Abstract

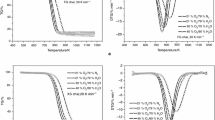

In this study, the combustion experiments were carried out in a simultaneous thermogravimetric analyzer and in an oxidizing atmosphere at four heating rates of 5, 10, 15, and 20 °C/min, respectively. The thermal decomposition kinetics of pyrolysis char of torrefied treatment (T-P-char) from camellia shell were invested by the isoconversional methods of Friedman and Ozawa. The results showed that the correlation coefficients of the experiment data fitting were all over 0.99, and both the average values of activation energy and pre-exponential from Ozawa were higher than those of Friedman method. The enthalpy analysis indicated that the energy difference between the activated complex and the reagent was consistent with activation energy. The Gibbs free energy changed from 185.08 kJ/mol to 204.87 kJ/mol, and the entropy changes were negative, implying that the disorder degree of the products was lower than that of the initial reactants. Moreover, the reaction mechanism transformed from the random nucleation and growth reaction to the nth order reaction when the pyrolysis temperature exceeded 450 °C.

Similar content being viewed by others

References

Qian K, Kumar A, Zhang H et al (2015) Recent advances in utilization of biochar[J]. Renew Sustain Energy Rev 42:1055–1064

Lawrence B, Annamalai K, Sweeten JM et al (2009) Cofiring coal and dairy biomass in a 29kWt furnace. Appl Energy 86(11):2359–2372

Yuan X, He T, Cao H et al (2017) Cattle manure pyrolysis process: Kinetic and thermodynamic analysis with isoconversional methods. Renew Energy 107:489–496

Chen Z, Wang M, Jiang E et al (2018) Pyrolysis of Torrefied Biomass. Trends Biotechnol 36(12):1287–1298

Hernandez JJ, Lapuerta M, Monedero E et al (2018) Biomass quality control in power plants: Technical and economical implications. Renew Energy 115:908–916

Tumuluru JS (2015) High moisture corn stover pelleting in a flat die pellet mill fitted with a 6 mm die: physical properties and specific energy consumption. Energy Sci Eng 3(4):327–341

Serowik M, Figiel A, Nejman M et al (2017) Drying characteristics and some properties of spouted bed dried semi-refined carrageenan[J]. J Food Eng 194:46–57

Eisenbies MH, Volk TA, Posselius J et al (2015) Quality and variability of commercial-scale short rotation willow biomass harvested using a single-pass cut-and-chip forage harvester. Bioenergy Res 8(2):546–559

Wannapeera J, Fungtammasan B, Worasuwannarak N (2011) Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J Anal Appl Pyrol 92(1):99–105

Yildiz S, Gezer ED, Yildiz UC (2006) Mechanical and chemical behavior of spruce wood modified by heat. Build Environ 41(12):1762–1766

Zheng A, Zhao Z, Chang S et al (2012) Effect of torrefaction temperature on product distribution from two-staged pyrolysis of biomass. Energy Fuels 26(5):2968–2974

Ren S, Lei H, Wang L et al (2013) The effects of torrefaction on compositions of bio-oil and syngas from biomass pyrolysis by microwave heating. Bioresour Technol 135:659–664

Apaydın-Varol E, Pütün AE (2012) Preparation and characterization of pyrolytic chars from different biomass samples. J Anal Appl Pyrol 98:29–36

Demiral İ, Kul ŞÇ (2014) Pyrolysis of apricot kernel shell in a fixed-bed reactor: characterization of bio-oil and char. J Anal Appl Pyrol 107:17–24

Zhu L, Lei H, Wang L et al (2015) Biochar of corn stover: microwave-assisted pyrolysis condition induced changes in surface functional groups and characteristics. J Anal Appl Pyrol 115:149–156

Khiari B, Ghouma I, Ferjani AI et al (2020) Kenaf stems: thermal characterization and conversion for biofuel and biochar production. Fuel 262:116654

Xu Y, Chen B (2013) Investigation of thermodynamic parameters in the pyrolysis conversion of biomass and manure to biochars using thermogravimetric analysis. Bioresour Technol 146:485–493

Maia AAD, de Morais LC (2016) Kinetic parameters of red pepper waste as biomass to solid biofuel. Bioresour Technol 204:157–163

Zhu G, Yang L, Gao Y et al (2019) Characterization and pelletization of cotton stalk hydrochar from HTC and combustion kinetics of hydrochar pellets by TGA. Fuel 244:479–491

Shanzhi X, Fang H, Xiaoye L et al (2019) Pyrolysis and combustion characteristics and kinetics of torrefied traditional Chinese medicine waste. J Chem Eng 70(08):3142–3150 (in Chinese with English abstract)

Xu X, Li Z, Jiang E (2019) Torrefaction performance of camellia shell under pyrolysis gas atmosphere. Bioresour Technol 284:178–187

Tu R, Jiang E, Sun Y et al (2018) The pelletization and combustion properties of torrefied Camellia shell via dry and hydrothermal torrefaction: a comparative evaluation. Bioresour Technol 264:78–89

Islam MA, Auta M, Kabir G et al (2016) A thermogravimetric analysis of the combustion kinetics of karanja (Pongamia pinnata) fruit hulls char. Bioresour Technol 200:335–341

Biagini E, Fantei A, Tognotti L (2008) Effect of the heating rate on the devolatilization of biomass residues. Thermochim Acta 472(1–2):55–63

Cai J, Xu D, Dong Z et al (2018) Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: case study of corn stalk. Renew Sustain Energy Rev 82:2705–2715

Chetehouna K, Belayachi N, Rengel B et al (2015) Investigation on the thermal degradation and kinetic parameters of innovative insulation materials using TGA-MS. Appl Therm Eng 81:177–184

Liu S, Chen M, Hu Q et al (2013) The kinetics model and pyrolysis behavior of the aqueous fraction of bio-oil. Bioresour Technol 129:381–386

Zhang J, Jiang B, Wang D (2016) Thermogravimetric and kinetic analysis of bio-crude from hydrothermal liquefaction of Enteromorpha prolifera. Algal Res 18:45–50

Mahmoud S, Samy S (2014) Thermogravimetric analysis of swine manure solids obtained from farrowing, and growing-finishing farms. J Sustain Bioenergy Syst 04(01):75–86

Wang M, Chen Z, Lv J et al (2018) Combustion characteristics and kinetic analysis of heavy tar from continuous pyrolysis of camellia shell. Fuel Process Technol 176:131–137

Yuan H, Yang Q, Wang Y et al (2018) Impact of torrefaction on the fuel properties and combustion characteristics of compost of food waste and sawdust. Energy Fuels 32(3):3469–3476

Chen Q, Zhou J, Liu B et al (2011) Influence of torrefaction pretreatment on biomass gasification technology. Chin Sci Bull 56(14):1449–1456

Chen D, Li Y, Deng M et al (2016) Effect of torrefaction pretreatment and catalytic pyrolysis on the pyrolysis poly-generation of pine wood. Bioresour Technol 214:615–622

Reza MT, Becker W, Sachsenheimer K et al (2014) Hydrothermal carbonization (HTC): near infrared spectroscopy and partial least-squares regression for determination of selective components in HTC solid and liquid products derived from maize silage. Bioresour Technol 161:91–101

Xu X, Tu R, Sun Y et al (2019) The influence of combined pretreatment with surfactant/ultrasonic and hydrothermal carbonization on fuel properties, pyrolysis and combustion behavior of corn stalk. Bioresour Technol 271:427–438

He C, Giannis A, Wang J-Y (2013) Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: hydrochar fuel characteristics and combustion behavior. Appl Energy 111:257–266

Kim YS, Kim YS, Kim SH (2010) Investigation of thermodynamic parameters in the thermal decomposition of plastic waste−waste lube oil compounds. Environ Sci Technol 44(13):5313–5317

Cao H, Xin Y, Wang D et al (2014) Pyrolysis characteristics of cattle manures using a discrete distributed activation energy model. Bioresour Technol 172:219–225

Funding

This work was financially supported by the National Natural Science Foundation of China (grant number: 51706074) and the Bureau of Guangdong Forestry (grant number: No.2020KJCX008).

Author information

Authors and Affiliations

Contributions

Mingfeng Wang: conceptualization, methodology, investigation, project administration, formal analysis.

Riying Qi: writing-original draft preparation, formal analysis.

Aihua Xiang: methodology.

Enchen Jiang: supervision.

Ziwei Li: methodology.

Haobin Xiao: resources.

Xiongquan Tan: data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Riying Qi and Aihua Xiang contributed equally to this work and are joint first authors.

Highlights

1. The kinetic reactions were random nucleation growth and nth order reaction.

2. The pyrolysis and torrefaction temperature had opposite effects on E and lgA under 550 °C.

3. The enthalpies (△H) were consistent with E.

4. The changes of entropies (△S) were negative.

Rights and permissions

About this article

Cite this article

Qi, R., Xiang, A., Wang, M. et al. Combustion characteristics and kinetic analysis for pyrolysis char of torrefied pretreament from camellia shell. Biomass Conv. Bioref. 14, 3501–3512 (2024). https://doi.org/10.1007/s13399-022-02486-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02486-1