Abstract

Volume transformation technology has become a key technology for developing low-permeability/tight oil and gas reservoirs. Evaluating the post-fracturing effect is very important for the development plan formulation and fracturing plan evaluation. In this paper, the vicinity of the main fracture is divided into the main fracture zone and the secondary fracture zone. The main fracture with infinite conductivity and the branch fracture with increased permeability are used to describe the transformation area. Based on this physical model, a numerical model considering the nonlinear seepage characteristics of the reservoir, stress sensitivity, wellbore storage and skin effects was established. Based on this numerical model, a comprehensive evaluation method for the fracturing effect of volume modification of vertical wells based on well test data and production data was established and this method was applied to three typical vertical wells. The results show that conventional vertical fracturing vertical wells can only form a single primary fracture and the range of equivalent permeability increase is very small. Volume fracturing can form a fracture network composed of primary fractures and secondary fractures, and increase the equivalent permeability of the fracture network area. The fracture half-length, equivalent permeability and reconstruction area of the volume fracturing well are dynamically changing and gradually decrease with the increase in production time and the fracturing effect becomes weak until it fails.

Similar content being viewed by others

Introduction

With the continuous development of medium and high-permeability reservoirs, the reserves of medium and high permeability have decreased, making it difficult to stabilize production (Zou et al. 2012). In PetroChina, in recent years, the newly added geological reserves of low-permeability and ultra-low-permeability oil and gas geological reserves have increased year by year. The new reserves of low-permeability/tight oil reservoirs account for more than 90% of the total new reserves and the contributions of both produced reserves and production are more than 40% (Hou et al. 2018). In this type of reservoir, the number of low-yield vertical wells of PetroChina reached nearly 90,000 in 2018, which severely restricted the effective development of this type of reservoir. Based on this and drawing on the concept of shale oil and gas volume reformation, PetroChina has carried out vertical well volume reformation fracturing tests in C, J, D and other oil fields and achieved good results (Wu et al. 2011, 2014; Xu et al. 2018).

At present, there are direct and indirect methods for evaluating fracturing effects of volume reconstruction. The direct method includes microseismic (Liu et al. 2013), inclinometer (Yan et al. 2016) and distributed optical fiber methods. This method is mainly affected by the accuracy of the sensor and the number of measurement points and the signal-to-noise ratio often obtained is low, resulting in poor interpretation results. And this method has high cost and can only evaluate the effect of reconstruction at a certain moment after fracturing. Based on the above reasons, some scholars (Liao et al. 2016; Zhou et al. 2012; Chen et al. 2016; Clarkson and Pedersen 2010; Brown et al. 2009; Brohi et al. 2011) explored the use of indirect methods to evaluate the fracturing effect of volume reconstruction. The indirect method is to use the data of well test, fracturing construction and development and production to evaluate the effect of volume reforming and fracturing through numerical methods.

Zhu used the seepage resistance method to obtain an analytical solution model for vertical fractured wells in shale gas reservoirs and conducted parameter studies (Zhu et al. 2014). Based on hydropower similar simulation experiments and seepage theory, Liu Xiaoqiang (Liu et al. 2015) established an analytical solution model for the formation of short and wide vertical fractures in low-permeability reservoirs after fracturing and deduced the corresponding fracturing productivity formula and the effects of half-fracture length, permeability and fluid viscosity on productivity are analyzed. Feng based on the principles of energy conservation and material balance, an analytical model was established to calculate the average fracture length and number in the SRV by means of a variation method, which can provide key parameters to describe the fracture density and conductivity in the SRV (Feng et al. 2020). Nassir established a volume calculation model for reservoir reconstruction and proposed the effect of volume fracturing using fracture complexity index (Nassir et al. 2014). Medeiros has established a semi-analytical model of fractured horizontal wells in heterogeneous reservoirs considering different fracture conditions and conducted pressure and productivity analysis (Medeiros et al. 2007). Zhou discretized the fractures monitored by the microseismic and proposed a semi-analytical model for simulating the seepage of complex fracture networks (Zhou et al. 2012). Wang has established a semi-analytical model of volume fracturing horizontal well, research on influencing factors of the spacing on effect of production (Wang et al. 2020).

For low-permeability/tight oil reservoirs, such reservoirs with strong heterogeneity and complex reservoir structure, analytical and semi-analytic models cannot accurately describe reservoir characteristics, faults and complex boundaries (Jiang et al. 2015). Numerical models came into being compared with analytical/semi-analytical methods; numerical methods are based on the most basic seepage equations and assumptions. There is no need to simplify reservoir boundaries, reservoir properties, fluid properties and fluid components and can be more realistic to describe the complex fracture network morphology formed after volume fracturing. Zhang based on the digital filtered fracturing pump-stop data method, Newman's product method and Duhamel principle are adopted to calculate the spread range of the pressure in the process of construction and then obtain the SRV fracturing region area (Zhang et al. 2020).At present, most of the fracturing effect evaluation of vertical well volume reconstruction is carried out with single data and the description of geological model and seepage model is not very accurate, which affects the effect of vertical well volume reconstruction fracturing effect.

Therefore, based on the geological characteristics of fractures and matrix after vertical well volume reformation, this paper divides the volume reformed seepage area, establishes a numerical model considering the effects of nonlinear seepage characteristics and stress sensitivity and proposes a vertical well volume reformation based on well test and production data. The comprehensive numerical evaluation method of fracturing effect was applied to three typical wells in C.

Description and establishment of the numerical model

The numerical model established in this paper is based on the black oil model, and its basic assumptions are: ①Only oil and water phases exist in the model. The two components of oil and water are incompatible with each other, and there is no mass exchange between the two components; ②the fluid in the reservoir is in a constant temperature and thermodynamic equilibrium; ③considering the pressure sensitivity, the fluid and the rock are compressible; ④the reservoir it has heterogeneity and anisotropy.

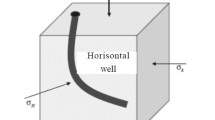

After vertical well fracturing, the reservoir reconstruction area is very complicated and a stimulated reservoir volume (SRV) will be formed. That is, the reservoir not only forms the main fracture zone controlled by the main fracture, but also produces a reservoir reform zone composed of secondary fractures, that is, a secondary fracture zone. In this paper, a PEBI grid that can describe complex geological features and flow characteristics is used to accurately describe the vertical well reconstruction area and the equivalent permeability is used to express the reconstruction effect of the reservoir reconstruction area. That is, the permeability of the core area is larger, followed by the permeability of the outer area, and the permeability of the unreformed area is the basic parameter of the reservoir. Figure 1 is a schematic diagram of the grid division of the straight well reconstruction area.

When the permeability is converted according to the phase permeability curve and the viscosity of the single-phase fluid is converted according to the water cut, the single-phase well test interpretation and the multi-phase well test interpretation are equivalent in pressure and the well test interpretation is often the solution of the single well pressure recovery data. The effective permeability and viscosity during single fitting are calculated according to the following formula (Li et al. 2016).

During the well test interpretation period, the saturation changes little and the oil saturation and water cut can be set as constants; then, Eq. (2) can be written as:

Low-permeability reservoirs have the characteristics of low porosity, low permeability and strong heterogeneity. When fluid passes through a narrow throat, it will increase the viscosity of fluid seepage. At the same time, the accumulation of formation fluid will cause the pore pressure to decrease. The rock structure of the reservoir is deformed, so the fluid seepage in the low permeability reservoir has nonlinear characteristics. The single-phase seepage velocity with pseudo-TPG is (Li et al. 2016):

where \(\beta\) is the nonlinear factor and the expressions are as follows:

where n is a nonlinear index, \(\lambda_{\min }\) is the minimum TPG, \(\lambda_{{{\text{pseduo}}}}\) is the pseudo-TPG, \(\lambda_{\max }\) is the maximum TPG. Substitute the corrected Darcy Eq. (4) into the following continuity equation:

where \(\rho\) is density, \({\text{Kg/m}}^{{3}}\), \({\mathbf{u}}\) is flow velocity, \({\text{m/s}}\), \(\phi\) is porosity, \(\overline{q}\) is mass flow, \({\text{Kg/(m}}^{{3}} \cdot {\text{s)}}\).

Dividing the ground density \(\rho\) by both sides of the equation at the same time, the governing equation can be obtained as:

Among them, \(K\) is the grid permeability,\({\mu m}^{2}\); \(\mu\) is the viscosity, mPa·s; \(B\) is the formation volume coefficient; \(p\) is the pressure, Pa; \(\phi\) is the reservoir porosity, the volume flow under surface conditions, \(q = \overline{q}/\rho\), \({\text{1/s}}\); make well production, \(q_{w} = \iiint\limits_{V} qdV\), the well production equation considering the table coefficients can be obtained as:

where \(r_{e}\) is the distance between adjacent grids of the fracture, m; \(r_{w}\) is the width of the fracture, m; \(h\) is the thickness of the grid, m; \(S\) is the wellbore pollution coefficient, dimensionless; \(p_{wf}\) is the wellbore pressure, Pa.

The well is produced with a fixed oil and water production volume Q. Considering the reservoir effect of the well, we can get:

To form a complete mathematical model, in addition to the basic seepage equation, boundary conditions and initial conditions are also required, two commonly used boundary conditions in numerical simulation:

-

1.

Constant pressure boundary

On the inner boundary or wellbore, it indicates that the well is producing or injecting at a constant production pressure. At the outer boundary, it means that the boundary pressure remains constant.

-

2.

Close the boundary

Usually used on the outer boundary, indicating that there is no flow on the boundary, that is:

In terms of initial conditions, for well test analysis, it can be considered that the initial formation pressure is a given value. In the multi-well test analysis, although the actual formation pressure is a pressure distribution, there is a long production time before the shut-in pressure measurement, and the initial pressure distribution has little effect on the bottom hole pressure of the shut-in section. It can be approximated that the formation pressure is a fixed value.

Numerical method for evaluating the fracturing effect of vertical well fracturing reformation

At present, the data commonly used in the evaluation methods of fracturing reconstruction mainly include well test and development production data. Well test data have high data quality due to many test data points. The differential pressure derivative curve can be solved, and the reaction fracture and formation parameters can be obtained. If well test is conducted before and after fracturing, not only the fracture and reservoir physical parameters can be obtained, but also the reservoir and the nonlinear seepage parameter of the fluid can be obtained. However, due to the relatively short test time of the well test data, the dynamic process of fracturing effect is still insufficient. The production data are the data of the whole process the well, which can be used to evaluate the dynamic changes in fracturing effects. However, when the data are used for the evaluation of the effect of reconstruction, the bottom hole pressure is calculated by using the height of the fluid level and casing pressure, the calculated data points are sparse and discontinuous and cannot obtain pressure derivative curve and nonlinear seepage parameter, so the parameters obtained by the fitting are not accurate, but the overall trend can only be given. Therefore, this paper explores the establishment of a comprehensive evaluation method of fracturing effect of vertical well based on well test data and production data, to accurately evaluate the fracturing effect of vertical well reconstruction and accurately obtain fracture and reservoir physical parameters, nonlinear seepage parameters.

Evaluation method of fracturing effect of vertical well based on production data

The principle is: according to the historical data of vertical well development and production, calculate the bottom hole pressure at different development times, then through the set vertical well fracturing area (core area, external area and unreformed area) to fit and combine the sensitivity. Parameter analysis is to obtain the primary and secondary fracture permeability, fracture half-length, SRV area and bedrock permeability and other parameters. Take a fracturing vertical well in a rectangular oil reservoir as an example to illustrate the evaluation principle of the fracturing effect of vertical well modification based on development and production data. Table 1 shows the basic parameters of the reservoir.

Figure 2 shows the fitting curve of the fracturing reformed area and pressure history of a fracturing reformed vertical well during a certain period. Figure 3 shows the different inversion parameters (matrix permeability, the permeability of the main fracture zone, the permeability of the secondary fracture zone and the influence of fracture half-length, etc.) on the pressure curve; through parameter analysis, the ambiguity of inversion parameters can be eliminated.

Figure 3(a)shows the bottom hole pressure curve of different matrix permeability (0.1mD, 0.3mD, 0.5mD and 0.7mD); it can be seen that the matrix permeability mainly affects the flow at the distal end of the fracture. When the matrix permeability decreases, the weakening of the flow capacity at the distal end of the fracture will also reduce the flow capacity of the matrix to the fracture. Therefore, the permeability of the matrix will affect the shape of the entire pressure curve. The matrix permeability is generally determined by the geological data during fitting and will not be changed in the later stage of the fitting. The pressure curves are shown in Fig. 3(b) and Fig. 3(c) shows that the fracture permeability of the core zone mainly affects the flow law near the well end and the permeability of the secondary fracture zone has a smaller effect on the early pressure curve and mainly affects the pressure in the middle. The curves of different fracture half-lengths shown in Fig. 3(d) show that the shape of the pressure curves in the early stage is different, but they remain parallel in the later stage. Therefore, the half-length of the fracture only affects the flow pattern in the early stage and the shape of the pressure curve at the back is determined by other parameters. The shorter the half-length of the fracture, the smaller the production index of the well, resulting in a faster drop in flow pressure.

Evaluation principle of the fracturing effect of vertical well based on well test data

Interpretation of well test data is to use the change law of pressure difference (\(\Delta p\)) and pressure difference derivative (\(d\Delta p/dt\)) obtained by shut-in to determine various fluid flow patterns in the reservoir. According to the fluid flow pattern, parameters such as primary and secondary fracture permeability, fracture half-length, SRV area and bedrock permeability are analyzed. Taking a vertical well as an example, the method of fracturing effect evaluation of vertical well fracturing reconstruction based on well test data is explained. The vertical well was shut-in pressure measurement before and after fracturing. The interpretation results of the two shut-in pressure measurements are shown in Fig. 4:

It can be seen from Fig. 4: (1) Before fracturing, the well test curve of the vertical well can be divided into four stages according to the shape of the curve (Fig. 4(a)), respectively: Zone 1 is the stage of well storage. The stage is mainly related to the permeability near the well circumference and the well storage coefficient; the second zone is the skin effect stage and the length of this stage is related to the size of the skin; the third zone is the second radial flow stage, which is mainly affected by the matrix permeability; Zone 4 is the boundary influence stage. This figure assumes a closed boundary. If it is a constant pressure boundary, the pressure difference derivative curve will decline in the later stage. (2) After fracturing of vertical wells, the vertical wells are partitioned according to the effect of fracturing. The well test curve can be divided into six stages according to the shape of the curve (Fig. 4(b)), which are: Zone 1 and Zone 2 are the well storage stage and the skin effect stage, respectively, and Zone 3 is the first radial flow. In the stage, this stage is mainly affected by the main fracture of the fracturing, that is, the red area. If the red zone is more permeated, the duration of the first radial flow is shorter; zone 4 is the transition stage between two radial flows; zone 5 is the second radial flow stage, which is mainly affected by the fracturing area of the secondary reformation has a greater impact, that is the yellow area; area 6 is the boundary influence stage, which is affected by the boundary type. The parameters of different positions in the reservoir determine the time point and duration of the appearance of different pressure characteristics of the well test curve, which can accurately inverse the formation parameters. (3) The pressure derivative in the well test curve is more sensitive than the pressure and can magnify the unclear features and subtle changes in the pressure analysis; especially for the fracturing area, the pressure derivative has very special characteristics; increasing the identifiability of the fracturing reconstruction area is improved, to better evaluate the effect of fracturing. This can also be verified from the figure. If you simply look at the pressure curves before and after fracturing, you cannot see the change characteristics of the pressure curve in the fracture area after the fracturing of this well. Only by observing the pressure, the characteristic of the derivative curve can inverse the parameters of the fracture zone after the reformation.

Field examples

The author selected 3 typical vertical wells of PetroChina to evaluate the fracturing effect. Well 1 was fractured twice, the first time was 145 m2 on September 19, 2013, and the second time was 638 m2 on August 10, 2018. Well 2 was also fractured twice, the first time was on June 22, 2016, and the second time was on August 29, 2018. Well 3 was tested before and after fracturing. The fracturing effects of 3 wells were evaluated using the above two methods and the interpretation results are shown in Table 2.

The first fracturing explained in Well 1 was a conventional fracturing. The main reason was that the amount of fracturing fluid entering the ground was small and only a single fracture was formed. As the development progressed, the fractures gradually closed and the equivalent permeability gradually changed from the 10.1mD is reduced to 6.3mD, which leads to the reduction of fracture conductivity and production. Finally, the fractures are closed and the equivalent permeability is gradually reduced from 6.3mD to 0.8mD. The fracturing effect has basically disappeared and the output has dropped significantly. In the second fracturing, a large amount of fracturing fluid was injected into the ground and a large-scale volume reconstruction area was formed underground. The explained fracture half-length is 110 m, the permeability of the core area is 15mD, and the reconstruction area is 5747.6 m2; the permeability is 1mD and the reconstructed area is 8471.8 m2.

The first fracturing of Well 2 was volume fracturing. Although no main fractures were formed, a reformed area composed of fracture networks was formed. The equivalent permeability of the core area is 15mD and the reconstruction area is 3678 m2; the equivalent permeability of the external reconstruction area is 1.5mD and the reconstruction area is 17,070 m2. With the increase in the oil well production time, the cracks gradually closed and the improvement effect slowly disappeared until it completely failed. The equivalent permeability of the core area dropped to 10mD, and after complete failure, it dropped to 0.8mD. The area of the improvement basically remained unchanged; the rate is reduced to 1mD, 0.5mD after complete failure and the reconstructed area is reduced to 16,591 m2, and after complete failure, it is reduced to 8678 m2. In the second fracturing, a large amount of liquid entered the ground and formed a larger core reconstruction area, explaining that the equivalent permeability is 90 mD and the reconstruction area is 7241 m2.

Well 3 formed a main fracture after fracturing, the equivalent permeability doubled, and the intended starting pressure gradient was reduced from 0.2 MPa/m to 0.18 MPa/m, effectively reducing the nonlinear seepage resistance of the fluid.

Through the above three well examples, the numerical method in this paper can effectively evaluate the fracturing effect of the well. According to the fracturing effect, it can be judged whether it is conventional fracturing or volume fracturing. The effect of conventional fracturing is relatively simple, only forming a single main fracture, increasing the equivalent permeability in a small area around the main fracture, while volume fracturing wells can not only form the main fracture, but also form many secondary fractures to form one The fracture network can increase the equivalent permeability of the reservoir in a larger range and at the same time reduce the nonlinear permeability resistance, creating a very favorable condition for the fluid in the tight reservoir fluid. After fracturing, the reforming effect of the well at different production stages is different. The fracture is half-length; the equivalent permeability and the reformed area gradually decrease with time, until the fracture is completely closed and the fracturing effect disappears.

Conclusions

-

1.

Use the method of zoning: divide the vicinity of the main fracture into different reformed zones (internal zone, external zone and unreformed zone), set the main fracture to infinite conductivity and use the increase in permeability to indicate the secondary fractures and establish low permeable/tight reservoir which is a numerical model with nonlinear seepage characteristics.

-

2.

A comprehensive evaluation method for fracturing effects of vertical well volume reformation based on well test and production data has been established, which can accurately obtain fracturing effects, crack parameters and fluid nonlinear characteristics and apply this method to 3 typical vertical wells

-

3.

The research results show that: conventional fracturing wells can only form a single main fracture and volume fracturing wells can form a fracture network composed of primary and secondary fractures; the fracturing effects of volumetric fracturing wells are different in different production periods. The fracture half-length, equivalent permeability and reconstruction area gradually decrease with time. After the fracture is completely closed, the fracturing effect basically disappears

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Brohi I, Pooladi-Darvish M, Aguilera R (2011) Modeling fractured horizontal wells as dual porosity composite reservoirs - application to tight gas, shale gas and tight oil cases[R]. Society of Petroleum Engineers, Anchorage, Alaska

Brown M, Ozkan E, Raghavan R et al (2009) Practical solutions for pressure transient responses of fractured horizontal wells in unconventional reservoirs[R]. Society of Petroleum Engineers, New Orleans, Louisiana

Xiaoming C, Xinwei L, Donghui Li et al (2014) Pressure transient analysis of volume fracturing vertical well: Double-porosity double-zone model[J]. Well Testing 23(4):4–8

Clarkson C, Pedersen P (2010) Tight oil production analysis: Adaptation of existing rate-transient analysis techniques[R]. Alberta, Society of Petroleum Engineers, Calgary

Fuping F, Rui H, Yang L et al (2019) Evaluation of engineering effectiveness of volume fracturing based on energy conservation principles and its application[J]. Journal of China University of Petroleum (Edition of Natural Science ) 43(1):81–89

Qijun H, Haiqing He, Jianzhang Li et al (2018) Recent progress and prospect of oil and gas exploration by PetroChina Company Limited [J]. China Petroleum Exploration 23(01):1–13

Liu Z, Liming Sa, Furong Wu et al (2013) Microseismic monitor technology status for unconventional resource E&P and its future development in CNPC [J]. Oil Geophys Prospec 48(05):843–853

Longyan J, Xiaoquan G, Nan W et al (2015) Non-steady state productivity evaluation model of volume fracturing for vertical well in tight oil reservoir [J]. Fault-Block Oil & Gas Field 22(01):82–86

Xinwei L, Xiaoming C, Xiaoliang Z et al (2016) Pressure transient analysis of volume fracturing well in low permeability oil reservoir. Science & Technology Review. 34(07):117–122

Daolun Li, Zhang Longjun Lu (2013) Equivalent study on well test interpretation of single-phase flow and multiphase flow. Well Testing. 22(01):10–12

Li D, Zha W, Liu S et al (2016) Pressure Transient Analysis of Low Permeability Reservoir with Pseudo Threshold Pressure Gradient[J]. Journal of Petroleum ence & Engineering 147:308–316

Xiaoqiang L, Tiankui G, Xiaolong Li et al (2015) Fracturing productivity calculation of vertical well with short and wide fractures. Fault-Block Oil & Gas Field. 22(2):217–220

Medeiros F, Ozkan E, Kazemi H (2007) Productivity and drainage area of fractured horizontal wells in tight gas reservoirs[R]. Colorado, Society of Petroleum Engineers, Denver

Nassir M, Settari M, Wan R (2014) Prediction of stimulated reservoir volume and optimization of fracturing in tight gas and shale with a fully elasto-plastic coupled geomechanical model[J]. SPE Journal 19(4):771–784

Wang Zhiyuan , Zhao,Xinli, Xiong Shengchun et al. Semi-analytical model-based research on influencing factors of the spacing of volume fracturing horizontal well in tight oil reservoirs via consideration of imbibition [J]. Journal of Petroleum Science and Engineering,

Wu Qi Xu, Yun WT et al (2011) A major change in the concept of increasing production and transformation - an introduction to volume transformation technology [J]. Nat Gas Ind 31(04):7–12

Wu Qi Xu, Yun ZS et al (2014) The core theories and key optimization designs of volume stimulation technology for unconventional reservoirs [J]. Acta Petrolei Sinica 35(04):706–714

Yun Xu, Qun L, Ming C et al (2018) Progress and development of volume stimulation techniques [J]. Petroleum Exploration and Development 45(05):874–887

Yan Xin Hu, Tianyue HY (2016) Application of surface tiltmeter in monitoring complicated hydraulic f ractures [J]. Oil Geophysical Prospecting 51(03):480–486

Zhonglin Z, Shen Feng Xu et al (2020) A New Inversion Method of Stimulated Reservoir Volume Fracturing Region Based on Pump-Stop Data and Its Application[J/OL]. Unconventional Oil & Gas. 5:1–18

Zhou WT, Banerjee R, Poe B (2012) Semi-analytical production simulation of complex hydraulic fracture networks[R]. Society of Petroleum Engineers, Doha, Qatar

Caineng Z, Rukai Z, Bin B et al (2015) Significance, geologic characteristics, resource potential and future challenges of tight oil and shale oil [J]. Bulletin of Mineralogy, Petrology and Geochemistry 34(01):3–17

Zhu Weiyao, Deng Jia, Yang Baohua, et al (2014) Seepage model of shale gas reservoir and productivity and analysis of practured vertical wells. Mechanics in Engineering. 36(2); 156–160.

Acknowledgements

The authors gratefully acknowledge financial support from the National Science and Technology Major Project (2017ZX05049005-004), National Science and Technology Major Project “Key Technologies for Effective Development of Low Permeability-Ultra-low Permeability Reservoirs” (2017ZX05013-001), National Science and Technology Major Demonstration Project “Tight Oil Seepage Characteristics and Development Optimization Research and Application" (2017ZX05069003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xia, D., Yang, Z., Li, D. et al. Research on numerical method for evaluation of vertical well volume fracturing effect based on production data and well test data. J Petrol Explor Prod Technol 11, 1855–1863 (2021). https://doi.org/10.1007/s13202-021-01091-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-021-01091-8