Abstract

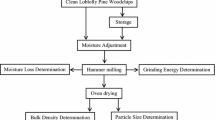

The impact of moisture content (MC of 8 to 27 % wet basis) on physical properties (particle size distribution, average size using Feret, chord, Martins, surface-volume, and area diameter measurement schemes, bulk density, and particle density), fluidization behavior, and minimum fluidization velocities (U mf) of loblolly pine wood grinds were studied. A new correlation for predicting the U mf of loblolly pine wood grinds at different moisture contents was also developed. Results showed that bulk density, particle density, and porosity of grinds were significantly affected by increase in MC (p < 0.05). Diameter of the grinds measured using Feret measurement scheme was consistently the highest while those measured by surface-volume scheme were consistently the lowest with the measured Feret-based diameter about three times the surface-volume based diameters. Particle size data showed that variations in sizes of particle within a sample reduced with increase in MC (coefficient of variation value was 90 at 8.45 % MC and 40 at 27.02 % MC). Generally, as MC increased, the minimum fluidization velocity values increased. The minimum fluidization velocity (Umf) was found to be 0.2 m/s for 8 % MC, 0.24 m/s at 14.86 % MC, 0.28 m/s at 19.86 % MC, and 0.32 m/s for 27.02 % MC. The correlation developed predicted the experimental data with mean relative deviation that was less than 10 %.

Similar content being viewed by others

References

EIA (2015) Short-term energy outlook (STEO). U. S Energy Information Administration, Washington D.C.

Cherubini F (2010) The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Convers Manag 51:1412–1421

Climent M, Corma A, Iborra S (2014) Conversion of biomass platform molecules into fuel additives and liquid hydrocarbon fuels. Green Chem 16:516–547

DOE (2011) US Billion-Ton Update: Biomass supply for a bioenergy and bioproducts industry. R.D. Perlack and B.J. Stokes (Leads), ORNL/TM-2011/224, Oak Ridge National Laboratory (ORNL), Oak Ridge, TN. 227p.

Wear D, Gries J (2011) The southern Forest futures project. Technical Report, USDA Forest Service, General Technical Report SRS, Asheville, NC

Frederick W, Lien S, Courchene C, DeMartini N, Ragauskas A, Iisa K (2008) Co-production of ethanol and cellulose fiber from southern pine: a technical and economic assessment. Biomass Bioenergy 32:1293–1302

Smith WB, Miles PD, Perry CH, Pugh SA (2009) Forest resources of the United States, 2007: a technical document supporting the forest service 2010 RPA Assessment. General Technical Report-USDA Forest Service (WO-78), Washington, DC.

Bhaskar T, Bhavya B, Singh R, Naik DV, Kumar A, Goyal HB (2011) Thermochemical conversion of biomass to biofuels. In biofuels. In: Pandey A, Larroche C, Ricke S, Dussap C, Gnansounou E (eds) Alternative feedstocks and conversion process. Academic Press, New York, NY, pp. 51–77

Oliveira TJP, Cardoso CR, Ataíde CH (2013) Bubbling fluidization of biomass and sand binary mixtures: minimum fluidization velocity and particle segregation. Chem Eng Process Process Intensif 72:113–121. doi:10.1016/j.cep.2013.06.010

Tumuluru JS, Tabil LG, Song Y, Iroba KL, Meda V (2014) Grinding energy and physical properties of chopped and hammer-milled barley, wheat, oat, and canola straws. Biomass Bioenergy 60:58–67. doi:10.1016/j.biombioe.2013.10.011

Littlefield B, Fasina OO, Shaw J, Adhikari S, Via B (2011) Physical and flow properties of pecan shells—particle size and moisture effects. Powder Technol 212:173–180. doi:10.1016/j.powtec.2011.05.011

Probst K, Kingsly A, Pinto R, Bali R, Krishnakumar P, Ileleji K (2013) The effect of moisture content on the grinding performance of corn and corncobs by hammermilling. Trans ASABE 56:10251–11033

Fasina O (2006) Flow and physical properties of switchgrass, peanut hull, and poultry litter. Trans ASABE 49:721–728

Wormsbecker M, Pugsley T (2008) The influence of moisture on the fluidization behaviour of porous pharmaceutical granule. Chem Eng Sci 63:4063–4069. doi:10.1016/j.ces.2008.05.023

Clarke KL, Pugsley T, Hill GA (2005) Fluidization of moist sawdust in binary particle systems in a gas solid fluidized bed. Chem Eng Sci 60:6909–6918. doi:10.1016/j.ces.2005.06.004

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48:89–94

Rao R, Ram T, Bheemarasetti JV (2001) Minimum fluidization velocities of mixtures of biomass and sands. Energy 26:633–644. doi:10.1016/S0360-5442(01)00014-7

Shao Y, Ren B, Jin B, Zhong W, Hu H, Chen X, Sha C (2013) Experimental flow behaviors of irregular particles with silica sand in solid waste fluidized bed. Powder Technol 234(0):67–75. doi:10.1016/j.powtec.2012.09.019

Yang W-C (2007) Modification and re-interpretation of Geldart's classification of powders. Powder Technol 171(2):69–74. doi:10.1016/j.powtec.2006.08.024

Geldart D (1972) The effect of particle size and size distribution on the behaviour of gas-fluidised beds. Powder Technol 6(4):201–215. doi:10.1016/0032-5910(72)83014-6

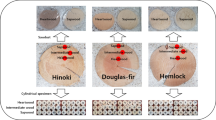

Olatunde G, Fasina O, Adhikari S, McDonald TP, Duke SR (2016) Size measurement method for loblolly pine grinds and influence on predictability of fluidization. Can Biosyst Eng 58:4.1–4.10

Rhodes M (2008) Particle size analysis. Introduction to Particle Technology, First edition. John Wiley & Sons, Ltd, Hoboken, NJ. doi: 10.1002/9780470727102.ch1.

Aznar MP, Gracia-Gorria FA, Corella J (1992) Minimum and maximum velocities for fluidization for mixtures of agricultural and forest residues with a second fluidized solid. II. Experimental results for different mixtures. Int Chem Eng 32:103–113

ASTM (2006) Standard Test Method for Moisture Analysis of Particulate Wood Fuels," ASTM International, West Conshohocken, PA, 2006, doi: 10.1520/E0870-82R06.

Allen T (1997) Particle Size Measurement Volume 2: Surface Area and Pore Size Determination. Chapman and Hall, London, UK

Kunii D, Levenspiel O (1991) Fluidization engineering, vol 2. Butterworth-Heinemann Boston, MA

Gupta CK, Sathiyamoorthy D (1998) Fluid bed technology in materials processing. CRC Press, Boca Raton, FL

SAS (2011) The SAS system for Windows. Release 9.2. edn. SAS Institute, Cary, NC.

Kenney KL, Smith WA, Gresham GL, Westover TL (2013) Understanding biomass feedstock variability. Biofuels 4:111–127

Hehar G, Fasina O, Adhikari S, Fulton J (2014) Ignition and volatilization behavior of dust from loblolly pine wood. Fuel Process Technol 127:117–123. doi:10.1016/j.fuproc.2014.04.036

Gil M, Schott D, Arauzo I, Teruel E (2013) Handling behavior of two milled biomass: SRF poplar and corn Stover. Fuel Process Technol 112:76–85. doi:10.1016/j.fuproc.2013.02.024

Deshpande SD, Bal S, Ojha TP (1993) Physical properties of soybean. J Agric Eng Res 56:89–98. doi:10.1006/jaer.1993.1063

Cui H, Grace JR (2007) Fluidization of biomass particles: a review of experimental multiphase flow aspects. Chem Eng Sci 62:45–55

Mattsson JE, Kofman PD (2002) Method and apparatus for measuring the tendency of solid biofuels to bridge over openings. Biomass Bioenergy 22:179–185. doi:10.1016/S0961-9534(01)00067-8

Yu A, Standish N (1993) Characterisation of non-spherical particles from their packing behaviour. Powder Technol 74:205–213

Manickam IN, Suresh S (2011) Effect of moisture content and particle size on bulk density, porosity, particle density and coefficient of friction of coir pith. International Journal of Engineering Science and Technology 3:2596–2602

Passarini L, Malveau C, Hernandez RE (2014) Water state study of wood structure of four hardwoods below fiber saturation point with nuclear magnetic resonance. Wood Fiber Sci 46:480–488

Almeida G, Hernández R (2006) Changes in physical properties of tropical and temperate hardwoods below and above the fiber saturation point. Wood Sci Technol 40:599–613

Colley Z, Fasina O, Bransby D, Lee Y (2006) Moisture effect on the physical characteristics of switchgrass pellets. Trans ASABE 49:1845–1851

Bernhart M, Fasina O (2009) Moisture effect on the storage, handling and flow properties of poultry litter. Waste Manag 29:1392–1398

Mani S, Tabil LG, Sokhansanj S (2004) Grinding performance and physical properties of wheat and barley straws, corn Stover and switchgrass. Biomass Bioenergy 27:339–352. doi:10.1016/j.biombioe.2004.03.007

Zhou B, Ileleji K, Ejeta G (2008) Physical property relationships of bulk corn Stover particles. Trans ASABE 51:581–590

Srivastava A, Sundaresan S (2002) Role of wall friction in fluidization and standpipe flow. Powder Technol 124:45–54

Gauthier D, Zerguerras S, Flamant G (1999) Influence of the particle size distribution of powders on the velocities of minimum and complete fluidization. Chem Eng J 74:181–196. doi:10.1016/S1385-8947(99)00075-3

Zhang Y, Jin B, Zhong W (2009) Experimental investigation on mixing and segregation behavior of biomass particle in fluidized bed. Chem Eng Process Process Intensif 48:745–754. doi:10.1016/j.cep.2008.09.004

Zhong W, Jin B, Zhang Y, Wang X, Xiao R (2008) Fluidization of biomass particles in a Gas−Solid fluidized bed. Energy Fuel 22:4170–4176. doi:10.1021/ef800495u

Nemec D, Levec J (2005) Flow through packed bed reactors: 1. Single-phase flow. Chem Eng Sci 60:6947–6957. doi:10.1016/j.ces.2005.05.068

Acknowledgments

We gratefully acknowledge funding support from USDA-NIFA Project through the Southeast Partnership for Integrated Biomass Supply Systems (IBSS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Olatunde., G., Fasina., O., McDonald., T. et al. Moisture effect on fluidization behavior of loblolly pine Wood grinds. Biomass Conv. Bioref. 7, 207–220 (2017). https://doi.org/10.1007/s13399-016-0223-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-016-0223-9