Abstract

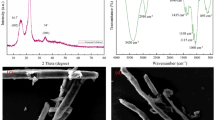

To increase the value of syngas produced by supercritical water gasification (SCWG), K2CO3/γ-Al2O3 composite adsorbents were used to remove CO2 from crude syngas with high content of CO2. Two kinds of γ-Al2O3 particles were evaluated and compared as K2CO3 carriers. Characterization using SEM and N2 adsorption/desorption found that K2CO3/nano-γ-Al2O3 had better dispersibility, larger specific surface area, and pore volume than K2CO3/normal γ-Al2O3; this increased the chance of mass transfer between K2CO3 and CO2. The effects of K2CO3 load ratio, adsorption temperature, gas flow rate, and regeneration temperature on CO2 adsorption performance of K2CO3/nano-γ-Al2O3 were also discussed. K2CO3/nano-γ-Al2O3 had the optimum CO2 adsorption capacity of 2.029 mmol/g at 60 °C. Low gas flow rate was found to produce better CO2 adsorption performance. And the adsorbent could be fully regenerated by heating. Moreover, the adsorption of CO2 by K2CO3/nano-γ-Al2O3 increased the heating value of the syngas from 8.56 MJ/Nm3 to 13.51 MJ/Nm3 and H2 concentration from 41.6% to 75.65%. High selectivity of CO2/H2 (23.5) and (CO2 + CO + CH4)/H2 (17.6) from K2CO3/nano-γ-Al2O3 revealed that it could be a suitable adsorbent for syngas upgrading.

Graphical abstract

Similar content being viewed by others

References

Gu B, Jiang S, Wang H, Wang Z, Jia R, Yang J, He S, Cheng R (2017) Characterization, quantification and management of China’s municipal solid waste in spatiotemporal distributions: A review. Waste Management 61:67–77. https://doi.org/10.1016/j.wasman.2016.11.039

Yan M, Liu J, Yoshikawa K, Jiang J, Zhang Y, Zhu G, Liu Y, Hantoko D (2022) Cascading disposal for food waste by integration of hydrothermal carbonization and supercritical water gasification. Renewable Energy 186:914–926. https://doi.org/10.1016/j.renene.2022.01.049

Kowalski Z, Kulczycka J, Makara A, Harazin P (2021) Quantification of material recovery from meat waste incineration – An approach to an updated food waste hierarchy. Journal of Hazardous Materials 416:126021. https://doi.org/10.1016/j.jhazmat.2021.126021

Mesbah M, Shahsavari S, Soroush E, Rahaei N, Rezakazemi M (2018) Accurate prediction of miscibility of CO2 and supercritical CO2 in ionic liquids using machine learning. Journal of CO2 Utilization 25:99–107. https://doi.org/10.1016/j.jcou.2018.03.004

Cherad R, Onwudili JA, Biller P, Williams PT, Ross AB (2016) Hydrogen production from the catalytic supercritical water gasification of process water generated from hydrothermal liquefaction of microalgae. Fuel 166:24–28. https://doi.org/10.1016/j.fuel.2015.10.088

Yan M, Liu Y, Song Y, Xu A, Zhu G, Jiang J, Hantoko D (2022) Comprehensive experimental study on energy conversion of household kitchen waste via integrated hydrothermal carbonization and supercritical water gasification. Energy 242:123054. https://doi.org/10.1016/j.energy.2021.123054

Su H, Liao W, Wang J, Hantoko D, Zhou Z, Feng H, Jiang J, Yan M (2020) Assessment of supercritical water gasification of food waste under the background of waste sorting: Influences of plastic waste contents. International Journal of Hydrogen Energy 45:21138–21147. https://doi.org/10.1016/j.ijhydene.2020.05.256

Su H, Zhou X, Zheng R, Zhou Z, Zhang Y, Zhu G, Yu C, Hantoko D, Yan M (2021) Hydrothermal carbonization of food waste after oil extraction pre-treatment: Study on hydrochar fuel characteristics, combustion behavior, and removal behavior of sodium and potassium. Science of Total Environment 754:142192. https://doi.org/10.1016/j.scitotenv.2020.142192

Hu M, Guo D, Ma C, Hu Z, Zhang B, Xiao B, Luo S, Wang J (2015) Hydrogen-rich gas production by the gasification of wet MSW (municipal solid waste) coupled with carbon dioxide capture. Energy 90:857–863. https://doi.org/10.1016/j.energy.2015.07.122

Zhang Y, Wibowo H, Zhong L, Horttanainen M, Wang Z, Yu C, Yan M (2021) Cu-BTC-based composite adsorbents for selective adsorption of CO2 from syngas. Separation&Purification Technology. 119644. https://doi.org/10.1016/j.seppur.2021.119644

Li X, Chen S, Liang D, Alvarado-Moralesa M (2020) Low-grade heat energy driven microbial electrosynthesis for ethanol and acetate production from CO2 reduction. Journal of Power Sources 477:228990. https://doi.org/10.1016/j.jpowsour.2020.228990

Yan M, Zhang Y, Grisdanurak N, Wibowo H, Yu C, Kanchanatip E (2022) CO2 adsorption on Cu-BTC to improve the quality of syngas produced from supercritical water gasification, Biomass Conversion. Biorefinery. https://doi.org/10.1007/s13399-021-02194-2

Wu Y, Chen X, Dong W, Zhao C, Zhang Z, Liu D, Liang C (2013) K2CO3/Al2O3 for Capturing CO2 in Flue Gas from Power Plants. Part 5: Carbonation and Failure Behavior of K2CO3/Al2O3 in the Continuous CO2 Sorption-Desorption System. Energy & Fuels 27:4804–4809. https://doi.org/10.1021/ef400778d

Rezakazemi M, Heydari I, Zhang Z (2017) Hybrid systems: Combining membrane and absorption technologies leads to more efficient acid gases (CO2 and H2S) removal from natural gas. Journal of CO2 Utillization 18:362–369. https://doi.org/10.1016/j.jcou.2017.02.006

Younas M, Rezakazemi M, Daud M, Wazir MB, Ahmad S, UllahInamuddin N, Ramakrishna S (2020) Recent progress and remaining challenges in post-combustion CO2 capture using metal-organic frameworks (MOFs). Progress in Energy Combustion Science 80:100849. https://doi.org/10.1016/j.pecs.2020.100849

Nie L, Mu Y, Jin J, Chen J, Mi J (2018) Recent developments and consideration issues in solid adsorbents for CO2 capture from flue gas, Chinese. Journal of Chemical Engineering 26:2303–2317. https://doi.org/10.1016/j.cjche.2018.07.012

Abuelnoor N, AlHajaj A, Khaleel M, Vega LF, Abu-Zahra MRM (2021) Activated carbons from biomass-based sources for CO2 capture applications. Chemosphere 282:131111. https://doi.org/10.1016/j.chemosphere.2021.131111

Lee S-Y, Park S-J (2015) A review on solid adsorbents for carbon dioxide capture. Journal of Indstrial Engineering Chemistry 23:1–11. https://doi.org/10.1016/j.jiec.2014.09.001

Soroush E, Mesbah M, Hajilary N, Rezakazemi M (2019) ANFIS modeling for prediction of CO2 solubility in potassium and sodium based amino acid Salt solutions. Journal of Environmental Chemical Engineering 7:102925. https://doi.org/10.1016/j.jece.2019.102925

Hauchhum L, Mahanta P (2014) Carbon dioxide adsorption on zeolites and activated carbon by pressure swing adsorption in a fixed bed. International Journal of Energy & Environment 5:349–356. https://doi.org/10.1007/s40095-014-0131-3

Shewchuk SR, Mukherjee A, Dalai AK (2021) Selective carbon-based adsorbents for carbon dioxide capture from mixed gas streams and catalytic hydrogenation of CO2 into renewable energy source: A review. Chemical Engineering Science 116735. https://doi.org/10.1016/j.ces.2021.116735

Jayakumar A, Gomez A, Mahinpey N (2016) Post-combustion CO2 capture using solid K2CO3: Discovering the carbonation reaction mechanism. Applied Energy 179:531–543. https://doi.org/10.1016/j.apenergy.2016.06.149

Zhao C, Chen X, Zhao C (2009) CO2 Absorption Using Dry Potassium-Based Sorbents with Different Supports. Energy & Fuels 23:4683–4687. https://doi.org/10.1021/ef900182d

Charoenchaipet J, Piumsomboon P, Chalermsinsuwan B (2020) Development of CO2 capture capacity by using impregnation method in base condition for K2CO3/Al2O3. Energy Reports 6:25–31. https://doi.org/10.1016/j.egyr.2019.11.037

Lee SC, Bo YC, Lee TJ, Chong KR, Ahn YS, Kim JC (2006) CO2 absorption and regeneration of alkali metal-based solid sorbents. Catalysis Today 111:385–390. https://doi.org/10.1016/j.cattod.2005.10.051

Zhu X, Chen C, Wang Q, Shi Y, O’Hare D, Cai N (2019) Roles for K2CO3 doping on elevated temperature CO2 adsorption of potassium promoted layered double oxides. Chemical Engineering Journal 366:181–191. https://doi.org/10.1016/j.cej.2019.01.192

Yan M, Huan Q, Zhang Y, Fang W, Chen F, Pariatamby A, Kanchanatip E, Wibowo H (2022) Effect of operating parameters on CO2 capture from biogas with choline chloride—monoethanolamine deep eutectic solvent and its aqueous solution. Biomass Conversion Biorefinery. https://doi.org/10.1007/s13399-021-02246-7

Zhao Y, Dong Y, Guo Y, Huo F, Yan F, He H (2021) Recent progress of green sorbents-based technologies for low concentration CO2 capture. Chinese Journal of Chemical Engineering 31:113–125. https://doi.org/10.1016/j.cjche.2020.11.005

Wang P, Sun J, Guo Y, Zhao C, Li W, Wang G, Lei S, Lu P (2019) Structurally improved, urea-templated, K2CO3-based sorbent pellets for CO2 capture. Chemical Engineeing Journal 374:20–28. https://doi.org/10.1016/j.cej.2019.05.091

Soroush E, Shahsavari S, Mesbah M, Rezakazemi M, Zhang Z (2018) A robust predictive tool for estimating CO2 solubility in potassium based amino acid salt solutions. Chinese Journal of Chemical Engineering 26:740–746. https://doi.org/10.1016/j.cjche.2017.10.002

Okunev AG, Sharonov VE, Aristov YI, Parmon VN (2000) Sorption of Carbon Dioxide from Wet Gases by K2CO3-in-Porous Matrix: Influence of the Matrix Nature. Reaction Kinetics Catalysis Letters 71:355–362. https://doi.org/10.1023/A:1010395630719

Qin C, Yin J, Ran J, Zhang L, Feng B (2014) Effect of support material on the performance of K2CO3-based pellets for cyclic CO2 capture. Applied Energy 136:280–288. https://doi.org/10.1016/j.apenergy.2014.09.043

Guo Y, Zhao C, Li C (2015) Thermogravimetric analysis of carbonation behaviors of several potassium-based sorbents in low concentration CO2. Journal of Thermal Analysis and Calorimtry 119:441–451. https://doi.org/10.1007/s10973-014-4207-3

Kopyscinski J, Rahman M, Gupta R, Mims CA, Hill JM (2014) Hill, K2CO3 catalyzed CO2 gasification of ash-free coal. Interactions of the catalyst with carbon in N2 and CO2 atmosphere. Fuel 117:1181–1189. https://doi.org/10.1016/j.fuel.2013.07.030

Jo SB, Lee SC, Chae HJ, Cho MS, Lee JB, Baek J-I, Kim JC (2016) Regenerable potassium-based alumina sorbents prepared by CO2 thermal treatment for post-combustion carbon dioxide capture. Korean Journal Chemical Engineering. https://doi.org/10.1007/s11814-016-0162-y

Veselovskaya JV, Derevschikov VS, Kardash TY, Stonkus OA, Trubitsina TA, Okunev AG (2013) Direct CO2 capture from ambient air using K2CO3/Al2O3 composite sorbent. International Journal of Greenhouse Gas Control 17:332–340. https://doi.org/10.1016/j.ijggc.2013.05.006

Park S, Sung D, Choi B, Oh K, Moon K (2006) Sorption of Carbon Dioxide onto Sodium Carbonate. Separation Science and Technology 41. https://doi.org/10.1080/01496390600826659

Jongartklang N, Chanchairoek S, Piumsomboon P, Chalermsinsuwan B (2016) Correlations of kinetic parameters with various system operating conditions for CO2 sorption using K2CO3/Al2O3 solid sorbent in a fixed/fluidized bed reactor. Journal of Environmental Chemical Engineering 4:1938–1947. https://doi.org/10.1016/j.jece.2016.03.019

Zhao C, Chen X, Zhao C (2012) K2CO3/Al2O3 for Capturing CO2 in Flue Gas from Power Plants. Part 1: Carbonation Behaviors of K2CO3/Al2O3. Energy & Fuels. https://doi.org/10.1021/ef200725z

Lee SC, Chae HJ, Lee SJ, Park YH, Ryu CK, Yi CK, Kim JC (2009) Novel regenerable potassium-based dry sorbents for CO2 capture at low temperatures. Journal of Molcular Catalysis B: Enzymatic 56:179–184. https://doi.org/10.1016/j.molcatb.2008.07.007

Ma J, Zhong J, Bao X, Chen X, Wu Y, Cai T, Liu D, Liang C (2021) Continuous CO2 capture performance of K2CO3/Al2O3 sorbents in a novel two-stage integrated bubbling-transport fluidized reactor. Chemical Engineering Journal 404:126465. https://doi.org/10.1016/j.cej.2020.126465

Zhao C, Chen X (2009) Carbonation characteristics of K2CO3/Al2O3 for CO2 capture. Journal of the Chemical Industry & Engineering Society 60:1022–1027

Zhao C, Chen X, Zhao C (2010) Multiple-Cycles Behavior of K2CO3/Al2O3 for CO2 Capture in a Fluidized-Bed Reactor. Energy & Fuels 24:1009–1012. https://doi.org/10.1021/ef901018f

Lee SC, Kim JC (2007) Dry Potassium-Based Sorbents for CO2 Capture. Catalysis Surveys from Asia 11:171–185. https://doi.org/10.1007/s10563-007-9035-z

Acknowledgements

The authors appreciate the financial support from the National Natural Science Foundation, China (51976196), and International Cooperation Project of Zhejiang Province (2019C04026).

Author information

Authors and Affiliations

Contributions

Mi Yan involved in writing—review & editing, supervision, funding acquisition. Yan Zhang took part in investigation, writing an original draft, data curation. Qun Huan took part in resources and supervision. Yucai Song took part in resources and investigation. Xuanyou Zhou took part in investigation and formal analysis. Haryo Wibowo involved in methodology and supervision. Caimeng Yu took part in resources and methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no financial interests or personal relationships that could influence work reported in this paper.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Effect of different γ-Al2O3 types as support of K2CO3 adsorbent of CO2.

• K2CO3/nano-γ-Al2O3 exhibited the highest CO2 adsorption capacity of 2.029 mmol/g at 60 °C.

• The CO2/H2 selectivity of K2CO3/nano-γ-Al2O3 was increased to 23.5.

Rights and permissions

About this article

Cite this article

Yan, M., Zhang, Y., Huan, Q. et al. Effect of operating parameters for CO2 capture from syngas of supercritical water gasification using K2CO3/γ-Al2O3 composite adsorbent. Biomass Conv. Bioref. 14, 3667–3677 (2024). https://doi.org/10.1007/s13399-022-02649-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02649-0