Abstract

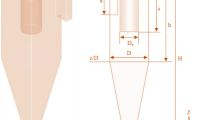

Spinning cone column (SCC) is a gas–liquid contacting device which is utilized in the food processing industries, and is useful in areas that require tolerance to the presence of solids and low-thermal impact of processing. The geometrical complexity, rotational parts, and different flow regimes inside SCC columns make modeling and simulation of these columns complicated, for which computational fluid dynamics (CFD) is used here. This work contains presenting the results of hydrodynamic parameters, including dry and two-phase pressure drops and flooding predictions in a pilot scale SCC. For expressing turbulence in gas and liquid phases, the standard \({k{-}\varepsilon }\) model and the zero equation model were utilized, respectively. For predicting flooding points, the dimensionless number Fr LG is used, when it is equal to 1 or more, flooding is occurred in the column. CFD results shows that increasing the rotating speed and also air flow rate at specific liquid flows would cause the pressure drop to increase at both states of dry and two-phase columns, which corresponds to the experimental data. This simulation results can be utilized for prediction of the industrial applications of SCC, including estimation of the pressure drop parameters, flooding, column efficiency and also designing the diameters of SCC column.

Similar content being viewed by others

Abbreviations

- A :

-

Cross-sectional flow area of the gas passage, m2

- B :

-

Spacing parameter, the ratio of the vertical distance between The fixed and the Spinning cone surfaces to the cone pitch

- C :

-

Gravity force

- Fr :

-

Froude number

- F :

-

Drag force, Nm−3

- G :

-

Gas flow rate per unit area, L m−2 min−1

- \({\overline{G}}\) :

-

Gas flow rate, L min−1

- G :

-

Acceleration due to gravity \({(\cong 9.81\,{\rm ms}^{-2})}\)

- L :

-

Liquid flow rate per unit area L m−2 min−1

- \({\overline L }\) :

-

Liquid flow rate, L min−1

- N :

-

Number of stages (cone sets) in SCC

- P C :

-

Cone pitch, vertical distance between two successive fixed or spinning cones, m

- P :

-

Pressure, Pa

- Δp :

-

Overall pressure drop through the column, Pa

- Δp stage :

-

Pressure drop of one stage, Pa

- Δp L :

-

Pressure drop in a liquid-only flow (wet column), Pa

- Δp G :

-

Pressure drop in a gas-only flow (dry column), Pa

- Q :

-

Volumetric flow rate, m3 s−1

- R H :

-

Hydraulic radius (width of the passage between cones in SCC), m

- R C :

-

Column inner radius, m

- R S :

-

Shaft radius, m

- R FI :

-

Inner radius of the fixed cone, m

- R SO :

-

Outer radius of the spinning cone, m

- R SI :

-

Inner radius of the spinning cone, m

- Re hyd :

-

Hydraulic Reynolds number

- Re rot :

-

Rotational Reynolds number

- Re Comb :

-

Combined Reynolds number

- t :

-

time, s

- U :

-

Real velocity, m s−1

- u r ,u θ ,u φ :

-

Radial, meridional and tangential velocities of the liquid flow, ms−1

- V :

-

Characteristic velocity, m/s

- X :

-

Flow parameter

- Y :

-

Capacity parameter

- ν :

-

Kinematics viscosity, m2 s−1

- θ :

-

Cone angle, degrees

- ρ :

-

Density, kg m−3

- ρ G :

-

Gas density, kg m−3

- ρ L :

-

Liquid density, kg m−3

- ω rot :

-

Angular velocity of the spinning cone rotation, s−1

- τ :

-

Shear stress, N m−2

- γ :

-

Volume fraction

- μ :

-

Molecular viscosity, kg m−1 s−1

- μ T :

-

Turbulent viscosity, kg m−1 s−1

- μ e :

-

Effective viscosity, kg m−1 s−1

References

Zivdar, M.: Distillation for Food Flavour Separation, Ph.D. Thesis. Department of Chemical Engineering, University of Sydney (1998)

Makarytechev, S.V.; Langrish, T.A.G.; Fletcher, D.F.: Mass Transfer Analysis of Spinning Cone Columns Using CFD. Chem. Eng. Res. Design 82, 752 (2004)

Langrish T.A.G., Makarytechev S.V., Fletcher D.F., Prince R.G.H.: Progress in Understanding the physical processes inside spining cone columns. Trans IChemE. 81, 122 (2003)

Makarytechev S.V., Langrish T.A.G., Fletcher D.F.: CFD analysis of spinning cone columns: prediction of unsteady gas flow and pressure drop in a dry column. Chem. Eng. J. 87, 301 (2002)

Makarytechev S.V., Langrish T.A.G., Prince R.G.H.: Thickness and velocity of wavy liquid films on rotating conical surfaces. Chem. Eng. Sci. 56, 77 (2001)

Makarytechev S.V., Langrish T.A.G.: Pressure drop and flooding limit in spinning cone columns.Chem. Eng. Comm. 192, 445 (2005)

Makarytechev S.V., Langrish T.A.G.: Dry column approximation for pressure drop in spinning cone columns. Chem. Eng. Commun. 191, 641 (2004)

Zivdar M., Hedayati B.: Analysis of gas flow using CFD. J. Chem. Eng. Iran 11, 26 (2004)

Makarytechev S.V., Langrish T.A.G., Fletcher D.F.: CFD Analysis of scale effects in spining cone columns. Trans IChemE 83, 951 (2005)

Zivdar M., Shirdel Sh.: CFD analysis of mass transfer parameter in scc distillation columns. J. Separat. Sci. Eng. 1, 23 (2009)

Zivdar M., Shirdel Sh., Khonsha I., Poorjafar L.: Review of CFD analysis in spinning cone columns. Iran. Chem. Eng. J. 46, 31 (2010)

Makarytechev S.V., Langrish T.A.G., Prince R.G.H.: Structure and regimes of liquid film flow in spinning cone columns. Chem. Eng. Sci. 53, 1541–1550 (1998)

Makarytechev S.V., Langrish T.A.G.: Dry column approximation for pressure drop in spinning cone columns. Chem. Eng. Comm. 191, 641 (2004)

Sykes, S.J., Prince, R.G.H.: The Design of Spinning Cone Distillation Columns. Csiro Division of Food Processing (1991)

Haghshenasfard, M.: The Design of Packed Column with Structured Packing Using CFD Analysis, Ph.D. Thesis. Department of Chemical Engineering, University of Sistan & Baluchestan. (2006)

Makarytechev S.V., Xue E., Langrish T.A.G., Prince R.G.H.: On modeling fluid flow over a rotating conical surface. Chem. Eng. Sci. 52, 1055 (1997)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khonsha, I., Zivdar, M. & Fard, M.H. Estimation of Hydrodynamic Parameters in Spinning Cone Column Using Computational Fluid Dynamics. Arab J Sci Eng 38, 767–776 (2013). https://doi.org/10.1007/s13369-012-0370-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-012-0370-7