Abstract

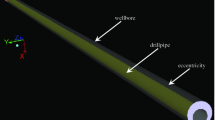

Coiled tubing sidetracking has proved to be an effective means of old well resurrection, which can accurately connect reservoirs to improve reserve production. However, it is difficult for the cuttings in the wellbore to circulate out of the bottom in this process. In this study, the coupling analysis method of the Computational Fluid Dynamics–Discrete Element Model (CFD-DEM) is applied to model the interaction between fluid and cuttings to characterize the migration process of cuttings. The influence of the cuttings shape and whether the lower part of the window needs to be plugged (whether there is a pocket in the wellbore) on the critical flow rate of cuttings are analyzed. The case studies indicate that the critical flow rate of the identical cuttings in the wellbore with a pocket is significantly higher than that without pockets, about 1.2 to 1.8 times, and the difference is more significant as the particle volume decreases. When the particle size is controlled to be 4 mm, the volume of cuttings in various shapes is different, and the critical flow rate is positively related to its volume. When there is a pocket in the wellbore, the volume of the cuttings increases to 3.6 times, and the critical flow rate increases to 1.15 times; while when there are no pockets in the wellbore, the critical flow rate increases to 1.69 times. Therefore, reducing the particle volume in the wellbore without pockets to reduce the drilling fluid flow rate is more effective than the wellbore with a pocket. Furthermore, a new three-dimensional quantitative model of flatness is proposed to describe the particles. The flatness of the particles is positively correlated with the critical flow rate under the conditions of the same volume and roughness of cuttings particles. When the flatness is reduced by 15%, 20% and 38%, its critical flow rate is reduced by 2.8%, 4.9% and 8.8%, respectively, and the ratio between them is about five times. It is an excellent choice to adopt flatness to measure the critical flow rate of non-spherical particles. The research results have a significant reference value for field drilling.

Similar content being viewed by others

Abbreviations

- \({\varvec{u}}_{{\text{f}}}\) :

-

Velocity of the fluid, \({\text{m}}/{\text{s}}\)

- \({\varvec{u}}_{{\text{s}}}\) :

-

Settling velocity of particle, \({\text{m}}/{\text{s}}\)

- \(p\) :

-

Fluid pressure, \({\text{Pa}}\)

- \({\varvec{F}}_{{\text{p}}}^{f}\) :

-

Momentum exchange term, \({\text{N}}/{\text{m}}^{3}\)

- \(m_{{\text{p}}}\) :

-

Mass of the particle, \({\text{N}}\)

- \({\varvec{u}}_{{\text{p}}}\) :

-

Velocity of the particle, \({\text{m}}/{\text{s}}\)

- \(V_{{\text{P}}}\) :

-

Volume of the particle, \({\text{m}}^{3}\)

- \({\varvec{F}}_{{{\text{c}},{\text{p}}}}\) :

-

Contact force on the particle, \({\text{N}}\)

- \({\varvec{F}}_{{\text{d}}}\) :

-

Drag force, \({\text{N}}\)

- \({\varvec{F}}_{{\text{M}}}\) :

-

Magnus force, \({\text{N}}\)

- \({\varvec{F}}_{{\text{S}}}\) :

-

Saffman force, \({\text{N}}\)

- \(I_{{\text{p}}}\) :

-

Moment of inertia, \({\text{kg}} \cdot {\text{m}}^{3}\)

- \({\varvec{\omega}}_{{\text{p}}}\) :

-

Rotational angular velocity of the particle, \({\text{rad}} \cdot {\text{s}}^{ - 1}\)

- \({\varvec{T}}_{{\text{p}}}\) :

-

Total torque experienced by the particle, \({\text{N}} \cdot {\text{m}}\)

- \({\varvec{T}}_{{{\text{t}},{\text{p}}}}^{{}} ,{\varvec{T}}_{{{\text{r}},{\text{p}}}}^{{}}\) :

-

Tangential and normal torque arising from the contact force, \({\text{N}} \cdot {\text{m}}\)

- \({\varvec{T}}_{{{\text{DT}}}}^{p}\) :

-

Fluid-induced torque, \({\text{N}} \cdot {\text{m}}\)

- \({\varvec{F}}_{{\text{n}}}\) :

-

Normal force, \({\text{N}}\)

- \({\varvec{F}}_{{\text{n}}}^{d}\) :

-

Normal damping force, \({\text{N}}\)

- \({\varvec{F}}_{{\text{t}}}\) :

-

Tangential force, \({\text{N}}\)

- \({\varvec{F}}_{{\text{t}}}^{d}\) :

-

Tangential damping force, \({\text{N}}\)

- \(E^{ * }\) :

-

Equivalent Young’ s modulus, \({\text{Pa}}\)

- \(R^{ * }\) :

-

Equivalent radius, \({\text{m}}\)

- \(m^{ * }\) :

-

Equivalent mass, \({\text{kg}}\)

- \(E_{{\text{p}}} ,E_{{\text{q}}}\) :

-

Young’s modulus, \({\text{Pa}}\)

- \(R_{{\text{p}}} ,R_{{\text{q}}}\) :

-

Radius of particles, \({\text{m}}\)

- \(\mathbf{v}_{{\text{n}}}^{{{\text{rel}}}}\) :

-

Normal component of the relative velocity, \({\text{m}}/{\text{s}}\)

- \(S_{{\text{n}}}\) :

-

Normal stiffness component, \({\text{N}}/{\text{m}}^{3}\)

- \(S_{{\text{t}}}\) :

-

Tangential stiffness, \({\text{N}}/{\text{m}}^{3}\)

- \(\mathbf{v}_{{\text{t}}}^{{{\text{rel}}}}\) :

-

Tangential component of the relative velocity, \({\text{m}}/{\text{s}}\)

- \(G^{ * }\) :

-

Equivalent shear modulus, \({\text{Pa}}\)

- \(C_{{\text{D}}}\) :

-

Drag coefficient

- \({\text{Re}}_{{\text{p}}}\) :

-

Particle Reynolds number

- \(C_{{{\text{LM}}}}\) :

-

Rotational lift coefficient

- \({\varvec{u}}_{{\text{r}}}\) :

-

Relative linear velocity of the particles relative to the fluid, \({\text{m}}/{\text{s}}\)

- \(C_{{{\text{LS}}}}\) :

-

Lift coefficient

- \({\text{Re}}_{{\text{s}}}\) :

-

Vorticity Reynolds number

- \(S_{{{\text{sp}}}}\) :

-

Spherical surface area of the same volume as the particle, \({\text{m}}^{2}\)

- \(S_{{\text{p}}}\) :

-

Surface area of the particle, \({\text{m}}^{2}\)

- \(\alpha_{{\text{f}}}\) :

-

Volume fraction of the fluid

- \(\rho_{{\text{f}}}\) :

-

Density of the fluid, \({\text{kg}}/{\text{m}}^{3}\)

- \(\rho_{{\text{p}}}\) :

-

Density of the particle, \({\text{kg}}/{\text{m}}^{3}\)

- \(\tau\) :

-

Fluid viscous stress tensor, \({\text{Pa}}\)

- \(\mu\) :

-

Fluid viscosity, \({\text{Pa}} \cdot {\text{s}}\)

- \(\delta_{{\text{n}}}\) :

-

Normal overlap, \({\text{m}}\)

- \(\beta\) :

-

Recovery coefficient

- \(\delta_{{\text{t}}}\) :

-

Tangential overlap, \(m\)

- \(\mu_{{\text{s}}}\) :

-

Sliding friction coefficient

- \(\phi\) :

-

Spherical coefficient

- \(\phi_{\rm o}\) :

-

Flatness

- \(\phi_{\rm s}\) :

-

Shape coefficient

- \(a_{{\text{R}}}\) :

-

Resistance acceleration, \({\text{m}}/{\text{s}}^{2}\)

- \(v_{\rm p}^{{}} ,v_{\rm q}^{{}}\) :

-

Poisson ratio

- \({\varvec{\omega}}_{{\text{r}}}\) :

-

Relative angular velocity of the particles relative to the fluid, \({\text{rad}} \cdot {\text{s}}^{ - 1}\),

- \({\varvec{\omega}}_{{\text{f}}}\) :

-

Rotation degree of the fluid velocity, \({\text{rad}} \cdot {\text{s}}^{ - 1}\)

References

Xu, J.; Zhao, C.; Zheng, J.; Xuan, G.; Liu, H.: Application of group fracturing technology in the old area of low permeable oilfield: a case from Jilin Oilfield, Songliao Basin. In: International Petroleum Technology Conference. (2019).

Zhang, J.; Wang, G.; Kai, H.E.; Chenglin, Y.E.: Practice and understanding of sidetracking horizontal drilling in old wells in Sulige Gas Field, NW China. Pet. Explor. Dev. 46(2), 9 (2019). https://doi.org/10.1016/S1876-3804(19)60018-2

Yue, Q.B.; Liu, J.B.; Zhang, L.G.; Zhang, Q.: The posting-buckling analysis and evaluations of limit drilling length for coiled tubing in the sidetrack horizontal well. J. Petrol. Sci. Eng. 164, 559–570 (2018). https://doi.org/10.1016/j.petrol.2018.01.061

Roehrlich, M.: Coiled tubing drilling-a concept for directional drilling in pressure depleted reservoirs. Oil Gas-Eur Mag 42(3), 121–122 (2016)

Bin, W.; Gensheng, L.; Zhongwei, H.; Jingbin, L.; Dongbo, Z.; Hao, L.: Hydraulics calculations and field application of radial jet drilling. SPE Drill. Complet. 31(01), 071–081 (2016)

Pineda, R.; Lindsey, B.J.; Taggart, M.; Smith, S.; Ababou, M.: A chronological review of concentric coiled tubing vacuum technology: past, present and future. In: SPE/ICoTA Coiled Tubing & Well Intervention Conference & Exhibition. SPE-163937-MS. Woodlands, Texas, USA (2012).

Qin, D.; Liu, Q.; Wu, Q.; Huang, S.: Hydraulic extension ability of radial jet drilling with multi-nozzles jet bit. IOP Conf. Ser. 474, 032043 (2020)

Wang, X.; Yu, J.; Sun, Y.; Yang, C.; Jiang, L.; Liu, C.: A solids-free brine drilling fluid system for coiled tubing drilling. Pet. Explor. Dev. 45(3), 529–535 (2018). https://doi.org/10.1016/S1876-3804(18)30058-2

Vaziri, E.; Simjoo, M.; Chahardowli, M.: Application of foam as drilling fluid for cuttings transport in horizontal and inclined wells: a numerical study using computational fluid dynamics. J. Petrol. Sci. Eng. 194, 107325 (2020). https://doi.org/10.1016/j.petrol.2020.107325

Sun, S.; Feng, J.; Hou, Z.; Yu, G.: Prediction of cuttings transport behavior under drill string rotation conditions in high-inclination section. Int. J. Pattern Recognit. Artif. Intell. 34(10), 2059035 (2020). https://doi.org/10.1142/S0218001420590351

Lin, P.; Zheng, W.; Wu, X.: Influencing factors of the wellbore cleaning efficiency in extended reach wells based on seawater drilling fluid. Arab. J. Sci. Eng. 46(7), 6979–6988 (2021). https://doi.org/10.1007/s13369-021-05386-0

Oseh, J.O.; Norddin, M.N.A.M.; Ismail, I.; Gbadamosi, A.O.; Agi, A.; Ismail, A.R.: Experimental investigation of cuttings transportation in deviated and horizontal wellbores using polypropylene-nanosilica composite drilling mud. J. Petrol. Sci. Eng. 189, 106958 (2020). https://doi.org/10.1016/j.petrol.2020.106958

Smith, S.R.; Rafati, R.; Haddad, A.S.; Cooper, A.; Hamidi, H.: Application of aluminium oxide nanoparticles to enhance rheological and filtration properties of water based muds at HPHT Conditions. Colloids Surf. A 537, 361–371 (2017). https://doi.org/10.1016/j.colsurfa.2017.10.050

Boyou, N.V.; Ismail, I.; Sulaiman, W.R.W.; Haddad, A.S.; Husein, N.; Hui, H.T.; Nadaraja, K.: Experimental investigation of hole cleaning in directional drilling by using nano-enhanced water-based drilling fluids. J. Petrol. Sci. Eng. 176, 220–231 (2019). https://doi.org/10.1016/j.petrol.2019.01.063

Tomren, P.H.; Iyoho, A.W.; Azar, J.J.: Experimental study of cuttings transport in directional wells. SPE Drill. Eng. 1(1), 43–56 (1986). https://doi.org/10.2118/12123-PA

Xiang, H.F.; Sun, B.J.; Li, H.; Niu, H.B.: Experimental research on cuttings transport in extended-reach horizontal well. Oil Drill. Prod. Technol. 36(3), 1–6 (2014). https://doi.org/10.13639/j.odpt.2014.03.001

Heshamudin, N.S.; Katende, A.; Rashid, H.A.; Ismail, I.; Sagala, F.; Samsuri, A.: Experimental investigation of the effect of drill pipe rotation on improving hole cleaning using water-based mud enriched with polypropylene beads in vertical and horizontal wellbores. J. Petrol. Sci. Eng. 179, 1173–1185 (2019). https://doi.org/10.1016/j.petrol.2019.04.086

Huque, M.M.; Rahman, M.A.; Zendehboudi, S.; Butt, S.; Imtiaz, S.: Investigation of cuttings transport in a horizontal well with high-speed visualization and electrical resistance tomography technique. J. Natl. Gas Sci. Eng. 92, 103968 (2021). https://doi.org/10.1016/j.jngse.2021.103968

Akhshik, S.; Behzad, M.; Rajabi, M.: CFD-DEM approach to investigate the effect of drill pipe rotation on cuttings transport behavior. J. Petrol. Sci. Eng. 127, 229–244 (2015). https://doi.org/10.1016/j.petrol.2015.01.017

Liu, Y.S.; Gao, D.L.; Li, X.; Qin, X.; Li, H.; Liu, H.: Investigating the jet comminuting process in cuttings transport by coupling the CFD/DEM method and bonded-particle model. SPE J. 24(5), 2020–2032 (2019). https://doi.org/10.2118/188917-PA

Huque, M.M.; Rahman, M.A.; Zendehboudi, S.; Butt, S.; Imtiaz, S.: Experimental and numerical study of cuttings transport in inclined drilling operations. J. Petrol. Sci. Eng. 208, 109394 (2021). https://doi.org/10.1016/j.petrol.2021.109394

Zhang, H.T.; Zhang, O.Y.; Li, B.T.; Zhang, J.; Xu, X.Y.; Wei, J.P.: Effect of drill pipe rotation on gas-solid flow characteristics of negative pressure pneumatic conveying using CFD-DEM simulation. Powder Technol. 387(4), 48–60 (2021). https://doi.org/10.1016/j.powtec.2021.04.017

Yan, T.; Qu, J.Y.; Sun, X.F.; Chen, Y.; Hu, Q.B.; Li, W.; Zhang, H.X.: Numerical investigation on horizontal wellbore hole cleaning with a four-lobed drill pipe using CFD-DEM method. Powder Technol. 375(1), 249–261 (2020). https://doi.org/10.1016/j.powtec.2020.07.103

Song, X.Z.; Xu, Z.M.; Li, G.S.; Pang, Z.Y.; Zhu, Z.P.: A new model for predicting drag coefficient and settling velocity of spherical and non-spherical particle in Newtonian fluid. Powder Technol. 321, 242–250 (2017). https://doi.org/10.1016/j.powtec.2017.08.017

Magnus, W.: On the exponential solution of differential equations for a linear operator. Commun. Pure Appl. Math. 7(4), 649–673 (2010)

Sommerfeld, M.: Theoretical and experimental modeling of particulate flows. Von Karman Institute for Fluid Dynamics Series (2000).

Altuhafi, F.; O’Sullivan, C.; Cavarretta, I.: Analysis of an image-based method to quantify the size and shape of sand particles. J. Geotech. Geoenviron. Eng. 139(8), 1290–1307 (2012). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000855

Li, W.; Chen, H.H.; Wan, Z.B.; Bian, X.C.: Quantify the size and shape of aggregate particles based on the double mirror method. In: International Symposium Environmental Vibration and Transportation Geodynamics. Hangzhou, China. (2018). https://doi.org/10.1007/978-981-10-4508-0_48

Acknowledgements

The authors gratefully acknowledge the financial support from the Natural Science Foundation of China (No. 42002307), Fundamental Research Funds for the Central Universities, China (No. 2652019070) and National Key Research and Development Program of China (No.2018YFC0603405, 2021YFA0719100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meng, Q., Liu, Y., Qin, X. et al. Investigation on the Critical Flow Rate of Cuttings Transport in Coiled Tubing Sidetracking by Using a CFD-DEM Coupled Model. Arab J Sci Eng 48, 9311–9327 (2023). https://doi.org/10.1007/s13369-022-07355-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07355-7