Abstract

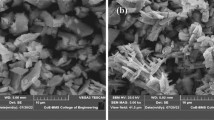

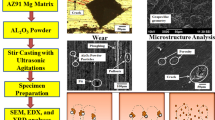

The present study aims to develop a new class of AZ91D magnesium metal matrix nanocomposites reinforced with varying wt.% (0–2%) of B4C nanoparticles through ultrasonic vibration-assisted stir casting technique and to evaluate the influence of B4C particles on the microstructure, micro-hardness and wear behaviour of AZ91D nanocomposites. Microstructural characterisation was performed using field emission scanning electron microscope (FESEM) and showed that the B4C nanoparticles were dispersed uniformly, refinement of grains and well-bonded between the AZ91D matrix and reinforcement particles. XRD patterns of as-cast MMNCs confirmed the presence of α-Mg, β-Mg17Al12, B4C and MgO phases. Micro-hardness value enhanced by 53.73% with incorporation of 2 wt.% B4C. The reciprocating wear tests of nanocomposites were examined using ball-on-disc tribotester under applied load of 2 N and observed that wear rate and friction behaviour of AZ91D-2.0B4C nanocomposites decreased by 48.67 and 28.32%, respectively. FESEM micrographs of worn surfaces indicate that abrasion, oxidation, adhesion and delamination were the main wear mechanisms.

Similar content being viewed by others

References

Huang S J, Subramani M, and Chiang C C, Compos Commun 25 (2021) 100772. https://doi.org/10.1016/j.coco.2021.100772

Ramalingam V V, Ramasamy P, Kovukkal M D, and Myilsamy G, Met Mater Int 26 (2020) 409. https://doi.org/10.1007/s12540-019-00346-8

Gnanavelbabu A, Surendran K T S, Loganathan P, and Vinothkumar E, J Alloys Compd 856 (2021) 158173. https://doi.org/10.1016/j.jallcom.2020.158173

Salevati M A, Imam A, Seifi R, and Akbaripanah F, Met Mater Int 27 (2021) 3538. https://doi.org/10.1007/s12540-020-00694-w

Shen M, Zhu X, Han B, Ying T, and Jia J, J Mater Res Technol 16 (2022) 814. https://doi.org/10.1016/j.jmrt.2021.12.048

Aatthisugan I, Rose A R, and Jebadurai D S, J Magnes Alloy 5 (2017) 20. https://doi.org/10.1016/j.jma.2016.12.004

Banerjee S, Poria S, Sutradhar G, and Sahoo P, J Magnes Alloy 7 (2019) 315. https://doi.org/10.1016/j.jma.2018.11.005

Mitra A, Mandal S K, and Rai R N, Proc Inst Mech Eng E: J Process Mech Eng (2023) 1. https://doi.org/10.1177/09544089231167758

Borodianskiy K, and Zinigrad M, Metall Mater Trans B 47 (2016) 1302. https://doi.org/10.1007/s11663-016-0586-0

Islam M S, Masoodi R, and Rostami H, Nanoscience 2013 (2013) 1. https://doi.org/10.1155/2013/275037

Pukanshi B, and Fekete E, Adv Polym Sci 139 (1999) 109. https://doi.org/10.1007/3-540-69220-7_3

Ghasali E, Alizadeh M, Niazmand M, and Ebadzadeh T, J Alloys Compd 697 (2017) 200. https://doi.org/10.1016/j.jallcom.2016.12.146

Zhang W, Prog Mater Sci 116 (2021) 100718. https://doi.org/10.1016/j.pmatsci.2020.100718

Baradeswaran A, Perumal A E, and Compos B, Eng 54 (2013) 146. https://doi.org/10.1016/j.compositesb.2013.05.012

Sankaranarayanan S, and Sabat R K, Jayalakshmi, and Gupta M. Mater Des 56 (2014) 428. https://doi.org/10.1016/j.matdes.2013.11.031

Casati R, and Vedani M, Metals 4 (2014) 65. https://doi.org/10.3390/met4010065

Chen L Y, Peng J Y, Xu J Q, Choi H, and Li X C, Scr Mater 69 (2013) 634. https://doi.org/10.1016/j.scriptamat.2013.07.016

Suslick K S, and Price G J, Annu Rev Mater Sci 29 (1999) 295. https://doi.org/10.1146/annurev.matsci.29.1.295

Nie K B, Wang X J, Hu X S, Xu L, Wu K, and Zheng M Y, Mater Sci Eng A 528 (2011) 5278. https://doi.org/10.1016/j.msea.2011.03.061

Thirugnanasambandham T, Chandradass J, Sethupathi P B, and Martin M L J, Mater Today: Proc 14 (2019) 211. https://doi.org/10.1016/j.matpr.2019.04.140

Nguyen Q B, Sim Y H M, Gupta M, and Lim C Y H, Tribol Int 82 (2015) 464. https://doi.org/10.1016/j.triboint.2014.02.024

Kumar D, and Thakur L, JOM 75 (2023) 2731. https://doi.org/10.1007/s11837-023-05845-z

Saleh B, Jiang J, Fathi R, Xu Q, Wang L, and Ma A, Archiv Civ Mech Eng 20 (2020) 71. https://doi.org/10.1007/s43452-020-00071-9

Ganguly S, Reddy S T, Majhi J, Nasker P, and Mondal A K, Mater Sci Eng A 799 (2021) 140341. https://doi.org/10.1016/j.msea.2020.140341

Aydin F, Sun Y, Ahlatci H, and Turen Y, Trans Indian Inst Met 71 (2018) 873. https://doi.org/10.1007/s12666-017-1219-2

Deng K K, Wu K, Wu Y W, Nie K B, and Zheng M Y, J Alloys Compd 504 (2010) 542. https://doi.org/10.1016/j.jallcom.2010.05.159

Kumar K R, Trans Indian Inst Met 73 (2020) 2539. https://doi.org/10.1007/s12666-020-02062-z

Haninnejad-Korayem M, and Mahmudi R, Ghasemi, and Poole W J. Wear 268 (2010) 405. https://doi.org/10.1016/j.wear.2009.08.031

Muley S V, Singh S P, Sinha P, Bhingole P P, and Chaudhari G P, Mater Des 53 (2014) 475. https://doi.org/10.1016/j.matdes.2013.07.056

Sahu P K, Singh S, Chen G, Yijun L, Zhang S, and Shi Q, Tribol Int 146 (2020) 106263. https://doi.org/10.1016/j.triboint.2020.106268

Sonber J K, Limaye P K, Ch Murthy T S R, Sairam K, Nagaraj A, Soni N L, Patel R J, and Chakravartty J K, Int J Refract Hard Met 51 (2015) 110. https://doi.org/10.1016/j.ijrmhm.2015.03.010

Banijamali S M, Najafi S, Sheikhani A, and Palizdar Y, Wear 508 (2022) 204487. https://doi.org/10.1016/j.wear.2022.204487

Wang C, Deng K, and Bai Y, Materials 12 (2019) 1190. https://doi.org/10.3390/ma12071190

Shanthi M, Nguyen Q B, and Gupta, Wear 269 (2010) 473. https://doi.org/10.1016/j.wear.2010.04.034

Azizieh M, Larki A N, Tahmasebi M, Bavi M, Alizadeh E, and Seop H, J of Materi Eng and Perform 27 (2018) 2010. https://doi.org/10.1007/s11665-018-3277-y

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mitra, A., Bera, T., Dey, V. et al. Investigation of Reciprocating Wear Characteristics of Nano-B4C Reinforced AZ91D Magnesium Metal Matrix Nanocomposites Prepared Through Ultrasonically Assisted Stir Casting Technique. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03344-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03344-6