Abstract

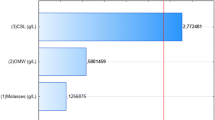

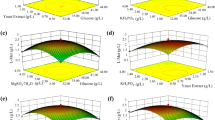

This study was aimed at using corn plasm, an industrial by-product, as the main culture medium in the process of optimizing a genetically engineered Escherichia coli strain for the biosynthesis of aspartic acid. The significant effect of corn plasm, peptone, lactose, and incubation period on the activity of aspartase were noted with Plackett-Burman design and Box-Behnken design, which showed that peptone of 1.05 % (w/v), corn plasm of 8.23 % (w/v), lactose of 1.12 % (w/v), and an incubation period of 20.78 h were the optimal culture conditions. Under these conditions, the maximum predicted activity of aspartase was 3,985 U. The optimized conditions were verified by scale-up experiments, and the maximum activity of aspartase was recorded as 4,100.5 U. Adding trace metallic ions in optimized medium have an effect on the activity of aspartase. As compared with the basal medium, the initial reaction rate of aspartase increased by 2-fold, and the molar conversion rate increased to 1.5-fold. Substrate concentration (maximum of 3 M) and bioconversion temperature tolerance (maximum of 50 °C) also have obviously improved.

Similar content being viewed by others

References

Aleboyeh A, Daneshvar N, Kasiri MB (2008) Optimization of C.I. Acid Red 14 azo dye removal by electrocoagulation batch process with response surface methodology. Chem Eng Process 47:827–832

Fenice M, Barghini P, Selbmann L, Federici F (2012) Combined effects of agitation and aeration on the chitinolytic enzymes production by the Antarctic fungus Lecanicillium muscarium CCFEE 5003. Microb Cell Factories 11:12

Gadomska G, Plucienniczak A, Chmiel A (2007) Recombinant strains of Escherichia coli for L-aspartic acid biosynthesis. Pol J Microbiol 56:77–82

Garza YG, Rodriguez MG, Hernandez CL, Rodriguez JM (2000) Optimization of aspartate ammonia lyase production by Bacillus cereus. J Ind Microbiol Biotechnol 25:225–228

Ghosalkar A, Sahai V, Srivastava A (2008) Optimization of chemically defined medium for recombinant Pichia pastoris for biomass production. Bioresour Technol 99:7906–7910

Gupta R, Beg QK, Lorenz P (2002) Bacterial alkaline proteases: molecular approaches and industrial applications. Appl Microbiol Biotechnol 59:15–32

Haaland PD (1989) Statistical problem solving. In Experimental Design in Biotechnology. New York and Basel, Marcel Dekker, Inc, USA

Hendrix C (1980) Through the response-surface with test tube and pipe wrench. Chemtech 10:488–497

Huang J, Jin N, Katsuda T, Fukuda H, Yamaji H (2009) Immobilization of Escherichia coli cells using polyethyleneimine-coated porous support particles for L-aspartic acid production. Biochem Eng J 46:65–68

Jayasekera MMK, Saribas AS, Viola RE (1997) Enhancement of catalytic activity by gene truncation: Activation of L-aspartase from Escherichia coli. Biochem Biophy Res Commun 238:411–414

Mennini N, Furlanetto S, Maestrelli F, Pinzauti S, Mura P (2008) Response surface methodology in the optimization of chitosan-Ca pectinate bead formulations. Eur J Pharm Sci 35:318–325

Mohana S, Shrivastava S, Divecha J, Madamwar D (2008) Response surface methodology for optimization of medium for decolorization of textile dye Direct Black 22 by a novel bacterial consortium. Bioresour Technol 99:562–569

Papierz M, Gadomska G, Sobierajski B, Chmiel A (2007) Selection and activation of Escherichia coli strains for L-aspartic acid biosynthesis. Pol J Microbiol 56:71–76

Psenicka I, Malanik V, Sojkova I, Malanikova M, Marek M (1988) Biotechnological preparation of L-aspartic acid. 1. Optimization of growth of Escherichia alcalescens with respect to its aspartate ammonia-lyase activity. Folia Microbiol 33:178–182

Wang LJ, Kong XD, Zhang HY, Wang XP, Zhang J (2000) Enhancement of the activity of L-aspartase from Escherichia coli W by directed evolution. Biochem Biophys Res Commun 276:346–349

Weiner B, Poelarends GJ, Janssen DB, Feringa BL (2008) Biocatalytic enantioselective synthesis of N-substituted aspartic acids by aspartate ammonia lyase. Chem Eur J 14:10094–10100

Zheng ZM, Hu QI, Hao J, Xu F, Guo NN, Sun Y, Liu DH (2008) Statistical optimization of culture conditions for 1,3-propanediol by Klebsiella pneumoniae AC 15 via central composite design. Bioresour Technol 99:1052–1056

Acknowledgments

This project was supported by the Key 863 Fund of China (No. 2009AA02Z305), Anhui Provincial Natural Science Foundation (1308085MA07).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, G., Gong, G., Wang, P. et al. Enzymatic synthesis of L-aspartic acid by Escherichia coli cultured with a cost-effective corn plasm medium. Ann Microbiol 64, 1615–1621 (2014). https://doi.org/10.1007/s13213-014-0805-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-014-0805-3