Abstract

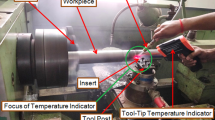

Nanocutting fluids are very popular due to their excellent thermo-physical and tribological properties which provide adequate cooling and lubrication during metal cutting. Conventional dry machining of difficult-to-cut superalloy Ti–6Al–4V faces several challenges. To overcome this, application of cutting fluid is indeed a necessity. However, performance of conventional minimum quantity lubrication (MQL) system, in which air–oil mist is sprayed into cutting zone, is somewhat limited due to inadequate penetration into tool–work and tool–chip interfacial regions, especially at high cutting speeds. MQL performance can further be enhanced by applying nanocutting fluid in which nano-sized additives are dispersed into the base cutting fluid; this is known as nanofluid MQL (NFMQL). In order to take care of several alarming issues related to environmental protection and occupational health hazards, the present study explores application feasibility of biodegradable Jatropha oil added with graphene nanoplatelets as nanocutting fluid. Machinability of Ti–6Al–4V is assessed under NFMQL; results are compared to that of dry and conventional MQL machining. Cutting force magnitude, tool-tip temperature, morphology of worn-out insert, chip’s macro/micro-morphology and surface roughness of the machined work part, etc., are studied in detail. For MQL and NFMQL, tool wear morphology detects existence of ‘unaffected zones’ which indicates sustenance of strong hydrodynamic tribo-film of cutting fluid, thus protecting the insert against wear. Up to 82 m/min cutting speed, NFMQL causes lower tool flank wear than dry and conventional MQL. On the other hand, superior machined surface finish is obtained under NFMQL up to 106 m/min cutting speed.

Similar content being viewed by others

References

Cui, C.; Hu, B.; Zhao, L.; Liu, S.: Titanium alloy production technology, market prospects and industry development. Mater. Des. 32(3), 1684–1691 (2011)

Ezugwu, E.O.; Wang, Z.M.: Titanium alloys and their machinability—a review. J. Mater. Proc. Technol. 68(3), 262–274 (1997)

Jianxin, D.; Yousheng, L.; Wenlong, S.: Diffusion wear in dry cutting of Ti–6Al–4V with WC/Co carbide tools. Wear 265(11–12), 1776–1783 (2008)

Gerez, J.M.; Sanchez-Carrilero, M.; Salguero, J.; Batista, M.; Marcos, M.: A SEM and EDS based study of the microstructural modifications of turning inserts in the dry machining of Ti6Al4 V alloy. AIP Conf. Proc. 1181(1), 567–574 (2009)

Jaffery, S.I.; Mativenga, P.T.: Assessment of the machinability of Ti–6Al–4V alloy using the wear map approach. Int. J. Adv. Manuf. Technol. 40(7–8), 687–696 (2009)

Sun, S.; Brandt, M.; Dargusch, M.S.: Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tools Manuf 49(7–8), 561–568 (2009)

Cantero, J.L.; Tardio, M.M.; Canteli, J.A.; Marcos, M.; Miguelez, M.H.: Dry drilling of alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf 45(11), 1246–1255 (2005)

Álvarez, M.; Gómez, A.; Salguero, J.; Batista, M.; Huerta, M.M.; Marcos Bárcena, M.: SOM–SEM–EDS identification of tool wear mechanisms in the dry-machining of aerospace titanium alloys. Adv. Mater. Res. 107, 77–82 (2010)

Ibrahim, G.A.; Che-Haron, C.H.; Ghani, J.A.: Tool wear mechanism in continuous cutting of difficult-to-cut material under dry machining. Adv. Mater. Res. 126, 195–201 (2010)

Muthukrishnan, N.; Davim, P.: Influence of coolant in machinability of titanium alloy (Ti–6Al–4V). J. Surf. Eng. Mater. Adv. Technol. 1(1), 9–14 (2011)

Yuan, S.M.; Yan, L.T.; Liu, W.D.; Liu, Q.: Effects of cooling air temperature on cryogenic machining of Ti–6Al–4V alloy. J. Mater. Process. Technol. 211(3), 356–362 (2011)

Su, Y.; He, N.; Li, L.; Li, X.L.: An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of Ti–6Al–4V. Wear 261(7–8), 760–766 (2006)

Davim, J.P.; Sreejith, P.S.; Gomes, R.; Peixoto, C.: Experimental studies on drilling of aluminium (AA 1050) under dry, minimum quantity of lubricant and flood-lubricated conditions. J. Eng. Manuf. Proc. Inst. Mech. Eng. Part B 220(10), 1605–1611 (2006)

Astakhov, V.P.: Ecological machining: near-dry machining. In: Machining, pp. 195–223. Springer, London (2008)

Sadeghi, M.H.; Haddad, M.J.; Tawakoli, T.; Emami, M.: Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy. Int. J. Adv. Manuf. Technol. 44(5–6), 487–500 (2009)

Rahim, E.A.; Sasahara, H.: A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol. Int. 44(3), 309–317 (2011)

Behera, B.C.; Ghosh, S.; Rao, P.V.: Wear behavior of PVD TiN coated carbide inserts during machining of Nimonic 90 and Ti6Al4 V superalloys under dry and MQL conditions. Ceram. Int. 42(13), 14873–14885 (2016)

Setti, D.; Sinha, M.K.; Ghosh, S.; Rao, P.V.: Performance evaluation of Ti–6Al–4V grinding using chip formation and coefficient of friction under the influence of nanofluids. Int. J. Mach. Tools Manuf 88, 237–248 (2015)

Paul, S.; Singh, A.K.; Ghosh, A.: Grinding of Ti–6Al–4V under small quantity cooling lubrication environment using alumina and MWCNT nanofluids. Mater. Manuf. Process. 32(6), 608–615 (2017)

Songmei, Y.; Xuebo, H.; Guangyuan, Z.; Amin, M.: A novel approach of applying copper nanoparticles in minimum quantity lubrication for milling of Ti–6Al–4V. Adv. Prod. Eng. Manag. 12(2), 139 (2017)

Sahu, N.K.; Andhare, A.B.; Raju, R.A.: Evaluation of performance of nanofluid using multiwalled carbon nanotubes for machining of Ti–6Al–4V. Mach. Sci. Technol. 22(3), 476–492 (2018)

Hegab, H.; Kishawy, H.A.; Gadallah, M.H.; Umer, U.; Deiab, I.: On machining of Ti–6Al–4V using multi-walled carbon nanotubes-based nano-fluid under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 97(5–8), 1593–1603 (2018)

Nam, J.; Lee, S.W.: Machinability of titanium alloy (Ti–6Al–4V) in environmentally-friendly micro-drilling process with nanofluid minimum quantity lubrication using nanodiamond particles. Int. J. Precis. Eng. Manuf. Green Technol. 5(1), 29–35 (2018)

Jamil, M.; Khan, A.M.; Hegab, H.; Gong, L.; Mia, M.; Gupta, M.K.; He, N.: Effects of hybrid Al2O3-CNT nanofluids and cryogenic cooling on machining of Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 102(9–12), 3895–3909 (2019)

Yi, S.; Li, N.; Solanki, S.; Mo, J.; Ding, S.: Effects of graphene oxide nanofluids on cutting temperature and force in machining Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 103(1–4), 1481–1495 (2019)

Rao, P.N.; Srikant, R.R.: Sustainable machining utilizing vegetable oil based nanofluids. In: Proceedings of IEEE International Conference on Smart Technologies and Management for Computing, Communication, Controls, Energy and Materials (ICSTM) 2015; Chennai, pp. 664–672

Lawal, S.A.: A review of application of vegetable oil-based cutting fluids in machining non-ferrous metals. Indian J. Sci. Technol. 6(1), 3951–3956 (2013)

Fox, N.J.; Stachowiak, G.W.: Vegetable oil-based lubricants—a review of oxidation. Tribol. Int. 40(7), 1035–1046 (2007)

Berman, D.; Erdemir, A.; Sumant, A.V.: Graphene: a new emerging lubricant. Mater. Today 17(1), 31–42 (2014)

Zin, V.; Barison, S.; Agresti, F.; Colla, L.; Pagura, C.; Fabrizio, M.: Improved tribological and thermal properties of lubricants by graphene based nano-additives. RSC Adv. 6(64), 59477–59486 (2016)

Samuel, J.; Rafiee, J.; Dhiman, P.; Yu, Z.Z.; Koratkar, N.: Graphene colloidal suspensions as high performance semi-synthetic metal-working fluids. J. Phys. Chem. C 115(8), 3410–3415 (2011)

Uysal, A.: Investigation of flank wear in MQL milling of ferritic stainless steel by using nano graphene reinforced vegetable cutting fluid. Ind. Lubr. Tribol. 68(4), 446–451 (2016)

Singh, R.K.; Sharma, A.K.; Mandal, V.; Gaurav, K.; Nag, A.; Kumar, A.; Dixit, A.R.; Mandal, A.; Das, A.K.: Influence of graphene-based nanofluid with minimum quantity lubrication on surface roughness and cutting temperature in turning operation. Mater. Today Proc. 5(11), 24578–24586 (2018)

Singh, H.; Sharma, V.S.; Singh, S.; Dogra, M.: Nanofluids assisted environmental friendly lubricating strategies for the surface grinding of titanium alloy: Ti6Al4 V-ELI. Journal of Manufacturing Processes 39, 241–249 (2019)

Sarker, K.: Review and comparison of various properties of jatropha oil biodiesel. Int. J. Eng. Technol. 7(6), 1965–1971 (2016)

Kikuchi, M.: The use of cutting temperature to evaluate the machinability of titanium alloys. Acta Biomater. 5(2), 770–775 (2009)

Shaw, M.C.: Metal Cutting Principles, 2nd edn. Oxford University Press, Oxford (2004)

Amrita, M.; Srikant, R.R.; Sitaramaraju, A.V.: Performance evaluation of nanographite-based cutting fluid in machining process. Mater. Manuf. Process. 29(5), 600–605 (2014)

Khan, M.A.; Mia, M.; Dhar, N.R.: High-pressure coolant on flank and rake surfaces of tool in turning of Ti–6Al–4V: investigations on forces, temperature, and chips. Int. J. Adv. Manuf. Technol. 90(5–8), 1977–1991 (2017)

Musfirah, A.H.; Ghani, J.A.; Haron, C.C.: Tool wear and surface integrity of inconel 718 in dry and cryogenic coolant at high cutting speed. Wear 376, 125–133 (2017)

Musavi, S.H.; Davoodi, B.; Niknam, S.A.: Effects of reinforced nanoparticles with surfactant on surface quality and chip formation morphology in MQL-turning of superalloys. J. Manuf. Process. 40, 128–139 (2019)

Li, A.; Zhao, J.; Luo, H.; Pei, Z.; Wang, Z.: Progressive tool failure in high-speed dry milling of Ti–6Al–4V alloy with coated carbide tools. Int. J. Adv. Manuf. Technol. 58(5–8), 465–478 (2012)

Sun, S.; Brandt, M.; Mo, J.P.: Evolution of tool wear and its effect on cutting forces during dry machining of Ti–6Al–4V alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 228(2), 191–202 (2014)

Pervaiz, S.; Deiab, I.; Rashid, A.; Nicolescu, M.: Minimal quantity cooling lubrication in turning of Ti–6Al–4V: influence on surface roughness, cutting force and tool wear. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 231(9), 1542–1558 (2017)

de Melo, A.C.; Milan, J.C.G.; Silva, M.B.D.; Machado, Á.R.: Some observations on wear and damages in cemented carbide tools. J. Braz. Soc. Mech. Sci. Eng. 28(3), 269–277 (2006)

da Silva, R.B.; Machado, Á.R.; Ezugwu, E.O.; Bonney, J.; Sales, W.F.: Tool life and wear mechanisms in high speed machining of Ti–6Al–4V alloy with PCD tools under various coolant pressures. J. Mater. Process. Technol. 213(8), 1459–1464 (2013)

Lin, H.; Wang, C.; Yuan, Y.; Chen, Z.; Wang, Q.; Xiong, W.: Tool wear in Ti–6Al–4V alloy turning under oils on water cooling comparing with cryogenic air mixed with minimal quantity lubrication. Int. J. Adv. Manuf. Technol. 81(1–4), 87–101 (2015)

Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş.: The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol. Int. 134, 443–456 (2019)

Wang, Z.G.; Rahman, M.; Wong, Y.S.; Neo, K.S.; Sun, J.; Tan, C.H.; Onozuka, H.: Study on orthogonal turning of titanium alloys with different coolant supply strategies. Int. J. Adv. Manuf. Technol. 42(7–8), 621–632 (2009)

Leksycki, K.; Feldshtein, E.: On the analysis of chip shaping after finishing turning of Ti6Al4 V titanium alloy under dry, wet and MQL conditions. Arch. Mech. Technol. Mater. 39(1), 36–40 (2019)

Machado, A.R.; Wallbank, J.: Machining of titanium and its alloys—a review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 204(1), 53–60 (1990)

Cotterell, M.; Byrne, G.: Dynamics of chip formation during orthogonal cutting of titanium alloy Ti–6Al–4V. CIRP Ann. 57(1), 93–96 (2008)

Sutter, G.; List, G.: Very high speed cutting of Ti–6Al–4V titanium alloy–change in morphology and mechanism of chip formation. Int. J. Mach. Tools Manuf 66, 37–43 (2013)

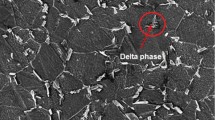

Joshi, S.; Tewari, A.; Joshi, S.S.: Microstructural characterization of chip segmentation under different machining environments in orthogonal machining of Ti6Al4 V. J. Eng. Mater. Technol. 137(1), 011005 (2015)

Shivpuri, R.; Hua, J.; Mittal, P.; Srivastava, A.K.; Lahoti, G.D.: Microstructure-mechanics interactions in modeling chip segmentation during titanium machining. CIRP Ann. 51(1), 71–74 (2002)

Upadhyay, V.; Jain, P.K.; Mehta, N.K.: Comprehensive study of chip morphology in turning of Ti–6Al–4V. In: Proceedings of 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, IIT Guwahati, Assam (2014)

Joshi, S.; Tewari, A.; Joshi, S.: Influence of preheating on chip segmentation and microstructure in orthogonal machining of Ti6Al4 V. J. Manuf. Sci. Eng. 135(6), 061017 (2013)

Khandekar, S.; Sankar, M.R.; Agnihotri, V.; Ramkumar, J.: Nano-cutting fluid for enhancement of metal cutting performance. Mater. Manuf. Process. 27(9), 963–967 (2012)

Pawade, R.S.; Joshi, S.S.: Mechanism of chip formation in high-speed turning of Inconel 718. Mach. Sci. Technol. 15(1), 132–152 (2011)

Pawade, R.S.; Reddy, D.S.N.; Kadam, G.S.: Chip segmentation behaviour and surface topography in high-speed turning of titanium alloy (Ti–6Al–4V) with eco-friendly water vapour. Int. J. Mach. Mach. Mater. 13(2–3), 113–137 (2013)

Iqbal, S.A.; Mativenga, P.T.; Sheikh, M.A.: A comparative study of the tool–chip contact length in turning of two engineering alloys for a wide range of cutting speeds. Int. J. Adv. Manuf. Technol. 42(1–2), 30–40 (2009)

Sutter, G.: Chip geometries during high-speed machining for orthogonal cutting conditions. Int. J. Mach. Tools Manuf 45(6), 719–726 (2005)

Kaynak, Y.; Gharibi, A.; Ozkutuk, M.: Experimental and numerical study of chip formation in orthogonal cutting of Ti-5553 alloy: the influence of cryogenic, MQL, and high pressure coolant supply. Int. J. Adv. Manuf. Technol. 94(1–4), 1411–1428 (2018)

Barry, J.; Byrne, G.; Lennon, D.: Observations on chip formation and acoustic emission in machining Ti–6Al–4V alloy. Int. J. Mach. Tools Manuf 41(7), 1055–1070 (2001)

Shyha, I.; Gariani, S.; El-Sayed, M.A.; Huo, D.: Analysis of microstructure and chip formation when machining Ti–6Al–4V. Metals 8(3), 185 (2018)

Shuang, Y.; John, M.; Songlin, D.: Experimental investigation on the performance and mechanism of graphene oxide nanofluids in turning Ti–6Al–4V. J. Manuf. Process. 43(1), 164–174 (2019)

Ezugwu, E.O.; Bonney, J.; Da Silva, R.B.; Cakir, O.: Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int. J. Mach. Tools Manuf 47(6), 884–891 (2007)

Sun, J.; Guo, Y.B.: A new multi-view approach to characterize 3D chip morphology and properties in end milling titanium Ti–6Al–4V. Int. J. Mach. Tools Manuf 48(12–13), 1486–1494 (2008)

Friedrich, K.; Breuer, U.: Multifunctionality of polymer composites: challenges and new solutions. William Andrew, Norwich (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahoo, S.P., Datta, S. Dry, MQL, and Nanofluid MQL Machining of Ti–6Al–4V Using Uncoated WC–Co Insert: Application of Jatropha Oil as Base Cutting Fluid and Graphene Nanoplatelets as Additives. Arab J Sci Eng 45, 9599–9618 (2020). https://doi.org/10.1007/s13369-020-04849-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04849-0