Abstract

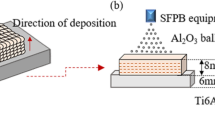

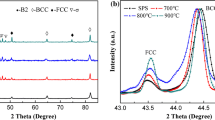

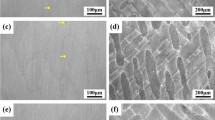

Hypereutectic Al-20Si alloy is widely used in automotive, aerospace, and other fields because of its lightweight, high thermal conductivity, good wear, and corrosion resistance. In this study, the effects of powder characteristics and aging treatment on the corrosion behavior of Al-20Si alloy prepared by selective laser melting (SLM) were systematically investigated. The results showed that the Al-20Si alloy synthesized with ball-milled powders (BMPs) presents a large number of pores and coarse Si particles, while the Al-20Si alloy prepared with atomized powders (APs) shows a uniform and dense microstructure with relatively small grain sizes. The Si phase was continuously precipitated and coarsened with increased aging temperature. Moreover, the fibrous eutectic Si prepared with APs was transformed to a particulate shape. The alloy manufactured with APs shows excellent corrosion resistance. Meanwhile, with the increase of aging treatment temperature, the corrosion resistance of the alloy was significantly reduced.

Similar content being viewed by others

References

Aversa A, Lorusso M, Trevisan F, Ambrosio E P, Calignano F, Manfredi D, Biamino S, Fino P, Lombardi M and Pavese M, Met 7 (2017) 68.

Li X P, O’Donnell K M and Sercombe T B, Addit Manuf 10 (2016) 10.

Deirmina F and Pellizzari M, J Alloys Compd 709 (2017) 742.

Liu Y J, Liu Z, Jiang Y, Wang G W, Yang Y and Zhang L C, J Alloys Compd 735 (2018) 1414.

Gao P H, Li J P, Yang Z, Guo Y C and Wang Y R, Mater Sci Forum 765 (2013) 639.

Revilla R I, Liang J, Godet S and De Graeve I, J Electrochem Soc 164 (2016) C27.

Cabrini M, Lorenzi S, Pastore T, Pellegrini S, Pavese M, Fino P, Ambrosio E P, Calignano F and Manfredi D, Surf Interf Anal 48 (2016) 818.

Han B, Chen Y B, Tao W, Li H and Li L Q, Mater Des 135 (2017) 353.

Zhang Y, Guo Y Q, Chen Y, Cao Y B, Qi H B and Yang S P, Mater (Basel) 13 (2019) 126.

Ma P, Wei Z J, Jia Y D, Zou C M, Scudino S, Prashanth K G, Yu Z S, Yang S L, Li C G and Eckert J, J Alloys Compd 688 (2016) 88.

Acharya M and Mandal A, Met Mater Int 27 (2019) 1578.

Ratnakumar K and Srinivasa Rao K, Trans Indian Inst Met 61 (2012) 283.

Trueba M and Trasatti S P, Mater Chem Phys 121 (2010) 523.

Kimura T and Nakamoto T, Mater Des 89 (2016) 1294.

Rao H, Giet S, Yang K, Wu X H and Davies C H J, Mater Des 109 (2016) 334.

Liu Y, Yang Y Q, Mai S Z, Wang D and Song C H, Mater Des 87 (2015) 797.

Kang N, Coddet P, Chen C, Wang Y, Liao H L and Coddet C, Mater Des 99 (2016) 120.

Yang Y, Chen Y, Zhang J X, Gu X H, Qin P, Dai N W, Li X P, Kruth J P and Zhang L C, Mater Des 146 (2018) 239.

Zhang S K, Ma P, Jia Y D, Yu Z S, Sokkalingam R, Shi X R, Ji P C, Eckert J and Prashanth K G, Mater 12 (2019) 2126.

Rathod H J, Nagaraju T, Prashanth K G and Ramamurty U, Tribol Int 137 (2019) 94.

Li R D, Shi Y S, Wang Z G, Wang L, Liu J H and Jiang W, Appl Surf Sci 256 (2010) 4350.

Chen Y M, Wang L Z, Feng Z X and Zhang W N, Prog Nat Sci 31 (2021) 714.

Yaokawa J, Oh-ishi K, Dong S X, Hara M, Masutani T and Sato H, Mater Charact 182 (2021) 11533.

Xu C L and Jiang Q C, Mater Sci Eng, A 437 (2006) 451.

Flemings M C, Solidification Processing, McGraw-Hill, New York (1974) p 24.

Gremaud M, Allen D R, Rappaz M and Perepezko J H, Acta Mater 44 (1996) 2669.

Pei Y T, Hosson J T M D, Acta Mater 48 (2000) 2617.

Prashanth K G, Scudino S, Klauss H J, Surreddi K B, Löber L, Wang Z, Chaubey A K, Kühn U and Eckert J, Mater Sci Eng, A 590 (2014) 153.

Cooke A and Slotwinski J A, Natl Inst Stand Technol IR 7873.

Lumley R N, Fundamentals of Aluminium Metallurgy, Woodhead Publisher, England (2018) p 47.

Aboulkhair N T, Simonelli M, Parry L, Ashcroft I, Tuck C and Hague R, Prog Mater Sci 106 (2019) 100578.

Kimura T, Nakamoto T, Mizuno M and Araki H, Mater Sci Eng, A 682 (2017) 593.

Weingarten C, Buchbinder D, Pirch N, Meiners W, Wissenbach K and Poprawe R, J Mater Process Technol 221 (2015) 112.

Hanza S S, Vrsalović L, Štic L and Liverić L, Eng Rev 41 (2021) 1.

Ahlatci H, Mater Lett 62 (2008) 3490.

Dai N W, Zhang L C, Zhang J X, Zhang X, Ni Q Z, Chen Y, Wu M L and Yang C, Corros Sci 111 (2016) 703.

Jorcin J B, Orazem M E, Pébère N, and Tribollet B, Electrochim Acta 51 (2006) 1473.

Wu J, Zhang S D, Sun W H, and Wang J Q, Surf Coat Technol 335 (2018) 205.

Pang H T, Li X Q and Wang J R, Mater Prot 11 (2002) 38.

Santos E C, Shiomi M, Osakada K and Laoui T, Mach Tools Manuf 46 (2006) 1459.

Laurino A, Andrieu E, Harouard J-P, Lacaze J, Lafont M-C, Odemer G and Blanc C, Electrochem Soc 160 (2013) C569.

Liu W, Li M C, Luo Q, Fan H Q, Zhang J Y, Lu H S, Chou K C, Wang X L, and Li Q, Corros Sci 104 (2016) 217.

Liao C M and Wei R P, Electrochim Acta 45 (1999) 881.

Andreatta F, Terryn H and Wit J H W D, Corros Sci 45 (2003) 1733.

Nesˇić S, Corros Sci 49 (2007) 4308.

Sekhar A P, Mandal A B and Das D, J Mate Res Technol 9 (2020) 1005.

Huang X, Yu L and Dong Y, Corros Sci 182 (2021) 109256.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, P., Zhang, Z., Ke, Y. et al. Effect of Powder Characteristic and Aging Treatment on the Corrosion Behavior of Selective Laser Melted Al-20Si Alloy. Trans Indian Inst Met 75, 2367–2377 (2022). https://doi.org/10.1007/s12666-022-02548-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02548-y