Abstract

Objectives

In this study, an effort is made to predict the optimized parameter combination in double-pulse MIG welding of stainless steel (SS 304H)—Inconel 617 (IN 617)

Methods

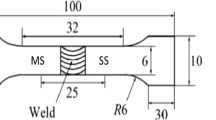

Butt joints were made between IN 617 and SS 304H using ER308 H filler wire having a diameter of 1.2 mm. Welding trials were done based on Taguchi L9 array with wire feed speed, frequency and amplitude as input parameters. The weld quality was evaluated by measuring bead width, depth of penetration, tensile strength and impact strength. The optimized parameter combination was identified using two multiobjective techniques, viz. grey relational analysis (GRA) and technique for order of preference by similarity to ideal solution (TOPSIS).

Conclusions

GRA and TOPSIS gave similar results with regard to optimized parameter combinations. Analysis of variance (ANOVA) was applied to find the most influential parameter on weld quality. From ANOVA, the amplitude was identified as the most influential parameter. The presence of M23C6 and M6C precipitates in the fusion zone helped in strengthening the weld. At higher wire feed speed, lack of side wall fusion was noted on the SS 304H side of the weld.

Similar content being viewed by others

References

Saito N, Komai N, Sumiyoshi Y, Takei Y, Tokairin T, and Kitamura M, Mitsubishi Heavy Ind Tech Rev 52 (2015) 27.

Dak G, and Pandey C, J. Manuf. Process., 58 377–406 (2020). doi: https://doi.org/10.1016/j.jmapro.2020.08.019.

[Pavan A V H, Ravibharath R, and Singh K, Mater. Sci. Forum. 830–831 199–202 (2015). doi: https://doi.org/10.4028/www.scientific.net/MSF.830-831.199.

Sahu A K, and Bag S, Metall Mater Trans A Phys Metall Mater Sci 51 (2020) 2192. doi: https://doi.org/10.1007/s11661-020-05705-4.

Aghayar Y, Naghashzadeh A R, and Atapour M, Vacuum 184 (2021) 109970. doi: https://doi.org/10.1016/j.vacuum.2020.109970

Zhang Y, Jing H, Xu L, Han Y, Zhao L, and Xiao B, Mater. Charact. 139 279–292 (2018). doi: https://doi.org/10.1016/j.matchar.2018.03.012.

Devendranath Ramkumar K, Chandrasekhar A, Srivastava A, Preyas H, Chandra S, Dev S, and Arivazhagan N, J Manuf Process 24 (2016) 46. doi: https://doi.org/10.1016/j.jmapro.2016.07.006.

Park J H, Cheepu M, and Cho S M, Metals (Basel) 10 (2020), doi: https://doi.org/10.3390/met10030365.

Kourdani A, and Derakhshandeh-Haghighi R, Metall Mater Trans A Phys Metall Mater Sci 49 (2018) 1231. doi: https://doi.org/10.1007/s11661-018-4469-7.

Pavan A H V, Vikrant K S N, Ravibharath R, Singh K, Mater. Sci. Eng. A 642 32–41 (2015). doi: https://doi.org/10.1016/j.msea.2015.06.065.

Ahmad H W, Hwang J H, Lee J H, and Bae D H, Metals (Basel) 8 (2018). doi: https://doi.org/10.3390/met8010021.

Tumer M, Karahan T, and Mert T, Evaluation of Microstructural and Mechanical Properties of Dissimilar Inconel 625 Nickel Alloy—UNS S32205 Duplex Stainless Steel Weldment Using MIG Welding, (2020) p 21.

Sudhagar S, Sakthivel M, Mathew P J, and Daniel S A A, Measurement 108 1–8 (2017). doi: https://doi.org/10.1016/j.measurement.2017.05.023.

Kesavan J, Velmurugan C, Senthilkumar V, and Dinesh S, Mater Today Proc (2020). doi: https://doi.org/10.1016/j.matpr.2020.11.616.

Deepan Bharathi Kannan T, Shegokar A R, Sathiya P, and Ramesh T, Mater Today Proc 4 (2017) 8883. doi: https://doi.org/10.1016/j.matpr.2017.07.239.

Sivakumar J, Vasudevan M, and Korra N N, Trans. Indian Inst. Met. 73 555–569 (2020). doi: https://doi.org/10.1007/s12666-020-01876-1.

Srinivasan L, Mohammad Chand K, Deepan Bharathi Kannan T, Sathiya P, and Biju S, Trans Indian Inst Met 71 (2018) 373. doi: https://doi.org/10.1007/s12666-017-1166-y.

QW 461.3, Section IX, ASME Boiler and Pressure Vessel Code (2010) p. 153.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arivarasan, J., Kannan, T.D.B. Optimization of Process Parameters in Double-Pulse MIG Welding of Inconel 617-SS 304 H. Trans Indian Inst Met 75, 1293–1307 (2022). https://doi.org/10.1007/s12666-021-02483-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02483-4