Abstract

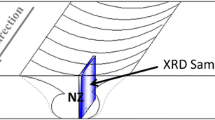

This study investigated the mechanical and corrosion properties of friction stir welded (FSWed) dissimilar AA5083-AA6061 joints by interchanging base material position on the advancing side (AS) and retreating side (RS). The dissimilar joints were also compared with FSWed similar joints of both base materials. The macrostructural images revealed that material mixing patterns in FSWed joints varied greatly depending on where the base metals were positioned. Results indicated that the mechanical and corrosion properties obtained at the stir zone were higher for the given aluminium alloys when placing AA5083-H111 on the AS and AA6061-T6 on the RS. AA5083-AA5083 joint fractured near the centre of the weld, while fractures in all other joints occurred in the heat-affected zone towards the AA6061 side alloy. Corrosion tests showed that dissimilar FSWed joint stir zone regions showed lower corrosion resistance than similar joints. In dissimilar joints, corrosion was initiated from the FSWed borderline and around intermetallic particles precipitated on the AA6061 side.

Similar content being viewed by others

References

Burger G B, Gupta A K, Jeffrey P W, and Lloyd D J, Mater Charact 35 (1995) 23.

Lumley R N, Fundamentals of aluminium metallurgy: Production, processing and applications, Epub ahead of print (2010).

Liu G, Murr L E, Niou C S, McClure J C, and Vega F R, Scr Mater 37 (1997) 355.

Kumar K K, Kumar A, and Satyanarayana M V N V, Proc Inst Mech Eng Part C J Mech Eng Sci 236 (2022) 2901.

Lee W B, Yeon Y M, and Jung S B, Scr Mater 49 (2003) 423.

Park S K, Hong S T, Park J H, Park K Y, Kwon Y J, and Son H J, Sci Technol Weld Join 15 (2010) 331.

Svensson L E, Karlsson L, Larsson H, Karlsson B, Fazzini M, and Karlsson J, Sci Technol Weld Join 5 (2000) 285.

Peel M J, Steuwer A, and Withers P J, Metall Mater Trans A Phys Metall Mater Sci 37 (2006) 2195.

Gungor B, Kaluc E, Taban E, and Sik A, Mater Des 56 (2014) 84.

Zhang C, Huang G, Cao Y, Zhu Y, and Liu Q, J Manuf Process 37 (2019) 470.

Fahimpour V, Sadrnezhaad S K, and Karimzadeh F, Mater Des 39 (2012) 329.

Bagheri Hariri M, Gholami Shiri S, Yaghoubinezhad Y, and Rahvard M M, Mater Des 50 (2013) 620.

Donatus U, Thompson G E, Zhou X, Wang J, Cassell A, and Beamish K, Mater Charact 107 (2015) 85.

Ahmed M M Z, Ataya S, El-Sayed Seleman M M, Ammar H R, and Ahmed E, J Mater Process Technol 242 (2017) 77.

Kumar K K, Kumar A, and Satyanarayana M V N V, Proc Inst Mech Eng Part L J Mater Des Appl 235 (2021) 2692.

Wang B, Lei B B, Zhu J X, Feng Q, Wang L, and Wu D, Mater Des 87 (2015) 593.

Kartsonakis I A, Dragatogiannis D A, Koumoulos E P, Karantonis A, and Charitidis C A, Mater Des 102 (2016) 56.

Choi D H, Ahn B W, Quesnel D J, and Jung S B, Intermetallics 35 (2013) 120.

Malopheyev S, Vysotskiy I, Kulitskiy V, Mironov S, and Kaibyshev R, Mater Sci Eng A 662 (2016) 136.

Goswami R, Spanos G, Pao P S, and Holtz R L, Mater Sci Eng A 527 (2010) 1089.

Blanc C, and Mankowski G, Corros Sci 39 (1997) 949.

Mehdizade M, Eivani A R, and Soltanieh M, J Alloys Compd 838 (2020) 155464

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, K.K., Kumar, A. & Nagu, K. Mechanical and Corrosion Behaviour of Friction Stir Welded 5083–6061 Aluminium Alloy Joints: Effect of Base Material Position. Trans Indian Inst Met 76, 1985–1996 (2023). https://doi.org/10.1007/s12666-023-02906-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02906-4