Abstract

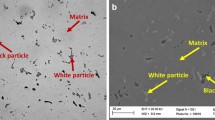

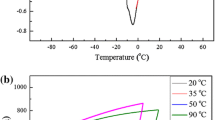

The effect of the hot rolling process on the wear properties of NiTi rods was investigated in this study. 10-mm diameter NiTi rods were rolled down to 5 mm in diameter, corresponding to 75% area reduction. The hot rolling process was conducted at different temperatures changing from 650 to 900 °C. After the hot rolling process was completed, the rods were tested using a pin-on-disk set-up to examine the wear properties. The friction coefficient and the specific wear rate were calculated for each rod. In addition to the wear tests, the macro-hardness of each rod was measured. Furthermore, X-ray, FESEM and EDS analyses were performed to visualize the worn surfaces. The hardness of the as-received sample was 60,5 HRA. It was observed that hardness increased after the hot rolling process. In particular, samples which were hot rolled at 700 °C and 900 °C showed ~ 10% increase in hardness according to as-received sample. The highest volume loss for all sliding distances occurred on the as-received sample. Also, as expected, the second-highest volume loss occurred in the sample rolled at 650 °C, due to the relation between hardness and volume loss. The wear behavior including surface adhesion may be affected by the hardening and the softening mechanisms happening during the hot rolling process.

Similar content being viewed by others

References

Kauffman GB, Mayo I, Chem. Educator, 1 (1997) https://doi.org/10.1007/s00897970111a

Jani JM, Levy M, Subic A, A review of shape memory alloy research, applications and opportunities, Mater. Des. 56 (2014) 1078–1113 https://doi.org/https://doi.org/10.1016/j.matdes.2013.11.084

Lagoudas DC (Ed.), Shape Memory Alloys, Modeling and Engineering Applications, Springer US (2008)

Liu F, Xu JL, Yu DZ, Wang FP & Zhao LC, Wear resistance of micro-arc oxidation coatings on biomedical NiTi alloy, J. Alloy Compd. 487 (2009) 391-394, https://doi.org/https://doi.org/10.1016/j.jallcom.2009.07.145

Khmelevskaya IY, Prokoshkin SD, Dobatkin SV, Tatyanin EV, Trubitsyna B, Studies of composition, deformation temperature and pressure effects on structure formation in severely deformed TiNi-based alloys, Mater. Sci. Eng. A 438–440 (2006) 472– 475 https://doi.org/https://doi.org/10.1016/j.msea.2006.02.088

Mitwally ME, Farag M, Effect of cold work and annealing on the structure and characteristics of NiTi alloy, Mater. Sci. Eng. A 519 (2009) 155–166 https://doi.org/https://doi.org/10.1016/j.msea.2009.04.057

Jiang D, Kyriakides S, Landis CM, Propagation of phase transformation fronts in pseudoelastic NiTi tubes under uniaxial tension, Extreme Mech. Lett. 15 (2017) 113-121 https://doi.org/https://doi.org/10.1016/j.eml.2017.06.006

Zhen-hua L, Cuo-quan X, Xian-hua C, Effects of ECAE process on microstructure and transformation behavior of TiNi shape memory alloy, Mater. Des. 27(4) (2006) 324–328 https://doi.org/https://doi.org/10.1016/j.matdes.2004.10.025

Gall K, Tyber J, Wilkesanders G, Robertson SW, Ritchie RO, Maier HJ, Effect of microstructure on the fatigue of hot-rolled and cold-drawn NiTi shape memory alloys, Mater. Sci. Eng. A 486 (1–2) (2008) 389–403 https://doi.org/https://doi.org/10.1016/j.msea.2007.11.033

Tsuchiya K, Hada Y, Koyano T, Nakajima K, Ohnuma M, Koike T, Todaka Y & Umemoto M, Scr. Mater. 60(9), 749 (2009)

Mehrabi K, Bahmanpour H, Skokuhfar A, Kneissl A, Influence of chemical composition and manufacturing conditions on properties of NiTi shape memory alloys, Mater. Sci. Eng. A 481– 482 (2008) 693–696 https://doi.org/https://doi.org/10.1016/j.msea.2006.12.230

Aksöz S, Microstructural and mechanical investigation of NiTi intermetallics produced by hot deformation technique, Arab. J. Sci. Eng. 42 (2017) 2573–2581 https://doi.org/https://doi.org/10.1007/s13369-017-2567-2

Li P, Karaca H, Cheng Y, Spherical indentation of NiTi-based shape memory alloys, J. Alloy Compd. 651 (2015) 724-730 https://doi.org/https://doi.org/10.1016/j.jallcom.2015.07.280

Khamei AA, Dehghani K, A study on the mechanical behavior and microstructural evolution of Ni60wt%– Ti40wt% (60Nitinol) intermetallic compound during hot deformation, Mater. Chem. Phys. 123 (2010) 269–277 https://doi.org/https://doi.org/10.1016/j.matchemphys.2010.04.010

Hutchings IM, Tribology, friction and wear of engineering materials, Edward Arnold, London (1992)

Glaeser WA, Materials for tribology, Elsevier Science, Amsterdam (1992)

Clayton P, Tribological behavior of a titanium-nickel alloy, Wear 162–164 (1993) 202-210 https://doi.org/https://doi.org/10.1016/0043-1648(93)90502-D

Singh J, Alpas AT, Dry sliding wear mechanisms in a Ti50Ni47Fe3 intermetallic alloy, Wear 181–183 (1995) 302-311 https://doi.org/https://doi.org/10.1016/0043-1648(95)90037-3

Li DY, Wear behaviour of TiNi shape memory alloys, Scripta Materialia 34 (2) (1996) 195-200 https://doi.org/https://doi.org/10.1016/1359-6462(95)00515-3

Abedini M, Ghasemi HM, Nili Ahmadabadi M, Tribological behavior of NiTi alloy in martensitic and austenitic states, Mater. Des. 30 (2009) 4493-4497 https://doi.org/https://doi.org/10.1016/j.matdes.2009.05.031

Liang YN, Li SZ, Jin YB, Jin W, Li S, Wear behavior of a TiNi alloy, Wear 198 (1–2) (1996) 236-241 https://doi.org/https://doi.org/10.1016/0043-1648(96)06989-X

Aksöz S, Wear behavior of hot forged NiTi parts produced by PM technique, Trans. Indian. Inst. Met. 72 (2019) 1949–1957 https://doi.org/https://doi.org/10.1007/s12666-019-01671-7

Mukunda S, Herbert MA, Mukunda PG, Effect of low temperature annealing on the wear properties of Nitinol, Mater. Sci. Eng. 114 (1) (2016) 012119 doi:https://doi.org/10.1088/1757-899X/114/1/012119

Qunfeng Z, A comparative study on the mechanical behaviors of surface-strengthened Nitinol 60 alloy and steel. Trans. Can. Soc. Mech. Eng. 43(4) (2019) 569-578 https://doi.org/https://doi.org/10.1139/tcsme-2018-0235

Kutita T, Matsumoto H, Abe H, Transformation behavior in rolled NiTi, J. Alloys Compd. 381 (2004) 158–161 https://doi.org/https://doi.org/10.1016/j.jallcom.2004.03.108

Li Y, Li JY, Liu M, Ren YY, F Chen, Yao GC & Mei QS, J. Alloys Compd. 653, 156 (2015) https://doi.org/10.1016/j.jallcom.2015.09.056

Chrobak D, Stróż D, Scr. Mater. 52 (2005) 757 https://doi.org/10.1016/j.scriptamat.2004.12.010

Ahadi A, Rezaei E, Karimi TA, Effect of hot rolling on microstructure and transformation cycling behaviour of equiatomic NiTi shape memory alloy, Mater. Sci. Tech. 28 (6) (2012) 727-732 https://doi.org/https://doi.org/10.1179/1743284711Y.0000000130

Sadrnezhaad SK, Raz SB, Effect of Microstructure on Rolling Behavior of NiTi Memory Alloy, Mater. Manuf. Process 23 (2008) 646-650 https://doi.org/https://doi.org/10.1179/1743284711Y.0000000130

London B, Fin J, Pelton A, Fuller C, Mahoney M, Friction stir processing of Nitinol K.V. Jata, M.W. Mahoney, R.S. Mishra, T.J. Lienert (Eds.). Friction Stir Welding and Processing III, TMS, Warrendale, PA, 67-74 (2005)

Lukina E, Kollerov M, Meswania J, Panin, P, Khon A & Blunn G, Mater. Today Proc. 4 (2017) 4675 https://doi.org/10.1016/j.matpr.2017.04.050

Rui Y, Wei MA, Chao W, Wang TM, Wang QH, Trans. Nonferr. Metal. Soc. 31 (2021). 967. https://doi.org/10.1016/S1003-6326(21)65553-X

[Aksöz S, Kaner S, Kaplan Y, Tribological and aging behavior of hybrid Al 7075 composite reinforced with B4C, SiC, and TiB2, Sci. Sinter. 53 (2021) 311-321 https://doi.org/https://doi.org/10.2298/SOS2103311A

Hornbuckle BC, Xiao XY, Noebe RD, Martens R, Weaver ML, & Thompson GB, Mater. Sci. Eng. A 639 (2015) 336 https://doi.org/10.1016/j.msea.2015.04.079

Ozyurek D, Ciftci I, An investigation into the wear behaviour of TiB2 particle reinforced aluminium composites produced by mechanical alloying, Sci. Eng. Compos. Mater. 18 (1-2) (2011) 5-12 https://doi.org/https://doi.org/10.1515/secm.2011.003

Shu X, Lu S, Wang K, Li G, Optimization of hot working parameters of as-forged Nitinol 60 shape memory alloy using processing maps, Met. Mater. Int. 21 (4) (2015) 726-733 https://doi.org/https://doi.org/10.1007/s12540-015-4485-8

Karolus M, Panek J, Nanostructured Ni–Ti alloys obtained by mechanical synthesis and heat treatment, J. Alloys Compd. 658 (2016) 709-715 https://doi.org/https://doi.org/10.1016/j.jallcom.2015.10.286

Chu CL, Chung JC, Chu PK, Effects of heat treatment on characteristics of porous Ni-rich NiTi SMA prepared by SHS technique, Trans. Nonferr. Metal. Soc., 16 (1) (2006) 49-53 https://doi.org/https://doi.org/10.1016/S1003-6326(06)60009-5

Suresh KS, Kim DI, Bhaumik SK, Suwas S, Interrelation of grain boundary microstructure and texture in a hot rolled Ni-rich NiTi alloy, Scr. Mater. 66 (8) (2012) 602-605 https://doi.org/https://doi.org/10.1016/j.scriptamat.2012.01.016

Gu YW, Tay BY, Lim CS, Yong MS, Characterization of bioactive surface oxidation layer on NiTi alloy, Appl. Surf. Sci. 252 (5) (2005) 2038-2049 https://doi.org/https://doi.org/10.1016/j.apsusc.2005.03.207

Ahadi A, Sun Q, Acta Mater. 90 (2015) 272 https://doi.org/10.1016/j.actamat.2015.02.024

Zhao C, Liang H, Luo S, Yang J, Wang Z. The effect of energy input on reaction, phase transition and shape memory effect of NiTi alloy by selective laser melting, J. Alloys Compd. 817, (2020) 153288 https://doi.org/https://doi.org/10.1016/j.jallcom.2019.153288

Funding

The funding was provided by The Scientific and Technological Research Council of TÜRKİYE (TÜBİTAK), Grant No 1512 (Sinan Aksoz).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aksöz, S., Arslan, R., Kardeş, N. et al. The Effect of Hot Rolling Temperature on the Wear Properties of NiTi Rods. Trans Indian Inst Met 76, 951–960 (2023). https://doi.org/10.1007/s12666-022-02801-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02801-4