Abstract

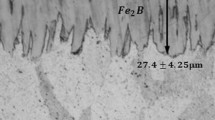

In this study, a plasma nitriding process was applied at 500 ℃ for 3 and 6 h and a pack boriding process was applied at 950 ℃ for 2 and 6 h to specimens of the biomaterial AISI 316L SS. After coating, open circuit potential and potentiodynamic polarization experiments were performed in simulated body fluid. Wear tests were conducted in both dry and simulated body fluid conditions to determine the tribological properties of untreated and coated samples. As observed in the study, both the applied surface treatments improved the structural, tribological, and mechanical properties of 316L stainless steel. According to the results, the best wear performance and hardness values were obtained from 6 h pack boronized samples at 950 °C. In addition, the corrosion resistance values of nitrided and borided samples were closer to each other than to those of untreated samples. The corrosion resistance values of untreated 316L stainless steel samples exceeded those of all coated samples.

Similar content being viewed by others

References

Dincel Ö, Şimşek I, and Özyürek D, Eng Sci Technol an Int J Eng Scı Technol 24 (2021) 35.

Díaz-Guillén J C, Naeem M, Acevedo-Dávila J L, Hdz-García H M, and Mayen J, J Mater Eng Perform 29 (2020) 877.

Kao W H, and Su Y L, Int J Eng Adv Technol 9 (2019) 5826.

Abdullah B, Basir M H, Yusof K, Alias S K, and Idham M F, Int J Eng Adv Technol 9 (2019) 5826.

Fernández-Valdés D, Meneses-Amador A, Ocampo-Ramírez A, López-Liévano A, and Campos-Silva I A, J Mater Eng Perform 30 (2021) 839.

Bahshwan M, Myant C W, Reddyhoff T, Pham M S, Mater Des 196 (2020).

Balusamy T, Sankara Narayanan T S N, Ravichandran K, Song Park I, and Lee M H, Vacuum 97 (2013) 36.

Braccini M, Volpi F, Devos A, Raymond G, Benoit G, and Morin P, Thin Solid Films 551 (2014) 120.

Murtaza G, Hussain S S, Sadiq M, and Zakaullah M, Thin Solid Films 517 (2009) 6777.

Çelik A, Aslan M, Yetim A F, and Bayrak Ö, J Bionic Eng 11 (2014) 303.

Neto J O P, Da Silva R O, Da Silva E H, Moreto J A, and Rossino L S, Mater Res 19 (2016) 1241.

Kim S, Yoon S, Kim J H, and Park S, Metals (Basel) 10 (2020) 1.

Çelik A, Arslan Y, Yetim A F, and Efeoglu I, Kov Mat 45 (2007) 35.

Liang W, Applied Surface Science 211 (2003) 308.

Esfandiari M, and Dong H, Surf Coat Technol 201 (2007) 6189.

Basu A, Majumdar J D, Alphonsa J, Mukherjee S, and Manna I, Mater Lett 62 (2008) 3117.

Yetim A F, Codur M Y, and Yazici M, Mater Lett 158 (2015) 170.

Ping J, Cui X, Pu J, Jiang X, Zhang X, Zhong Y, Surf Topogr Metrol Prop 8 (2020).

Yang W J, Zhang M, Zhao Y H, Shen M L, and Sun C, Surf Coat Technol 298 (2016) 64.

Fernandes F A P, Heck S C, Pereira R G, Lombardi-Neto A, Totten G E, and Casteletti L C, J Achiev Mater Manuf Eng 40 (2010) 175.

Yetim A F, Yazıcı M, J Bionic Eng 11 (2014) 620–629. https://doi.org/10.1016/S1672-6529(14)60073-1.

Alsaran A, Yetim A F, Yildiz F, Alsaran A, and Celik A, Kov Mater 46 (2008) 105.

Hernández-Sánchez E, Velázquez J C, Castrejón-Flores J L, Chino-Ulloa A, and Orozco-Alvarez C, Mater Trans 60 (2019) 156.

García-Léon R A, Martínez-Trinidad J, Campos-Silva I, and Wong-Angel W, DYNA (Colombia) 87 (2020) 34.

Sezgin C T, and Hayat F, J. Mater. Process. Technol 300 (2022) 117421.

Türkmen I, Yalamaç E, and Keddam M, Surf Coatings Technol 377 (2019) 124888.

Jain V, and Sundararajan G, Surf. Coatings Technol 149 (2002) 21.

Yang H, Wu X, Cao G, and Yang Z, Surf Coatings Technol 307 (2016) 506.

Özbek I, Konduk B A, Bindal C, and Ucisik A H, Vacuum 65 (2002) 521.

Kayali Y, Büyüksaǧiş A, Güneş I, and Yalçin Y, Prot Met Phys Chem Surfaces 49 (2013) 348.

García-León R A, Martínez-Trinidad J, Campos-Silva I, Figueroa-López U, and Guevara-Morales A, Tribol Int 163 (2021) 107161.

Campos-Silva I, et al., Surf Coatings Technol 349 (2018) 986.

Çetin M, Günen A, Kalkandelen M and Karakaş, M S. Vacuum 187 (2021).

Resendiz-Calderon C D, Farfan-Cabrera L I, Rodrı´guez-Castro G A, and GallardoHernandez E A, J Mater Eng Perform 30 (2021) 3955.

Kokubo T, and Takadama H, Biomaterials 27 (2006) 2907.

Ahadi Damar Prasetya A D, Muhammad Rifai M, Miyamoto M, Miyamoto H, J Phys Conf 436 (2020) 012113

Stern M, and Geary A L, J Electrochem Soc 104 (1957) 751.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Çakır, M.A., Köseoğlu, B. Investigation of the Structural, Tribological, and Electrochemical Properties of Nitrided and Boronized AISI 316L Stainless Steel. Trans Indian Inst Met 76, 1517–1533 (2023). https://doi.org/10.1007/s12666-022-02853-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02853-6