Abstract

The use of readily available water treatment residuals (WTR) as a low-cost material for removal of colour from real textile wastewater was investigated. WTR was used in three forms, namely in raw wet form as a coagulant, in the dried form as an adsorbent and as a filtration media in column tests. The results showed a maximum colour removal of 55 and 36% by coagulation and adsorption, respectively, and the corresponding COD removals were 35 and 37%. Coagulation and batch sorption tests showed the effect of initial pH on the colour removal, and maximum colour removal was obtained at an initial pH of 3.0. Long-duration continuous-flow column test using WTR as a filtration/sorption media showed that a maximum colour removal of 60% can be achieved. In column studies, complete exhaustion of the media occurred at 180 and 120 bed volumes, respectively, for initial pHs of 3.0 and 6.2. The study thus shows the potential of WTR for primary treatment of real textile dye wastewater.

Similar content being viewed by others

Introduction

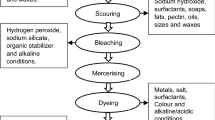

With the increasing demand for textile products, management of huge quantity of textile and dyeing wastewater generated from textile industries has become a major concern as it contains a variety of pollutants and toxic substances such as dyes (Kadam et al. 2015). Nowadays, the synthetic origin of dyes to produce strong fastness has produced several detrimental effects on the environment and human health. Firstly, very low concentration of dyes in water makes water highly coloured and unpleasant (Paz et al. 2017; Sultan 2017), and the discharge of coloured wastewater and their metabolites in aquatic ecosystems reduces sunlight penetration to cause inhibitory effects on photosynthesis (Hassine et al. 2016). Several treatment processes used for colour removal are based on physiochemical and biological processes. Compounds produced when textile wastewater undergoes anaerobic degradation for colour removal are reported to be toxic, carcinogenic and mutagenic (Paz et al. 2017; Ponraj et al. 2017). Thus, the usual approaches used for colour removal are coagulation, sedimentation, adsorption, photocatalysis, degradation and ion-floatation (Ponraj 2017; Mashkoor et al. 2018; Inamuddin 2019).

To achieve the sustainable development goal, reuse and recycle of waste materials are essential. In view of the same, several research efforts have been made particularly to recover and reuse waterworks sludge in beneficial ways. Waterworks sludge is a by-product generated as a result of coagulation and flocculation process due to the addition of coagulant (aluminium or ferrous salts) in water treatment plants (Jiao et al. 2016) and is generally known as water treatment residuals (WTR). In India, alum is commonly used as a coagulant. As alum is added to water, it precipitates as aluminium hydroxide as amorphous and semi-crystalline form together with which suspended impurities are removed in settling unit (Benjamin and Lawler 2013; Keeley et al. 2014). However, due to lack of sustainable approaches towards utilisation of WTR in beneficial and economical way WTR are still disposed of in water bodies in developing countries, while another option used for disposal is landfill (Wang et al. 2016). As million of tons of WTR are generated annually around the world, scarcity of landfill sites and stringent environmental legislation makes disposal of WTR more problematic and costlier. Thus, reuse of WTR for potential applications has received much attention in recent years.

Water treatment residuals can be used by first recovering the coagulant. Direct reuse with or without alteration is also possible. Recovery of coagulant from WTR involves process such as acidification, basification, ion exchange and membrane separation (Nair and Ahammed 2014b; Keeley et al. 2012) which are effective if they are economical. The WTR management approaches include reuse in construction materials (Babatunde and Zhao 2007; Verma et al. 2012; Ahmad et al. 2016), wastewater treatment (Wang et al. 2016; Nair and Ahammed 2015; Maghaddam et al. 2010) and for soil improvement (Soleimanifar et al. 2016). WTR have been used in two different forms in wastewater treatment. It can be used in its raw wet form as a coagulant or as an adsorbent in its dried form. The effective reuse of WTR as a coagulant has been reported for colour removal from acid dye (Maghaddam et al. 2010) and disperse dye (Gadekar and Ahammed 2016) and for posttreatment of up-flow anaerobic sludge blanket reactor (UASBR)-treated wastewater (Nair and Ahammed 2014a). The WTR have been widely used as an adsorbent for removal of anionic/cationic compounds such as phosphorus (Wang et al. 2016; Soleimanifar et al. 2016; Quiñones et al. 2016) and heavy metals (Jiao et al. 2016; Soleimanifar et al. 2016; Quiñones et al. 2016; Ociński et al. 2016; Zhou and Hyenes 2011). WTR have been used for colour removal by Gadekar and Ahammed (2016), Moghaddam et al. (2011) and Moghaddam et al. (2010) in its wet form. No studies have been reported on the use of WTR as a sorbent for colour removal. Also, no studies have been reported on their use for treatment of real textile dye wastewater. Further, studies comparing the application of WTR in different forms such as dry and wet form and also as a filtration material for colour removal from real textile wastewater are also lacking. This work aimed to use water treatment residuals in its available form without modification for treatment of coloured textile wastewater.

In the present study, water treatment residuals were characterised. The raw wet form of WTR as a coagulant and dry form as an adsorbent were used for colour removal from a real textile dye wastewater. The effects of two parameters, namely WTR dose and initial pH, were studied. Further, continuous-flow fixed-bed column studies were also carried out.

Materials and methods

Textile dye wastewater

Textile dye wastewater was collected from a common effluent treatment plant run by Palsana Enviro Care, Surat, Gujarat, India. This plant treats wastewater collected from different textile dye industries. These industries mostly use disperse dyes in their processes. The collected wastewater was stored at 4 °C and was used as required. Colour was measured at a wavelength corresponding to the maximum absorbance of 350 nm for the wastewater used. Table 1 shows the characteristics of the wastewater used in the study.

Water treatment residuals

Water treatment residuals were collected from the coagulation/flocculation unit of a water treatment plant in Bhandup, Mumbai, India, where polyaluminium chloride (PACl) is used as a coagulant. A portion of the collected sludge was stored at room temperature (27–30 °C) in its original form, and this was used in tests of WTR as a coagulant. Another portion of the WTR was sun-dried and ground, and the fraction passing through 216-µm sieve was used as a sorbent and in the column tests without further modification.

Characterisation of water treatment residuals

The elemental composition of WTR was analysed using inductively coupled plasma atomic emission spectroscopy (ICP-AES) (ARCOS Spectro, Germany) after acid digestion as per USEPA method 3050B (USEPA 1996). Scanning electron microscope (SEM) with energy-dispersive spectroscopy was used to analyse the constituents and nature of particles present in the WTR.

The point zero charge (pHzpc) of WTR was determined adopting the following procedure of Mehdi et al. (2014): 0.01 M·NaCl solution with different pHs in the range of 2–10 was prepared by adding HCl/NaOH. Thereafter, 0.20 g of the WTR was added to 50 mL of 0.01 M NaCl solution of different pHs in reagent bottles. The samples were centrifuged after allowing them to react for 48 h at room temperature, and the pH of each solution was measured.

Analysis

The colour removal was calculated using the following equation (Gadekar and Ahammed 2016).

where Co and Ce are colour concentration measured as absorbance at maximum absorbing wavelength of raw and treated wastewater, respectively.

The chemical oxygen demand of samples was analysed using the closed reflux volumetric analysis, while pH and electrical conductivity (EC) were determined by potentiometric method. Biochemical oxygen demand was analysed by titrimetric method and total solids by gravimetric method. All of methods performed were in accordance with the Standard Methods (1998).

Coagulation/flocculation tests

To simulate coagulation/flocculation process at laboratory scale, a six-beaker jar-test apparatus (DBK Instruments, Mumbai) was used. Raw wet-form WTR as a coagulant was added to 250 mL of wastewater. The WTR dosages were calculated based on dry weight. The standard procedure consisted of 2-min flash mixing at 150 rpm, 30-min slow mixing at 25 rpm and 20-min settling. Effects of two parameters, namely effect of WTR dose and initial pH, were studied. Samples of desired initial pHs were obtained by addition of 1 N H2SO4 or NaOH. The wastewater was tested with an initial pH range of 3.0–7.0 and WTR dose of 2 to 12 g/L. The supernatant sample was centrifuged at 5000 rpm for 3 min and was analysed for colour removal.

Batch sorption tests

Batch sorption studies were carried out using different doses of WTR with 50 mL of wastewater. Dye solution with WTR was mixed on the orbital shaker at 150 rpm for 60 min. Based on the equilibrium studies an equilibrium time of 60 min was found enough to reach the equilibrium. The wastewater was tested in initial pH range of 3.0–7.0 and WTR dose of 10–50 g/L. Treated samples were centrifuged and analysed for colour removal.

Fixed-bed continuous-flow column study

Continuous-flow column experiments were performed in a transparent cylindrical acrylic column (2.5 cm internal diameter and 30 cm height) with a medium bed height of 15 cm. Glass wool was used at inlet and outlet to avoid the loss of the media. The column was operated in upward mode by pumping the wastewater solution through the column at a flow rate of 50 mL/h using a peristaltic pump. Samples were collected at different time intervals and were analysed for colour removal.

Results and discussion

Characteristics of water treatment residuals

Chemical composition of WTR is shown in Table 2. Composition of WTR depends on the source water quality and the coagulant used (Nair and Ahammed 2014a). Aluminium and iron concentrations were found to be 64.60 and 93.01 mg/g, respectively, while cations like calcium, magnesium and potassium were also detected in ample amounts. The literature reports typical aluminium content of 27.09–171.77 mg/g dry WTR (Jiao 2016; Dassanayake et al. 2015; Agyin-Birikorang and O’Connor 2009, Gadekar and Ahammed 2019). Most of the studies reported are based on alum-based WTR, but the present study was carried out employing PACl-based WTR. Scanning electron micrographs (SEM) (Fig. 1 a, b) show the amorphous nature of WTR, obtained as a result of aggregation, rearrangement and hydrolyses to amorphous hydroxide precipitate (Shi et al. 2007).

The point zero charge (pHzpc) of WTR was found to be 6.9. The surface of WTR becomes positively charged at pH < pHzpc favouring the adsorption of anionic pollutants, whereas cationic pollutant sorption would be favourable at pH > pHzpc (Peláez-Cid et al. 2016). Point zero charge for WTR reported in the literature varies between 5.5 and 6.8 (Zhou and Haynes 2011; Putra and Tanaka 2011). Moreover, morphology of sorbent is important in the sorbent process (Ociński et al. 2016).

Coagulation study

Effect of pH

In coagulation/flocculation process initial solution pH is a key parameter (Merzouk et al. 2011; Verma et al. 2012), and maximum pollutant removal will be obtained at optimal pH with optimal coagulant dosage. Figure 2 presents the effect of initial solution pH on colour removal efficiency at different WTR dosages. It can be noticed that maximum colour removal occurred at an initial pH value of 3.0 for all the three WTR dosages. Colour removal was significantly low at all other pHs and was nearly constant for a particular WTR dosage. Final solution pH is a major influencing parameter in coagulation and flocculation phase (Gadekar and Ahammed 2016). Figure 3 presents the effect WTR dose on final pH at different initial pH values. In general, the final pH increased with increase in WTR dosage. However, this increase was more pronounced at lower initial pH values. The aluminium hydroxide in WTR balances the anionic charge of dye and thus increases the wastewater pH. Maximum colour removal recorded at an initial pH value of 3.0 and WTR dose of 10 g/L which had a final pH around 5.30. This implies that maximum colour removal can be obtained using WTR at system pH around 5.0–5.5. The results presented show similar trends as reported by Gadekar and Ahammed (2016), and Moghaddam et al. (2011) for disperse dye removal and acid dye removal, respectively. Maximum colour removal was obtained at an acidic pH value 3.0 (Gadekar and Ahammed 2016) and at 3.42 (Moghaddam et al. 2011). This behaviour may be explained based on the effect of fresh coagulant on pollutant removal. Shi et al. (2007) investigated the colour removal performance with different aluminium species and found that coagulation efficiency significantly increased with decrease in pH and complete dye removal was obtained at sufficiently lower pH of 5.6. The formation of Al(OH)3 responsible for pH change in coagulation process, which precipitates when the final pH is around 4.0 for alum (Merzouk et al. 2011). Thus, WTR as coagulant can be effective when addition of WTR can increase the initial pH of solution to around 5.0.

Effect of WTR dose

Figure 4 shows the effect of WTR dose on colour and COD removals. Maximum colour removal obtained was 56% at an initial WTR dose of 10 g/L. Maximum removal reported for removal of colour from synthetic disperse dye solution using WTR was 88% for an initial dye concentration of 25 mg/L, which was reduced to 76% when dye concentration was increased to 75 mg/L which was obtained at a WTR dose of 3 g/L (Gadekar and Ahammed 2016). With fresh coagulant (alum) a colour removal of 78.9% was observed for synthetic disperse dye solution at an alum dose of 200 mg/L (El-Gohary and Tawfik 2009), while Merzouk et al. (2011) reported a colour removal of 94% with an alum dose of 40 mg/L. It is seen that (Fig. 4) colour removal increased with WTR dose and similar trends have been reported with WTR (Gadekar and Ahammed 2016), alum (Merzouk et al. 2011; El-Gohari and Tawfik 2009), FeCl3 and alum combined with polysaccharides (Huang et al. 2015) for disperse dye wastewater. Higher colour removal was observed at a WTR dose of 10 g/L, and further increase in WTR results reduction in the colour removal. This behaviour may be due to the fact that addition of excessive WTR might reduce the zeta potential to zero and thus produce adverse effect on the colour removal (Merzouk et al. 2011). Work carried out by Moghaddam et al. (2010, 2011) using ferrous-based and aluminium-based WTR on acid dye removal showed similar trends of increase in colour removal with increase in WTR dose. In the present study, COD removal increased with increase in WTR from 18 to 30% as WTR dose increased from 2 to 10 g/L and further increase in the WTR dose reduced the COD removal.

Batch sorption study

Effect of WTR dose

The effects of the sorbent dosage were investigated, and the data are shown in Fig. 5. The colour removal increased with increase in adsorbent dosage from 10 to 30 g/L, and no further increase in removal was observed beyond 30 g/L. The percentage removal at the adsorbent dosage of 30 g/L was 36%, and further addition of WTR did not have a significant effect on removal of colour. Maximum colour removal obtained was 52.6% for disperse navy blue 3G dye at WTR dose of 30 g/L (Gadekar and Ahammed 2019). Similar trends were observed for COD removal also. Maximum COD removal obtained was 37%.

Effect of pH

Figure 6a presents the effect of initial pH on adsorption of colour onto WTR. It was observed that the colour removal was decreased with increase in initial pH which implies that the dye sorption was largely controlled by initial solution pH. This could be due to dissolution of aluminium at low pHs (Eq. 2, 3) (Keeley et al. 2014; Nair and Ahammed 2016b), which later precipitates in hydroxide form to produce a flocculation effect and subsequent colour removal. However, at lower pHs of 3.0 and 4.0 significant colour removal was observed. This implies that aluminium leaching is not the only parameter which affects the colour removal process. Another reason behind this could be explained by the charge-neutralising capacity of the WTR. The point zero charge of WTR was 6.9, and decreasing pH below pHzpc indicates surface of the material would attain a net cationic charge and thus adsorption of anionic dye is favoured. In charge neutralisation, the increase in pH leads to change of surface charge from positive to negative (Yang et al. 2006) and thus reduction in dye removal. Figure 6b shows the COD removal of wastewater at different initial pHs. A drastic reduction in COD removal was observed as pH increased from 3.0 to 4.0. It was observed that COD removal was high due to the surface charge neutralisation effect and thus at lower pH maximum colour removal was obtained. However, as pH was increased to 4.0 the charge neutralisation was not significant to adsorb dyes and organic matter in wastewater, which resulted in reduction in COD removal.

Fixed bed continuous flow column study

Results of the column tests are presented in the form of breakthrough curve for unchanged initial pH of 6.2 (Fig. 7a) and modified initial pH 3.0 (Fig. 7b). The breakthrough curves show that a good colour removal of 60–70% was obtained in the beginning of the column operation for both the initial pH values. A comparison of the column performance at two initial pHs indicates that at the lower initial pH of 3.0, the column could be operated for longer duration. In this, the colour removal remained above 60% for about 80 bed volumes, while in the other column, it was only about 50 bed volumes. Further, complete exhaustion of the column occurred at about 180 and 120 bed volumes, respectively, for initial pH of 3.0 and 6.2. This difference was not surprising as the colour removal of wastewater using WTR is majorly controlled by the pH of solution as discussed in earlier on effect of pH. Figure 8 shows the spectral variation of influent and effluent colour at different time intervals. It is observed that peak obtained for colour removal was at 350 nm wavelength. Moreover, there was no significant peak change observed in the effluent. Thus, colour removal using sorption was significant and constant over complete visual spectrum. Further, it can be concluded from spectral variation that WTR can be used for colour removal as no colour was imparted by WTR.

Comparison of the different options

In this study, the use of WTR in their different forms was compared for the colour removal from a real textile dye wastewater. The results show that WTR has the potential to be used for colour removal. A comparison of colour removal by different processes shows that while coagulation/flocculation process gave a maximum removal of 57%, sorption process showed a maximum colour removal of 36%. Even in column operation, which generally shows a greater removal could not produce complete removal of colour, and gave colour removal in the range of 60–70%. All the processes were controlled by the initial solution pH which showed that WTR was more effective for colour removal in acidic solutions. This indicates that WTR can be utilised as a primary treatment for colour removal from textile wastewater. Though the capacity of the WTR would be less compared to commonly available sorbents, its availability in large quantities at free of cost can be used advantageously. In this case regeneration or recycling of WTR used is not recommended.

One of the major concerns with the use of WTR for industrial application is the transportation cost of the material. If WTR has to be used in wet form for coagulation, due to high moisture content in WTR, transportation cost from production site will be high. Otherwise WTR produced has to be pretreated to reduce moisture content with sludge thickeners. Another issue with the use of WTR as a coagulant is that it would result in sludge generation and subsequent load on the drying beds. On the other hand, applicability of WTR in dry form for sorption process would be cheaper due to low transport cost of WTR.

Conclusions

Water treatment residuals (WTR), a by-product of water treatment plants, which are available in huge quantities were used in different forms. The use of WTR as a coagulant gave a maximum colour and COD removal of 55 and 35%, respectively, at a WTR dose of 10 g/L and an initial pH of 3.0. In batch sorption tests, maximum colour removal obtained was 36% at a WTR dose of 30 g/L. Initial pH had a significant effect on the colour removal. Continuous-flow column studies showed the potential of WTR for treatment of real textile dye wastewater. Up to 180 and 120 bed volume could be treated before exhaustion of the media at initial pH values of 3.0 and 6.2, respectively, and the maximum colour removal obtained was 65%. Overall, the study showed the potential of WTR for treating real textile dye wastewater.

References

Agyin-Birikorang S, O’Connor G (2009) Aging effects on reactivity of an aluminum-based drinking-water treatment residual as a soil amendment. Sci Total Environ 407:826–834. https://doi.org/10.1016/j.scitotenv.2008.09.025

Ahmad T, Ahmad K, Alam M (2016) Sustainable management of water treatment sludge through 3’R’ concept. J Clean Prod 124:1–13. https://doi.org/10.1016/j.jclepro.2016.02.073

Babatunde AO, Zhao YQ (2007) Constructive approaches toward water treatment works sludge management: an international review of beneficial reuses. Crit Rev Environ Sci Technol 37:129–164. https://doi.org/10.1080/10643380600776239

Benjamin MM, Lawler DF (2013) Water quality engineering: physical/chemical treatment processes. Wiley, Hoboken

Dassanayake KB, Jayasinghe GY, Surapaneni A, Hetherington C (2015) A review on alum sludge reuse with special reference to agricultural applications and future challenges. Waste Manag 38:321–335. https://doi.org/10.1016/j.wasman.2014.11.025

El-Gohary F, Tawfik A (2009) Decolorization and COD reduction of disperse and reactive dyes wastewater using chemical-coagulation followed by sequential batch reactor (SBR) process. Desalination 249:1159–1164. https://doi.org/10.1016/j.desal.2009.05.010

Gadekar MR, Ahammed MM (2016) Coagulation/flocculation process for dye removal using water treatment residuals: modelling through artificial neural networks. Desalin Water Treat 57:26392–26400. https://doi.org/10.1080/19443994.2016.1165150

Gadekar MR, Ahammed MM (2019) Modelling dye removal by adsorption onto water treatment residuals using combined response surface methodology-artificial neural network approach. J Environ Manage 231:241–248. https://doi.org/10.1016/J.JENVMAN.2018.10.017

Hassine AB, Ayari F, Salah MB, Trabelsi-Ayadi M (2016) Adsorption of an anionic textile dye from wastewater by bentonitic clay mineral. Surf Eng Appl Electrochem 52:572–578. https://doi.org/10.3103/S1068375516060089

Huang X, Gao B, Yue Q, Zhang Y, Sun S (2015) Compound bioflocculant used as a coagulation aid in synthetic dye wastewater treatment : the effect of solution pH. Sep Purif Technol 154:108–114. https://doi.org/10.1016/j.seppur.2015.09.018

Inamuddin AM (2019) Xanthan gum/titanium dioxide nanocomposite for photocatalytic degradation of methyl orange dye. Int J of Biol Macromol 121:1046–1053. https://doi.org/10.1016/j.ijbiomac.2018.10.064

Jiao J, Zhao J, Pei Y (2016) Adsorption of Co(II) from aqueous solutions by water treatment residuals. J Environ Sci (China) 52:232–239. https://doi.org/10.1016/j.jes.2016.04.012

Kadam AA, Lade HS, Lee DS, Govindwar SP (2015) Zinc chloride as a coagulant for textile dyes and treatment of generated dye sludge under the solid state fermentation: Hybrid treatment strategy. Bioresour Technol 176:38–46. https://doi.org/10.1016/j.biortech.2014.10.137

Keeley J, Jarvis P, Judd SJ (2012) An economic assessment of coagulant recovery from water treatment residuals. Desalination 287:132–137. https://doi.org/10.1016/j.desal.2011.09.013

Keeley J, Smith AD, Judd SJ, Jarvis P (2014) Reuse of recovered coagulants in water treatment : an investigation on the effect coagulant purity has on treatment performance. Sep Purif Technol 131:69–78. https://doi.org/10.1016/j.seppur.2014.04.033

Mashkoor F, Nasar A, Inamuddin AAM (2018) Exploring the reusability of synthetically contaminated wastewater containing crystal violet dye using tectona grandis sawdust as a very low-cost adsorbent. Sci Rep 8(1):1–16. https://doi.org/10.1038/s41598-018-26655-3

Mehdi SS, Khataee A, Joo SW (2014) Kinetics and equilibrium studies of removal of an azo dye from aqueous solution by adsorption onto scallop. J Ind Eng Chem 20:610–615. https://doi.org/10.1016/j.jiec.2013.05.023

Merzouk B, Gourich B, Madani K, Vial C, Sekki A (2011) Removal of a disperse red dye from synthetic wastewater by chemical coagulation and continuous electrocoagulation a comparative study. Desalination 272:246–253. https://doi.org/10.1016/j.desal.2011.01.029

Moghaddam SS, Moghaddam AMR, Arami M (2010) Coagulation/flocculation process for dye removal using sludge from water treatment plant: optimization through response surface methodology. J Hazard Mater 175:651–657. https://doi.org/10.1016/j.jhazmat.2009.10.058

Moghaddam SS, Moghaddam ARM, Arami M (2011) Response surface optimization of acid red 119 dye from simulated wastewater using Al based waterworks sludge and polyaluminium chloride as coagulant. J Environ Manage 92:1284–1291. https://doi.org/10.1016/j.jenvman.2010.12.015

Nair AT, Ahammed MM (2014a) The reuse of water treatment sludge as a coagulant for post-treatment of UASB reactor treating urban wastewater. J Clean Prod 96:272–281. https://doi.org/10.1016/j.jclepro.2013.12.037

Nair AT, Ahammed MM (2014b) Coagulant recovery from water treatment plant sludge and reuse in post-treatment of UASB reactor effluent treating municipal wastewater. Environ Sci Pollut Res 21:10407–10418. https://doi.org/10.1007/s11356-014-2900-1

Nair AT, Ahammed MM (2015) Water treatment sludge for phosphates removal from the effluent of UASB reactor treating municipal wastewater. Process Saf Environ Prot 94:105–112. https://doi.org/10.1016/j.psep.2015.01.004

Ociński D, Jacukowicz-Sobala I, Mazur P, Raczyk J, Kociołek-Balawejder E (2016) Water treatment residuals containing iron and manganese oxides for arsenic removal from water—characterization of physicochemical properties and adsorption studies. Chem Eng J 294:210–221. https://doi.org/10.1016/j.cej.2016.02.111

Paz A, Carballo J, Perez MJ, Domínguez JM (2017) Biological treatment of model dyes and textile wastewaters. Chemosphere 181:168–177. https://doi.org/10.1016/j.chemosphere.2017.04.046

Peláez-Cid A, Herrera-González AM, Salazar-Villanueva M, Bautista-Hernández A (2016) Elimination of textile dyes using activated carbons prepared from vegetable residues and their characterization. J Environ Manage 181:269–278. https://doi.org/10.1016/j.jenvman.2016.06.026

Ponraj C, Vinitha G, Daniel J (2017) A review on the visible light active BiFeO3 nanostructures as suitable photocatalyst in the degradation of different textile dyes. Environ Nanotechnol Monit Manag Manag 7:110–120. https://doi.org/10.1016/j.enmm.2017.02.001

Putra RS, Tanaka S (2011) Aluminum drinking water treatment residuals (Al-WTRs) as an entrapping zone for lead in soil by electrokinetic remediation. Sep Purif Technol 79:208–215. https://doi.org/10.1016/j.seppur.2011.02.015

Quiñones KD, Hovsepyan A, Oppong-Anane A, Bonzongo JCJ (2016) Insights into the mechanisms of mercury sorption onto aluminum based drinking water treatment residuals. J Hazard Mater 307:184–192. https://doi.org/10.1016/j.jhazmat.2016.01.001

Shi B, Li G, Wang D, Feng C, Tang H (2007) Removal of direct dyes by coagulation: the performance of preformed polymeric aluminum species. J Hazard Mater 143:567–574. https://doi.org/10.1016/j.jhazmat.2006.09.076

Soleimanifar H, Deng Y, Wu L, Sarkar D (2016) Water treatment residual (WTR)-coated wood mulch for alleviation of toxic metals and phosphorus from polluted urban stormwater runoff. Chemosphere 154:289–292. https://doi.org/10.1016/j.chemosphere.2016.03.101

Standard Methods for the Examination of Water and Wastewater 1998 20th edn, American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC, USA

Sultan M (2017) Polyurethane for removal of organic dyes from textile wastewater. Environ Chem Lett 15:347–366. https://doi.org/10.1007/s10311-016-0597-8

USEPA (1996) Test method 3050B: acid digestion of sediments, sludges, and soils, in: hazard. waste test methods / SW-846. https://www.epa.gov/hw-sw846/sw-846-test-method-3050b-acid-digestion-sediments-sludges-and-soils Accessed 24 Dec 2016

Verma AK, Dash RR, Bhunia P (2012) A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J Environ Manage 93:154–168. https://doi.org/10.1016/j.jenvman.2011.09.012

Wang W, Ma C, Zhang Y, Yang S, Shao Y, Wang X (2016) Phosphate adsorption performance of a novel filter substrate made from drinking water treatment residuals. J Environ Sci 45:191–199. https://doi.org/10.1016/j.jes.2016.01.010

Yang Y, Zhao YQ, Babatunde AO, Wang L, Ren YX, Han Y (2006) Characteristics and mechanisms of phosphate adsorption on dewatered alum sludge. Sep Purif Technol 51:193–200. https://doi.org/10.1016/j.seppur.2006.01.013

Zhou YF, Haynes RJ (2011) Removal of Pb(II), Cr(III) and Cr(VI) from aqueous solutions using alum-derived water treatment sludge. Water Air Soil Pollut 215:631–643. https://doi.org/10.1007/s11270-010-0505-y

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gadekar, M.R., Ahammed, M.M. Use of water treatment residuals for colour removal from real textile dye wastewater. Appl Water Sci 10, 160 (2020). https://doi.org/10.1007/s13201-020-01245-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-020-01245-9