Abstract

Fluid/fluid and fluid/rock interfaces have large influence on the microscopic sweep efficiency of an enhanced oil recovery process. Therefore, modification of these interfaces using nanoparticles to suitable conditions might lead to better recovery factors. Particularly, wettability alteration and interfacial tension reduction are the two key mechanisms which should be considered. This study was designed to address the capability of nanoparticles to be used as a chemical agent for enhanced oil recovery by several core flooding experiments. The injected chemical solution was prepared using synthetic brine containing %3 NaCl, silica nanoparticles, and SDS surfactant. Contact angle in rock/oil/solution system and interfacial tension between oil/solution were measured. In addition, SEM pictures and XRD analysis were taken to conduct a more thorough investigation of effect of nanoparticles on sandstone core plugs. Nanoparticles and surfactant mixture were flooded with various concentrations under different scenarios. The results show the incremental oil recovery of nanoparticles floods in sandstone core samples which ranged from 4.85 to 11.7%. Conversely, the enhanced oil recovery of high concentration of nanoparticle floods in cores was small. It is deduced that the mechanisms responsible for incremental oil recovery are mainly interfacial tension reduction and wettability alteration toward water-wet condition. However, the flooding results as well as experimental study of possible retention revealed that nanoparticles can be considered as an effective chemical agent in enhanced oil recovery.

Similar content being viewed by others

Introduction

Traditional enhanced oil recovery (EOR) methods might not be suitable for all oil reservoirs. Hence, for special situations new processes such as nanoparticles flooding might be useful to increase the oil recovery factor. Nanoparticle-based fluid technology results in changes of reservoir rock and fluid properties such as wettability and capillary pressure.

Nanoparticles with high surface area to volume ratio (enhanced activity and contact area) and structure properties provide interesting chemical and physical properties. Nanofluids can increase oil recovery from reservoirs by modifying the rock–fluid and fluid–fluid interfaces during injection in porous media (Ayatollahi et al. 2012; Mcelfresh et al. 2012).

Based on previous studies, reduction of the interfacial tension between oil and water and alteration of the rock wettability toward water-wet condition can be identified as the chief mechanisms of improving oil recovery by silica nanoparticle (Ayatollahi et al. 2012; Mcelfresh et al. 2012; Roustaei et al. 2012; Torsater et al. 2012; Giraldo et al. 2013). In other words, oil recovery factor can be improved by nanoparticles through various mechanisms from IFT reduction to decreasing the oil viscosity to wettability alteration and improving the mobility ratio (Khademolhosseini et al. 2015). Skauge et al. 2010 investigated the oil mobilization properties of nano-sized silica particles and explained the basic mechanism of microscopic flow diversion by colloidal dispersion gels. Surface-coated silica nanoparticles have been used in order to stabilize both water-in-oil and oil-in-water emulsions (Zhang et al. 2010). Displacement of concentrated surface-coated silica nanoparticles in sedimentary rocks was examined by Rodriguez et al. (2009). Wettability alteration influences and significantly oil recovery were observed for nanoparticles known as hydrophilic polysilicon (Ju and Fan 2009). It has been reported that the adsorption of nanoparticles on pore walls may cause wettability alteration from oil-wet toward more water-wet condition (Ayatollahi 2012; Mcelfresh 2012). Onyekonwu and Ogolo (2010) studied capability of three different nanoparticles as an operator to change wettability and oil recovery purposes. Studies also involved particle size and shape (Hunter et al. 2008; Madivala and Fransaer 2009), particle concentration (Zhang et al. 2010; Zhou et al. 2013; Chevalier and Bolzinger 2013). Moreover, the effects of salinity (Yoon et al. 2012; Lee et al. 2014) on emulsion stability have also been studied (Lee et al. 2014). It should be noticed that numerous factors play a vital role in stability of nanoparticles such as: the particle size, pressure, temperature, and ions or molecules present in a system (Esmaeeli et al. 2014). For instance, nanoparticle dispersion stability depends on temperature. In fact, temperature has a kinetic role in this issue (Kanj et al. 2009).

Experimental investigations of nano-EOR performed on low-medium permeability sandstone cores have also confirmed that silica nanoparticles cause incremental oil recovery by IFT reduction and wettability alteration (Torsater et al. 2013).

Smart nano-EOR has also been examined via the use of carbonate rocks. Several types of nanoparticles have been tested to enhance oil recovery by different scenarios. The results verified the effectiveness of nanoparticle flooding in carbonate reservoirs (Haroun et al. 2012).

The underlying mechanisms in surfactant injection are change in wettability and reduction of IFT between oil and water, which result in the reducing the residual oil saturation and increasing the sweep efficiency. However, the adsorption of surfactant on rock surface is a crucial matter as it results in solution loss while it makes the rock surface more water-wet (Sheng 2010). Moreover, when the adsorption is too high, it is necessary to implement larger amount of surfactants to produce small amount of extra oil (Zargartalebi et al. 2015).

While implementing chemical EOR methods, certain challenges must be faced, namely high temperature condition, high salinity, geochemical lithology variation, and heterogeneity of formation. Various types of traditional fluids were designed to overcome these challenges, and yet they persist. Using nanoparticles has been identified as a convenient way of conquering the above-mentioned challenges owing to their uniqueness and worthwhile properties (Ayatollahi et al. 2012; Mcelfresh et al. 2012). The small size of nanoparticles in a key factor contributes to enhancing the recovery oil. Due to their insignificant size, they can easily move through porous media for substantial lengths. Since the particle size is not high enough to block the pore throats in porous media, nanoparticles can survive the transport through pores (Ayatollahi et al. 2012; Mcelfresh et al. 2012). It is, however, up to the point where the nanoparticles’ agglomeration process causes the blockage of pore throats leading to permeability impairment of the porous media. Kanj et al. identified the usable size of nanoparticles in reservoir rocks through nanofluid core flooding experiments (McElfresh et al.2012).

This study is aimed at evaluating and comparing the effectiveness of using silica nanoparticles in improving enhanced oil recovery processes. The experiments in this study supply additional information on nanofluid mechanisms in improving oil recovery. Moreover, in order to investigate the effect of nanoparticles on reservoir properties, new porosity and permeability values were measured. SEM pictures were taken for qualitative observation to find out the impact of nanoparticles on sand grain surface. The IFT measurements between the crude oil and nanoparticle solution were performed using spinning drop. Furthermore, the contact angle technique was used to determine the wettability condition of the rock surface.

Apparatus and materials

Figure 1 is a schematic image of the core flooding setup with the key components labeled. An HPLT pump was used to inject water into the accumulator. The pump was connected to a series of vessels to inject fluid through tubes. The confining pressure was set at 1000 psi on the core plug during the flow experiment.

A pressure transducer was used to measure the pressure drop across the core. The core plug was cleaned by toluene and methanol solvent in soxhlet extraction cleaning system, and then an oven was used to dry the core plugs. In order to establishing initial condition, synthetic brine and crude oil were injected in core, respectively.

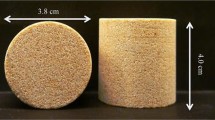

All the experiments were performed at room temperature (26 °C). The core flooding experiments used sandstone core samples with dimensions of 11 cm in length and 3.8 cm in diameter. The pore volume of the core plugs was approximately 20 cc.

Nanoparticles and surfactant

The materials under study are solution of silica nanoparticles and SDS surfactant. Fumed silica nanoparticles (commercially known as AEROSIL®300) were used in this study. These colloidal particles are prepared by hydrolysis of silicon tetrachloride in which silanol groups (Si–OH) are generated on silica surface. AEROSIL®300 is hydrophilic amorphous silica with reported average diameter of about 7 nm and BET surface area of 300 ± 30 m2/g. It must be mentioned that nanoparticles are approximately spherical in shape as observed in TEM images represented in Fig. 2. The particles were supplied by Degussa (Evonik).

An anionic surfactant namely sodium dodecyl sulfate (SDS), bought from Merck, was used in this work. The CMC value of the surfactant was determined to be approximately 2200 mg/l in distilled water and 450 mg/l in brine using conductivity measurement technique, as shown in Figs. 3 and 4.

Crude oil and brine

Azadeghan crude oil sample was used. The physical properties of the crude oil are given in Table 1.

The synthetic brine was made as a base fluid solution using NaCl (3 wt.%) and deionized water. The synthetic brine was used to initially saturate the core plugs. The synthetic brine compositions are present in Table 2.

Porous medium

Sandstone core plugs were used for flooding experiments. In all the experiments, the core samples were approximately 11 cm long and had diameters of 3.8 cm.

The more detailed information is summarized in Table 3.

Fluid design and properties

The phase behavior of nanofluid as a function of salinity and nanoparticle concentration was evaluated. Stability of nanofluid decreases exponentially with the increase in salinity and nanoparticle concentration in the same concentration. In addition to understanding the effect of temperature on nanofluids, different concentrations of nanoparticle dispersion were tested. The results show that in high temperatures, nanoparticle solutions become less stable with increasing salinity.

Over a certain range of salinities, nanofluid can be stable for a long period of time. Hence, during the experiments the solution was stable and no agglomerates were observed. In this case, a stable solution was observed at 30000 ppm of NaCl and agglomerations above of 4000 ppm, as shown in Fig. 5.

Core flooding experiments

Five core flooding experiments were conducted at different injected nanoparticle concentrations (500, 1000, 2000, 3000, and 5000 ppm) to investigate the effect of silica nanoparticle on oil recovery from sandstone core plugs.

All of these flooding tests were performed with similar core plugs which have almost near characterizations; Table 4 summarizes the initial condition of core properties.

All of the core plugs were initially saturated with brine, with 0.2 cc/min flow rate (equal to flow velocity of one foot per day in actual reservoir rock), and the water was injected at the same flow rate for all the experiments to establish initial water saturation. Afterward, over 3 pore volumes of oil were injected to ensure complete saturation of core plugs. After establishing the irreducible water saturation, the core was immersed in the crude oil while aging at 90 °C for 15 days to establish oil-wet condition. After aging, core samples were tested for wettability with brine. Then, different nanoparticle dispersions were flooded to investigate their ability to improve oil recovery from sandstone core samples. Furthermore, oil production values were recorded versus time based on the amount of oil produced. Finally, recovery versus the pore volumes of injected water profile was recorded in all experiments.

Afterward, test tube samples with 5 ml of aqueous nanoparticle solution and 5 ml of crude oil were prepared. After mixing, the fluids were allowed to reach phase equilibrium (7 days). This procedure was performed for nanoparticle solutions with various concentrations and at different temperatures.

The phase characteristics of each system, the relative volumes of the aqueous and oil phases, and the middle phase (if present) were observed, as shown in Fig. 6.

Interfacial tension measurement

Microscopic displacement efficiency can be improved by increasing the capillary number through decreasing the interfacial tension (IFT). Hence, to gain further insight on the interactions between fluids in the presence of nanoparticles, IFT measurement was used to investigate the ability of nanoparticles to change the interfacial tension.

The interfacial tension between oil and aqueous phases was measured. The aqueous phases are included with nanoparticle solution which has different concentration. The interfacial tension was measured with the use of the spinning drop method.

Figure 7 shows interfacial tension measurement of crude oil and nanoparticle solutions with various concentrations.

Figure 8 shows interfacial tension measurement of crude oil and nanoparticle solution with 1000 ppm concentration under various concentrations of surfactant.

Wettability measurement

Contact angle measurement was performed in order to investigate fluid–rock interactions, i.e., interactions between nanoparticles solution and rock surface.

Contact angle was measured on aged sandstone mineral plates (Fig. 9) for various nanoparticle solution concentrations at room condition. Sandstone mineral plate was aged for 3 weeks to be made almost oil-wet, at 90 °C.

Measurement of the contact angle was done with the sessile drop method. The contact angle is measured through the denser phase, which in this case would be the brine/nanoparticle solutions. The contact angle of oil droplet placed under a mineral plate of sandstone submerged in an aqueous phase is measured, Fig. 10.

Figure 11 shows the evolution of wettability changes when sandstone mineral plates are in contact with different concentration of nanoparticle solution.

Viscosity, density, and pH measurement

The compatibility of formation water and injected water is a key factor for water flooding. Viscosity, density, and pH are important fluid properties at reservoir conditions. During water flooding, the density contrast between phases in porous media affects the breakthrough of water and thus the oil recovery.

Densities of brine, oil, and nanoparticle solution were measured using a pycnometer. The results are presented in Table 5.

pH measurement for different nanoparticle concentrations was studied. pH of the solutions was measured by a pH meter. The results are shown in Table 6.

The results presented here have shown that adding nanoparticles decreases pH of the solution. There are some possibilities that may occur when pH of the injected fluid is decreased. Decreasing pH might be influential on clay swelling (causing a reduction in permeability) and asphaltene deposition. As might be expected, low pH could result in the retention of polar oil components such as asphaltenes on rock surface. However, wettability alteration toward water-wetness could hinder the mentioned deposition onto the rock surface. Also, it is important to notice that scale formation depends on the pH of the solution; thus, nanoparticle solution will increase the probability of the sulfate scaling.

Another factor which may influence the water flooding is viscosity of the injected fluid. Various nanoparticle solution viscosities were measured with viscometer. Figure 12 shows the results of viscosity measurements for five different nanoparticle solution concentrations.

Results and discussion

Results of oil recovery from core plugs through core flooding for nanoparticle solutions and synthetic brine are shown in Table 7.

These results show additional oil recovery ranged from 4.85 to 11.7 OOIP, for various concentrations of silica nanoparticle solution, when compared with recovery using synthetic brine. Increasing the nanoparticle solution concentration led to decreasing the required time to achieve maximum oil recovery. The most additional oil recovery is achieved when injecting solution was with the 2000 ppm silica nanoparticle concentration. However, when the 5000 ppm concentration of nanoparticle solution was used for core flooding, pressure dropped increased during the course of the experiment and the incremental oil recovery decreased. This behavior indicates that core plugging and a permeability reduction was occurring. This could be due to the retention of nanoparticles in rock because of the instability of the aqueous solution.

It seems necessary to find the critical solution concentration for chemical solution injection in reservoirs. Due to the heterogeneous nature of most reservoirs, finding this critical concentration might be difficult.

According to the results, it is found that nanoparticle solution with 2000 ppm for this type of rock is more appropriate. Hence, in the following set of experiments, nanoparticle solution with 2000 ppm concentration and surfactant with 400 ppm concentration were used. The experiment was conducted in two scenarios. Firstly, core plug #7 was used for tertiary recovery, and secondly, core plug #8 was used for secondary recovery. The results are shown in Table 8.

The results indicate that additional oil recovery in tertiary mode for nanoparticle solution with surfactant after 2 pore volume injection increased to 14.5%, and totally 58.2% oil recovery was obtained. While in the secondary mode after 4 PV solutions injection 61.4% oil recovery is achieved.

Since oil recovery in secondary mode requires more chemical solution injection, it is not economically feasible.

Retesting of the samples showed permeability and porosity of the core are damage. The results compared with the initial values indicate alterations. The most probable cause of this damage is particle adsorption on rock surface. As a consequence of nanoparticle adsorption, pore throats were blocked and permeability was reduced. Furthermore, SEM pictures were taken to support this conclusion.

Yu et al. (2012) reported that silica nanoparticle adsorption is low in sandstone sample and could easily pass through the sandstone core without causing devastating impact on the permeability. They assumed that the cause of the low adsorption of silica particles in sandstone was because sandstones and silica particles were the same in nature and both were comprised of SiO2 (Yu et al. 2012). However, environmental condition is very important.

Although nanoparticle can easily pass through porous media, but if nanoparticle solution becomes unstable in porous media, because of harsh condition, particle will clog together and retained on rock surface; thus, pore throat might be blocked or formed a bridge. Since the size of pore space in porous media is not uniform, it is expected that the particle retention reduces the permeability or even porosity by pore throat blocking and/or bridge formation. Consequently, particle retention could cause resistance to fluid flow and distribution in drainage and imbibition.

It was observed that there is retention of nanoparticle during the flooding experiments. The retention of nanoparticle was dependent on the composition of brine and environmental condition. The concentration solution of nanoparticle also affects the retention of nanoparticle on the reservoir rock minerals.

Figure 13 shows the profile of recovery versus pore volume injected for two PV water injection and two PV nanoparticle flooding injection. It is worth mentioning that most of the recovered oil in all experiments was obtained in first pore volume of injected nanoparticle flooding.

Effects of nanoparticle on porous media

In order to investigate the effect of nanoparticles on reservoir properties after nano-flood, porosity and permeability of all core samples were measured. The results are presented in Table 9 and compared with the initial values to detect any alterations. The initial permeability of the cores ranges from about 143 to 172 mD and shows variations in porosity ranging from 16.8 to 18.2%. New tests of porosity and permeability were conducted after all 5 cores were flooded with different concentration of nanoparticle solution.

Effect of nanoparticles on porous media was tested by measuring new porosity and permeability after nanoparticle flooding, as shown in Fig. 14. The results show reduction in the porosity and permeability due to the retention of nanoparticles in porous media. A part of the results is probably caused by errors in measuring core dimensions and apparatus. However, the reduction is a linear function of the increase in concentration of injected nanoparticle flooding. The measurement showed a small reduction in porosity, ranging from 0.19 to 2.4%. This indicates that a portion of the injected particles are retained in the pore walls during nanoparticle flooding. Likewise, reduction of permeability at high concentration of nanoparticle flooding significantly increased, and thus, it decreased oil recovery.

A scanning electron microscope (SEM) was used to observe the effect of nanoparticle on pore wall and grain rock surface. SEM observation of extracts samples shows the adsorption of nanoparticle on rock surface. Comparing the influences of three different nanoparticle flooding concentrations on the rock surface indicates that injecting nanoparticles disposition in higher concentration, e.g., 5000 ppm, was altered rock surface property and caused changing pore geometry and thus flow pattern.

In order to verify the effect of the nanoparticles on pore walls, a scanning electron microscope (SEM) is used to achieve the more realistic insight about the concentration of nanoparticle flooding for an EOR purpose, as shown in Fig. 12.

SEM pictures for different concentrations of injected nanoparticle flooding have shown nanoparticle adsorption increment on pore walls as a function of nanoparticle flooding concentration.

It seems at the certain concentration; nanoparticles can change wettability by adsorbing on pore walls. On the contrary, at 5000 ppm concentration adsorption and accumulation of particles lead to blockage pore throats. Hence, the most crucial point is the concentration of injected nanoparticle flooding.

It should be noticed that the clay swelling process can also cause negative influences on the permeability of the reservoir rock. Since nanoparticles are less stable in high saline water, the salinity of brine was chosen to be 3 wt.%, a value which is much lower than the salinity of the original formation brine. This may lead to clay swelling and consequently permeability reduction of the sandstone cores.

XRD

X-ray diffraction (XRD) was used to identify minerals of rock. The results show that most of minerals are silica and shale, Fig. 15.

Retention of nanoparticles in porous media

When injecting nanoparticles into a porous media, the particle concentration will decrease during transport for long distance from the injection point. Indeed, nanoparticles retain or adsorb on rock grain surfaces. This adsorption causes two effects in porous media. One may prevent transport across a long distance and thus cause disruptive influence on the reservoir properties such as porosity and permeability. Another, adsorption of particle onto the rock surface may lead to wettability alteration toward water-wet condition.

Retention of nanoparticles in the porous media stems from different mechanisms such as particle aggregation and adsorption. In these experiments, the adsorption of particles is most probably the dominant mechanism because of the low specific gravity and small particle size.

The capability of nanoparticle for EOR in actual reservoirs requires the critical conditions. Specially, nanoparticle flooding needs long-term stability without aggregates during transport in porous media. In addition, nanoparticles must be able to transport a long distance through porous media with minimum retention on pore walls.

Stability of silica nanoparticle solutions at reservoir conditions is the most important key in nanoparticle flooding. The aggregation of nanoparticles to quantify their stability in aqueous solution containing different concentration of salts at various temperatures was studied.

The approach to study the stability of nanoparticles was to examine them visually over a broad range of ionic strengths, temperature, and particle concentration and to assess whether any precipitation could be observed, Fig. 3.

The observations revealed that aggregation was temperature dependent and also increase the concentration nanoparticle in aqueous solution resulting more instability. Moreover, in the same temperature, as concentration nanoparticle increased aggregation of nanoparticles in aqueous solution was increased. At high temperature and salinity, e.g., 90 °C and 40,000 ppm salt concentration, they immediately aggregated in the brine solution.

Furthermore, the aqueous solution prepared by silica nanoparticles and SDS surfactant have shown more stability in harsh condition. For instance, at 70 °C this solution shows more stability of nanoparticle solution at high concentration.

It is found that the stability of nanoparticle solution with co-solvent, SDS surfactant, be more effective in the avoidance of nanoparticle aggregation than nanoparticle solution individual. Therefore, stabilized aqueous solutions consisting of nanoparticle in water stabilized with sodium dodecyl sulfate (SDS) are more stable.

Conclusion

This study indicates that it is almost possible to gain partially high oil recovery by using silica nanoparticles as the additives in the injection fluids. Key findings from this study include:

-

1.

Silica hydrophilic nanoparticles have positive potential for EOR at certain nanofluids concentration.

-

2.

Over a certain range of salinities and nanoparticle concentrations, the modification of fluid/fluid and fluid/rock interface by nanoparticle can make it possible to recover more oil.

-

3.

The critical concentration of nanoparticle injection for sandstone cores was approximately 2000 ppm (permeability ranging from 138 to 172 mD).

-

4.

Nanoparticles’ deposition on pore walls of porous media could lead to a wettability alternation toward water-wet, while at higher concentration it has a tendency to block pore throats.

-

5.

In order to increase oil recovery, nanoparticles must be able to transport a long distance and long-term stability without aggregates and retention.

-

6.

As salinity and temperature increase, aqueous nanoparticle solutions become less stable and thus tend to retention, in porous media, and aggregation of particle in aqueous solution.

-

7.

Contact angle measurement shows that the silica nanoparticles concentration is inversely proportional with the value of contact angles so that silica nanoparticles can change wettability of rock surface form oil-wet toward water-wet.

-

8.

Nano-flooding processes improve oil recovery by lowering the interfacial tension (IFT) between oil and water, alteration of the wettability of the rock, and enhancement of the mobility of the displacing fluids.

References

Ayatollahi S, Zerafat MM (2012) Nanotechnology-assisted EOR techniques: new solutions to old challenges. In: SPE international oilfield nanotechnology conference and exhibition, Noordwijk, The Netherlands, 12–14 June

Chevalier Y, Bolzinger MA (2013) Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf A 439:23–34

Esmaeeli J, Kharrat R, Barati N, Sobhani A (2014) Stability of silica nanoparticle dispersion in brine solution: an experimental study. Iran J Oil Gas Sci Technol 3(4):26–40

Giraldo J et al (2013) Wettability alteration of sandstone cores by alumina-based nanofluids. Energy Fuels 27(7):3659–3665

Haroun MR et al (2012) Smart nano-EOR process for Abu Dhabi carbonate reservoirs. In: International petroleum conference and exhibition, Abu Dhabi, UAE 11–14 November

Hunter TN, Pugh RJ, Franks GV, Jamenson GJ (2008) The role of particles in stabilizing foams and emulsions. Adv Colloid Interface Sci 137:57–81

Ju B, Fan T (2009) Experimental study and mathematical model of nanoparticle transport in porous media. Powder Technol 192:195–202

Kanj MY, Funk JJ, Al-Yousif Z (2009) Nanofluid coreflood experiments in the ARAB-D, SPE Saudi Arabia section technical symposium, Al-Khobar, Saudi Arabia, 9–11 May

Khademolhosseini R, Jafari A, Shabani MH (2015) Micro scale investigation of enhanced oil recovery using nano/bio materials. Procedia Mater Sci 11:171–175

Lee GJ, Son HA, Cho JW, Choi SK, Kim HT, Kim JW (2014) Stabilization of Pickering emulsions by generating complex colloidal layers at lquid-lquid interfaces. J. Colloidal Interface Sci. 413:100–105

Madivala B, Fransaer J (2009) Self-assembly and rheology of ellipsoidal particles at interfaces. Langmuir 25(5):2718–2728

Mcelfresh PM, Holcomb DL, Ector D (2012) Application of nanofluid technology to improve recovery in oil and gas wells. In: SPE International oilfield nanotechnology conference and exhibition, Noordwijk, The Netherlands, 12–14 June

McElfresh P, Wood M, Ector D (2012) Stabilizing nanoparticle dispersions in high salinity, high temperature downhole environments. In: SPE international oilfield nanotechnology conference and exhibition, Noordwijk, The Netherlands, 12–14

Onyekonwu MO, Ogolo NA (2010) Investigating the use of nanoparticles in enhancing oil recovery. In: Nigeria annual international conference and exhibition, Tinapa–Calabar, Nigeria 31 July–7 August

Rodriguez E, Roberts MR, Yu H, Huh H, Bryant SL (2009) Enhanced migration of surface-treated nanoparticles in sedimentary rocks. In: SPE annual technical conference and exhibition, New Orleans, Louisiana, 4–7 October

Roustaei A, et al (2012) An experimental investigation of polysilicon nanoparticles’ recovery efficiencies through changes in interfacial tension and wettability alteration. In: SPE international oilfield nanotechnology conference and exhibition, Noordwijk, The Netherlands, 12–14 June

Sheng J (2010) Modern chemical enhanced oil recovery: theory and practice, 1st edn. Gulf Professional Publishing, Houston

Skauge T, Spildo K, Skauge A (2010) Nano-sized particles for EOR. SPE improved oil recovery symposium, Tulsa, Oklahoma, USA, 24–28 April

Torsater O et al (2012) Improved oil recovery by nanofluids flooding: an experimental study. In: SPE Kuwait international petroleum conference and exhibition, Kuwait City, Kuwait 10–12 December

Torsater O, Li S, Hendraningrat L (2013) A coreflood investigation of nanofluid enhanced oil recovery in low-medium permeability Berea sandstone. In: SPE international symposium on oilfield chemistry, The Woodlands, Texas, USA, 8–10 April

Yoon KY, Li Z, Neilson BM, Lee W, Huh C, Bryant SL, Bielawski CW, Johnston KP (2012) Effect of adsorbed amphiphilic copolymers on the interfacial activity of superparamagnetic nanoclusters and emulsification of oil in water. Macromolecules 45:5157–5166

Yu J, An C, Mo D, Liu N, Lee R (2012) Study of adsorption and transportation behavior of nanoparticles in three different porous media. In: SPE improved oil recovery symposium, 14-18 April, Tulsa, Oklahoma, USA

Zargartalebi M, Kharrat R, Barati N (2015) Enhancement of surfactant flooding performance by the use of silica nanoparticles. Fuel 143:21–27

Zhang T, Davidson A, Bryant SL, Huh C (2010) Nanoparticle-stabilized emulsions for applications in enhanced oil recovery. In: SPE improved oil recovery symposium, Tulsa, Oklahoma, USA, 24–28 April

Zhang T, Davidson A, Bryant SL, Huh C (2010) Nanoparticle-stabilized emulsions for applications in enhanced oil recovery. In: SPE improved oil recovery symposium, 24–28 April, Tulsa, Oklahoma, USA

Zhou H, Shi T, Zhou X (2013) Preparation of polystyrene/SiO2 microsphere via Pickering emulsion polymerization: synergistic effect of SiO2 concentrations and initiator sorts. Appl Surf Sci 266:33–38

Acknowledgments

The authors would like to thank the technical support of Tehran Petroleum Research Center of the Petroleum University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zallaghi, M., Kharrat, R. & Hashemi, A. Improving the microscopic sweep efficiency of water flooding using silica nanoparticles. J Petrol Explor Prod Technol 8, 259–269 (2018). https://doi.org/10.1007/s13202-017-0347-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-017-0347-x