Abstract

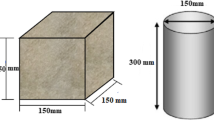

Two types of elastomeric polymers commonly used in gulf area are selected to modify the asphalt concrete mixtures produced from local materials that can serve at high temperatures and very heavy traffic loads. These polymers are styrene/butadiene/styrene (SBS), crumb rubber (CR). Because of significant contribution of asphalt binder on the performance of the mix at high temperatures, the objective of the study is to predict the dynamic moduli of asphalt concrete mixtures having polymer-modified binders satisfying the latest performance grading \(\hbox {(PG}^{+})\). Results showed that 5–10% of CR-modified binders and 2% of SBS-modified binders have elastomeric properties only at temperatures lower than \(58\,{}^{^{\circ }}\hbox {C}\). While 6% SBS-modified binder have shown elastomeric behavior at any temperature between 58 and \(76\,{}^{^{\circ }}\hbox {C}\). In the case of 4% of SBS-modified sample; the elastomeric properties are affected when testing temperature is above \(67\,{}^{^{\circ }}\hbox {C}\). It is concluded that PG 70(V) grade can be obtained by adding at least 3.9% of SBS, while 5.2% of SBS is required to reach PG 76(V) grade. In case of CR-modified binders, adding a minimum amount of 12.1 and 12.9% of CR is required to achieve the \(\hbox {PG}^{+}\) grade of PG 70(V) and PG 76(H), respectively. The measurement of dynamic modulus \({\vert }E^*{\vert }\) values of modified asphalt concrete samples was conducted utilizing the asphalt mixtures performance tester (AMPT) then the results were used to create master curves using symmetrical sigmoidal model at any given performance grade of the asphalt binder in terms of polymer type and content.

Similar content being viewed by others

References

Wahhab, H.A.A.; Al-Dubabe, I.A.; Asi, I.M.; Ali, M.F.: Performance-based characterization of Arab asphalt. Build. Environ. 33(6), 375–383 (1998)

AASHTO M-332: Standard specification for performance-graded asphalt binder using multiple stress creep recovery (MSCR) test. American Association of State and Highway Transportation Officials, Washington, DC (2014).

AASHTO M-320: Standard specification for performance-graded asphalt binder. American Association of State Highway and Transportation Officials, Washington, DC (2010)

Moreno-Navarro, F.; Sol-Snchez, M.; Rubio-Gmez, M.; Segarra-Martnez, M.: The use of additives for the improvement of the mechanical behavior of high modulus asphalt mixes. Constr. Build. Mater. 70(1), 65–70 (2014)

Hafeez, I.; Kamal, M.A.: An experimental-based approach to predict asphalt mixtures permanent deformation behavior. Arab. J. Sci. Eng. 39(12), 8681–8690 (2014)

Isacsson, U.; Zeng, H.: Cracking of asphalt at low temperature as related to bitumen rheology. J. Mater. Sci. 33(8), 2165–2170 (1998)

Al-Abdul-Wahhab, H.I.; Asi, I.M.; Al-Dubabe, I.A.; Ali, M.F.: Development of performance-based bitumen specifications for the Gulf countries. Constr. Build. Mater. 11(1), 15–22 (1997)

Wahhab, H.I.; Asi, I.M.; Ali, F.M.; Al-Dubabe, I.A.: Prediction of asphalt rheological properties using HP-GPC. J. Mater. Civ. Eng. 11(1), 6–14 (1999)

Alataş, T.; Yılmaz, M.; Kök, B.V.; fatih Koral, A.: Comparison of permanent deformation and fatigue resistance of hot mix asphalts prepared with the same performance grade binders. Constr. Build. Mater. 30, 66–72 (2012)

Singh, M.; Kumar, P.; Maurya, M.R.: Strength characteristics of SBS modified asphalt mixes with various aggregates. Constr. Build. Mater. 41, 815–823 (2013)

Kumar, S.; Veeraragavan, A.: Dynamic mechanical characterization of asphalt concrete mixes with modified asphalt binders. Mater. Sci. Eng. A 528(21), 6445–6454 (2011)

Kök, B.; Çolak, V.: Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 25(8), 3204–3212 (2011)

Xiao, F.; Amirkhanian, S.: Special issue on utilization of crumb rubber in asphalt mixtures. Constr. Build. Mater. 67, 1–216 (2014)

Xiang, L.; Cheng, J.; Kang, Sh: Thermal oxidative aging mechanism of crumb rubber/SBS composite modified asphalt. Constr. Build. Mater. 75(1), 169–175 (2015)

Irfan, M.; Ali, Y.; Ahmed, S.; Hafeez, I.: Performance evaluation of crumb rubber-modified asphalt mixtures based on laboratory and field investigations. Arab. J. Sci. Eng. (2017). https://doi.org/10.1007/s13369-017-2729-2

Paje, E.; Luong, J.; Vázquez, F.; Bueno, M.; Miró, R.: Road pavement rehabilitation using a binder with a high content of crumb rubber: influence on noise reduction. Constr. Build. Mater. 47(3), 789–798 (2013)

Lee, S.; Akisetty, Ch; Amirkhanian, S.: The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements. Constr. Build. Mater. 22(7), 1368–1376 (2008)

Jeong, K.; Lee, S.; Amirkhanian, S.; Kim, K.: Interaction effects of crumb rubber modified asphalt binders. Constr. Build. Mater. 24(5), 824–831 (2010)

Cong, P.; Xun, P.; Xing, M.; Chen, Sh: Investigation of asphalt binder containing various crumb rubbers and asphalts. Constr. Build. Mater. 40(3), 632–641 (2013)

Nejad, M.; Aghajani, P.; Modarres, A.; Firoozifar, H.: Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr. Build. Mater. 26(1), 481–489 (2012)

Bai, F.; Yang, X.; Zeng, G.: A stochastic viscoelastic–viscoplastic constitutive model and its application to crumb rubber modified asphalt mixtures. Mater. Des. 89(3), 802–809 (2016)

Wonga, G.; Hana, H.; Hea, G.; Wang, P.; Lu, W.: Rutting response of hot-mix asphalt to generalized dynamic shear moduli of asphalt binder. Constr. Build. Mater. 18(6), 399–408 (2004)

Zhu, H.; Sun, L.; Yang, J.; Chen, Z.; Gu, W.: Developing master curves and predicting dynamic modulus of polymer-modified asphalt mixtures. J. Mater. Civ. Eng. 23(2), 131–137 (2011)

Al-Adham, K.H.; Wahhab, H.I.A.: Effect of polymer type on improving rheological parameters related to rutting resistance of asphalt binders. Bitum. Mixtures Pavements VI, 89 (2015)

AASHTO TP-79: Standard method of test for determining the dynamic modulus and flow number for asphalt mixtures using the asphalt mixture performance tester (AMPT), Washington, DC (2015)

AASHTO TP 70: Standard method of test for multiple stress creep recovery (MSCR) test of asphalt binder using a dynamic shear rheometer (DSR). American Association of State Highway and Transportation Officials, Washington, DC (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Adham, K., Baig, M.G. & Wahhab, H.AA. Prediction of Dynamic Modulus for Elastomer-Modified Asphalt Concrete Mixes at Desert Environment. Arab J Sci Eng 44, 4141–4149 (2019). https://doi.org/10.1007/s13369-018-3348-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3348-2