triploid Musa AAA group) plants. World J Microbiol Biotechnol 29:2259–2270

Yilmaz F, Kökdemir Ünşar E, Perendeci NA (2019) Enhancement of methane production from banana harvesting residues: optimization of thermal–alkaline hydrogen peroxide pretreatment process by experimental design. Waste Biomass Valorization 10:3071–3087

Pei P, Zhang C, Li J, Chang S, Li S, Wang J, Zhao M, Jiang L, Yu M, Chen X (2014) Optimization of NaOH pretreatment for enhancement of biogas production of banana pseudostem fiber using response surface methodology. BioResources 9:5073–5087

Li C, Liu G, Nges IA, Deng L, Nistor M, Liu J (2016) Fresh banana pseudo-stems as a tropical lignocellulosic feedstock for methane production. Energy Sustain Soc 6:1–9. https://doi.org/10.1186/s13705-016-0093-9

Acknowledgements

This work was funded by the Indian Department of Science and Technology (DST) and the German Federal Ministry of Education and Research (BMBF) under Indo-German Science and Technology Centre (IGSTC) (grant number 01DQ15007A) under the 2+2 Project “RESERVES—Resource and energy reliability by co-digestion of veg-market and slaughterhouse waste”. The authors thank the Director, CSIR-Central Leather Research Institute for providing support for this research work. The communication number of the manuscript is 1678. This research work was carried out as a part of the Ph.D degree of the candidate Mr. Benish Rose P.M, registered under Anna University, Chennai, India.

Funding

This work was funded by the Indian Department of Science and Technology (DST) and the German Federal Ministry of Education and Research (BMBF) under the Indo-German Science and Technology Centre (IGSTC) (grant number 01DQ15007A) under the 2 + 2 Project “RESERVES—Resource and energy reliability by co-digestion of veg-market and slaughterhouse waste.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Affiliation 2 was incorrectly given as 'Anna University, Chennai, 600025, India' but should have been 'Department of Leather Technology, AC Tech campus (Housed at CSIR-CLRI), Anna University, Chennai, 600025, India

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Benish, P.M.R., Mozhiarasi, V., Nagabalaji, V. et al. Optimization of process parameters for enhanced methane production from banana peduncle by thermal pretreatment. Biomass Conv. Bioref. 13, 15251–15265 (2023). https://doi.org/10.1007/s13399-022-02917-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02917-z