Abstract

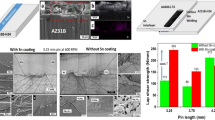

In this investigation, Zn and brass interlayers were used for friction stir welding (FSW) of AA6061-T6 and investigated the weld joint’s microstructure, mechanical, and wear behavior. From microstructural analysis, it was observed that Zn dissolved in Al matrix at FSW process temperature and formed a solid solution. Brass particles distributed uniformly throughout the stir zone (SZ) formed a composite-like structure and intermetallic compounds (IMCs) such as Al2Cu and Al4Cu9. The grain size obtained for weld without interlayer, with Zn and brass interlayer, was 5.6 µm, 3.6 µm, and 2.3 µm, respectively. Hardness in SZ improved with brass interlayer. Marginal strength was enhanced for weld with Zn interlayer, and better strength was obtained with brass interlayer due to reduced softening and formation of IMCs than for weld without interlayer. The surface hardening mechanism reduced the wear rate for weld with brass interlayer.

Similar content being viewed by others

References

Satyanarayana M V N V, and Kumar A, Proc Instit Mech Eng Part L: J Mater: Design Appl (2021). https://doi.org/10.1177/14644207211005790

Mishra R S, and Ma Z Y, Friction Stir Welding Process 50 (2005) 1–78.

Wang T, Zou Y, and Matsuda K, Mater Design 90 (2016) 13–21.

Gharavi F, Amin K, and Yunus R, Integr Med Res 4 (2015) 314.

Chandran R, Kumar S, Santhanam V. Submerged Friction Stir Welding of 6061-T6 Aluminium Alloy under Different Water Heads. 21.

Yi J, Wang G, Li S, Liu Z W, and Gong Y, Trans Nonferrous Met Soc China 29 (2019) 2035.

Khojastehnezhad V M, and Pourasl H H, Trans Nonferrous Met Soc China 28 (2018) 415.

Mokabberi S R, Movahedi M, and Kokabi A H, Mater Sci Eng A 727 (2018) 1.

Wilson A, Lenin A, Periyasamy N, and George L, Mat Res 19 (2016) 817–823.

Alishavandi M, RazmjooKhollari M A, Ebadi M, Alishavandi S, and Kokabi A H, J Alloys Compd 83 (2020) 2. https://doi.org/10.1016/j.jallcom.2020.153964

Zohoor M, Givi M K B, and Salami P, Mater Design 39 (2012) 358–365.

Esmaeili A, Givi M K B, and Rajani H R Z, Mater Sci Eng: A 528 (2011) 7093.

Malopheyev S, Vysotskiy I, Kulitskiy V, Mironov S, and Kaibyshev R, Mater Sci Eng A 662 (2016) 136.

Esmaeili A, Rajani H R Z, Sharbati M, Givi M B, and Shamanian M, Intermetallics 19 (2011) 1711–1719.

Yu P, Wu C S, and Shi L, Acta Mater 20 (2021) 7. https://doi.org/10.1016/j.actamat.2021.116692

Mcnelley T R, Swaminathan S, and Su J Q, Recrystall Mech During Friction Stir Welding/Process Aluminum Alloys 58 (2008) 349–354.

Satyanarayana M V N V, Adepu K, and Chauhan K, Metals Mater Int 27 (2021) 3563.

Palanivel R, Dinaharan I, Laubscher R F, and Davim J P, JMADE 106 (2016) 195.

Mehta K M, and Badheka V J, Wear 426–427 (2019) 975.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nagu, K., Satyanarayana, M., Harikrishna, K. et al. Influence of Interlayer Material on Softening and Wear Behavior of Friction Stir Welded AA6061-T6 alloy. Trans Indian Inst Met 76, 3347–3355 (2023). https://doi.org/10.1007/s12666-023-03007-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03007-y