Abstract

Our aim is to establish a more efficient and reliable method for the bio-fabrication of pure SnO2 and SnO2-doped graphene oxide nanocomposites through a green chelating agent called Moringa Oleifera extract by sol-gel method. A sintered SnO2-doped GO nanocomposite exhibited increased crystallinity and size with increasing temperature, as determined by XRD studies. An FTIR investigation shows that the SnO2-doped GO nanocomposite exhibits two distinct bands at 733 cm−1 and 438 cm−1 due to terminal oxygen vibrations, while samples treated with G-O-Sn-O exhibit bands at 733 cm−1 due to antisymmetric stretching. By increasing the SnO2 peak, SnO2 nanoparticle sizes decrease, which results in a broadened GO, as well as a reduced IR intensity. By SEM and EDAX, the size and morphology of SnO2-doped GO nanocomposites were clearly observed. It was calculated that the optical bandgap of SnO2-doped GO nanostructures is 4.48 eV. It has been demonstrated that SnO2-doped GO nanocomposite can be used as an organic photocatalyst against organic pollutants methyl orange (MO) dye; despite its fast charge recombination when illuminated with visible light, these findings have been reported in detail.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Materials with nanostructures are the subject of nanoscience and nanotechnology. They are synthesized, characterized, and exploited to improve their qualities [1]. Among them are metal oxide nanocomposite, semiconductor nanocrystals, nanotubes, nanowires, and nanobiological systems. Solar cells that are dye-sensitized are cheaper, more efficient, and can be readily manufactured when compared with conventional solar cells [2]. A photo-anode, which is involved both in separating charges and generating charges, holds a significant position in a DSSC as it relates to PCE. As a result of recent industrialization, wastewater has become more and more hazardous to the environment [3]. The recent global energy crisis has also made the purification of the produced wastewater a growing concern [4]. Due to its non-toxicity, strong oxidizing power, and chemical inertness, SnO2 is the most suitable semiconductor material for water purification [5]. The past few decades have seen a variety of approaches implemented to reduce toxic pollution [6]. An effective semiconductor photocatalyst has been suggested for the complete degradation of organic pollutants in industrial wastewater. A sustainable solution for wastewater treatment is to use photocatalysts containing semiconductor nanomaterials to degrade organic pollutants [7]. Photocatalysts made from semiconductors, however, have major disadvantages. Since TiO2 semiconductor nanocomposite have a bandgap of approximately 3.2 eV, they only absorb ultraviolet light of the solar spectrum [8]. As a result of being exposed to sunlight, cadmium sulfide corrodes. To utilize semiconductor materials for dye degradation of organic pollutants, it is therefore a challenge to prepare inexpensive and efficient semiconductor materials [9].

It is an n-type semiconductor material with a bandgap that is photosensitive, transparent, environmentally friendly, and stable chemically [10]. Sensors [11], solar cells [12], energy storage [13], electronics [14], and photocatalysis [15, 16] have been repeatedly used as research subjects for SnO2 semiconductor material in recent years. The researchers found that SnO2 semiconductor was better in electron capture than TiO2 or SnO2 when used as a photocatalyst [17]. Water splitting and hydrogen production are also other areas where this potential value has been realized [18, 19]. The fast charge recombination of SnO2 semiconductor is considered to be its major disadvantage when illuminated by UV light in practical applications, despite the fact that it has proved to be a successful photocatalyst against organic pollutants. The synthesis of nanostructures of SnO2 has used a variety of techniques, including chemical vapor deposition [20], solvothermal synthetics [21], templates [22], sol-gel methods [23], and hydrothermal routes [24]. It has been demonstrated that hydrothermal routes can generate hierarchical SnO2 nanostructures efficiently and at low costs [25], and they also yield high yields when modified. Due to UV light’s limited absorption, SnO2 sensors are currently limited in their practical application [26, 27]. SnO2-doped GO photocatalysts by simple chemical precipitation are few, to the best of our knowledge. The aim of this study is to synthesize graphene oxide in the presence of SnO2 based on the co-precipitation method. A sol-gel procedure was used to prepare graphene oxide decorated tin oxide hierarchical nanorod SnO2-doped GO. The preparation process included a one-step GO process followed by a one-step SnO2-doped GO. By X-ray diffraction (XRD) analyses, morphological analyses, and Fourier transform infrared (FTIR) spectroscopy, a detailed analysis of GO-modified SnO2 hierarchical nanoparticles samples was presented. We observed in this study, composite materials containing graphene accepts photogenerated electrons and suppresses recombination by accepting photogenerated electrons.

2 Experimental Section

2.1 Materials

It was not necessary to purify any chemicals prior to use because they belonged to the analytical grade. It was purchased from Alfa Aesar, India, that tin chloride dihydradrate (SnCl4.2H2O) and sodium hydroxide (NaOH) are used in this study. It was obtained from Alfa Aesar, India, (99.99 %) graphite powder. Preparation and washing of the aqueous solutions were carried out using deionized water.

2.2 Preparation of Moringa Leaf Extracts

Using moringa oleifera leaves (MLE), we prepared MLE by mixing the leaves with 250 mL of 30% ethanol and leaving them at room temperature for 8 h, occasionally mixing manually. Filtered extracts were re-suspended in 20% ethanol after drying with Whatman filter paper. The final concentrations of 5 and 10 g/L of MLE were achieved through re-suspension in ethanol. By using the normal heating extraction method, bioactive compounds were extracted from dried leaves. A Whatman filter paper No. 10 was used to filter the extracted extracts. In order to continue the analysis, the material was stored at room temperature in a closed container.

2.3 Preparation of Sno2 Nanocomposite

In this study, the SnO2 NPs were synthesized by a sol-gel method. A 200-mL beaker containing 1.6 g of (NaOH) and 100 mL of water was added 1.51 g of (SnCl4.2H2O). After 20 min of sonication with an ultrasonicator, the solution was removed from the ultrasonicator. Stirring the white colored sol for 30 min followed by drying at 80 °C for 7 h and cooling at room temperature were performed immediately after the sol was obtained. Following several washes of distilled water and filtering with Whatman paper, the white precipitates were re-washed. It was then heated at 80 °C for 6 h to obtain white sol containing SnO2. To determine the final consistency of the product, it was ground well into fine powder and then calcined at 600 °C for 8 h.

2.4 Preparation of SnO2 NPs with Graphene Oxide Nanocomposite (SnO2/GO)

A 0.5g sample of the prepared SnO2 NPs was dissolved in 100 mL of DD water and sonicated for 30 min with stirring. In the following step, 0.1 weight percent of graphene oxide is added, followed by 15 ml of solvent. A separate addition of moringa leaf extract was made to the solution containing SnO2 NPs. During heating at 80 °C, the mixture was continuously stirred for 2 h. Following precipitation, deionized water was repeatedly used to wash the gray colored precipitates. During the heating process, the decorated SnO2-doped GO nanoparticle precipitates were kept at 90 °C for seven hours. In the next step, the material was ground well and calcined at 600 °C for 8 h until fine powder was obtained.

3 Results and Discussion

3.1 XRD Analysis

It is one of the most powerful methods for studying solid materials to use X-ray diffraction. In addition to being non-destructive, this method provides multiple results, including atomic-level details on crystal lattices. Phase formation and identification can also be confirmed with XRD. To determine the purity and crystalline phase composition of pure SnO2 nanoparticles synthesized, an X-ray diffraction analysis was conducted as shown in Fig. 1a. XRD patterns of SnO2-doped GO nanocomposites annealed at 600 °C showed that 2θ = 10° – 80°. This binary SnO2 sample appears to be highly crystalline due to the intense and sharp diffraction peaks. Particle size is a primary reason for the expansion of the XRD peaks. It is undisputed that all the diffraction patterns in the XRD indicate SnO2 with a tetragonal rutile structure, as the phase was in close conformity with the standard data (JCPDS Card 41-1445).

According to the XRD pattern, SnO2-doped GO nanocomposites, several sharp crystalline diffraction peaks are observed at 25.83o, 29.15o, 32.58o, 40.98o, 48.62o, 51.16°; 51.80o, 61.34o, 72.83o, and 77.49o, corresponding to (002), (110), (101), (100), (211), (220); (310), (301), (321), and (222), respectively, in the pure SnO2 nanoparticles. An XRD pattern indicating graphene’s characteristic peaks at 2θ there are 25.83° associated with (002) and 40.98° associated with (100), respectively and the formation of GO nanocomposites was associated with the new peaks at 36.6°. It should be noted that the peaks of GO are well in agreement with the tetragonal structure (JCPDS Card No. 01-0646) as shown in Fig. 1b. In the presence of binary nanostructures, all diffraction peaks shift and peak intensities decrease as a result of the interaction with Sn:G:O2 nanostructure. The average crystallite size of synthesized binary metal oxide nanocomposite samples is calculated by Scherer’s formula. Also, no other characteristic peaks are observed for impurities. Dhkl=0.98λ/βcosθ; where d is the average crystallite size; λ, the X-ray wavelength (0.1546 nm); θ, Bragg’s angle; and β the peak position and the FWHM (full width at half maximum) obtained by putting two Gaussian curves on the measured peaks to get the true peak positions and widths of monochromatic CuKα radiation. In SnO2-doped GO nanostructures, the average crystallite size is 28 nm. According to the XRD pattern results, graphene has a dominant peak corresponding to (002) plane, similar to graphite’s (002) plane. Since the peak of graphene (002) overlaps with the peak of SnO2 (110) in composite SnO2-graphene, the peak of graphene was observed. In addition, graphene inhibited the growth of SnO2 by making its peaks weaker, indicating that graphene could suppress its growth.

3.2 FTIR Investigation

In Fig. 2, Fourier transform infrared (FTIR) spectrum of pure SnO2 and SnO2-doped GO nanocomposite were analyzed in order to identify structural information of functional groups. In the original SnO2 nanoparticles, 4000–500 cm−1; 1639 cm−1 C=O stretching band vibration, 1494 cm−1, 1011 cm−1 bands, 733 cm−1 bands, and 438 cm−1 bands were observed [28, 29]. It is apparent from graphene’s absorption peak at 1494 cm−1 that the vibration of C=C aromatics is responsible for the absorption peak, and that of -OH stretching at 3479 cm−1 is responsible for the absorption peak. At 1763 cm−1, there is a very small peak that indicates C=O; 1369 cm−1 is a stretching vibration. There are peaks at 1494 cm−1 and 1011 cm−1 this is caused by C-O carboxy, and C-O hydroxyl groups vibrations associated with alkoxy groups. However, peaks are seen at 3479 cm−1 for SnO2-doped GO 1639 cm−1 (C=O stretching vibration), and 1642 cm−1 (OH stretching vibration). In addition to vibration, C-O vibration is 1494 cm−1 (C-C aromatics), and 1011 cm−1 (C-C aromatics). The stretching vibrations of O-Sn-O and G-Sn-O range from 733 to 438 [30].

3.3 Optical Properties

Figure 3 shows optical absorption profiles observed over 200-–900-nm wavelengths using ultraviolet diffused reflectance spectrometry (UV-DRS-Shimadzu-UV-3600 plus). An analysis of the UV-vis absorption spectra of pure SnO2 and SnO2-doped GO nanocomposite was performed. There are no significant differences in the optical quality of the samples in the UV region. A total of three absorbance edges were observed in the range of 230 nm and 318 nm. Overall, the GO reduction was initially monitored by recording the UV-vis absorption spectroscopy analysis. The comparison of the pure SnO2 and SnO2 doped-GO nanocomposite spectrum as shown in Fig. 3a–b. Pure SnO2 exhibited an absorption peak at 230 nm, which attributed to the π–π* transitions of the aromatic C=C bonds, and there were no other peaks identified for another transition. After SnO2-doped GO, the spectrum exhibited other peaks, which confirmed the reduction located at around 220–318 nm [11, 15, 26]. The identified absorption peak at 220 nm in SnO2-doped GO nanocomposite are confirmed the restoration of electronic conjugation within the graphene nanocomposite that red shifted from 220 to 318 nm due to the reduction of the GO [17, 19, 21]. In SnO2-doped GO nanocomposite, the absorption edge was at 318 nm due to the photoexcitation of electrons from the valence band (VB) to the conduction band (CB). A clear shift in maximum peak position occurs towards longer wavelengths indicating blue shift after the addition of GO. With the added GO, absorption edges are increased. In the case of treated SnO2-doped GO nanocomposite, the Eg value was found to be 4.48 eV, respectively. This is evident from the fact that pure SnO2 NPS shows a higher Eg value than graphene oxide-treated SnO2 composites [31]. Thus, SnO2 can be tuned with respect to its bandgap by changing its dopant composition. In SnO2, the bandgap energy (Eg) is determined by the wavelength value that coincides with the intersection point between the horizontal and vertical parts of the spectrum.

3.4 Morphological Analysis

A diagram of the morphology of pure SnO2 nanocomposite can be seen in Fig. 4a and b. A scanning electron microscope image shows nearly uniformly sized SnO2 nanocomposite. SEM images revealed agglomerated particles, the size of the particles determines the agglomeration effect. In fact, XRD measurements estimated the particle size to be 28 nm. In the nanoscale, particles agglomerate more readily, in Fig. 4c and d, SnO2-doped GO integration reduce the size of nanocomposite but maintain their shape. In other studies, the size of the NPs has also been reported to increase following doping and GO incorporation. A high level of lattice fringes without distortion are depicted in these images of SnO2-doped GO nanocomposite. Particularly, SnO2-doped GO nanocomposite were calculated to have tetragonal rutile structures with interplanar spacings of 0.345 nm, and 0.340 nm in the (101) plane of adjacent lattice fringes as shown in Fig. 4d–f. A study of SnO2 lattice fringes revealed that they were 0.334 nm and 0.338 nm, which correspond to the (110) planes of the tetragonal phase [32]. XRD results confirmed the measurement of lattice fringes. In addition, SEM images revealed all grown particles had high crystallinity, which demonstrates they were incorporated into the crystalline matrix of SnO2-doped GO without causing lattice defects. Sn, O, and G were stoichiometrically present in EDX spectra of SnO2-doped GO nanocomposite as shown in Fig. 5. As shown in the XRD results, the GO peak is a result of graphene lattices. Based on SEM mappings of elemental distributions, pure SnO2 and SnO2-doped GO nanocomposite were uniformly distributed with GO [33]. The GO does not presents the layered surface structure, which was similar as previously reported [34]. After modification with SnO2-doped GO, the composite showed a distributed particle in irregular forms, reflecting the SnO2 nanoparticles on the surface. The EDX analysis confirmed the Sn peak, which is associated with the SnO2 content at 82.7% wt%.

3.5 Photocatalytic Dye Degradation Test

A degradation test was conducted on methyl orange (MO) under visible light irradiation to evaluate the photocatalytic activity of the photocatalysts. A halogen lamp (500 W) was used as the light source that produces visible light (> 420 nm) as the background illumination. As synthesized photocatalysts were added to an aqueous solution of 100 mL of MO with constant magnetic stirring. To achieve an equilibrium of MO adsorption/desorption on photocatalyst surfaces, the solution was kept in dark adsorption with stirring for 30 min. After that, the light was switched on, and the solutions were stirred continuously [35]. An UV-vis spectrometer was used to analyses the remaining photocatalyst every 30 min after centrifuging the suspension at 6000 rpm. According to the U.S. Environmental Protection Agency, MO degradation can be calculated by measuring the decrease in intensity of 463 nm characteristic band absorption. As a result of recording the absorbance of withdrawn solutions at 463 nm, the rate of degradation of MO dyes under sunlight irradiation was calculated using the equation below [36].

where Co = initial concentration and Ct is reaction concentration at time t, respectively.

3.5.1 Photocatalytic Activity

The characterization study above clearly showed that the prepared materials were highly crystalline, and they showed enhanced visibility absorption. Decolorization of MO dye under visible light irradiation is used to evaluate the photocatalytic ability of prepared samples. An UV-vis test was conducted to determine how well the photocatalysts performed. Absorption spectra recorded by a spectrophotometer. It took 150 min to eliminate the dye pollutant after all dye degradation experiments. Increasing irradiation time gradually decreases the peak at 463 nm. A complete photodegradation of the MO dye is evident after 150 min when the dye absorbed no longer, and the blue color of the solution disappeared. In this example, Co represents the initial concentration of catalyst, and C represents the concentration of methyl orange (MO) during the reaction at time t. An experimental description of the reaction can be found in the experiment section of the presentation [36]. Various samples were measured in order to compare the photocatalytic performance. According to Fig. 6, the absorption intensity of the aqueous solution gradually decreased with increased irradiation time [37].

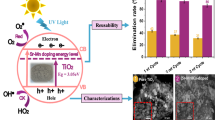

The figure shows graph to compare the photocatalytic degradation performance of all the prepared photocatalyst with other samples based on their kinetic performance (C/Co). As shown in Fig. 7a, the degradation efficiency chart for the photocatalysts was prepared. As seen in Fig. 8 based on the degradation efficiency of SnO2 NPs and SnO2-doped GO samples, respectively, 86% and 93% were determined. As compared to pure SnO2 NPs (86%) in 150 min of visible irradiation, SnO2-doped GO photocatalyst achieved the highest degradation efficiency (93%) out of all the synthesized photocatalysts [38, 39]. Two reasons can be attributed to this phenomenon. At the interface between SnO2 and GO, efficient heterojunction is formed by forming GO nanosheets that transfer electrons/holes effectively. The efficiency of the activity can be attributed to the efficient separation of electron hole pairs created by photosynthesis. GO nanocomposite with SnO2-doped surfaces may exhibit higher photocatalytic activity because they have a higher specific surface area, which results in a higher surface-active site for MO dye molecules to adhere to for more efficient catalysis [40, 41]. In the final composite, the highest amount of GO can harvest the lowest light absorption and act as a shield for the active sites as a result of the highest amount of GO in the final composite. SnO2 NPs and SnO2-doped GO exhibit the highest photocatalytic activity among the samples. It was investigated how the degradation reaction behaves using pseudo first order kinetics. In Fig. 7b, we illustrate a linear relationship between the irradiation time (t) and the plot’s slope. A pseudo first order equation function model can explain the kinetic values found for MO dye degradation, which are ln (Co/Ct) = −kt, where k is the rate constant, Co is the initial concentration (0 min), and Ct is the final concentration [42]. In all cases, pseudo-first-order kinetics was used to describe the photocatalytic degradation curves. Considering the observed results, the pure SnO2 NPs did not achieve the maximum degradation efficiency, whereas the SnO2-doped GO nanocomposite photocatalyst did as shown in Fig. 8.

3.5.2 Proposed Photocatalytic Mechanism

According to Fig. 9, SnO2 has a bandgap of about 3.89 eV and conduction band potential of about 0.07 V. A SnO2 valance band can be irradiated, causing electrons to leave their condition band [38, 39]. A low photocatalytic activity to organic pollutants can be achieved without combining other materials, as electrons will transition quickly to the valance band as a result of the instability of excited states [43, 44]. The photo-excited electrons will transfer from SnO2 to graphene when SnO2 nanocomposite are combined with reduced grapheme, preventing the recombination of electrons and holes [45]. Aside from the fact that graphene has oxygen containing functional groups, it can be used to enhance a wide range of applications because of its inorganic nanocrystal properties [46]. Graphene had greater light absorption intensity and MO adsorption than some other semiconductors, such as pure SnO2, while SnO2-doped GO had a higher work function [47, 48]. Various reactive oxygen species could also be formed on SnO2 surface when the electrons were trapped by dissolved oxygen, increasing MO degradation.

4 Conclusion

Through a green chelating agent called Moringa Oleifera extract, we successfully synthesized pure SnO2 and SnO2-doped GO nanocomposite using sol-gel method. A variety of techniques were used for characterization of the prepared materials, including X-ray analysis, UV-vis, and FTIR spectral analysis. Through the use of XRD patterns, tetragonal structures were characterized in SnO2-doped GO nanocomposites. As seen in the optical absorption spectrum, the prepared product has a shorter wavelength. In the FTIR spectrum, oxygen bending vibrations are observed, which indicates functional groups are present. There is no doubt that doping has affected the functional structure of graphene structural layer, and the morphologies of the particles have affected the size of the particles. Moreover, the EDAX mapping image confirms that SnO2 nanoparticles have been successfully incorporated with GO. Graphene oxide can be applied to a wide range of applications in the energy and environmental sectors when designed properly with pure SnO2 nanoparticles. It remains a challenge to synthesize large-scale GO nanocomposite with SnO2 doping on a large scale. After 150 min, the absorption peak of the dye was no longer evident due to the photocatalytic activity of nanocomposite. A study demonstrating the degradability of toxic organic dyes like MO through the use of pure SnO2 and SnO2-doped GO nanocomposite has been performed using an environmentally friendly route.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Wang, Z. L., & Wu, W. Z. (2012). Nanotechnology enabled energy harvesting for self-powered micro-nanosystems. Angew Chem Int Eds., 51, 11700–11721.

Zhu, Y. P., Ren, T. Z., & Yuan, Z. Y. (2015). Mesoporous phosphorus-doped g-C3N4 nanostructured flowers with superior photocatalytic hydrogen evolution performance. ACS Appl. Mater. Interfaces, 7, 16850–16856.

Hashimoto, K., Irie, H., Fujishima, A., & Jpn. (2005). TiO2 photocatalysis: A historical overview and future prospects. J. Appl. Phys., 44, 8269–8285.

Pan, J., Huhne, S. M., Shen, H., Xiao, L., Born, P., Mader, W., & Mathur, S. (2011). SnO2-TiO2 core-shell nanowire structures: Investigations on solid state reactivity and photocatalytic behavior. J. Phys. Chem. C, 115, 17265–17269.

Yeber, M. C., Rodriguez, J., Freer, J., Duran, N., & Mansilla, H. D. (2000). Photocatalytic degradation of cellulose bleaching effluent by supported TiO2 and ZnO. Chemosphere, 41, 1193–1197.

Kaviyarasu, K., Devarajan, P. A., Xavier, S. S. J., Thomas, S. A., & Selvakumar, S. (2012). One pot synthesis and characterization of cesium doped SnO2 nanocrystals via a hydrothermal process. Journal of Materials Science & Technology, 28(1), 15–20.

Sayama, K., & Arakawa, H. (1993). Photocatalytic decomposition of water and photocatalytic reduction of carbon dioxide over zirconia catalyst. J. Phys. Chem., 97, 531–533.

Konta, R., Ishii, T., Kato, H., & Kudo, A. (2004). Photocatalytic activities of noble metal ion doped SrTiO3 under visible light irradiation. J. Phys. Chem. B, 108, 8992–8995.

Yan, H. J., Yang, J. H., Ma, G. J., Wu, G. P., Zong, X., Lei, Z., Shi, J. Y., & Li, C. (2009). Visible-light-driven hydrogen production with extremely high quantum efficiency on Pt-PdS/CdS photocatalyst. J. Catal., 266, 165–168.

Hu, L. X., Chen, F. Y., Hu, P. F., Zou, L. P., & Hu, X. (2016). Hydrothermal synthesis of SnO2/ZnS nanocomposite as a photocatalyst for degradation of Rhodamine B under simulated and natural sunlight. J. Mol. Catal. A: Chem., 411, 203–213.

Pan, J., Ganesan, R., Shen, H., & Mathur, S. (2010). Plasma-modified SnO2 nanowires for enhanced gas sensing. J. Phys. Chem. C, 114, 8245–8250.

Panimalar, S., Uthrakumar, R., Tamil Selvi, E., Gomathy, P., Inmozhi, C., Kaviyarasu, K., & Kennedy, J. (2020). Studies of MnO2/g-C3N4 hetrostructure efficient of visible light photocatalyst for pollutants degradation by sol-gel technique. Surfaces and Interfaces, 20, 100512.

Lou, X. W., Li, C. M., & Archer, L. A. (2009). Designed synthesis of coaxial SnO2@carbon hollow nanospheres for highly reversible lithium storage. Adv. Mater., 21, 2536–2539.

Pan, J., Ganesan, R., Shen, H., & Mathur, S. (2011). Heteroepitaxy of SnO2 nanowire arrays on TiO2 single crystals: Growth patterns and tomographic studies. J. Phys. Chem. C, 115, 15191–15197.

Pan, J., Li, J. T., Yan, Z. L., Zhou, B. H., Wu, H. S., & Xiong, X. (2013). SnO2@CdS nanowire - quantum dots heterostructures: Tailoring optical properties of SnO2 for enhanced photodetection and photocatalysis. Nanoscale, 5, 3022–3029.

Yuan, J. J., Zhang, X. K., Li, H. D., Wang, K., Gao, S. Y., Zhu, X. R., Xiong, Z. Z., & Xie, Y. M. (2015). TiO2/SnO2 double-shelled hollow spheres-highly efficient photocatalyst for the degradation of rhodamine B. Catal. Commun., 60, 129–133.

Gunasekaran, A., Kumar Rajamani, A., Masilamani, C., Chinnappan, I., Ramamoorthy, U., & Kasinathan, K. (2023). Synthesis and characterization of ZnO doped TiO2 nanocomposites for their potential photocatalytic and antimicrobial applications. Catalysts, 13(2), 215.

Kim, S. P., Choi, M. Y., & Choi, H. C. (2016). Photocataytic activity of SnO2 nanocomposites in methylene blue degradation. Mater Res Bull., 74, 85–89.

Rotte, N. K., Subbareddy, Y., Puttapati, S. K., Srikanth, V., & Kaviyarasu, K. (2023). Morphological features and photoluminescence of ZnO and ZnO decorated S, N-doped few-layered graphene (ZnO–S, N-FLGs). Journal of Physics and Chemistry of Solids, 174, 111175.

Wang, Q. Q., Lin, B. Z., & Xu, B. (2010). Preparation and photocatalytic properties of mesoporous SnO2-hexaniobate layered nanocomposite. Microporous Mesoporous Mater., 130, 344–351.

Cheng, L., Ma, S. Y., Wang, T. T., & Luo, J. (2015). Synthesis and enhanced acetone sensing properties of 3D porous flower-like SnO2 nanostructures. Mater Lett, 143, 84–87.

Xu, G., Zhang, X., Cui, H., Chen, Z., Ding, J., & Zhan, X. (2016). Preparation of mesoporous SnO2 by solvothermal method using stahlianthus involucratus leaves and application to n-butanol sensor. Powder Technol, 302, 283–287.

Alinauskas, L., Brooke, E., Regoutz, A., Katelnikovas, A., Raudonis, R., Yitzchaik, S., Payne, D. J., & Garskaite, E. (2017). Nanostructuring of SnO2 via solution-based and hard template assisted method. Thin Solid Films, 626, 38–45.

Luo, W., Deng, J., Fu, Q., Zhou, D., Hu, Y., Gong, S., & Z. (2015). Zheng Nanocrystalline SnO2 film prepared by the aqueous sol–gel method and its application as sensing films of the resistance and SAW H2S sensor. Sensors Actuators B Chem, 217, 119–128.

Wang, Q., Kou, X., Liu, C., Zhao, L., Lin, T., Liu, F., Yang, X., Lin, J., & Lu, G. (2017). Hydrothermal synthesis of hierarchical CoO/SnO2 nanostructures for ethanol gas sensor. J Colloid Interface Sci, 513, 760–766.

Li, Z., & Yi, J. (2017). Enhanced ethanol sensing of Ni-doped SnO2 hollow spheres synthesized by a one-pot hydrothermal method. Sensors Actuators B Chem, 243, 96–103.

Liu, S. H., Wei, Y. S., & Lu, J. S. (2016). Visible-light-driven photodegradation of sulfamethoxazole and methylene blue by Cu2O/rGO photocatalysts. Chemosphere., 154, 118–123.

Seema, H., Christian, K., Chandra, V., & Kim, K. S. (2012). Graphene-SnO2 composites for highly efficient photocatalytic degradation of methylene blue under sunlight. Nanotechnology., 23, 355705.

Kim, T., Parale, V., Jung, N. R., Kim, Y., & Driss, Z. (2019). Facile synthesis of SnO2 aerogel/reduced graphene oxide nanocomposites via in situ annealing for the photocatalytic degradation of methyl orange. Nanomaterials., 9, 358.

Sahu, B. K., Juine, R. N., Sahoo, M., Kumar, R., & Das, A. (2021). Interface of GO with SnO2 quantum dots as an efficient visible light photocatalyst. Chemosphere, 276, 130142.

Panimalar, S., Logambal, S., Thambidurai, R., Inmozhi, C., Uthrakumar, R., Muthukumaran, A., Rasheed, R. A., Gatasheh, M. K., Raja, A., Kennedy, J., & Kaviyarasu, K. (2022). Effect of Ag doped MnO2 nanostructures suitable for wastewater treatment and other environmental pollutant applications. Environmental Research, 205, 112560.

Wang, C., Zhou, Y., Ge, M. Y., Xu, X. B., Zhang, Z. L., & Jiang, J. Z. (2010). Large-scale synthesis of SnO2 nanosheets with high lithium storage capacity. J. Am. Chem. Soc., 132, 46–47.

Tao, T., He, L. J., Li, J., & Zhang, Y. H. (2015). A new way for synthesizing SnO2 nanosheets. Mater. Lett., 138, 45–47.

Wang, C., Zhou, Y., Ge, M., Xu, X., Zhan, Z., & Jiang, J. Z. (2010). Large-scale synthesis of SnO2 nanosheets with high lithium storage capacity. J. Am. Chem. Soc., 132, 46–47.

Hou, D., Liu, Q., Cheng, H., Zhang, H., & Wang, S. (2017). Green reduction of graphene oxide via Lycium barbarum extract. J Solid State Chem., 246, 351–356.

Perumal, V., Sabarinathan, A., Chandrasekar, M., Subash, M., Inmozhi, C., Uthrakumar, R., Isaev, A. B., Raja, A., Elshikh, M. S., Almutairi, S. M., & Kaviyarsu, K. (2022). Hierarchical nanorods of grapheme oxide decorated SnO2 with high photocatalytic performance for energy conversion applications. Fuel, 324, 124599.

Seema, H., Kemp, K. C., Chandra, V., & Kim, K. S. (2012). Graphene-SnO2 composites for highly efficient photocatalytic degradation of methylene blue under sunlight. Nanotechnology, 23, 355705.

Panimalar, S., Subash, M., Chandrasekar, M., Uthrakumar, R., Inmozhi, C., Al-Onazi, W. A., Al-Mohaimeed, A. M., Tse-Wei Chen, J., Kennedy, M., & Maaza, K. K. (2022). Reproducibility and long-term stability of Sn doped MnO2 nanostructures: Practical photocatalytic systems and wastewater treatment applications. Chemosphere, 293, 13364.

Arularasu, M. V., Anbarasu, M., Poovaragan, S., Sundaram, R., Kanimozhi, K., Maria Magdalane, C., Kaviyarasu, K., Thema, F. T., Letsholathebe, D., Mola, G. T., & Maaza, M. (2018). Structural, optical, morphological and microbial studies on SnO2 nanoparticles prepared by co-precipitation method. Journal of nanoscience and nanotechnology, 18(5), 3511–3517.

Maria Magdalane, C., Kanimozhi, K., Arularasu, M. V., & Kaviyarasu, K. (2019). Self-cleaning mechanism of synthesized SnO2/TiO2 nanostructure for photocatalytic activity application for wastewater treatment. Surfaces and Interfaces, 17, 100346.

Yang, H. X., Qian, J. F., Chen, Z. X., Ai, X. P., & Cao, Y. L. (2007). Multilayered nanocrystalline SnO2 hollow microspheres synthesized by chemically induced self-assembly in the hydrothermal environment. Journal of Physics and Chemistry, 111(38), 14067–14071.

Zhou, K., Zhu, Y., Yang, X., Jiang, X., & Li, C. (2011). Preparation of graphene-TiO2 composites with enhanced photocatalytic activity. New J. Chem., 35, 353–359.

Anguraj, G., Ashok Kumar, R., Inmozhi, C., Uthrakumar, R., Elshikh, M. S., Almutairi, S. M., & Kaviyarasu, K. (2023). MnO2 doped with Ag nanoparticles and their applications in antimicrobial and photocatalytic reactions. Catalysts, 13(2), 397.

Kannan, K., Radhika, D., Gnanasangeetha, D., Krishna Lakkaboyana, S., Kumar Sadasivuni, K., Gurushankar, K., & Hanafiah, M. M. (2021). Photocatalytic and antimicrobial properties of microwave synthesized mixed metal oxide nanocomposite. Inorganic Chemistry Communications, 125, 108429.

Suganthi, N., Thangavel, S., & Kannan, K. (2020). Hibiscus subdariffa leaf extract mediated 2-D fern-like ZnO/TiO2 hierarchical nanoleaf for photocatalytic degradation. FlatChem, 24, 100197.

Kannan, K., Radhika, D., Nesaraj, A. S., Kumar Sadasivuni, K., & Sivarama Krishna, L. (2020). Facile synthesis of NiO-CYSO nanocomposite for photocatalytic and antibacterial applications. Inorganic Chemistry Communications, 122, 108307.

Alshorifi, F. T., Ali, S. L., & Salama, R. S. (2022). Promotional Synergistic Effect of Cs-Au NPs on the Performance of Cs-Au/MgFe2O4 Catalysts in catalysis 3,4-dihydropyrimidin-2(1H)-ones and degradation of RhB dye. Journal of Inorganic and Organometallic Polymers and Materials, 32, 3765–3776.

Kannan, K., Radhika, D., Gnanasangeetha, D., Sivarama Krishna, L., & Gurushankar, K. (2021). Y3+ and Sm3+ co-doped mixed metal oxide nanocomposite: Structural, electrochemical, photocatalytic, and antibacterial properties, Applied Surface Science. Advances, 4, 100085.

Acknowledgements

In their acknowledgement, the authors express their gratitude to management. Also, this work was supported by the Distinguished Scientist Fellowship Program (DSFP) at King Saud University, Riyadh, Saudi Arabia.

Funding

Open access funding provided by University of South Africa.

Author information

Authors and Affiliations

Contributions

K. Kaviyarasu: investigation, supervision, original draft, project administration, software, writing - review & editing; Mohamed S. Elshikh: formal analysis, methodology & visualization; Saeedah Musaed Almutairi: software, formal analysis, funding acquisition, methodology, review & editing, R. Uthrakumar: validation, formal analysis, writing, review & editing; Azhaguchamy Muthukumaran: formal analysis, software, data curation, visualization, writing & editing.

Corresponding author

Ethics declarations

Ethical Statement

A component of the research process, whose purpose is to protect both the researcher and the participants in the research, which should have their dignity, rights, safety, and welfare respected.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kaviyarasu, K., Elshikh, M.S., Almutairi, S.M. et al. Reactive Oxygen Species (ROS) Are Generated as Organic Contaminants Are Broken Down: SnO2-Doped Graphene Oxide Nanocomposites Are Investigated Under Visible Light Illumination for their Photocatalytic Activity. BioNanoSci. 13, 920–928 (2023). https://doi.org/10.1007/s12668-023-01111-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12668-023-01111-3