Abstract

This study demonstrates a simple centrifugal coating method to prepare high-quality pure cubic phase CsPbBr3 nanocrystal film. The resultant perovskite layers possess a uniform and dense 500 nm-thick, with a bandgap of 2.38 eV, a low trap-state density of 6.9 × 10− 15 cm− 3, and carrier mobility of approximately 19.8 cm2V− 1s− 1. Furthermore, CsPbBr3 NCs-based self-powered photodetectors with high charge carriers’ charge transfer are fabricated. The device shows a low dark current density of 1.93 × 10− 7 A/cm2 at room temperature. Such photodetectors show the highest responsivity of 3.0 AW− 1, specific detectivity of 1.2 × 1013 Jones, and external quantum efficiency (EQE) of 920% at zero bias voltage. The proposed method shows significant promise for use in the lab fabrication of optoelectronic devices based on thin films of nanocrystal perovskite materials.

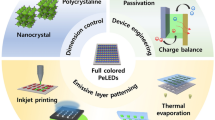

Graphical Abstract

Similar content being viewed by others

1 Introduction

Metal halide perovskite quantum dots semiconductor materials have attracted tremendous attention in recent years for the next-generation optoelectronic devices due to their outstanding optoelectronic characteristics, such as cheap materials and simple fabrication processing. It has been widely used in next-generation solar cells, light-emitting diodes (LEDs), highly sensitive photodetectors, lasers, and so on [1,2,3,4,5]. Compared to the Organic-Inorganic Hybrid Perovskite (OIHP), all-inorganic perovskite shows better thermal and moisture stability [6]. Cubic CsPbBr3, one of the most stable inorganic perovskite materials, has been studied for many applications such as Xray scintillators [7], color enhancement film for wide color gamut liquid crystal displays [8], and photodetector as an absorbed layer or color-converting layer [9, 10]. The nanocrystal and bulk CsPbBr3 film has been fabricated by various methods, such as spin coating; spray coating [11]; thermal evaporation coating method [12], etc… Except for single crystal, the bulk polycrystal perovskite with weak chemical-ionic bonding can transform different crystal systems, including tetragonal and orthorhombic, making it unstable. Thin films of nanocrystal-assembled perovskite have emerged as a promising alternative to bulk films for suppressing ion migration. The nano grain of perovskite film prevents the phase transition from the perovskite to the photoinactive non-perovskite phase, light-induced phase segregation, and decomposition [13]. Moreover, the metastable multi-excitonic states (MESs) in semiconductor nanocrystals can affect multi-electron transfer reactions or multi-photocurrent gain, providing optoelectronic devices with high external quantum efficiency (EQE) [14, 15]. The spin-coating method is usually used for lab-scale fabricating nanocrystal film. Typically, CsPbBr3 nanoparticles are dispersed in a suitable solvent, such as chloroform or toluene, to create a solution with a desired concentration and drop onto the spinning substrate to spread out over the substrate. After that, the substrate is heated to evaporate the solvent, leaving a thin film of CsPbBr3 nanoparticles. However, achieving a dense film with good electrical connectivity between nanoparticles by solution process can be challenging.

In this work, we reported a facile method to produce pure cubic phase CsPbBr3 nanocrystal film using a centrifuge coating method. As a result, compact and crack-free films from particle sizes of 15–30 nm were achieved with a suitable toluene/ethyl acetate solvent ratio for visible light self-powered photodetector application. As a result, the optimized device has an on/off ratio of 7.9 × 104, detectivity of 1.2 × 1013 Jones, and responsivity of 3 A/W at zero bias.

2 Experimental Section

2.1 Synthesis of CsPbBr3 Cubic Nanocrystal

A Typical Hot Injection Process was Applied to Synthesize CsPbBr3 NCs

First, 120 mg of Cs2CO3, 0.5 ml OA and 5 ml ODE are mixed and heated at 120 ˚C until Cs2CO3 powder is completely dissolved to form Cs-oleate solution. Next, 70 mg PbBr2 with 0.5 ml OA, 0.5 ml OLA, and 5 ml ODE was heated at 140 ˚C with magnetic stirring until completely dissolved. Then, 0.5 ml of Cs-oleate rapid is injected into the PbBr2 precursor at 160 °C continued to stir for 1 min. After that, the solution is immediately soaked in ice water. Finally, CsPbBr3 nanocrystals were washed with methyl acetate and centrifuged at 6000 rpm three times to remove the excess organic ligand and redispersed in toluene at 10 mg/ml.

2.2 Centrifuge Coating α-CsPbBr3 NCs Film

Before coating, ethyl acetate was added to the α-CsPbBr3 solution at a volume ratio of 7/3 to help CsPbBr3 precipitate. The FTO (0.8 × 2 cm2) substrate was placed vertically into a centrifuge tube (Φ = 1 cm) and faced with the direction of applied centrifuge force with CsPBr3 NCs dispersed in toluene/methyl acetate mixed solvent at a rotational speed of 15,000 rpm for 5 min. The resulting substrate was gently removed from the tube and dried at ambient air temperature to evaporate any remaining solvent completely.

Device fabrication: laser-patterned Fluorine-doped tin oxide (FTO)-coated glass substrates were washed in an ultrasonic cleaner sequentially using acetone, methanol, isopropyl alcohol, and deionized water. For compact TiO2 as electron transport layers, 0.5 M of titanium butoxide in n-butanol was spin-coated at 3000 rpm for 30 s. The samples were then annealed at 500 °C for 30 min in a furnace. After CsPbBr3 centrifugal coated, 50 nm NiO hole transport layers and 200 nm Al top electrode were coated by sputtering. The active area is 0.04 cm2.

2.2.1 Characterization

Nanocrystal dimensional and lattice planes were confirmed by transmission electron microscopy (TEM, JEM 2100, JEOL). The phase structure and preferred orientation were characterized by X-ray diffraction (Rigaku smart lab, japan) (XRD) with the radiation of Cu-Kα (λ = 1.54 Å), surface and cross-section morphology were viewed by field-emission scanning electron microscopy (SEM, JEOL 760). The AFM image was captured by Scanning Probe Microscope (SPM) SmartSPM-1000. Impedance spectra were observed by Zahner Zenium potentiostat/galvanostat and a frequency response analyzer. For photoresponse characterization, Oscilloscope (LeCroy WaveSurfer) and Keithley model 4200 digital source meter (Keithley, USA) under illumination from a 405 nm laser light source coupled with a chopper. The optical power meter consoler (Thorlabs PM100D) was used to measure the light intensity. A 450 W monochromatic light source Xe arc and spectrometer (NanoLog, Horiba).

3 Results and Discussion

The CsPbBr3 NCs were synthesized by the hot injection method and dispersed in toluene at a concentration of 10 mg/mL. The results of HRTEM, fast Fourier transform (FFT), Fig. 1(a), and XRD analysis (Fig. 1(b)) measurements determine that the fabricated sample is a cubic structure (α-CsPbBr3). By adding ethyl acetate antisolvent and applying centrifugal force, the NCs were assembled into the film. Figure 1 (c) shows the schematic illustration for fabricating CsPbBr3 NCs film via the centrifuge coating. Cross-section and surface scanning electron microscopy (SEM) results reveal that approximately 500 nm-thick films of interconnected CsPbBr3 nanoparticles with dimensions around 10–30 nm adhered directly to the substrate (Fig. 1 (d), (e)). The roughness of the film has a value of 13.5 nm (Fig. 1 (f)), which is equivalent to the average size of the CsPbBr3 crystals as shown in SEM image. The chemical compositions (Cs, Pb, and Br) were identified from the EDS spectra (Fig. 1 (g)). Integrating the characteristic elemental peaks gives quantified atomic ratios (%) 21.7:21.1:57.2 for Cs:Pb:Br, which is consistent with the expected stoichiometric ratio of α-CsPbBr3.

We next study the optical properties of the centrifugal-coated film. Steady-state absorption spectra show the film’s sharp absorption edge at 515 nm (Fig. 2a). A narrow PL emission peak is observed at 520 nm. The Tauc plot indicates a bandgap of 2.38 eV (inset of Fig. 2a), which is the higher bandgap energy of CsPbBr3 bulk film or single crystal (2.21 eV). The PL decay dynamic was further studied, and a bi-exponential function fitted the traces (Fig. 2b). It could be noted that the isolate CsPbBr3 nanocrystal usually exhibits fast radiative recombination with a short PL decay time of nano-second scale. The α-CsPbBr3 NCs films prepared by the centrifugal coated method have an average PL lifetime of τaver. = 60 ns. The long carrier lifetime observed in the centrifuged CsPbBr3 film indicates that the rate of nonradiative recombination is slower, which is likely due to the lower density of defects present in the film. Impedance spectroscopy (IS) was used to measure the charge transfer resistivity in the dark and relative permittivity of the film. The average resistivity, Rct, of the NCs film was found to be ∼ 9.7 in the dark and reduced to 0.3 kΩ under light irradiated, respectively, by fitting the simple RC equivalent circuit. The reduction of resistivity is related to the photoconductive characteristic of the film. To find the relative permittivity (εr), the simple capacitor vs. IS curve relation at high frequencies is defined [16]: \({C_{(\omega \to \infty )}} = \frac{{A{\varepsilon _0}{\varepsilon _r}}}{d} = \frac{1}{{2\pi f{z_{Im}}}}\), which can be reorganized to: \({\rm{log(}}{z_{{\mathop{\rm Im}\nolimits} }}{\rm{)}}\,{\rm{ = }}\, - \,{\rm{log(f)}}\, - \,{\rm{log (2\pi }}\frac{{A{\varepsilon _0}{\varepsilon _r}}}{d}{\rm{)}}\). Where A is the contact area, d is the distance between the electrodes, \({}_{0}\) is the permittivity of the vacuum, ZIm is the imaginary impedance, and f is the frequency. Then the permittivity of CsPbBr3 film εr ≈ 22.5 was extracted from the intercept of a linear fit at the 104 to 105 Hz region (slope fixed at ~ − 1). This value was agreed upon in the previous publication [13]. The I-V characteristic of the electron-only device was determined by employing the space charge-limited current technique [17]. Figure 2c shows the I-V log scale curve, which indicates the presence of a trap-filling region, which starts at VTFL = 0.7 V. The trap-state density, ntrap = 6.9 × 1015 cm−3, was obtained from the provided data using equation: ntrap = 2\({\varepsilon _r}{\varepsilon _0}\)VTFL/qL2; where ε is the CsPbBr3 dielectric constant ≈ 22.5, q is the elemental charge, and L is the thickness of the CsPbBr3 NCs layer. This value is much higher than the CsPbBr3 film prepared by a conventional spin coating method [18]. Further, the mobility of charge carriers was determined by identifying the point where the current demonstrated a linear correlation with the square of the voltage (SCLC region, n ≥ 2). The mobility µ = 19.8 cm2V−1s−1 was deduced using the Mott Gurney law [19] and equation: Jd = \(\frac{{9{\varepsilon _r}{\varepsilon _0}\mu {V^2}}}{{8{L^3}}}\) (4). Jd is the dark-current density, and V is the applied bias in the SCLC region. From the estimate, the magnitude trap-state density and mobility values for the electron-only device were similar to that reported in the literature on the monocrystal film but far better than the spin-coated polycrystal film [20].

(a) Steady-state PL and absorption spectra. Insert: calculation of the optical band gap using the Tauc method. (b) Transient PL (λex = 405 nm). (c) Impedance Spectroscopy (IS) for the calculations of the dielectric constant. Insert: calculations of the charge transfer resistivity. (d) Dark I–V trace of α-CsPbBr3 NCs films

Next, the performance of a self-powered perovskite photodetector fabricated via centrifugal-coated perovskite films was investigated. First, we deposited a TiO2 (50 nm) thin layer by spin coating as an electron transportation layer on the FTO glass substrate. Then we deposited 500 nm thick CsPbBr3 NCs by centrifugal on TiO2/FTO glass substrate. Finally, NiO (50 nm) electron transportation layer and Al top electrode were coated by the sputtering method to receive N-I-P self-powered photodetector device (with 0.04 cm2 active area), as depicted in Fig. 3 (a), and the energy band diagram structure shown in Fig. 3(b). Figure 3(c) shows the photodetector’s dark and light (405 nm, 1 mW/cm2) log scale I-V profile. It could be seen that the high Ion/Ioff ratio of the device located in the range of -1 to + 1 V is related to the low dark current value. The increase of the dark current in extra bias voltage could be related to mobile ionic defects of the perovskite material under electrostatic fields in devices [21].

A detailed study of the self-powered photodetector was performed by assessing their photocurrent as a function of light intensity at zero bias voltage, as shown in Fig. 3(d). As expected, the photocurrent linear increased with increasing illumination intensity from 0.01 to 45 mW/cm− 2. The photodetector made of CsPbBr3 NCs film exhibits a minimal dark current (Idark) of 1.93 × 10− 7 A/cm2, and upon exposure to light with an intensity of 45 mW/cm2, the photocurrent (IPh) surges to a value of 1.5 × 10− 2 A/cm2; this leads to a high Iph/dark of 7.9 × 104. Furthermore, the correlation between Iph and the intensity of the light (P) excitation was modeled using the power law equation Iph = α×Pβ, where α is a constant of proportionality, and β is the exponent that relates to the photoresponse to the light intensity. After fitting the curve shown in Fig. 3e, we determined that the value of β is 0.78. This value is quite close to the ideal value of 1, suggesting minimal recombination and linearity for the photodetection of the device. Two important parameters of the device, the responsivity (R) and specific detectivity (D*), can be obtained from equation [22]: R = Jph-Jdark/Plight, D = R/\(\sqrt{2q{J}_{dark}}\). As shown in Fig. 3f, the highest values achieved for responsivity of 3 A/W corresponds to an EQE of 920% (EQE = \(\frac{{{\rm{Rhc}}}}{{\lambda q}}100\left( \% \right),\) where h denotes Planck’s constant, c represents the speed of light, q is the charge of an electron, and λ is the incident light wavelength), and specific detectivity was 1.2 × 1013 Jones, respectively, when the devices were exposed to illumination with intensity from 0.1 to 1 mW cm−2. The value of EQE greater than 100% is due to the effect of photoconductive gain, G, where G ~ \(\frac{\tau }{{{\tau _t}}}\), with τ and τt corresponding to the lifetime and transit time of the photogenerated carrier [τ ≅ L2/(µeVbi)] (with L being the thickness of the perovskite layer, µe being the electron mobility, and Vbi being the built-in voltage), respectively [3]. The high electron mobility mentioned earlier results in a significantly reduced transit time for photogenerated electrons from CsPbBr3 nanocrystals. This reduction is primarily attributed to the film’s dense structure without any pinholes, which leads to a high value of photoconductive gain (G). Many previous reports have demonstrated a direct correlation between G » 1 and EQE exceeding 100% [3, 23, 24].

As can be seen in Table 1, our photodetectors based on perovskite exhibit performance that is either comparable to or even better than that of other CsPbBr3-based perovskite photodetectors.

Figure 4 shows the photoresponse features that have been plotted to infer the rise time and decay time (τf: time taken for the photocurrent to drop from 90 to 10% of its amplitude). The rise and decay times of devices were evaluated at about 0.58 ms and 3 ms, respectively, as derived from the magnified response curve at 100 Hz (see Fig. 4(a-b)). Due to the long decay time, the Jon/Joff ratio was linearly reduced with the increase of light frequency as shown in Fig. 4 (c-d). In fact, The response times of the photodetectors are anticipated to be in the same range as the carrier lifetimes of the CsPbBr3 nanocrystal film, which is in the nanosecond time scale. Thus, the low carrier mobility exhibited by the NiO and TiO2 hole transport layers may result in slow photoresponse characteristics of the complete device.

4 Conclusion

The high quality of the dense, pinhole, and crack-free α-CsPbBr3 NCs film was achieved by the simple method of applying centrifugal force for coating. The CsPbBr3 NCs film collects superiority of the charge transfer collection, high carrier mobility, and low trap-state density. As a result, the PIN vertically configured perovskite NCs-based photodetectors exhibited excellent figure-of-merit values, such as high responsivity and specific detectivity of 3.0 A/W and 1.2 × 1013 Jones at zero bias.

References

Gong, O., Seo, M., Choi, J., Kim, S., Kim, D., Cho, I., Park, N., Han, G., Jung, H.: High-performing laminated perovskite solar cells by surface engineering of perovskite films. Appl. Surf. Sci. 591, 153148 (2022)

Park, J., Kim, S., Kim, J., Heo, J., Im, S.: Spray-coated nanocrystalline CsPbBr3 perovskite thin-films for large area and efficient rigid and flexible light emitting diodes. J. Alloys Compd. 918, 165560 (2022)

Pammi, S., Maddaka, R., Tran, V., Eom, J., Pecunia, V., Majumder, S., Kim, M., Yoon, S.: Bromine Doping of MAPbI3 Films deposited via Chemical Vapor Deposition enables efficient and photo-stable self-powered photodetectors Adv. Opt. Mater. 8(19), 2000845 (2020)

Guo, Y., Su, J., Wang, L., Lin, Z., Hao, Y., Chang, J.: Improved Doping and Optoelectronic Properties of Zn-Doped CsPbBr3 Perovskite through Mn Codoping Approach. J. Phys. Chem. Lett. 12, 3393–3400 (2021)

Yang, Y., Gao, F., Liu, Q., Dong, J., Li, D., Luo, X., Guo, J., Shi, J., Lin, Y., Song, W., Wang, X., Li, S.: Long and Ultrastable All-Inorganic single-crystal CsPbBr3 microwires: One-step solution In-Plane self-assembly at low temperature and application for high-performance photodetectors. J. Phys. Chem. Lett. 11, 7224–7231 (2020)

Sun, H., Zhang, J., Gan, X., Yu, L., Yuan, H., Shang, M., Lu, C., Hou, D., Hu, Z., Zhu, Y., Han, L.: Pb-Reduced CsPb0.9Zn0.1I2Br thin Films for efficient Perovskite Solar cells. Adv. Energy Mater. 9, 1900896 (2019)

Mykhaylyk, V., Kraus, H., Kapustianyk, V., Kim, H., Mercere, P., Rudko, M., Da Silva, P., Antonyak, O., Dendebera, M.: Bright and fast scintillations of an inorganic halide perovskite CsPbBr3 crystal at cryogenic temperatures. Sci. Rep. 10, 1–11 (2020)

Nguyen, T., Luu, T., Nguyen, D., Duong, T.: Comparative study on Backlighting Unit using CsPbBr3 Nanocrystals/KSFM phosphor + blue LED and commercial WLED in Liquid Crystal. Disp. J Electron Mater. 50(4), 1827–1834 (2021)

Miao, J., Zhang, F.: Recent progress on highly sensitive perovskite photodetectors. J. Mater. Chem. C. 7, 1741–1791 (2019)

Kang, C., Dursun, I., Liu, G., Sinatra, L., Sun, X., Kong, M., Pan, J., Maitry, P., Ooi, E., Ng, T., Mohammed, O., Bakr, O., Ooi, B.: High-speed colour-converting photodetector with all-inorganic CsPbBr3 perovskite nanocrystals for ultraviolet light communication, Light: Science & Applications 8, 94 (2019)

Duan, J., Dou, D., Zhao, Y., Wang, Y., Yang, X., Yuan, H., He, B., Tang, Q.: Spray-assisted deposition of CsPbBr3 films in ambient air for large-area inorganic perovskite solar cells. Mater. Today Energy. 10, 146–152 (2018)

Li, J., Gao, R., Gao, F., Lei, J., Wang, H., Wu, X., Li, J., Liu, H., Hua, X.: Frank) Liu, fabrication of efficient CsPbBr3 perovskite solar cells by single-source thermal evaporation. J. Alloys Compd. 818, 152903 (2020)

Ho, K., Wei, M., Sargent, E., Walker, G.: Grain Transformation and Degradation mechanism of formamidinium and cesium lead Iodide Perovskite under Humidity and Light. ACS Energy Lett. 6, 3, 934–940 (2021)

Mandal, S., Tkachenko, N.V.: Multiphoton Excitation of CsPbBr3 Perovskite Quantum Dots (PQDs): How many Electrons can one PQD donate to multiple molecular acceptors? J. Phys. Chem. Lett. 10, 2775–2781 (2019)

Pammi, S., Maddaka, R., Tran, V.D., Eom, J.H., Pecunia, V., Majumder, S., Kim, M.D., Yoon, S.G.: CVD-deposited hybrid lead halide perovskite films for high-responsivity,self-powered photodetectors with enhanced photo stability under ambient conditions. Nano Energy. 74, 104872 (2020)

Rakita, Y., Kedem, N., Gupta, S., Sadhanala, A., Kalchenko, V., Böhm, M.L., Kulbak, M., Friend, R.H., Cahen, D., Hodes, G.: Low-temperature solution-grown CsPbBr3 single crystals and their characterisation. Cryst. Growth Des. 16, 5717–5725 (2016)

Duijnstee, E., Ball, J., Corre, V., Koster, L., Snaith, H., Lim, J.: Toward understanding space-charge Limited current measurements on metal Halide Perovskites. ACS Energy Lett. 5, 2, 376–384 (2020)

Cai, L., Liang, D., Wang, X., Zang, J., Bai, G., Hong, Z., Zou, Y., Song, T., Sun, B.: Efficient and bright pure-blue all-inorganic Perovskite Light-Emitting Diodes from an eco-friendly Alloy. J. Phys. Chem. Lett. 12(6), 1747–1753 (2021)

Almora, O., Matt, G., These, A., Kanak, A., Levchuk, L., Shrestha, S., Osvet, A., Brabec, C.: Garcia-Belmonte. Surface versus bulk currents and Ionic Space-Charge Effects in CsPbBr3 single crystals. J. Phys. Chem. Lett. 13(17), 3824–3830 (2020)

Futscher, M., Gangishetty, M., Congreve, D., Ehrler, B.: Quantifying mobile ions and electronic defects in perovskite-based devices with temperature-dependent capacitance measurements: Frequency vs time domain. J. Chem. Phys. 152, 044202 (2020)

Zhou, H., Fan, L., He, G., Yuan, C., Wang, Y., Shi, S., Sui, N., Chen, B., Zhang, Y., Yao, Zhao, J., Zhang, X., Yin, J.: Low defects, large area and high stability of all-inorganic lead halide perovskite CsPbBr3 thin films with micron-grains: Via heat-spraying process for self-driven photodetector. RSC Adv. 8(51), 29089–29095 (2018)

Tran, P., Tran, B., Nguyen, D., Nguyen, T., Tran, V., Duong, T.: A Facile Centrifuge Coating Method for High-Performance CsPbBr3 Compact and Crack-Free Nanocrystal Thin Film Photodetector. Crystals. 12(5), 587 (2022)

Mondal, H., Ray, S.K., Chakrabarty, P., Pal, S., Gangopadhyay, G., Das, S., Das, S., Basori, R.: High-performance Chlorophyll-b/Si Nanowire Heterostructure for Self-Biasing Bioinorganic Hybrid Photodetectors, ACS Appl. Nano Mater. 4, 5726–5736 (2021)

Shen, K., Xu, H., Li, X., Guo, J., Sathasivam, S., Wang, M., Ren, A., Choy, K.L., Parkin, I.P., Guo, Z., Wu, J.: Flexible and self-powered photodetector arrays based on All-Inorganic CsPbBr3 Quantum Dots. Adv. Mater. 32, 2000004 (2020)

Wang, R., Zhou, H., Wu, B., Wu, D., Tao, L., Wang, H., Peng, X., Zhang, J., Wang, H.: Self-powered CsPbBr3 Perovskite Nanonet Photodetector with a Hollow Vertical structure. J. Phys. Chem. Lett. 12, 7519–7525 (2021)

Cao, F., Tian, W., Deng, K., Wang, M., Li, L.: Self-powered UV–Vis–NIR Photodetector based on Conjugated‐Polymer/CsPbBr3 nanowire array. Adv. Funct. Mater. 29(48), 1906756 (2019)

Zhou, H., Zeng, J., Song, Z., Grice, C.R., Chen, C., Song, Z., Zhao, D., Wang, H., Yan, Y.: Self-powered All-Inorganic Perovskite Microcrystal Photodetectors with High Detectivity. J. Phys. Chem. Lett. 9(8), 2043–2048 (2018)

Acknowledgements

This research was funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant No. 103.02-2020.46.

Author information

Authors and Affiliations

Contributions

Phuong-Nam Tran: Investigation, Methodology. Tuan- Pham Van: Validation,, Duy-Hung Nguyen, Writing - original draft. Van-Dang Tran: Writing - original draft. Thanh-Tung Duong: Supervision, Conceptualization, Writing - review & editing.

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Duong, TT., Tran, PN., Van, TP. et al. A Dense, Pinholes-free Pure Cubic Phase CsPbBr3 Nanocrystals Film for High-performance Photodetector. Electron. Mater. Lett. 20, 217–223 (2024). https://doi.org/10.1007/s13391-023-00448-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-023-00448-x