Abstract

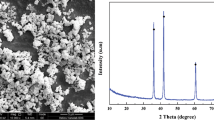

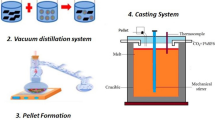

This study investigated the effect of extrusion ratio on the microstructural evolution and mechanical properties of the as-extruded short carbon fibers (SCFs) reinforced AZ31 alloy composite, and the microstructural development of the composite during extrusion was thoroughly investigated. The dominant dynamic recrystallization (DRX) mechanisms are particle simulated nucleation, continuous DRX, and discontinuous DRX. The addition of SCFs promotes the dynamic recrystallization during hot extrusion. As extrusion ratio increases, the interfacial bonding degree of the composite increases gradually, and the composite with an extrusion ratio of 25:1 exhibits the finest DRXed grains and the best mechanical performance with a yield strength of 171 MPa, an ultimate tensile strength of 258 MPa and an elongation of 6.0%. The enhanced strength is mainly attributed to grain refinement strengthening and dislocation strengthening, which are induced by the DRXed grains and the added SCFs.

Similar content being viewed by others

References

Liu Z Y, Chen B, Zhao P Y, Yu L P, Pei Z R, Zhou B, and Zeng X, Vacuum 207 (2023) 111668. https://doi.org/10.1016/j.vacuum.2022.111668

Yang Z, Wang G, Chao X, Wang M, Nakata T, Hongyu X, Geng L, and Kamado S, J Mater Res Technol 21 (2022) 3756. https://doi.org/10.1016/j.jmrt.2022.11.015

Dai Y, Xiao M, Hu Y, Yang Y, Jiang B, Zheng T, Dong L, Yang B, and Zheng C, J Mater Res Technol 20 (2022) 1570. https://doi.org/10.1016/j.jmrt.2022.07.166

Li W J, Deng K K, Zhang X, Wang C J, Kang J W, Nie K B, and Liang W, Microstructures, tensile properties and work hardening behavior of sicp/Mg-Zn-Ca composites. J Alloys Compd 695 (2017) 2215. https://doi.org/10.1016/j.jallcom.2016.11.070

Zhang J H, Nie K B, Deng K K, Han J G, and Yi J Y, Compos Commun 27 (2021) 100. https://doi.org/10.1016/j.coco.2021.100847

Shen M J, Wang X J, Zhang M F, Hu X S, Zheng M Y, and Wu K, Mater Sci Eng A 601 (2014) 58. https://doi.org/10.1016/j.msea.2014.02.035

Xiong B W, Wang Z J, Wang C W, Xiong Y Z Y, and Cai C, Intermetallics 106 (2019) 59. https://doi.org/10.1016/j.intermet.2018.12.010

Yang Z, Xu H Y, Wang Y, Hu M L, and Ji Z S, Mater Res Express 6 (2019) 106547. https://doi.org/10.1088/2053-1591/ab38d0

Xu H Y, Zhao Y, Hu M L, and Ji Z S, Results Phys 17 (2020) 103074. https://doi.org/10.1016/j.rinp.2020.103074

Ye J, Chen X, Luo H, Zhao J, Li J, Tan J, Yang H, Feng B, Zheng K, and Pan F, J Magn Alloys 10 (2022) 2266. https://doi.org/10.1016/j.jma.2022.06.012

Sun S, Deng N, Zhang H, He L, Zhou H, Han B, Gao K, and Wang X, J Mater Res Technol 15 (2021) 1789. https://doi.org/10.1016/j.jmrt.2021.09.015

Feng J, Song K X, Liang S H, Guo X H, and Li S L, J Mater Res Technol 20 (2022) 1470. https://doi.org/10.1016/j.jmrt.2022.07.131

Yuan Q H, Zhou G H, Liao L, Liu Y, and Luo L, Carbon 127 (2018) 177. https://doi.org/10.1016/j.carbon.2017.10.090

Nie K B, Guo Y C, Deng K K, and Kang X K, J Alloys Compd 792 (2019) 267. https://doi.org/10.1016/j.jallcom.2019.04.028

Xiao L, Yang G Y, Chen J M, Luo S F, Li J H, and Jie W Q, Mater Sci Eng A 744 (2019) 277. https://doi.org/10.1016/j.msea.2018.11.142

Nie K B, Zhu Z H, Deng K K, and Han J G, J Magn Alloy 8 (2020) 676. https://doi.org/10.1016/j.jma.2020.04.006

Yan K, Sun J P, Liu H, Cheng H H, Bai J, and Huang X, Mater Lett 242 (2019) 87. https://doi.org/10.1016/j.matlet.2019.01.089

Asgharzadeh H, Joo S H, and Kim H S, Metall Mater Trans A 45 (2014) 4129. https://doi.org/10.1007/s11661-014-2354-6

Nakata T, Xu C, Ajima R, Matsumoto Y, Shimizu K, Sasaki T T, Hono K, and Kamado S, Mater Sci Eng A 712 (2018) 12. https://doi.org/10.1016/j.msea.2017.11.085

Xu C, Nakata T, Qiao X G, Jiang H S, Sun W T, Chi Y C, Zheng M Y, and Kamado S, Mater Sci Eng: A 685 (2017) 159. https://doi.org/10.1016/j.msea.2016.12.121

Yang Z, Xu C, Nakata T, and Kamado S, Mater Sci Eng A 800 (2021) 140330. https://doi.org/10.1016/j.msea.2020.140330

Park S H, You B S, Mishra R K, and Sachdev A K, Mater Sci Eng A 598 (2014) 396. https://doi.org/10.1016/j.msea.2014.01.051

Liu H, Ju J, Yang X, Yan J, Song D, Jiang J, and Ma A, J Alloys Compd 704 (2017) 509. https://doi.org/10.1016/j.jallcom.2017.02.107

Jiang M G, Xu C, Yan H, Fan G H, Nakata T, Lao C S, Chen R S, Kamado S, Han E H, and Lu B H, Acta Materialia 157 (2018) 53. https://doi.org/10.1016/j.actamat.2018.07.014

Yu Z J, Xu C, Meng J, Liu K, and Fu J L, Mater Sci Eng A 762 (2019) 138080. https://doi.org/10.1016/j.msea.2021.142521

Chi Y Q, Xu C, Qiao X G, and Zheng M Y, J Alloys Compd 789 (2019) 416. https://doi.org/10.1016/j.jallcom.2019.03.066

Liu W, Su Y, Zhang Y, Chen L, Hou H, and Zhao Y, J Magn Alloys 11 (4), (2023) 1408. https://doi.org/10.1016/j.jma.2022.03.018

Jiang M G, Xu C, Yan H, Lu S H, Nakata T, Lao C S, Chen R S, Kamado S, and Han E H, Sci Rep 8 (1), (2018) 16800. https://doi.org/10.1038/s41598-018-35170-4

Zhang L, Wang Q, Liao W, Guo W, Li W, Jiang H, and Ding W, Mater Sci Eng A 689 (2017) 427. https://doi.org/10.1016/j.msea.2017.02.076

Pan H, Qin G, Huang Y, Ren Y, Sha X, Han X, Liu Z Q, Li C, Wu X, Chen H, and He C, Acta Materialia 149 (2018) 350. https://doi.org/10.1016/j.actamat.2018.03.002

Yang Z, Xu H Y, Wang Y, Hu M L, and Ji Z S, Results Phys 12 (2019) 888. https://doi.org/10.1016/j.rinp.2018.12.039

Chen F Y, Ying J M, Wang Y F, Du S Y, Liu Z, and Huang Q, Carbon 96 (2016) 836. https://doi.org/10.1016/j.carbon.2015.10.023

Rashad M, Pan F S, Hu H H, Asif M, Hussain S, and She J, Mater Sci Eng A 630 (2015) 36–44. https://doi.org/10.1016/j.msea.2015.02.002

Acknowledgements

This work was supported by the Natural Science Foundation of Heilongjiang Province (LH2020E083), Scientific Research Starting Foundation of Anhui Polytechnic University of China (2020YQQ036), Research Project of Anhui Polytechnic University of China (Xjky2022025), and the Open Research Fund of Anhui Key Laboratory of High-Performance Non-Ferrous Metal Materials (YSJS-2023-06).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Z., Xu, Hy., Jiang, B. et al. Study of Microstructure and Mechanical Properties of Short Carbon Fibers Reinforced Mg Matrix Composites Fabricated by Hot Extrusion. Trans Indian Inst Met 77, 583–591 (2024). https://doi.org/10.1007/s12666-023-03130-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03130-w