Abstract

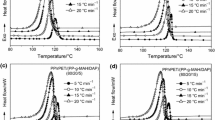

Dimethyl 1,4-cyclohexane dicarboxylate (DMCD) is formed as an impurity when dimethyl terephthalate (DMT) is manufactured from biomass. Because the boiling point of DMCD is similar to that of DMT, DMCD is known to add considerable cost to the separation and refinement. This prompted us to investigate the effect of the presence of varying amounts of DMCD on the physical properties of poly(trimethylene terephthalate) (PTT), which is manufactured from DMT. In the present study, a small amount of DMCD (1-5 mol% of DMT) was added when manufacturing PTT through the polycondensation of DMT and propanediol (PDO). The results of the analysis of the thermal properties indicated that the glass transition temperature and melting temperature showed a decreasing tendency as the DMCD content increased. The thermal stability increased by 25 °C compared to that of virgin PTT. The iso-thermal scanning analysis showed that the crystallization rate with 1 mol% of DMCD increased compared to that of virgin PTT, whereas the crystallization rate decreased with a higher DMCD content. The mechanical properties are noteworthy. The tensile strength and the tensile strain were simultaneously improved with the addition of DMCD, and the initial modulus remained nearly constant within the range of this experiment. Particularly, the tensile strength increased by a maximum of 15% (76.5 MPa) compared to that of virgin PTT. The physical properties of the PTT co-polyester significantly changed when the DMCD content was 2 mol%. Overall, the thermal properties remained similar, the crystallization rate increased, and the thermal stability and mechanical properties were significantly improved up to 2 mol%. Furthermore, the viscosity and crystal structure were examined by capillary rheometry and X-ray diffraction (XRD) to investigate the changes in these two properties. We concluded that the presence of bio-byproducts such as DMCD enhances the mechanical properties of PTT, such as the tensile strength and strain.

Similar content being viewed by others

References

S. Spierling, E. Knüpffer, H. Behnsen, M. Mudersbach, H. Krieg, S. Springer, S. Albrecht, C. Herrmann, and H. J. Endres, J. Cleaner Prod., 185, 476 (2018).

H. Kawaguchi, C. Ogino, and A. Kondo, Bioresour. Technol., 245, 1413 (2017).

H. H. Chuah, Polym. Eng. Sci., 41, 308 (2001).

S. Kim, H. Kim, and B. Nam, Asian J. Chem., 25, 5143 (2013).

W. J. Bae, W. H. Jo, and Y. H. Park, Macromol. Res., 10, 145 (2002).

W. Liu, A. K. Mohanty, L. T. Drzal, M. Misra, J. V. Kurian, R. W. Miller, and N. Strickland, Ind. Eng. Chem. Res., 44, 857 (2005).

J. Wang, C. Wang, and M. Run, Int. J. Polym. Sci., 2013 (2013).

S. K. Na, B. G. Kong, C. Choi, M. K. Jang, J. W. Nah, J.-G. Kim, and B. W. Jo, Macromol. Res., 13, 88 (2005).

Z. Liu, K. Chen, and D. Yan, Eur. Polym. J., 39, 2359 (2003).

N. Dangseeyun, P. Srimoaon, P. Supaphol, and M. Nithitanakul, Thermochim. Acta, 409, 63 (2004).

K. J. Hsiao, S. P. Lee, D. C. Kong, and F. L. Chen, J. Appl. Polym. Sci., 102, 1008 (2006).

H. Zou, C. Yi, L. Wang, and W. Xu, Polym. Bull., 64, 471 (2010).

J. M. Huang and F. C. Chang, J. Polym. Sci., Part B: Polym. Phys., 38, 934 (2000).

W. J. Yoon, K. S. Oh, J. M. Koo, J. R. Kim, K. J. Lee, and S. S. Im, Macromolecules, 46, 2930 (2013).

P. D. Hong, W. T. Chung, and C. F. Hsu, Polymer, 43, 3335 (2002).

C. Berti, A. Celli, P. Marchese, E. Marianucci, G. Barbiroli, and F. Di Credico, Macromol. Chem. Phys., 209, 1333 (2008).

Y. Liu and S. R. Turner, J. Polym. Sci., Part A: Polym. Chem., 48, 2162 (2010).

M. Albanese, J. Boyenval, P. Marchese, S. Sullalti, and A. Celli, AIMS Mol. Sci., 3, 32 (2016).

A. Celli, P. Marchese, S. Sullalti, C. Berti, and G. Barbiroli, Macromol. Chem. Phys., 212, 1524 (2011).

C. Berti, E. Binassi, A. Celli, M. Colonna, M. Fiorini, P. Marchese, E. Marianucci, M. Gazzano, F. Di Credico, and D. J. Brunelle, J. Polym. Sci., Part B: Polym. Phys., 46, 619 (2008).

B. Vanhaecht, M. N. Teerenstra, D. R. Suwier, R. Willem, M. Biesemans, and C. E. Koning, J. Polym. Sci., Part A: Polym. Chem., 39, 833 (2001).

C. Berti, A. Celli, P. Marchese, E. Marianucci, S. Sullalti, and G. Barbiroli, Macromol. Chem. Phys., 211, 1559 (2010).

T. Sandhya, C. Ramesh, and S. Sivaram, Macromolecules, 40, 6906 (2007).

L. Wang, Z. Xie, X. Bi, X. Wang, A. Zhang, Z. Chen, J. Zhou, and Z. Feng, Polym. Degrad. Stab., 91, 2220 (2006).

S. W. Hu, H. S. Myung, J. S. Bae, E. S. Yoo, and S. S. Im, Fibers Polym., 1, 76 (2000).

Y. M. Sun and C. S. Wang, Eur. Polym. J., 35, 1087 (1999).

H. Ki and O. O. Park, Polymer, 42, 1849 (2001).

S. Paszkiewicz, A. Szymczyk, K. Livanov, H. Wagner, and Z. Roslaniec, eXPRESS Polym. Lett., 9, 509 (2015).

C. F. Ou, J. Polym. Sci., B: Polym. Phys., 41, 2902 (2003).

G. Wei, D. Hua, and L. Gu, J. Appl. Polym. Sci., 101, 3330 (2006).

S. H. Kim, S. H. Ahn, and T. Hirai, Polymer, 44, 5625 (2003).

T. Gopakumar, J. Lee, M. Kontopoulou, and J. Parent, Polymer, 43, 5483 (2002).

S. Paszkiewicz, A. Szymczyk, Z. Špitalský, J. Mosnácek, K. Kwiatkowski, and Z. Roslaniec, Eur. Polym. J., 50, 69 (2014).

A. Szymczyk, S. Paszkiewicz, and Z. Roslaniec, Polym. Bull., 70, 1575 (2013).

R. Sharma, P. Jain, and S. D. Sadhu, Arabian J. Sci. Eng., 1 (2018).

A. Pei, Q. Zhou, and L. A. Berglund, Compos. Sci. Technol., 70, 815 (2010).

P. Srimoaon, N. Dangseeyun, and P. Supaphol, Eur. Polym. J., 40, 599 (2004).

P. Krutphun and P. Supaphol, Eur. Polym. J., 41, 1561 (2005).

I. Aravind, A. Boumod, Y. Grohens, and S. Thomas, Ind. Eng. Chem. Res., 49, 3873 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Acknowledgment: This work was supported by the Ministry of Strategy and Finance (MOSF, Korea) [No.JA180036].

Rights and permissions

About this article

Cite this article

Kim, H.N., Park, D., Youm, J.S. et al. Effect of Dimethyl 1,4-Cyclohexane Dicarboxylate on Mechanical Properties and Crystallization Behavior of Polytrimethylene Terephthalate Co-Polymer. Macromol. Res. 27, 182–190 (2019). https://doi.org/10.1007/s13233-019-7049-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-019-7049-9