Abstract

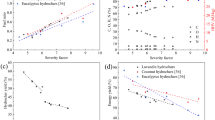

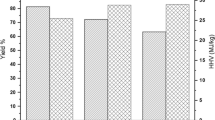

Hydrothermal carbonization (HTC) was employed to convert macadamia nut shell (MCNS) into solid fuel. The effect of hydrothermal conditions was examined by varying the reaction temperature (170, 200, and 230 °C) and water/biomass ratio (2, 3, and 5). The properties of hydrochar were assessed in term of mass yield, energy recovery, higher heating value (HHV), and atomic H/C and O/C ratios. The results showed that HHV of hydrochar was significantly higher than raw MCNS, and progressively increased with increasing HTC temperature while mass yield showed opposite trend. The solid yield from HTC process varied between 58.38 and 78.43% of the initial dry MCNS with HHV around 22-27 MJ/kg. The energy recovery of hydrochars via HTC was in a range of 82.5-93.2%. Higher HTC temperature also increased the degree of coalification and thermal stability of hydrochar by removing volatile matters from the biomass. The removal of carboxyl and -OH groups reduces the O/C ratio leading to the higher energy densification of hydrochars. Hydrochar produced via HTC at 230 °C possessed the highest HHV of 27 MJ/kg, and had the O/C and H/C ratios close to sub-bituminous coal. The findings indicated that hydrothermal carbonization is a potential method to convert agricultural waste such as macadamia nut shell into solid fuel without pre-drying process.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Fan F, Yang Z, Li H, Shi Z, Kan H (2018) Preparation and properties of hydrochars from macadamia nut shell via hydrothermal carbonization. R Soc Open Sci 5(10):181126. https://doi.org/10.1098/rsos.181126

Xavier TP, Lira TS, Schettino MA Jr, Barrozo MAS (2016) A study of pyrolysis of macadamia nut shell: parametric sensitivity analysis of the ipr model. Braz J Chem Eng 33:115–122. https://doi.org/10.1590/0104-6632.20160331s00003629

Tanger P, Field J, Jahn C, DeFoort M, Leach J (2013) Biomass for thermochemical conversion: targets and challenges. Front Plant Sci 4(218):1–20. https://doi.org/10.3389/fpls.2013.00218

Cai J, Liu R (2007) Research on water evaporation in the process of biomass pyrolysis. Energy Fuel 21(6):3695–3697. https://doi.org/10.1021/ef700442n

Owkusumsirisakul J, Keeriang T, Laosiripojana N, Issro C (2020) Investigation on the effects of carbonization parameters on carbon material produced from durian shell. Biomass Conv Biorefin. https://doi.org/10.1007/s13399-020-01033-0

Sikarwar VS, Zhao M, Fennell PS, Shah N, Anthony EJ (2017) Progress in biofuel production from gasification. Prog Energy Combust Sci 61:189–248. https://doi.org/10.1016/j.pecs.2017.04.001

Nakason K, Panyapinyopol B, Kanokkantapong V, Viriya-empikul N, Kraithong W, Pavasant P (2018) Characteristics of hydrochar and hydrothermal liquid products from hydrothermal carbonization of corncob. Biomass Conv Biorefin 8(1):199–210. https://doi.org/10.1007/s13399-017-0279-1

Libra JA, Ro KS, Kammann C, Funke A, Berge ND, Neubauer Y, Titirici MM, Fühner C, Bens O, Kern J, Emmerich KH (2011) Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2(1):71–106. https://doi.org/10.4155/bfs.10.81

Islam MA, Akber MA, Limon SH, Akbor MA, Islam MA (2019) Characterization of solid biofuel produced from banana stalk via hydrothermal carbonization. Biomass Conv Biorefin 9(4):651–658. https://doi.org/10.1007/s13399-019-00405-5

Ding L, Zou B, Li Y, Liu H, Wang Z, Zhao C, Su Y, Guo Y (2013) The production of hydrochar-based hierarchical porous carbons for use as electrochemical supercapacitor electrode materials. Colloids Surf A Physicochem Eng Asp 423:104–111. https://doi.org/10.1016/j.colsurfa.2013.02.003

Shan Y-Q, Deng X-Q, Luque R, Xu Z-X, Yan L, Duan P-G (2020) Hydrothermal carbonization of activated sewage sludge over ammonia-treated Fenton sludge to produce hydrochar for clean fuel use. Green Chem 22(15):5077–5083. https://doi.org/10.1039/D0GC01701A

Chen X, Ma X, Peng X, Lin Y, Yao Z (2018) Conversion of sweet potato waste to solid fuel via hydrothermal carbonization. Bioresour Technol 249:900–907. https://doi.org/10.1016/j.biortech.2017.10.096

Román S, Libra J, Berge N, Sabio E, Ro K, Li L, Ledesma B, Alvarez A, Bae S (2018) Hydrothermal carbonization: Modeling, final properties design and applications: a review. Energies 11(1):216. https://doi.org/10.3390/en11010216

Funke A, Ziegler F (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod Biorefin 4(2):160–177. https://doi.org/10.1002/bbb.198

Volpe M, Fiori L (2017) From olive waste to solid biofuel through hydrothermal carbonisation: the role of temperature and solid load on secondary char formation and hydrochar energy properties. J Anal Appl Pyrolysis 124:63–72. https://doi.org/10.1016/j.jaap.2017.02.022

Hansen LJ, Fendt S, Spliethoff H (2020) Impact of hydrothermal carbonization on combustion properties of residual biomass. Biomass Conv Biorefin. https://doi.org/10.1007/s13399-020-00777-z

Reza MT, Uddin MH, Lynam JG, Hoekman SK, Coronella CJ (2014) Hydrothermal carbonization of loblolly pine: reaction chemistry and water balance. Biomass Conv Biorefin 4(4):311–321. https://doi.org/10.1007/s13399-014-0115-9

Chowdhury ZZ, Krishnan B, Sagadevan S, Rafique RF, Hamizi NAB, Abdul Wahab Y, Khan AA, Johan RB, Al-Douri Y, Kazi SN, Tawab Shah S (2018) Effect of temperature on the physical, electro-chemical and adsorption properties of carbon micro-spheres using hydrothermal carbonization process. Nanomaterials (Basel) 8(8):597. https://doi.org/10.3390/nano8080597

Fan F, Zheng Y, Huang Y, Lu Y, Wang Z, Chen B, Zheng Z (2017) Combustion kinetics of biochar prepared by pyrolysis of macadamia shells. BioResources 12(2):3918–3932. https://doi.org/10.15376/biores.12.2.3918-3932

Basu P (2018) Chapter 3 - Biomass Characteristics. In: Basu P (ed) Biomass gasification, pyrolysis and torrefaction, 3rd edn. Academic Press, pp 49–91. https://doi.org/10.1016/B978-0-12-812992-0.00003-0

Tasca AL, Puccini M, Gori R, Corsi I, Galletti AMR, Vitolo S (2019) Hydrothermal carbonization of sewage sludge: a critical analysis of process severity, hydrochar properties and environmental implications. Waste Manag 93:1–13. https://doi.org/10.1016/j.wasman.2019.05.027

Peng C, Zhai Y, Zhu Y, Xu B, Wang T, Li C, Zeng G (2016) Production of char from sewage sludge employing hydrothermal carbonization: char properties, combustion behavior and thermal characteristics. Fuel 176:110–118. https://doi.org/10.1016/j.fuel.2016.02.068

Cai J, Li B, Chen C, Wang J, Zhao M, Zhang K (2016) Hydrothermal carbonization of tobacco stalk for fuel application. Bioresour Technol 220:305–311. https://doi.org/10.1016/j.biortech.2016.08.098

Agraniotis M, Bergins C, Stein-Cichoszewska M, Kakaras E (2017) 5 - High-efficiency pulverized coal power generation using low-rank coals. In: Luo Z, Agraniotis M (eds) Low-Rank Coals for Power Generation. Woodhead Publishing, Fuel and Chemical Production, pp 95–124. https://doi.org/10.1016/B978-0-08-100895-9.00005-X

Parihar A, Vongsvivut J, Bhattacharya S (2019) Synchrotron-based infra-red spectroscopic insights on thermo-catalytic conversion of cellulosic feedstock to levoglucosenone and furans. ACS Omega 4(5):8747–8757. https://doi.org/10.1021/acsomega.8b03681

Lynam JG, Reza MT, Yan W, Vásquez VR, Coronella CJ (2015) Hydrothermal carbonization of various lignocellulosic biomass. Biomass Conv Biorefin 5(2):173–181. https://doi.org/10.1007/s13399-014-0137-3

Yi Q, Qi F, Cheng G, Zhang Y, Xiao B, Hu Z, Liu S, Cai H, Xu S (2013) Thermogravimetric analysis of co-combustion of biomass and biochar. J Therm Anal Calorim 112(3):1475–1479. https://doi.org/10.1007/s10973-012-2744-1

Naderi M, Vesali-Naseh M (2019) Hydrochar-derived fuels from waste walnut shell through hydrothermal carbonization: characterization and effect of processing parameters. Biomass Conv Biorefin. https://doi.org/10.1007/s13399-019-00513-2

Demirbaş A (2004) Relationships between carbonization temperature and pyrolysis products from biomass. Energy Explor Exploit 22(6):411–419. https://doi.org/10.1260/0144598043749129

Li J, Zhao P, Li T, Lei M, Yan W, Ge S (2020) Pyrolysis behavior of hydrochar from hydrothermal carbonization of pinewood sawdust. J Anal Appl Pyrolysis 146:104771. https://doi.org/10.1016/j.jaap.2020.104771

Funding

This work has received scholarship under the Post-Doctoral Training Program from Khon Kaen University, Thailand. This research was also financially supported by the Faculty of Engineering Research Fund, Thammasat University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samaksaman, U., Pattaraprakorn, W., Neramittagapong, A. et al. Solid fuel production from macadamia nut shell: effect of hydrothermal carbonization conditions on fuel characteristics. Biomass Conv. Bioref. 13, 2225–2232 (2023). https://doi.org/10.1007/s13399-021-01330-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01330-2