Abstract

This work aims to produce a virgin coconut oil (VCO) creamer through two drying stages; spray drying followed by fluidised bed drying, and to examine its antioxidant properties and oxidative stability during different storage conditions. Evaluation of the physicochemical properties of spray dry VCO and oxidative stability of the VCO creamer were performed using peroxide value (PV), antioxidant activity (DPPH), and total phenolic content (TPC) at 25, 4, and 25 °C, respectively, for 8 weeks. Agglomeration process has improved the agglomerated VCO creamer’s properties in terms of moisture content (4.34%), solubility (85.2%), water activity (0.32%), and bulk density (0.36 g/cm3). The morphology of agglomerated VCO creamer showed cluster and irregular shapes with enlargement in the particle size, (d32) 395 µm and (d43) 426 µm. The overall oxidative results showed stability for the agglomerated VCO creamer stored at 4 °C in terms of TPC, DPPH and PV over 8 weeks followed by creamer stored at 25 °C which had similar stability with slight differences. The creamer stored at 38 °C showed rapid degradation for all oxidation tests from week 2 onwards. Agglomeration technology has indicated to be effective in the stabilization of virgin coconut oil against lipid oxidation and prolonging its shelf-life.

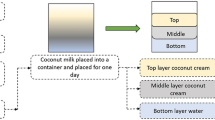

Graphical abstract

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Act MF (2004) Food act 1983 (Act 281) and regulations. Kuala Lumpur Int Law B Serv

AOAC (1995) Official Methods of Analyzes. In: Association of Official Analytical Chemist. Washington, DC

AOCS (2004) Method Cd 3–25. Estimation of saponification value

Ban Z, Zhang J, Li L et al (2020) Ginger essential oil-based microencapsulation as an efficient delivery system for the improvement of Jujube (Ziziphus jujuba Mill.) fruit quality. Food Chem 306:125628

Blois MS (1958) Antioxidant determinations by the use of a stable free radical. Nature 181:1199

Do GY, Kwon E-Y, Kim YJ et al (2019) Supplementation of non-dairy creamer-enriched high-fat diet with D-allulose ameliorated blood glucose and body fat accumulation in C57BL/6J Mice. Appl Sci 9:2750

Fabra MJ, Marquez E, Castro D, Chiralt A (2011) Effect of maltodextrins in the water-content–water activity–glass transition relationships of noni (Morinda citrifolia L.) pulp powder. J Food Eng 103:47–51

Geranpour M, Assadpour E, Jafari SM (2020) Recent advances in the spray drying encapsulation of essential fatty acids and functional oils. Trends Food Sci Technol 102:71–90

Haas K, Dohnal T, Andreu P et al (2020) Particle engineering for improved stability and handling properties of carrot concentrate powders using fluidized bed granulation and agglomeration. Powder Technol 370:104–115

Hedayatnia S, Mirhosseini H, Amid BT et al (2016) Effect of different fat replacers and drying methods on thermal behaviour, morphology and sensory attributes of reduced-fat coffee creamer. LWT-Food Sci Technol 72:330–342

Hitlamani V, Asha MR, Kumar GS, Chetana R (2023) Formulation of a virgin coconut oil based spicy spread and its physico-chemical properties. Food Humanit 1:933–939

Kumar R, Sabikhi L, Rathod G, Chaudhary N (2020) Storage studies of flaxseed oil encapsulated by buttermilk solids. Food Bioprocess Technol 13:1392–1404

Lazarin RA, Falcão HG, Ida EI et al (2020) Rotating-pulsed fluidized bed drying of okara: evaluation of process kinetic and nutritive properties of dried product. Food Bioprocess Technol 13:1611–1620

Li X, Wu M, Xiao M et al (2019) Microencapsulated β-carotene preparation using different drying treatments. J Zhejiang Univ B 20:901–909

Linke A, Linke T, Hinrichs J, Kohlus R (2019) Factors determining the surface oil concentration of encapsulated lipid particles—impact of the spray drying conditions. Dry Technol 39(2):173–186

Linke A, Hinrichs J, Kohlus R (2020) Impact of the powder particle size on the oxidative stability of microencapsulated oil. Powder Technol 364:115–122

Liu X, Xu W, Wang W et al (2023) Physicochemical properties and feasibility of coconut oil-based diacylglycerol as an alternative fat for healthy non-dairy creamer. Food Chem X. https://doi.org/10.1016/j.fochx.2023.100749

Lucas-Aguirre JC, Giraldo-Giraldo GA, Cortés-Rodríguez M (2019) Stability during storage of coconut powder fortified with active components. Biotecnol En El Sect Agropecu y Agroindustrial 17:66–76

Mohammed NK, Meor Hussin AS, Tan CP et al (2017a) Quality changes of microencapsulated Nigella sativa oil upon accelerated storage. Int J Food Prop 20:S2395–S2408

Mohammed NK, Tan CP, Manap YA et al (2017b) Process conditions of spray drying microencapsulation of Nigella sativa oil. Powder Technol 315:1–14. https://doi.org/10.1016/j.powtec.2017.03.045

Mohammed NK, Tan CPCP, Abd Manap MY et al (2019) Production of functional non-dairy creamer using Nigella sativa oil via fluidized bed coating technology. Food Bioprocess Technol 12:1–14. https://doi.org/10.1007/s11947-019-02294-y

Mohammed NK, Muhialdin BJ, Meor Hussin AS (2020a) Characterization of nanoemulsion of Nigella sativa oil and its application in ice cream. Food Sci Nutr 8:2608–2618. https://doi.org/10.1002/fsn3.1500

Mohammed NK, Tan CP, Manap YA et al (2020b) Spray drying for the encapsulation of oils—A review. Molecules 25:3873

Mohammed NK, Alhelli AM, Meor Hussin AS (2021) Influence of different combinations of wall materials on encapsulation of Nigella sativa oil by spray dryer. J Food Process Eng 44:e13639

Negrão-Murakami AN, Nunes GL, Pinto SS et al (2017) Influence of DE-value of maltodextrin on the physicochemical properties, antioxidant activity, and storage stability of spray dried concentrated mate (Ilex paraguariensis A. St. Hil.). LWT-Food Sci Technol 79:561–567

Ngan CL, Basri M, Lye FF et al (2014) Comparison of Box-Behnken and central composite designs in optimization of fullerene loaded palm-based nano-emulsions for cosmeceutical application. Ind Crops Prod 59:309–317

Obidziński S, Joka M, Fijoł O (2017) Two-stage agglomeration of fine-grained herbal nettle waste. Int Agrophysics 31:515

Oliveira ÉR, Fernandes RVB, Botrel DA et al (2018) Study of different wall matrix biopolymers on the properties of spray-dried pequi oil and on the stability of bioactive compounds. Food Bioprocess Technol 11:660–679

Pitt K, Peña R, Tew JD et al (2018) Particle design via spherical agglomeration: a critical review of controlling parameters, rate processes and modelling. Powder Technol 326:327–343

Pordy WT (1994) Low fat, low cholesterol, and low calorie dairy creamer

Rodchuajeen K, Niamnuy C, Charunuch C et al (2016) Stabilization of rice bran via different moving-bed drying methods. Dry Technol 34:1854–1867

Sanchez V, Baeza R, Chirife J (2015) Comparison of monomeric anthocyanins and colour stability of fresh, concentrate and freeze-dried encapsulated cherry juice stored at 38 C. J Berry Res 5:243–251

Santhalakshmy S, Bosco SJD, Francis S, Sabeena M (2015) Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol 274:37–43

Shofinita D, Langrish TAG (2014) Spray drying of orange peel extracts: yield, total phenolic content, and economic evaluation. J Food Eng 139:31–42

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) [14] Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. In: Methods in enzymology. Elsevier, 152–178

Soo P, Ali Y, Lai O et al (2020) Enzymatic and mechanical extraction of virgin coconut oil. Eur J Lipid Sci Technol 122:1900220

Sun HY, Kim JK, Kim HM et al (2018) Effect of non-dairy creamer supplementation to corn-soybean meal based diet on growth performance, nutrient digestibility and meat quality in broilers. J Anim Sci 96:128–129

Yekdane N, Goli SAH (2019) Effect of pomegranate juice on characteristics and oxidative stability of microencapsulated pomegranate seed oil using spray drying. Food Bioprocess Technol 12:1614–1625

Acknowledgements

The authors are grateful to the Faculty of Food Science and Technology laboratory staff, Universiti Putra Malaysia (UPM), for their kind assistance.

Funding

Authors received support from Universiti Putra Malaysia under the Geran Universiti Putra Malaysia (GP-IPS/2017/9578000).

Author information

Authors and Affiliations

Contributions

ASMH: Supervision; Formal analysis; Methodology; Project administration; Funding acquisition; Validation. NKM: Data curation; Formal analysis; Methodology; Resources; Validation; Writing-original draft; Validation. NHA: Data curation; Methodology; Validation; Writing-review & editing. BJM: Data curation; Methodology; Validation; Validation; Writing-review & editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interests of any kind.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammed, N.K., Ahmad, N.H., Muhialdin, B.J. et al. Modulating of microencapsulated virgin coconut oil-based creamer. J Food Sci Technol 61, 528–538 (2024). https://doi.org/10.1007/s13197-023-05860-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05860-7