Abstract

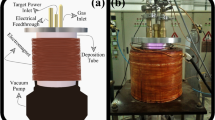

Effects of sputtering power, working pressure, and bias on the growth rate, crystallinity, and resistivity of Ag thin films deposited by direct current (DC) magnetron sputtering were investigated. Thin films were deposited on the substrate under the electric biases of − 300, 0, and + 300 V for 30 min with sputtering powers of 20, 50, 100, and 200 W and working pressures of 2.5, 5, 10, and 20 mTorr. Under all sputtering powers, the growth rate of the thin film was increased by the positive bias, whereas it was decreased by the negative bias. For example, the film thicknesses were 345.7, 377.9, and 416.0 nm at − 300, 0, and + 300 V, respectively, at a sputtering power of 100 W and a working pressure of 2.5 mTorr. The bias effect was enhanced as the working pressure decreased. Considering the change of the film growth rate according to the bias, the amount of negatively charged flux was estimated to be roughly 10%. As the working pressure decreased, the crystallinity of the deposited films increased by the positive bias whereas it decreased by the negative bias, which is indicated by the full width at half maximum (FWHM) determined by X-ray diffraction of the Ag (111) peak. The film resistivity had the same tendency. This change in the deposition behavior of the Ag film can be understood as the effect of the charged flux.

Graphic Abstract

Similar content being viewed by others

References

Markov, I.V.: Crystal Growth for Beginners. World Scientific (2003)

Cölfen, H.: Mesocrystals and Nonclassical Crystallization. Wiley, England (2008)

De Yoreo, J.J., Gilbert, P.U.P.A., Sommerdijk, N.A.J.M., Penn, R.L., Whitelam, S., Joester, D., Zhang, H., Rimer, J.D., Navrotsky, A., Banfield, J.F., Wallace, A.F., Michel, F.M., Meldrum, F.C., Cölfen, H., Dove, P.M.: Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science 349(6247), aaa6760 (2015)

Gebauer, D., Völkel, A., Cölfen, H.: Stable prenucleation calcium carbonate clusters. Science 322(5909), 1819 (2008)

Jehannin, M., Rao, A., Cölfen, H.: New horizons of nonclassical crystallization. J. Am. Chem. Soc. 141(26), 10120–10136 (2019)

Niederberger, M., Cölfen, H.: Oriented attachment and mesocrystals: non-classical crystallization mechanisms based on nanoparticle assembly. Phys. Chem. Chem. Phys. 8(28), 3271–3287 (2006)

Song, R., Krasia-Christoforou, T., Debus, C., Cölfen, H.: Structure and magnetic property control of copper hydroxide acetate by non-classical crystallization. Small 13(9), 1602702 (2017)

Abd El-Fattah, H.A., El-Mahallawi, I., Shazly, M.H., Khalifa, W.A.: Microstructure evolution of NiTi magnetron sputtered thin film on different substrates. Key Eng. Mater. 835, 68–74 (2020)

Feng, X., Gao, R., Wang, R., Zhang, G.: Non-classical crystal growth on a hydrophobic substrate: learning from bivalve nacre. CrystEngComm 22(18), 3100–3105 (2020)

Lizandara-Pueyo, C., Dilger, S., Wagner, M.R., Gerigk, M., Hoffmann, A., Polarz, S.: Li-doped ZnO nanorods with single-crystal quality—non-classical crystallization and self-assembly into mesoporous materials. CrystEngComm 16(8), 1525–1531 (2014)

Sadri, B., Pernitsky, D., Sadrzadeh, M.: Aggregation and deposition of colloidal particles: effect of surface properties of collector beads. Colloids Surfaces A: Physicochemical and Engineering Aspects 530, 46–52 (2017)

Ivanov, V.K., Fedorov, P.P., Baranchikov, A.Y., Osiko, V.V.: Oriented attachment of particles: 100 years of investigations of non-classical crystal growth. Russ. Chem. Rev. 83(12), 1204–1222 (2014)

Grüner, D., Shen, Z.: Ordered coalescence of nano-crystals during rapid solidification of ceramic melts. CrystEngComm 13(17), 5303–5305 (2011)

Hu, M., Jiang, J.-S., Ji, R.-P., Zeng, Y.: Prussian Blue mesocrystals prepared by a facile hydrothermal method. CrystEngComm 11(11), 2257–2259 (2009)

Jin, B., Liu, Z., Tang, R.: Recent experimental explorations of non-classical nucleation. CrystEngComm 22(24), 4057–4073 (2020)

Banner, D.J., Firlar, E., Rehak, P., Phakatkar, A.H., Foroozan, T., Osborn, J.K., Sorokina, L.V., Narayanan, S., Tahseen, T., Baggia, Y., Král, P., Shokuhfar, T., Shahbazian-Yassar, R.: In situ liquid-cell tem observation of multiphase classical and nonclassical nucleation of calcium oxalate. Adv. Func. Mater. 31(18), 2007736 (2021)

Cookman, J., Hamilton, V., Hall, S.R., Bangert, U.: Non-classical crystallisation pathway directly observed for a pharmaceutical crystal via liquid phase electron microscopy. Sci. Rep. 10(1), 19156 (2020)

Liao, H.-G., Cui, L., Whitelam, S., Zheng, H.: Real-time imaging of Pt3Fe nanorod growth in solution. Science 336(6084), 1011–1014 (2012)

Hwang, N.M.: Non-Classical Crystallization of Thin Films and Nanostructures in CVD and PVD Processes. Springer, Netherlands (2016)

Youn, W.K., Lee, S.S., Lee, J.Y., Kim, C.S., Hwang, N.M., Iijima, S.: Comparison of the deposition behavior of charged silicon nanoparticles between floating and grounded substrates. J. Phys. Chem. C 118(22), 11946–11953 (2014)

Park, S.-W., Jung, J.-S., Kim, K.-S., Kim, K.-H., Hwang, N.-M.: Effect of bias applied to the substrate on the low temperature growth of silicon epitaxial films during RF-PECVD. Cryst. Growth Des. 18(10), 5816–5823 (2018)

Lee, Y., Han, H.N., Kim, W., Hwang, N.M.: Effect of bipolar charging of SiH4 on the growth rate and crystallinity of silicon films grown in the atmospheric pressure chemical vapor deposition process. Electron. Mater. Lett. 16(4), 385–395 (2020)

Kim, D., Kim, D., Kwon, J.H., Kim, K.S., Hwang, N.M.: Generation of charged SiC nanoparticles during HWCVD process. Electron. Mater. Lett. 16(5), 498–505 (2020)

Jeon, I.-D., Kim, D.-Y., Hwang, N.-M.: Spontaneous generation of charged atoms or clusters during thermal evaporation of silver. Z. Met. 96(2), 186–190 (2005)

Jang, G.-S., Kim, D.-Y., Hwang, N.-M.: The effect of charged ag nanoparticles on thin film growth during DC magnetron sputtering. Coatings 10(8), 736 (2020)

Kwon, J.-H., Kim, D.-Y., Hwang, N.-M.: Generation of charged Ti nanoparticles and their deposition behavior with a substrate bias during RF magnetron sputtering. Coatings 10(5), 443 (2020)

Kwon, J.H., Kim, D., Kim, K.S., Hwang, N.M.: Preparation of highly (002) oriented Ti films on a floating Si (100) substrate by RF magnetron sputtering. Electron. Mater. Lett. 16(1), 14–21 (2020)

Zhang, C., Ding, W., Wang, H., Chai, W., Ju, D.: Influences of working pressure on properties for TiO2 films deposited by DC pulse magnetron sputtering. J. Environ. Sci. 21(6), 741–744 (2009)

Seidl, M., Perdew, J.P., Brajczewska, M., Fiolhais, C.: Ionization energy and electron affinity of a metal cluster in the stabilized jellium model: Size effect and charging limit. J. Chem. Phys. 108(19), 8182–8189 (1998)

Muniz, F.T., Miranda, M.A., Morilla Dos Santos, C., Sasaki, J.M.: The Scherrer equation and the dynamical theory of X-ray diffraction. Acta Crystallogr. Sect. A: Found. Adv. 72(Pt 3), 385–390 (2016)

Jang, G.S., Kim, D.Y., Hwang, N.M.: Dependence of the generation behavior of charged nanoparticles and Ag film growth on sputtering power during DC magnetron sputtering. Electron. Mater. Lett. 17(2), 172–180 (2021)

Acknowledgements

This work was supported by the Global Frontier Program through the Global Frontier Hybrid Interface Materials (GFHIM) of the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (MSIT) (No. NRF-2013M3A6B1078874), the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2020R1A5A6017701), and Samsung Electronics Co., Ltd. (0417-20200170).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jang, G.S., Ahn, S.M. & Hwang, NM. Effects of Sputtering Power, Working Pressure, and Electric Bias on the Deposition Behavior of Ag Films during DC Magnetron Sputtering Considering the Generation of Charged Flux. Electron. Mater. Lett. 18, 57–68 (2022). https://doi.org/10.1007/s13391-021-00314-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-021-00314-8