Abstract

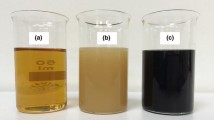

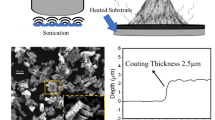

Tribological performance comparison of Graphene nanoplatelet and Halloysite clay nanotube-based nanolubricants in an aluminum-based hybrid composite/steel tribo-contact was addressed by suspending nanoparticles in concentrations of 0.025, 0.05, 0.1 and 0.5%wt within SAE 5W40 motor oil. Dispersion stability and thermophysical properties of the designed nanolubricants were also evaluated. In order to perform tribological experiments by using a pin-on-ring configuration tribometer at various loads and rotation speeds, a hybrid composite was fabricated by powder metallurgy-extrusion method and characterized. The lubrication regime was characterized using stribeck curves and minimum film thickness. The worn surfaces morphology of the pin materials were characterized by Scanning electron microscopy images, Energy-dispersive X-ray spectroscopy and surface roughness measurements. The obtained highest friction coefficient and wear rate reductions were 40 and 36% with 0.5%wt Graphene nanoplatelet, and 25 and 10% for 0.1%wt Halloysite clay nanotube-based nanolubricants, respectively, during a mixed lubrication regime. The wear mechanism on the worn surface of the hybrid composite was predominantly abrasive with plastic yielding and delamination. Scanning electron microscopy images, Energy-dispersive X-ray spectroscopy and surface roughness measurements confirmed the Graphene nanoplatelet and Halloysite clay nanotube deposition on the worn surfaces and the formation of tribo-films that protect the sliding contacts.

Similar content being viewed by others

References

Singh, J.P.; Singh, S.; Nandi, T.; Ghosh, S.K.: Development of graphitic lubricant nanoparticles based nanolubricant for automotive applications: Thermophysical and tribological properties followed by IC engine performance. Powder Technol. 387, 31–47 (2021)

Flores-Castañeda, M.; Camps, E.; Camacho-López, M.; Muhl, S.; García, E.; Figueroa, M.: Bismuth nanoparticles synthesized by laser ablation in lubricant oils for tribological tests. J. Alloy. Compd. 643, S67–S70 (2015)

Koshy, C.P.; Rajendrakumar, P.K.; Thottackkad, M.V.: Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS2 nanoparticles at elevated temperatures. Wear 330, 288–308 (2015)

Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E.J.T.I.: Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 65, 28–36 (2013)

Elomaa, O.; Oksanen, J.; Hakala, T.J.; Shenderova, O.; Koskinen, J.: A comparison of tribological properties of evenly distributed and agglomerated diamond nanoparticles in lubricated high-load steel–steel contact. Tribol. Int. 71, 62–68 (2014)

Xie, H.; Jiang, B.; He, J.; Xia, X.; Pan, F.: Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol. Int. 93, 63–70 (2016)

Dai, W.; Kheireddin, B.; Gao, H.; Liang, H.: Roles of nanoparticles in oil lubrication. Tribol. Int. 102, 88–98 (2016)

Xu, N.; Zhang, M.; Li, W.; Zhao, G.; Wang, X.; Liu, W.: Study on the selectivity of calcium carbonate nanoparticles under the boundary lubrication condition. Wear 307, 35–43 (2013)

Borda, F.L.G.; De Oliveira, S.J.R.; Lazaro, L.M.S.M.; Leiróz, A.J.K.: Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 117, 52–58 (2018)

Keklikcioglu, O.; Dagdevir, T.; Ozceyhan, V.: Heat transfer and pressure drop investigation of graphene nanoplatelet-water and titanium dioxide-water nanofluids in a horizontal tube. Appl. Therm. Eng. 162, 114256 (2019)

Berman, D.; Erdemir, A.; Sumant, A.V.: Graphene: a new emerging lubricant. Mater. Today 17(1), 31–42 (2014)

del Río, J.M.; López, E.R.; Fernández, J.; García, F.: Thermophysical and tribological properties of dispersions based on graphene and a trimethylolpropane trioleate oil. J. Mol. Liq. 268, 854–866 (2018)

Ramón-Raygoza, E.D.; Rivera-Solorio, C.I.; Giménez-Torres, E.; Maldonado-Cortés, D.; Cardenas-Alemán, E.; Cué-Sampedro, R.: Development of nanolubricant based on impregnated multilayer graphene for automotive applications: analysis of tribological properties. Powder Technol. 302, 363–371 (2016)

Wang, J.; Guo, X.; He, Y.; Jiang, M.; Gu, K.: Tribological characteristics of graphene as grease additive under different contact forms. Tribol. Int. 127, 457–469 (2018)

Patel, J.; Kiani, A.: Tribological capabilities of graphene and titanium dioxide nano additives in solid and liquid base lubricants. Appl. Sci. 9(8), 1629 (2019)

Eswaraiah, V.; Sankaranarayanan, V.; Ramaprabhu, S.: Graphene-based engine oil nanofluids for tribological applications. ACS Appl. Mater. Interfaces 3(11), 4221–4227 (2011)

Azman, S.S.N.; Zulkifli, N.W.M.; Masjuki, H.; Gulzar, M.; Zahid, R.: Study of tribological properties of lubricating oil blend added with graphene nanoplatelets. J. Mater. Res. 31(13), 1932 (2016)

Guo, Y.B.; Zhang, S.W.: The tribological properties of multi-layered graphene as additives of PAO2 oil in steel–steel contacts. Lubricants 4(3), 30 (2016)

Lin, J.; Wang, L.; Chen, G.: Modification of graphene platelets and their tribological properties as a lubricant additive. Tribol. Lett. 41(1), 209–215 (2011)

Fan, X.; Xia, Y.; Wang, L.; Li, W.: Multilayer graphene as a lubricating additive in bentone grease. Tribol. Lett. 55(3), 455–464 (2014)

Suresha, B.; Hemanth, G.; Rakesh, A.; Adarsh, K.M.: Tribological behaviour of neem oil with and without graphene nanoplatelets using four-ball tester. Adv. Tribol. (2020).

Rasheed, A.K.; Khalid, M.; Javeed, A.; Rashmi, W.; Gupta, T.C.; Chan, A.: Heat transfer and tribological performance of graphene nanolubricant in an internal combustion engine. Tribol. Int. 103, 504–515 (2016)

Gürses, A.: Introduction to polymer–clay nanocomposites. CRC Press, Boca Raton (2016)

Peña-Parás, L.; Maldonado-Cortés, D.; García, P.; Irigoyen, M.; Taha-Tijerina, J.; Guerra, J.: Tribological performance of halloysite clay nanotubes as green lubricant additives. Wear 376, 885–892 (2017)

Peña-Parás, L.; Sánchez-Fernández, J.A.; Martínez, C.R.; Ontiveros, J.A.; Saldívar, K.I.; Urbina, L.M.; Arias, M.J.; García-Pineda, P.; Castaños, B.: Evaluation of anti-wear properties of metalworking fluids enhanced with halloysite nanotubes. Appl. Sci. 7(10), 1019 (2017)

Rebis, J.; Frydrych, J.; Skibinski, J.; Rozniatowski, K.: Cheap nano-clay additive as a lubricating enhancer. J. Power Technol. 97(2), 103–109 (2017)

Pena-Paras, L.; Maldonado-Cortes, D.; Castillo, F.; Leal, J.; Garza, S.: Application of nanoclay lubricants for lowering wear of tools for steel meshing—a case study. IOP Mater. Sci. Eng. 400(7), 072004 (2018)

Suresha, B.; Hemanth, G.; Rakesh, A.; Adarsh, K.M.: Tribological behaviour of pongamia oil as lubricant with and without halloysite nanotubes using four-ball tester. AIP Conference Proceedings, vol. 2128, p. 030011 (2019)

Singh, H.; Bhowmick, H.: Influence of nanoclay on the thermophysical properties and lubricity characteristics of mineral oil. Mater. Today Proc. 18, 1058–1066 (2019)

Nair, F.; Karamis, M.B.: An investigation of the tribological interaction between die damage and billet deformation during MMC extrusion. Tribol. Int. 43(1–2), 347–355 (2010)

Alaneme, K.K.; Fajemisin, A.V.; Maledi, N.B.: Development of aluminium-based composites reinforced with steel and graphite particles: structural, mechanical and wear characterization. J. Market. Res. 8(1), 670–682 (2019)

Eslamian, M.; Rak, J.; Ashgriz, N.: Preparation of aluminum/silicon carbide metal matrix composites using centrifugal atomization. Powder Technol. 184(1), 11–20 (2018)

Pournaderi, S.; Mahdavi, S.; Akhlaghi, F.: Fabrication of Al/Al2O3 composites by in-situ powder metallurgy (IPM). Powder Technol. 229, 276–284 (2012)

Singh, H.; Bhowmick, H.: Tribological behaviour of hybrid AMMC sliding against steel and cast iron under MWCNT-Oil lubrication. Tribol. Int. 127, 509–519 (2018)

Singh, H.; Bhowmick, H.: Lubrication characteristics and wear mechanism mapping for hybrid aluminium metal matrix composite sliding under surfactant functionalized MWCNT-oil. Tribol. Int. 145, 106152 (2020)

Dixit G.; Khan M.M.: Sliding wear response of an aluminium metal matrix composite: effect of solid lubricant particle size. Jordan J. Mech. Ind. Eng. 8(6) (2014)

Rooj, S.; Das, A.; Thakur, V.; Mahaling, R.N.; Bhowmick, A.K.; Heinrich, G.: Preparation and properties of natural nanocomposites based on natural rubber and naturally occurring halloysite nanotubes. Mater. Des. 31(4), 2151–2156 (2010)

Sezer, N.; Atieh, M.A.; Koç, M.: comprehensive review on synthesis, stability, thermophysical properties, and characterization of nanofluids. Powder Technol. 344, 404–431 (2019)

Li, B.; Li, R.: Preparation and property of ultrahigh molecular weight polyethylene/halloysite nanotube fiber. Fibers Polym. 17(7), 1043–1047 (2016)

Lin, T.; Zhao, S.; Niu, S.; Lyu, Z.; Han, K.; Hu, X.: Halloysite nanotube functionalized with La-Ca bimetallic oxides as novel transesterification catalyst for biodiesel production with molecular simulation. Energy Convers. Manag. 220, 113138 (2020)

Asadi, A.; Aberoumand, S.; Moradikazerouni, A.; Pourfattah, F.; Żyła, G.; Estellé, P.; Arabkoohsar, A.: Recent advances in preparation methods and thermophysical properties of oil-based nanofluids: a state-of-the-art review. Powder Technol. 352, 209–226 (2019)

Zuin, A.; Cousseau, T.; Sinatora, A.; Toma, S.H.; Araki, K.; Toma, H.E.: Lipophilic magnetite nanoparticles coated with stearic acid: a potential agent for friction and wear reduction. Tribol. Int. 112, 10–19 (2017)

Chamsa-Ard, W.; Brundavanam, S.; Fung, C.C.; Fawcett, D.; Poinern, G.: Nanofluid types, their synthesis, properties and incorporation in direct solar thermal collectors: a review. Nanomaterials 7(6), 131 (2017)

Wadi, V.T.; Özmen, Ö.; Karamış, M.B.: Experimental analysis and modeling of viscosity and thermal conductivity of GNPs/SAE 5W40 nanolubricant. Ind. Lubr. Tribol. 73(1), 74–81 (2020)

Dardan, E.; Afrand, M.; Isfahani, A.M.: Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl. Therm. Eng. 109, 524–534 (2016)

Ali, M.K.A.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C.: Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 103, 540–554 (2016)

Kamel, B.M.; Mohamed, A.; Sherbiny, M.; El, A.K.A.; Abd-Rabou, M.: Tribological properties of graphene nanosheets as an additive in calcium grease. J. Dispers. Sci. Technol. 38(10), 1495–1500 (2017)

Xia, W.; Zhao, J.; Wu, H.; Jiao, S.; Jiang, Z.: Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles on the tribological behaviour of oxidised high-speed steel. Tribol. Int. 110, 77–85 (2017)

Sia, S.Y.; Bassyony, E.Z.; Sarhan, A.A.: Development of SiO2 nanolubrication system to be used in sliding bearings. Int. J. Adv. Manuf. Technol. 71(5–8), 1277–1284 (2014)

Wu, H.; Qin, L.; Dong, G.; Hua, M.; Yang, S.; Zhang, J.: An investigation on the lubrication mechanism of MoS2 nano sheet in point contact: the manner of particle entering the contact area. Tribol. Int. 107, 48–55 (2017)

Lee, H.-Y.: Effect of changing sliding speed on wear behavior of mild carbon steel. Met. Mater. Int. 26, 1749–1756 (2020)

Khonsari, M.M.; Booser, E.R.: Applied tribology: bearing design an lubrication, 2nd edn. John Wiley and sons, Louisiana (2008)

Iranmanesh, S.; Mehrali, M.; Sadeghinezhad, E.; Ang, B.C.; Ong, H.C.; Esmaeilzadeh, A.: Evaluation of viscosity and thermal conductivity of graphene nanoplatelets nanofluids through a combined experimental–statistical approach using respond surface methodology method. Int. Commun. Heat Mass Transf. 79, 74–80 (2016)

Wu, L.; Gu, L.; Xie, Z.; Zhang, C.; Song, B.: Improved tribological properties of Si3N4/GCr15 sliding pairs with few layer graphene as oil additives. Ceram. Int. 43(16), 14218–14224 (2017)

Farsadi, M.; Bagheri, S.; Ismail, N.A.: Nanocomposite of functionalized graphene and molybdenum disulfide as friction modifier additive for lubricant. J. Mol. Liq. 244, 304–308 (2017)

Acknowledgements

Authors express their gratitude to the Scientific Research Projects Division of Erciyes University for financial support through contracts FDK-2018-8351 and FBA-2019-9301.

Author information

Authors and Affiliations

Contributions

VTW: Conceptualization, Methodology, Investigation, Writing- Original draft preparation. AG: Conceptualization, Methodology, Analysis, Validation. MBK: Supervision, Funding acquisition, Writing- Reviewing and Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data Availability

The dataset used in the manuscript is available from the corresponding author on reasonable request.

Rights and permissions

About this article

Cite this article

Wadi, V.T., Göçer, A. & Karamiş, M.B. Tribological Characteristics of GNPs and HNTs as Lubricant Additives in an Aluminum-Based Hybrid Composite-Steel Contact. Arab J Sci Eng 47, 9099–9118 (2022). https://doi.org/10.1007/s13369-022-06569-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06569-z