Abstract

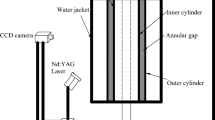

A partially averaged Navier–Stokes model is used to simulate the fluid field in the coaxial cylindrical gap, and the reliability of numerical simulation is verified by comparing with the particle image velocimetry experiment. Firstly, the influence of structural parameters and physical parameters on heat transfer enhancement of the slit model is investigated. In the next step, response surface method is adopted to obtain the slit parameter structure with optimal heat transfer performance. Slit width (2.5 mm < w < 15 mm), slit number (9 < N < 15), Reynolds number (2000 < Re < 4652) and Prandtl number (5.90 < Pr < 6.22) are selected as design parameters while the average Nusselt number is taken as the objective function. The results show that the increasing of Reynolds number strengthens the jet flow of vortex pairs, which enhances the heat transfer capacity of the Taylor vortex. As increasing the slit width, heat transfer performance of the model increases first and then decreases. The optimized model with slit structure parameters of N = 12 and w = 13.15 mm has the best heat transfer capacity, which increases by 12.42% when Reynolds Numbers is 4652.

Similar content being viewed by others

Abbreviations

- A 0 :

-

Heat transfer area (mm2)

- C p :

-

Specific heat of fluid at constant pressure (J/kg·K)

- d :

-

Annular gap width (mm)

- D h :

-

Hydraulic diameter (mm)

- G k :

-

Term of turbulent kinetic energy generated by time average velocity gradient

- L :

-

Length of the cylinders (mm)

- N :

-

Slit number

- \(\overline{{{\text{Nu}}}}\) :

-

Average Nusselt number

- Pr:

-

Prandtl number

- p :

-

Pressure (pa)

- \(\overline{{{{q}}}}\) :

-

Average heat flux (W mm−2)

- Re:

-

Reynolds number

- r i :

-

Radius of the inner cylinder (mm)

- r o :

-

Radius of the outer cylinder (mm)

- R*:

-

Dimensionless number of radial position

- S T :

-

Viscous dissipation term

- T out :

-

Temperature of the stationary outer cylinder wall (°C)

- T in :

-

Temperature of the rotating inner cylinder wall (°C)

- ΔT :

-

Temperature gradient (°C)

- v r :

-

Radial velocity (m/s)

- v z :

-

Axial velocity (m/s)

- w :

-

Slit width (mm)

- z :

-

Axial position (mm)

- z*:

-

Dimensionless number of axial position

- Ω :

-

Angular velocity (rad/s)

- λ :

-

Coefficient of thermal conductivity (W mm−1 K−1)

- ω :

-

Vorticity

- η :

-

Radius ratio

- Г :

-

Aspect ratio

- f k :

-

Turbulent kinetic energy term

- f ε :

-

Turbulent kinetic energy dissipation term

- k :

-

Total turbulent kinetic energy

- ε :

-

Total dissipation rate

- σ k, σ ε :

-

Modified Prandtl number corresponding to k and ε

- ν :

-

Kinematical viscosity of the working fluid (Pa s)

- α :

-

Thermal expansion coefficient (1/°C)

References

Nachouane, A.B.; Abdelli, A.; Friedrich, G. et al: Numerical approach for thermal analysis of heat transfer into a very narrow air gap of a totally enclosed permanent magnet integrated starter generator. In: Energy Conversion Congress and Exposition, pp. 1749–1756 (2015)

Lian, W.; Chang, W.; Xuan, Y.: Numerical investigation on flow and thermal features of a rotating heat pipe. Appl. Therm. Eng. 101, 92–100 (2016)

Zhu, X.; Ostilla-Mónico, R.; Verzicco, R.; Lohse, D.: Direct numerical simulation of Taylor–Couette flow with grooved walls: torque scaling and flow structure. J. Fluid Mech. 794, 746–774 (2015)

Liu, D.; Wang, Y.Z.; Ding, S.C., et al.: Slit wall and heat transfer effect on the Taylor vortex flow. Energies 8(3), 1958–1974 (2015)

Nicolas, L.; Federico, T.; Franccedil, B., et al.: Taylor–Couette–Poiseuille flow and heat transfer in an annular channel with a slotted rotor. Int. J. Therm. Sci. 112, 92–103 (2017)

Nouri-Borujerdi, A.; Nakhchi, M.E.: Experimental study of convective heat transfer in the entrance region of an annulus with an external grooved surface. Exp. Therm. Fluid Sci. 98, 557–656 (2018)

Nouri-Borujerdi, A.; Nakhchi, M.E.: Prediction of local shear stress and heat transfer between internal rotating cylinder and longitudinal cavities on stationary cylinder with various shapes. Int. J. Therm. Sci. 138, 512–520 (2019)

Yang, H.; Zhang, W.; Zhu, Z.C.: Unsteady mixed convection in a square enclosure with an inner cylinder rotating in a bi-directional and time-periodic mode. Int. J. Heat Mass Transf. 136, 563–580 (2019)

Yeh, J.P.; Tzeng, S.C.; Tseng, H.C.: Temperature distributions in rotary-blade coupling of a 4WD vehicle with longitudinal ribbed turbulators. Appl. Energy 80(2), 155–167 (2005)

Sébastien, P.; Haddadi, S.; Stéphane, V.: Numerical modeling of fluid flow and heat transfer in a narrow Taylor–Couette–Poiseuille system. Int. J. Heat Fluid Flow 32(1), 128–144 (2011)

Abou-Ziyan, H.Z.; Helali, A.H.B.; Selim, M.Y.: Enhancement of forced convection in wide cylindrical annular channel using rotating inner pipe with interrupted helical fins. Heat Mass Transf. 95, 996–1007 (2016)

Shi, L.; Rampp, M.; Hof, B., et al.: A hybrid MPI-OpenMP parallel implementation for pseudospectral simulations with application to Taylor–Couette flow. Comput. Fluids 106, 1–11 (2013)

Nemri, M.; Charton, S.; Climent, E.: Mixing and axial dispersion in Taylor–Couette flows: the effect of the flow regime. Chem. Eng. Sci. 139, 109–124 (2015)

Aubert, A.; Poncet, S.; Le Gal, P.; Viazzo, S., et al.: Velocity and temperature measurements in a turbulent water-filled Taylor–Couette–Poiseuille system. Int. J. Therm. Sci. 90, 238–247 (2015)

Tuliszka-Sznitko, E.; Kiełczewski, K.: The numerical simulation of Taylor–Couette flow with radial temperature gradient. J. Phys. Conf. Ser. 760, 012035 (2016)

Spandan, V.; Ostilla-Monico, R.; Lohse, D., et al.: Identifying coherent structures and vortex clusters in Taylor–Couette turbulence. J. Phys. Conf. Ser. 708(1), 012006 (2016)

Ouallia, H.; Mekadem, M.; Bouabdallah, A.; Gad-El-Hak, M.: Enhanced turbulence in the Taylor–Couette flow system. Procedia Eng. 157, 443–450 (2016)

Fujii, T.; Oishi, Y.; Kawai, H., et al.: Frequency analysis of chaotic flow in transition to turbulence in Taylor–Couette system with small aspect ratio. J. Phys. Conf. Ser. 801, 012063 (2017)

Hosain, M.L.; Fdhila, R.B.: Air-gap heat transfer in rotating electrical machines: a parametric study. Energy Procedia 142, 4176–4181 (2017)

Hosain, M.L.; Fdhila, R.B.; Nnberg, K.R.: Air-gap flow and thermal analysis of rotating machines using CFD. Energy Procedia 105, 5153–5159 (2017)

Masuda, H.; Yoshida, S.; Horie, T., et al.: Flow dynamics in Taylor–Couette flow reactor with axial distribution of temperature. AIChE J. 64(3), 1075–1082 (2017)

Schneider, M.; Younis, B.A.; Weigand, B.: Large-eddy simulations of flow and heat transfer in heated concentric annulus with inner cylinder rotation. Int. J. Heat Mass Transf. 114, 1248–1262 (2017)

Naseem, U.; Awan, M.B.; Aseem, S.B., et al.: Experimental investigation of flow instabilities in a wide gap turbulent rotating Taylor–Couette flow. Case Stud. Therm. Eng. 14, 100449 (2019)

Wang, G.H.; Wang, D.B.; Deng, J., et al.: Experimental and numerical study on the heat transfer and flow characteristics in shell side of helically coiled tube heat exchanger based on multi-objective optimization. Int. J. Heat Mass Transf. 137, 349–364 (2019)

Mohapatra, T.; Sahoo, S.S.; Padhi, B.N.: Analysis, prediction and multi-response optimization of heat transfer characteristics of a three fluid heat exchanger using response surface methodology and desirability function approach. Appl. Therm. Eng. 151, 536–555 (2019)

Khalajzadeh, V.; Heidarinejad, G.; Srebric, J.: Parameters optimization of a vertical ground heat exchanger based on response surface methodology. Energy Build. 43(6), 1288–1294 (2011)

Salviano, L.O.; Dezan, D.J.; Yanagihara, J.I.: Optimization of winglet-type vortex generator positions and angles in plate-fin compact heat exchanger: response surface methodology and direct optimization. Int. J. Heat Mass Transf. 82, 373–387 (2015)

Nouri-Borujerdi, A.; Nakhchi, M.E.: Optimization of the heat transfer coefficient and pressure drop of Taylor–Couette–Poiseuille flows between an inner rotating cylinder and an outer grooved stationary cylinder. Int. J. Heat Mass Transf. 108(part_PB), 1449–1459 (2017)

Liu, D.; Kang, I.S.; Cha, J.E.; Kim, H.B.: Experimental study on radial temperature gradient effect of a Taylor–Couette flow with axial wall slits. Exp. Therm. Fluid Sci. 35, 1282–1292 (2011)

Zhu, F.N.; Liu, D.; Zhang, P., et al.: Effect of exterior cylinder slit wall on wavy vortex flow n gap of concentric cylinders. J. Drain. Irrig. Mach. Eng. 33(6), 516–520 (2015)

Fénot, M.; Bertin, Y.; Dorignac, E., et al.: A review of heat transfer between concentric rotating cylinders with or without axial flow. Int. J. Therm. Sci. 50(7), 1138–1155 (2011)

Li, Q.; Kang, C.; Zhu, Y.: Influence of volute structure on rotor operational stability in high-temperature centrifugal molten-salt pump. J. Drain. Irrig. Mach. Eng. 38(1), 15–20 (2020)

Girimaji, S.S.: Partially-averaged Navier–Stokes model for turbulence: a Reynolds-averaged Navier–Stokes to direct numerical simulation bridging method. J. Appl. Mech. 73(3), 413–421 (2006)

Liu, D.; Ding, S.C., et al.: Turbulent Taylor–Couette flow and its heat transfer characteristic based on PANS model. J. Drain. Irrig. Mach. Eng. 37(10), 889–894 (2019)

Wang, Y.J.; Wang, D.Z.; Guo, W.Z., et al.: The effect of smaller turbulent motions on heat transfer in the annular gap flow of flywheel. Ann. Nucl. Energy 91, 1–7 (2016)

Acknowledgements

This study is supported by the National Natural Science Foundations of China (51676086), Natural Science Foundation of Jiangsu Province (BK20161351), and the 15th Six Talents Peak Project of Jiangsu Province (TD-JNHB-002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Sl., Liu, D., Shi, WD. et al. Numerical Simulations of Heat Transfer Performance of Taylor–Couette Flow in Slit Model. Arab J Sci Eng 46, 7153–7170 (2021). https://doi.org/10.1007/s13369-021-05338-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05338-8