Abstract

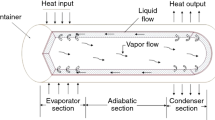

The nanofluid is a colloidal solid–liquid mixture obtained by the dispersing nanoparticles with a high heat transfer coefficient in the base fluid. In general, metal, metal oxide, ceramic and magnetic nanoparticles are used in nanofluids. The nanoparticles suspended in the base fluid of heat pipes effectively increased the heat transfer rate and thermal conductivity properties of the base fluid. The nanofluids have been found to be acting much better for some problems such as sedimentation, erosion, clogging and pressure drop compared to common slurries. The energy transfer is carried out by two-phase heat transfer mechanism in heat pipes. There are many parameters and factors that have an effect in the boiling heat transfer coefficient. It is not easy to understand the positive and negative changes caused by nanofluids in this complex heat transfer mechanism. The surface geometry is a significant indicator on the boiling heat transfer mechanism. Investigation into nanofluid effects besides the surface geometry is very important in the experimental studies. In addition, it is known that nanofluids change the properties of the heater surface, apart from the thermophysical properties. The synthesis methods of nanofluids are presented in this article. Then, the physical and chemical mechanisms determining the long-term stability of nanofluids are explained in detail. Finally, some useful information about the use of nanofluids in heat pipes and pool boiling of nanofluids is given. The presented study also describes the pool boiling mechanism of nanofluids to understand the positive effects of nanofluids on the heat pipes heat transfer mechanism.

Similar content being viewed by others

References

Jouhara, H.; Chauhan, A.; Nannou, T.; Almahmoud, S.; Delpech, B.; Wrobel, L.C.: Heat pipe based systems: advances and applications. Energy 128, 729–754 (2017). https://doi.org/10.1016/j.energy.2017.04.028

Sureshkumar, R.; Mohideen, S.T.; Nethaji, N.: Heat transfer characteristics of nanofluids in heat pipes: a review. Renew. Sustain. Energy Rev. 20, 397–410 (2013). https://doi.org/10.1016/j.rser.2012.11.044

Anderson, W.G.: Evaluation of heat pipe working fluids in the temperature range 450 to 700 K. AIP Conf. Proc. 699, 20–27 (2004). https://doi.org/10.1063/1.1649553

Touloukian, Y.S.; Powell, R.W.; Ho, C.Y.; Klemens, P.G.: Thermal Conductivity - Metallic Elements and Alloys, vol. 1. IFI/PLENUM, New York-Washington (1970)

Paul, G.; Chopkar, M.; Manna, I.; Das, P.K.: Techniques for measuring the thermal conductivity of nanofluids: a review. Renew. Sustain. Energy Rev. 14, 1913–1924 (2010). https://doi.org/10.1016/j.rser.2010.03.017

Che Sidik, N.A.; Mahmud Jamil, M.; Aziz Japar, W.M.A.; Muhammad Adamu, I.: A review on preparation methods, stability and applications of hybrid nanofluids. Renew. Sustain. Energy Rev. 80, 1112–1122 (2017). https://doi.org/10.1016/j.rser.2017.05.221

Ramezanizadeh, M.; Alhuyi Nazari, M.; Ahmadi, M.H.; Açıkkalp, E.: Application of nanofluids in thermosyphons: a review. J. Mol. Liq. 272, 395–402 (2018). https://doi.org/10.1016/j.molliq.2018.09.101

Tawfik, M.M.: Experimental studies of nanofluid thermal conductivity enhancement and applications: a review. Renew. Sustain. Energy Rev. 75, 1239–1253 (2017). https://doi.org/10.1016/j.rser.2016.11.111

Ganvir, R.B.; Walke, P.V.; Kriplani, V.M.: Heat transfer characteristics in nanofluid: a review. Renew. Sustain. Energy Rev. 75, 451–460 (2017). https://doi.org/10.1016/j.rser.2016.11.010

Wang, X.Q.; Mujumdar, A.S.: A review on nanofluids - part II: experiments and applications. Braz. J. Chem. Eng. 25, 631–648 (2008). https://doi.org/10.1590/S0104-66322008000400002

Wang, X.-Q.; Mujumdar, A.S.: Heat transfer characteristics of nanofluids: a review. Int. J. Therm. Sci. 46, 1–19 (2007). https://doi.org/10.1016/j.ijthermalsci.2006.06.010

Wen, D.; Lin, G.; Vafaei, S.; Zhang, K.: Review of nanofluids for heat transfer applications. Particuology 7, 141–150 (2009). https://doi.org/10.1016/j.partic.2009.01.007

Choi, S.U.S., Eastman, J.A.: Enhancing thermal conductivity of fluids with nanoparticles. In: ASME International Mechanical Engineering Congress and Exposition, pp. 99–105 (1995)

Ahuja, A.S.: Thermal design of a heat exchanger employing laminar flow of particle suspensions. Int. J. Heat Mass Transf. 25, 725–728 (1982). https://doi.org/10.1016/0017-9310(82)90179-X

Gupta, N.K.; Tiwari, A.K.; Ghosh, S.K.: Heat transfer mechanisms in heat pipes using nanofluids: a review. Exp. Therm. Fluid Sci. 90, 84–100 (2018). https://doi.org/10.1016/j.expthermflusci.2017.08.013

Azmi, W.H.; Sharma, K.V.; Mamat, R.; Najafi, G.; Mohamad, M.S.: The enhancement of effective thermal conductivity and effective dynamic viscosity of nanofluids: a review. Renew. Sustain. Energy Rev. 53, 1046–1058 (2016). https://doi.org/10.1016/j.rser.2015.09.081

Murshed, S.M.S.; Leong, K.C.; Yang, C.: Investigations of thermal conductivity and viscosity of nanofluids. Int. J. Therm. Sci. 47, 560–568 (2008). https://doi.org/10.1016/j.ijthermalsci.2007.05.004

Mahbubul, I.M.; Saidur, R.; Amalina, M.A.: Latest developments on the viscosity of nanofluids. Int. J. Heat Mass Transf. 55, 874–885 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2011.10.021

Nguyen, C.T.; Desgranges, F.; Roy, G.; Galanis, N.; Maré, T.; Boucher, S.; Angue Mintsa, H.: Temperature and particle-size dependent viscosity data for water-based nanofluids—hysteresis phenomenon. Int. J. Heat Fluid Flow 28, 1492–1506 (2007). https://doi.org/10.1016/j.ijheatfluidflow.2007.02.004

Kole, M.; Dey, T.K.: Viscosity of alumina nanoparticles dispersed in car engine coolant. Exp. Therm. Fluid Sci. 34, 677–683 (2010). https://doi.org/10.1016/j.expthermflusci.2009.12.009

Prasher, R.; Song, D.; Wang, J.; Phelan, P.: Measurements of nanofluid viscosity and its implications for thermal applications. Appl. Phys. Lett. 89, 133108 (2006). https://doi.org/10.1063/1.2356113

Chevalier, J.; Tillement, O.; Ayela, F.: Rheological properties of nanofluids flowing through microchannels. Appl. Phys. Lett. 91, 233103 (2007). https://doi.org/10.1063/1.2821117

Namburu, P.K.; Kulkarni, D.P.; Dandekar, A.; Das, D.K.: Experimental investigation of viscosity and specific heat of silicon dioxide nanofluids. Micro Nano Lett. 2, 67 (2007). https://doi.org/10.1049/mnl:20070037

Pastoriza-Gallego, M.J.; Casanova, C.; Legido, J.L.; Piñeiro, M.M.: CuO in water nanofluid: influence of particle size and polydispersity on volumetric behaviour and viscosity. Fluid Phase Equilibria 300, 188–196 (2011). https://doi.org/10.1016/j.fluid.2010.10.015

Anoop, K.B.; Sundararajan, T.; Das, S.K.: Effect of particle size on the convective heat transfer in nanofluid in the developing region. Int. J. Heat Mass Transf. 52, 2189–2195 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2007.11.063

He, Y.; Jin, Y.; Chen, H.; Ding, Y.; Cang, D.; Lu, H.: Heat transfer and flow behaviour of aqueous suspensions of TiO\(_{2}\) nanoparticles (nanofluids) flowing upward through a vertical pipe. Int. J. Heat Mass Transf. 50, 2272–2281 (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.024

Lu, W.-Q.; Fan, Q.-M.: Study for the particle’s scale effect on some thermophysical properties of nanofluids by a simplified molecular dynamics method. Eng. Anal. Bound. Elem. 32, 282–289 (2008). https://doi.org/10.1016/j.enganabound.2007.10.006

Nguyen, C.T.; Desgranges, F.; Galanis, N.; Roy, G.; Maré, T.; Boucher, S.; Angue Mintsa, H.: Viscosity data for Al\(_{2}\)O\(_{3}\)–water nanofluid—hysteresis: is heat transfer enhancement using nanofluids reliable? Int. J. Therm. Sci. 47, 103–111 (2008). https://doi.org/10.1016/j.ijthermalsci.2007.01.033

Timofeeva, E.V.; Yu, W.; France, D.M.; Singh, D.; Routbort, J.L.: Nanofluids for heat transfer: an engineering approach. Nanoscale Res. Lett. 6, 182 (2011). https://doi.org/10.1186/1556-276X-6-182

Timofeeva, E.V.; Routbort, J.L.; Singh, D.: Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 106, 14304 (2009). https://doi.org/10.1063/1.3155999

Masuda, H.; Ebata, A.; Teramae, K.; Hishinuma, N.: Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles. Dispersion of Al\(_{2}\)O\(_{3}\), SiO\(_{2}\) and TiO\(_{2}\) ultra-fine particles. Netsu Bussei 7, 227–233 (1993). https://doi.org/10.2963/jjtp.7.227

Maxwell, J.: A Treatise on Electricity and Magnetism: Vol II, vol. 1, pp. 333–335. Clarendon Press, Oxford (1873). https://doi.org/10.1017/CBO9780511709333

Wang, X.; Xu, X.; S. Choi, S.U.: Thermal conductivity of nanoparticle-fluid mixture. J. Thermophys. Heat Transf. 13, 474–480 (1999). https://doi.org/10.2514/2.6486

Xuan, Y.; Roetzel, W.: Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 43, 3701–3707 (2000). https://doi.org/10.1016/S0017-9310(99)00369-5

Wang, B.X.; Li, H.; Peng, X.F.: Research on the heat-conduction enhancement for liquid with nano-particle suspensions. J. Therm. Sci. 11, 214–219 (2002). https://doi.org/10.1007/s11630-002-0057-6

Xuan, Y.; Li, Q.: Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 21, 58–64 (2000). https://doi.org/10.1016/S0142-727X(99)00067-3

Sözen, A.; Menlik, T.; Gürü, M.; Boran, K.; Kılıç, F.; Aktaş, M.; Çakır, M.T.: A comparative investigation on the effect of fly-ash and alumina nanofluids on the thermal performance of two-phase closed thermo-syphon heat pipes. Appl. Therm. Eng. 96, 330–337 (2016). https://doi.org/10.1016/j.applthermaleng.2015.11.038

Witharana, S.; Palabiyik, I.; Musina, Z.; Ding, Y.: Stability of glycol nanofluids: the theory and experiment. Powder Technol. 239, 72–77 (2013). https://doi.org/10.1016/j.powtec.2013.01.039

Kostic, M.; Golubovic, M.; Hull, J.R.; Choi, S.U.S.: One-step method for the production of nanofluids. US Patent 7,718,033 B1 (2010)

Li, Y.; Zhou, J.; Tung, S.; Schneider, E.; Xi, S.: A review on development of nanofluid preparation and characterization. Powder Technol. 196, 89–101 (2009). https://doi.org/10.1016/j.powtec.2009.07.025

Ghadimi, A.; Saidur, R.; Metselaar, H.S.C.: A review of nanofluid stability properties and characterization in stationary conditions. Int. J. Heat Mass Transf. 54, 4051–4068 (2011). https://doi.org/10.1016/j.ijheatmasstransfer.2011.04.014

Wen, D.; Ding, Y.: Experimental investigation into the pool boiling heat transfer of aqueous based \(\gamma \)-alumina nanofluids. J. Nanopart. Res. 7, 265–274 (2005). https://doi.org/10.1007/s11051-005-3478-9

Missana, T.; Adell, A.: On the applicability of DLVO theory to the prediction of clay colloids stability. J. Colloid Interface Sci. 230, 150–156 (2000). https://doi.org/10.1006/jcis.2000.7003

Tang, C.; Zhou, T.; Yang, J.; Zhang, Q.; Chen, F.; Fu, Q.; Yang, L.: Wet-grinding assisted ultrasonic dispersion of pristine multi-walled carbon nanotubes (MWCNTs) in chitosan solution. Colloids Surf. B Biointerfaces 86, 189–197 (2011). https://doi.org/10.1016/j.colsurfb.2011.03.041

Chandler, D.: Interfaces and the driving force of hydrophobic assembly. Nature 437, 640–647 (2005). https://doi.org/10.1038/nature04162

Hashim, A.A. (ed.): Smart Nanoparticles Technology. InTech, Croatia (2012)

Yang, L.; Du, K.: A thermal conductivity model for low concentrated nanofluids containing surfactants under various dispersion types. Int. J. Refrig. 35, 1978–1988 (2012). https://doi.org/10.1016/j.ijrefrig.2012.07.013

Griffin, W.C.: Classification of surface-active agents by “ HLB”. J. Soc. Cosmet. Chem. 1, 311–326 (1946)

Griffin, W.C.: Calculation of HLB values of non-ionic surfactants. Am. Perfum. Essent. Oil Rev. 65, 26–29 (1955)

Kole, M.; Dey, T.K.: Thermophysical and pool boiling characteristics of ZnO–ethylene glycol nanofluids. Int. J. Therm. Sci. 62, 61–70 (2012). https://doi.org/10.1016/j.ijthermalsci.2012.02.002

Tang, E.; Cheng, G.; Ma, X.; Pang, X.; Zhao, Q.: Surface modification of zinc oxide nanoparticle by PMAA and its dispersion in aqueous system. Appl. Surf. Sci. 252, 5227–5232 (2006). https://doi.org/10.1016/j.apsusc.2005.08.004

Zhu, H.; Zhang, C.; Tang, Y.; Wang, J.; Ren, B.; Yin, Y.: Preparation and thermal conductivity of suspensions of graphite nanoparticles. Carbon 45, 226–228 (2007). https://doi.org/10.1016/j.carbon.2006.07.005

Wang, X.; Zhu, D.; Yang, S.: Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids. Chem. Phys. Lett. 470, 107–111 (2009). https://doi.org/10.1016/j.cplett.2009.01.035

Popa, M.; Pradell, T.; Crespo, D.; Calderón-Moreno, J.M.: Stable silver colloidal dispersions using short chain polyethylene glycol. Colloids Surf. A Physicochem. Eng. Asp. 303, 184–190 (2007). https://doi.org/10.1016/j.colsurfa.2007.03.050

Hassan, M.I.; Singh, P.K.; Tesfai, W.; Shatilla, Y.: An experimental study of heat pipe performance using nanofluids. Int. J. Green Energy 12, 225–229 (2015). https://doi.org/10.1080/15435075.2014.891518

Hung, Y.-H.; Teng, T.-P.; Lin, B.-G.: Evaluation of the thermal performance of a heat pipe using alumina nanofluids. Exp. Therm. Fluid Sci. 44, 504–511 (2013). https://doi.org/10.1016/j.expthermflusci.2012.08.012

Sözen, A.; Gürü, M.; Menlik, T.; Karakaya, U.; Çiftçi, E.: Experimental comparison of Triton X-100 and sodium dodecyl benzene sulfonate surfactants on thermal performance of TiO\(_{2}\)-deionized water nanofluid in a thermosiphon. Exp. Heat Transf. 31, 450–469 (2018). https://doi.org/10.1080/08916152.2018.1445673

Daghigh, R.; Zandi, P.: Experimental analysis of heat transfer in spiral coils using nanofluids and coil geometry change in a solar system. Appl. Therm. Eng. 145, 295–304 (2018). https://doi.org/10.1016/j.applthermaleng.2018.09.053

Al-Waeli, A.H.A.; Chaichan, M.T.; Sopian, K.; Kazem, H.A.: Influence of the base fluid on the thermo-physical properties of PV/T nanofluids with surfactant. Case Stud. Therm. Eng. 13, 100340 (2019). https://doi.org/10.1016/j.csite.2018.10.001

Sözen, A.; Öztürk, A.; Özalp, M.; Çiftçi, E.: Influences of alumina and fly ash nanofluid usage on the performance of recuperator including heat pipe bundle. Int. J. Environ. Sci. Technol. (2018). https://doi.org/10.1007/s13762-018-1832-6

Dehaj, M.S.; Mohiabadi, M.Z.: Experimental investigation of heat pipe solar collector using MgO nanofluids. Sol. Energy Mater. Sol. Cells 191, 91–99 (2019). https://doi.org/10.1016/j.solmat.2018.10.025

Ozsoy, A.; Corumlu, V.: Thermal performance of a thermosyphon heat pipe evacuated tube solar collector using silver–water nanofluid for commercial applications. Renew. Energy 122, 26–34 (2018). https://doi.org/10.1016/j.renene.2018.01.031

Sundar, L.S.; Singh, M.K.; Sousa, A.C.M.: Turbulent heat transfer and friction factor of nanodiamond-nickel hybrid nanofluids flow in a tube: an experimental study. Int. J. Heat Mass Transf. 117, 223–234 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.109

Ravi Kumar, N.T.; Bhramara, P.; Kirubeil, A.; Syam Sundar, L.; Singh, M.K.; Sousa, A.C.M.: Effect of twisted tape inserts on heat transfer, friction factor of Fe\(_{3}\)O\(_{4}\) nanofluids flow in a double pipe U-bend heat exchanger. Int. Commun. Heat Mass Transf. 95, 53–62 (2018). https://doi.org/10.1016/j.icheatmasstransfer.2018.03.020

Raei, B.; Peyghambarzadeh, S.M.; Salehi Asl, R.: Experimental investigation on heat transfer and flow resistance of drag-reducing alumina nanofluid in a fin-and-tube heat exchanger. Appl. Therm. Eng. 144, 926–936 (2018). https://doi.org/10.1016/j.applthermaleng.2018.09.006

Zhao, S.; Xu, G.; Wang, N.; Zhang, X.: Experimental study on the thermal start-up performance of the graphene/water nanofluid-enhanced solar gravity heat pipe. Nanomaterials 8, 72 (2018). https://doi.org/10.3390/nano8020072

Eiamsa-ard, S.; Wongcharee, K.: Convective heat transfer enhancement using Ag–water nanofluid in a micro-fin tube combined with non-uniform twisted tape. Int. J. Mech. Sci. 146–147, 337–354 (2018). https://doi.org/10.1016/j.ijmecsci.2018.07.040

Krishnakumar, T.S.; Viswanath, S.P.; Varghese, S.M.; Prakash, M.J.: Experimental studies on thermal and rheological properties of Al\(_{2}\)O\(_{3}\)–ethylene glycol nanofluid. Int. J. Refrig. 89, 122–130 (2018). https://doi.org/10.1016/j.ijrefrig.2018.03.008

Sarafraz, M.M.; Nikkhah, V.; Nakhjavani, M.; Arya, A.: Thermal performance of a heat sink microchannel working with biologically produced silver–water nanofluid: experimental assessment. Exp. Therm. Fluid Sci. 91, 509–519 (2018). https://doi.org/10.1016/j.expthermflusci.2017.11.007

Mahbubul, I.M.: Preparation, Characterization, Properties and Application of Nanofluid. William Andrew (Elsevier), Norwich, NY (2019). https://doi.org/10.1016/C2016-0-04294-8

Teng, T.-P.; Hung, Y.-H.; Teng, T.-C.; Mo, H.-E.; Hsu, H.-G.: The effect of alumina/water nanofluid particle size on thermal conductivity. Appl. Therm. Eng. 30, 2213–2218 (2010). https://doi.org/10.1016/j.applthermaleng.2010.05.036

Haddad, Z.; Abu-Nada, E.; Oztop, H.F.; Mataoui, A.: Natural convection in nanofluids: are the thermophoresis and Brownian motion effects significant in nanofluid heat transfer enhancement? Int. J. Therm. Sci. 57, 152–162 (2012). https://doi.org/10.1016/j.ijthermalsci.2012.01.016

Shima, P.D.; Philip, J.; Raj, B.: Role of microconvection induced by Brownian motion of nanoparticles in the enhanced thermal conductivity of stable nanofluids. Appl. Phys. Lett. 94, 223101 (2009). https://doi.org/10.1063/1.3147855

Jang, S.P.; Choi, S.U.S.: Role of Brownian motion in the enhanced thermal conductivity of nanofluids. Appl. Phys. Lett. 84, 4316–4318 (2004). https://doi.org/10.1063/1.1756684

Prasher, R.; Bhattacharya, P.; Phelan, P.E.: Brownian-motion-based convective–conductive model for the effective thermal conductivity of nanofluids. J. Heat Transf. 128, 588 (2006). https://doi.org/10.1115/1.2188509

Evans, W.; Fish, J.; Keblinski, P.: Role of Brownian motion hydrodynamics on nanofluid thermal conductivity. Appl. Phys. Lett. 88, 93116 (2006). https://doi.org/10.1063/1.2179118

Turgut, A.; Tavman, I.; Chirtoc, M.; Schuchmann, H.P.; Sauter, C.; Tavman, S.: Thermal conductivity and viscosity measurements of water-based TiO\(_{2}\) nanofluids. Int. J. Thermophys. 30, 1213–1226 (2009). https://doi.org/10.1007/s10765-009-0594-2

Anoop, K.B.; Kabelac, S.; Sundararajan, T.; Das, S.K.: Rheological and flow characteristics of nanofluids: influence of electroviscous effects and particle agglomeration. J. Appl. Phys. 106, 34909 (2009). https://doi.org/10.1063/1.3182807

Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G.: Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transf. 48, 1107–1116 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2004.09.038

Mahbubul, I.M.; Chong, T.H.; Khaleduzzaman, S.S.; Shahrul, I.M.; Saidur, R.; Long, B.D.; Amalina, M.A.: Effect of ultrasonication duration on colloidal structure and viscosity of alumina–water nanofluid. Ind. Eng. Chem. Res. 53, 6677–6684 (2014). https://doi.org/10.1021/ie500705j

Kulkarni, D.P.; Das, D.K.; Vajjha, R.S.: Application of nanofluids in heating buildings and reducing pollution. Appl. Energy 86, 2566–2573 (2009). https://doi.org/10.1016/j.apenergy.2009.03.021

Namburu, P.K.; Das, D.K.; Tanguturi, K.M.; Vajjha, R.S.: Numerical study of turbulent flow and heat transfer characteristics of nanofluids considering variable properties. Int. J. Therm. Sci. 48, 290–302 (2009). https://doi.org/10.1016/j.ijthermalsci.2008.01.001

Sohel Murshed, S.M.; Tan, S.-H.; Nguyen, N.-T.: Temperature dependence of interfacial properties and viscosity of nanofluids for droplet-based microfluidics. J. Phys. D Appl. Phys. 41, 85502 (2008). https://doi.org/10.1088/0022-3727/41/8/085502

Chen, H.; Ding, Y.; He, Y.; Tan, C.: Rheological behaviour of ethylene glycol based titania nanofluids. Chem. Phys. Lett. 444, 333–337 (2007). https://doi.org/10.1016/j.cplett.2007.07.046

Chen, H.; Ding, Y.; Tan, C.: Rheological behaviour of nanofluids. New J. Phys. 9, 367–367 (2007). https://doi.org/10.1088/1367-2630/9/10/367

Mahbubul, I.M.; Saidur, R.; Amalina, M.A.: Thermal conductivity, viscosity and density of R141b refrigerant based nanofluid. Procedia Eng. 56, 310–315 (2013). https://doi.org/10.1016/j.proeng.2013.03.124

Elias, M.M.; Mahbubul, I.M.; Saidur, R.; Sohel, M.R.; Shahrul, I.M.; Khaleduzzaman, S.S.; Sadeghipour, S.: Experimental investigation on the thermo-physical properties of Al\(_{2}\)O\(_{3}\) nanoparticles suspended in car radiator coolant. Int. Commun. Heat Mass Transf. 54, 48–53 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2014.03.005

Kedzierski, M.A.: Viscosity and density of CuO nanolubricant. Int. J. Refrig. 35, 1997–2002 (2012). https://doi.org/10.1016/j.ijrefrig.2012.06.012

Vajjha, R.S.; Das, D.K.: A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power. Int. J. Heat Mass Transf. 55, 4063–4078 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2012.03.048

Pantzali, M.N.; Kanaris, A.G.; Antoniadis, K.D.; Mouza, A.A.; Paras, S.V.: Effect of nanofluids on the performance of a miniature plate heat exchanger with modulated surface. Int. J. Heat Fluid Flow 30, 691–699 (2009). https://doi.org/10.1016/j.ijheatfluidflow.2009.02.005

Saeedinia, M.; Akhavan-Behabadi, M.A.; Razi, P.: Thermal and rheological characteristics of CuO–base oil nanofluid flow inside a circular tube. Int. Commun. Heat Mass Transf. 39, 152–159 (2012). https://doi.org/10.1016/j.icheatmasstransfer.2011.08.001

Shin, D.; Banerjee, D.: Enhancement of specific heat capacity of high-temperature silica-nanofluids synthesized in alkali chloride salt eutectics for solar thermal-energy storage applications. Int. J. Heat Mass Transf. 54, 1064–1070 (2011). https://doi.org/10.1016/j.ijheatmasstransfer.2010.11.017

Pak, B.C.; Cho, Y.I.: Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. 11, 151–170 (1998). https://doi.org/10.1080/08916159808946559

Fakoor Pakdaman, M.; Akhavan-Behabadi, M.A.; Razi, P.: An experimental investigation on thermo-physical properties and overall performance of MWCNT/heat transfer oil nanofluid flow inside vertical helically coiled tubes. Exp. Therm. Fluid Sci. 40, 103–111 (2012). https://doi.org/10.1016/j.expthermflusci.2012.02.005

Mohebbi, A.: Prediction of specific heat and thermal conductivity of nanofluids by a combined equilibrium and non-equilibrium molecular dynamics simulation. J. Mol. Liq. 175, 51–58 (2012). https://doi.org/10.1016/j.molliq.2012.08.010

De Robertis, E.; Cosme, E.H.H.; Neves, R.S.; Kuznetsov, A.Y.; Campos, A.P.C.; Landi, S.M.; Achete, C.A.: Application of the modulated temperature differential scanning calorimetry technique for the determination of the specific heat of copper nanofluids. Appl. Therm. Eng. 41, 10–17 (2012). https://doi.org/10.1016/j.applthermaleng.2012.01.003

Kumaresan, V.; Velraj, R.: Experimental investigation of the thermo-physical properties of water–ethylene glycol mixture based CNT nanofluids. Thermochim. Acta 545, 180–186 (2012). https://doi.org/10.1016/j.tca.2012.07.017

Liu, J.; Wang, F.; Zhang, L.; Fang, X.; Zhang, Z.: Thermodynamic properties and thermal stability of ionic liquid-based nanofluids containing graphene as advanced heat transfer fluids for medium-to-high-temperature applications. Renew. Energy 63, 519–523 (2014). https://doi.org/10.1016/j.renene.2013.10.002

Ghazvini, M.; Akhavan-Behabadi, M.A.; Rasouli, E.; Raisee, M.: Heat transfer properties of nanodiamond-engine oil nanofluid in laminar flow. Heat Transf. Eng. 33, 525–532 (2012). https://doi.org/10.1080/01457632.2012.624858

He, Q.; Wang, S.; Tong, M.; Liu, Y.: Experimental study on thermophysical properties of nanofluids as phase-change material (PCM) in low temperature cool storage. Energy Convers. Manag. 64, 199–205 (2012). https://doi.org/10.1016/j.enconman.2012.04.010

Mariano, A.; Pastoriza-Gallego, M.J.; Lugo, L.; Mussari, L.; Piñeiro, M.M.: Co\(_{3}\)O\(_{4}\) ethylene glycol-based nanofluids: thermal conductivity, viscosity and high pressure density. Int. J. Heat Mass Transf. 85, 54–60 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.061

Anoop, K.; Sadr, R.; Al-Jubouri, M.; Amani, M.: Rheology of mineral oil-SiO\(_{2}\) nanofluids at high pressure and high temperatures. Co3O4 ethylene glycol-based nanofluids: thermal conductivity, viscosity and high pressure density 77, 108–115 (2014). https://doi.org/10.1016/j.ijthermalsci.2013.10.016

Chien, H.-T., Tsai, C.-I., Chen, P.-H., Chen, P.-Y.: Improvement on thermal performance of a disk-shaped miniature heat pipe with nanofluid. In: Fifth International Conference on Electronic Packaging Technology Proceedings, 2003. ICEPT2003, pp. 389–391. IEEE (2003)

Manimaran, R.; Palaniradja, K.; Alagumurthi, N.; Hussain, J.: Experimental comparative study of heat pipe performance using CuO and TiO\(_{2}\) nanofluids. Int. J. Energy Res. 38, 573–580 (2014). https://doi.org/10.1002/er.3058

Saleh, R.; Putra, N.; Prakoso, S.P.; Septiadi, W.N.: Experimental investigation of thermal conductivity and heat pipe thermal performance of ZnO nanofluids. Int. J. Therm. Sci. 63, 125–132 (2013). https://doi.org/10.1016/j.ijthermalsci.2012.07.011

Senthilkumar, R.; Vaidyanathan, S.; Sivaraman, B.: Performance analysis of heat pipe using copper nanofluid with aqueous solution of n-butanol. Int. J. Mech. Mater. Eng. 1, 251–256 (2010)

Shanbedi, M.; Heris, S.Z.; Baniadam, M.; Amiri, A.; Maghrebi, M.: Investigation of heat-transfer characterization of EDA-MWCNT/DI–water nanofluid in a two-phase closed thermosyphon. Ind. Eng. Chem. Res. 51, 1423–1428 (2012). https://doi.org/10.1021/ie202110g

Yang, X.F.; Liu, Z.-H.; Zhao, J.: Heat transfer performance of a horizontal micro-grooved heat pipe using CuO nanofluid. J. Micromech. Microeng. 18, 35038 (2008). https://doi.org/10.1088/0960-1317/18/3/035038

Naphon, P.; Thongkum, D.; Assadamongkol, P.: Heat pipe efficiency enhancement with refrigerant–nanoparticles mixtures. Energy Convers. Manag. 50, 772–776 (2009). https://doi.org/10.1016/j.enconman.2008.09.045

Liu, Z.-H.; Li, Y.-Y.; Bao, R.: Compositive effect of nanoparticle parameter on thermal performance of cylindrical micro-grooved heat pipe using nanofluids. Int. J. Therm. Sci. 50, 558–568 (2011). https://doi.org/10.1016/j.ijthermalsci.2010.11.013

Yang, X.F.; Liu, Z.H.: Application of functionalized nanofluid in thermosyphon. Nanoscale Res. Lett. 6, 494 (2011). https://doi.org/10.1186/1556-276X-6-494

Noie, S.H.; Heris, S.Z.; Kahani, M.; Nowee, S.M.: Heat transfer enhancement using Al\(_{2}\)O\(_{3}\)/water nanofluid in a two-phase closed thermosyphon. Int. J. Heat Fluid Flow 30, 700–705 (2009). https://doi.org/10.1016/j.ijheatfluidflow.2009.03.001

Huminic, G.; Huminic, A.; Morjan, I.; Dumitrache, F.: Experimental study of the thermal performance of thermosyphon heat pipe using iron oxide nanoparticles. Int. J. Heat Mass Transf. 54, 656–661 (2011). https://doi.org/10.1016/j.ijheatmasstransfer.2010.09.005

Bhullar, B.S.; Gangacharyulu, D.; Das, S.K.: Augmented thermal performance of straight heat pipe employing annular screen mesh wick and surfactant free stable aqueous nanofluids. Heat Transf. Eng. 38, 217–226 (2017). https://doi.org/10.1080/01457632.2016.1177418

Ghanbarpour, M.; Nikkam, N.; Khodabandeh, R.; Toprak, M.S.: Improvement of heat transfer characteristics of cylindrical heat pipe by using SiC nanofluids. Appl. Therm. Eng. 90, 127–135 (2015). https://doi.org/10.1016/j.applthermaleng.2015.07.004

Buschmann, M.H.; Franzke, U.: Improvement of thermosyphon performance by employing nanofluid. Int. J. Refrig. 40, 416–428 (2014). https://doi.org/10.1016/j.ijrefrig.2013.11.022

Buschmann, M.H.: Thermal conductivity and heat transfer of ceramic nanofluids. Int. J. Therm. Sci. 62, 19–28 (2012). https://doi.org/10.1016/j.ijthermalsci.2011.09.019

Nine, M.J.; Chung, H.; Tanshen, M.R.; Osman, N.A.B.A.; Jeong, H.: Is metal nanofluid reliable as heat carrier? J. Hazard. Mater. 273, 183–191 (2014). https://doi.org/10.1016/j.jhazmat.2014.03.055

Vijayakumar, M.; Navaneethakrishnan, P.; Kumaresan, G.; Kamatchi, R.: A study on heat transfer characteristics of inclined copper sintered wick heat pipe using surfactant free CuO and Al\(_{2}\)O\(_{3}\) nanofluids. J. Taiwan Inst. Chem. Eng. 81, 190–198 (2017). https://doi.org/10.1016/j.jtice.2017.10.032

Nazari, M.A.; Ghasempour, R.; Ahmadi, M.H.; Heydarian, G.; Shafii, M.B.: Experimental investigation of graphene oxide nanofluid on heat transfer enhancement of pulsating heat pipe. Int. Commun. Heat Mass Transf. 91, 90–94 (2018). https://doi.org/10.1016/j.icheatmasstransfer.2017.12.006

Zhou, Y.; Cui, X.; Weng, J.; Shi, S.; Han, H.; Chen, C.: Experimental investigation of the heat transfer performance of an oscillating heat pipe with graphene nanofluids. Powder Technol. 332, 371–380 (2018). https://doi.org/10.1016/j.powtec.2018.02.048

Das, S.K.; Putra, N.; Roetzel, W.: Pool boiling characteristics of nano-fluids. Int. J. Heat Mass Transf. 46, 851–862 (2003). https://doi.org/10.1016/S0017-9310(02)00348-4

Liu, Z.; Xiong, J.; Bao, R.: Boiling heat transfer characteristics of nanofluids in a flat heat pipe evaporator with micro-grooved heating surface. Int. J. Multiph. Flow 33, 1284–1295 (2007). https://doi.org/10.1016/j.ijmultiphaseflow.2007.06.009

Wen, D.; Corr, M.; Hu, X.; Lin, G.: Boiling heat transfer of nanofluids: the effect of heating surface modification. Int. J. Therm. Sci. 50, 480–485 (2011). https://doi.org/10.1016/j.ijthermalsci.2010.10.017

Bang, I.C.; Heung Chang, S.: Boiling heat transfer performance and phenomena of Al\(_{2}\)O\(_{3}\)–water nano-fluids from a plain surface in a pool. Int. J. Heat Mass Transf. 48, 2407–2419 (2005). https://doi.org/10.1016/j.ijheatmasstransfer.2004.12.047

Shoghl, S.N.; Bahrami, M.: Experimental investigation on pool boiling heat transfer of ZnO, and CuO water-based nanofluids and effect of surfactant on heat transfer coefficient. Int. Commun. Heat Mass Transf. 45, 122–129 (2013). https://doi.org/10.1016/j.icheatmasstransfer.2013.04.015

Kwark, S.M.; Kumar, R.; Moreno, G.; Yoo, J.; You, S.M.: Pool boiling characteristics of low concentration nanofluids. Int. J. Heat Mass Transf. 53, 972–981 (2010). https://doi.org/10.1016/j.ijheatmasstransfer.2009.11.018

Song, S.L.; Lee, J.H.; Chang, S.H.: CHF enhancement of SiC nanofluid in pool boiling experiment. Exp. Therm. Fluid Sci. 52, 12–18 (2014). https://doi.org/10.1016/j.expthermflusci.2013.08.008

Kim, H.D.; Kim, J.; Kim, M.H.: Experimental studies on CHF characteristics of nano-fluids at pool boiling. Int. J. Multiph. Flow 33, 691–706 (2007). https://doi.org/10.1016/j.ijmultiphaseflow.2007.02.007

Kim, S.J.; Bang, I.C.; Buongiorno, J.; Hu, L.W.: Surface wettability change during pool boiling of nanofluids and its effect on critical heat flux. Int. J. Heat Mass Transf. 50, 4105–4116 (2007). https://doi.org/10.1016/j.ijheatmasstransfer.2007.02.002

Zhang, F.; Jacobi, A.M.: Aluminum surface wettability changes by pool boiling of nanofluids. Colloids Surf. A Physicochem. Eng. Asp. 506, 438–444 (2016). https://doi.org/10.1016/j.colsurfa.2016.07.026

Quan, X.; Wang, D.; Cheng, P.: An experimental investigation on wettability effects of nanoparticles in pool boiling of a nanofluid. Int. J. Heat Mass Transf. 108, 32–40 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.098

Binks, B.P.; Horozov, T.S.: Aqueous foams stabilized solely by silica nanoparticles. Angew. Chem. 117, 3788–3791 (2005). https://doi.org/10.1002/ange.200462470

Sarafraz, M.M.; Hormozi, F.: Nucleate pool boiling heat transfer characteristics of dilute Al\(_{2}\)O\(_{3}\)–ethyleneglycol nanofluids. Int. Commun. Heat Mass Transf. 58, 96–104 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2014.08.028

Shahmoradi, Z.; Etesami, N.; Nasr Esfahany, M.: Pool boiling characteristics of nanofluid on flat plate based on heater surface analysis. Int. Commun. Heat Mass Transf. 47, 113–120 (2013). https://doi.org/10.1016/j.icheatmasstransfer.2013.06.006

Amiri, A.; Shanbedi, M.; Amiri, H.; Heris, S.Z.; Kazi, S.N.; Chew, B.T.; Eshghi, H.: Pool boiling heat transfer of CNT/water nanofluids. Appl. Therm. Eng. 71, 450–459 (2014). https://doi.org/10.1016/j.applthermaleng.2014.06.064

Sarafraz, M.M.; Hormozi, F.: Pool boiling heat transfer to dilute copper oxide aqueous nanofluids. Int. J. Therm. Sci. 90, 224–237 (2015). https://doi.org/10.1016/j.ijthermalsci.2014.12.014

Paul, G.; Chopkar, M.; Manna, I.; Das, P.K.: Techniques for measuring the thermal conductivity of nanofluids: a review. Renew. Sustain. Energy Rev. 14, 1913–1924 (2010). https://doi.org/10.1016/j.rser.2010.03.017

Acknowledgements

This work was supported by Suleyman Demirel University Scientific Research Unit, Project No. 4209 D1-14.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Corumlu, V., Ozsoy, A. & Ozturk, M. Evaluation of Heat Transfer Mechanisms in Heat Pipe Charged with Nanofluid. Arab J Sci Eng 44, 5195–5213 (2019). https://doi.org/10.1007/s13369-019-03742-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03742-9