Abstract

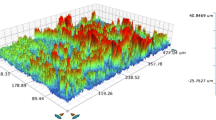

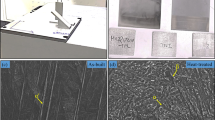

The current research is devoted to assessing the bioactivity of different surface-treated Ti–6Al–7Nb samples by assessing the formation of calcium phosphate compounds. Three surface modification processes were performed, followed by dynamic immersion in Hanks’ solution for 32 days at the body temperature. The first set of samples was treated by oxidation at 400, 500 and 600 °C for 1 and 2 h to study the optimum oxidation condition. The second group was alkaline-treated using different concentrations of NaOH and aged at 400 and 600 °C. The third group was treated by a strong acidic solution (H2SO4 and HCl) for 0.5–1.5 h and then aged at 400 and 600 °C. Growth of calcium phosphate compounds (CPC) was generally enhanced with the formation of NaCl dendritic network, as it worked as an adhesive layer. Formation of the oxide layer enhanced the affinity to precipitate CPC, and the optimum oxidation condition was 500 °C for 1 h; higher temperatures and/or longer periods tended to dissolve back the built-up regions. Alkaline treatment prior to aging resulted in the formation of uneven build-up of CPC. Increasing the aging temperature at constant concentration encouraged the formation of dendritic structure (NaCl) and increased the width of the branches resulting in increased precipitation of CPC. Alkaline treatment and aging for 1 h using 2 M solution at 400 °C was the best condition to grow dense flower-shaped precipitates of CPC. However, increasing the aging temperature to 600 °C using the same solution resulted in the formation of TiO2 which created more sites for CPC growth, and hence more homogenously distributed particles with less concentration were obtained. In case of the acidic treatment, increasing the immersion time in the acidic solution beyond 1 h dissolved back NaCl built-up regions and thus decreased the surface ability to grow CPC. A palette of colors was obtained on the samples’ surfaces after the different treatments, which was beneficial in improving the esthetics of implant components and implant prosthesis substructures.

Similar content being viewed by others

References

Lutjering G, and Williams J C. Titanium, 2nd ed., Springer, Berlin (2007).

Leyens C, and Peters M (eds), Titanium and Titanium Alloys, fundamentals and applications, Wiley-VCH Verlag GmbH, Weinheim, Germany (2003).

Divi S, and Grauman J, in Environmental Degradation of Advanced and Traditional Engineering Materials, (eds) Hihara L, Adler R, and Latanision, CRC Press, Boca Raton (2014).

Reda R, Nofal A, and Hussein A, Metallogr Microstruct Anal 2 (2013) 388.

El-Hadad S, Nady M, and Khalifa W, Can Metall Q 57 (2018) 186.

El-Hadad S, Mhaede M, and Ibrahiem K M, Int J Cast Met Res 29 (2015) 243.

HinTeoh S, Agrawal M, de Bruijn J D, and Tabata Y, Engineering Materials for Biomedical Applications. Biomaterials Engineering and Processing Series, Mainland Press, Singapore (2004).

Singh M, Mater Sci Eng C 102 (2019) 844.

Park J, Lakes R S, Biomaterials, An introduction, 3rd ed., Springer Science & Business Media, Technology & Engineering (2007).

Okazakia Y, and Gotohb E, Biomaterials 26 (2005) 11.

Semlitsch M, Staub F, and Weber H, Biomed Tech 30 (1985) 334.

Hanawa T, Sci Technol Adv Mater 13 (2012) 064102.

ASTM F1295-11 Standard Specification for Wrought Titanium-6Al-7Nb Alloy for Surgical Implant Applications (UNS R56700).

Fityan A, El-Hadad S, and Khalifa W, in Ceramic Transactions series, Processing, Properties, and Design of Advanced Ceramics and Composites II, (eds) Bansal N P, Castro H R, Jenkins M, Bandyopadhyay A, Bose S, Bhalla A S, Singh J P, Mahmoud M, Pickrell G, Johnson S, and Göçmez H, Wiley Publisher, vol. 261 (2017), p. 169. ISBN: 978-1-119-42380-5.

Boehlert C J, Cowen C J, Quast J P, Akahori T, and Niinomi M, Mater Sci Eng C 28 (2008) 323.

Zaki A, El-Hadad S, and Khalifa W, Assessment of Tribological Properties of Cast and Forged Ti-6Al-7Nb and Ti-6Al-4V Alloys for Dental Applications, TMS 2016: 145 Annual Meeting & Exhibition: Supplemental Proceedings. Phase Transformations and Microstructural Evolution Session (2016), p. 693.

Dong H, Bloyce A, Morton P H, and Bell T, Surf Eng 13 (1997) 402.

Zaki A, El-Hadad S, and Khalifa W, Mater Sci Forum 909 (2017) 199.

Aniołek K, Surf Eng (2020), https://doi.org/10.1080/02670844.2020.1711631.

El-Hadad S, Safwat E, and Sharaf N, Mater Sci Eng C 93 (2018) 987.

Abdel-salam M, Khalifa W, and El-Hadad S, in Ceramic Transactions series, Processing, Properties, and Design of Advanced Ceramics and Composites II, (eds) Bansal N P, Castro H R, Jenkins M, Bandyopadhyay A, Bose S, Bhalla A S, Singh J P, Mahmoud M, Pickrell G, Johnson S, and Göçmez H, Wiley Publisher, vol. 261 (2017), p. 153. ISBN: 978-1-119-42380-5.

Abdel-salam M, Khalifa W, and El-Hadad S, Mater Sci Eng C 104 (2019) 109974.

Liu X, Chu P K, and Ding C, Mater Sci Eng R 47 (2004) 49.

Wang G, Li J, Lv K, Zhang W, Ding X, Yang G, Liu X, and Jiang X, Sci Rep 6 (2016) 31769.

Leyens C, and Gedanitz H, Scr Mater 41 (1999) 901.

Zhang S, and Zhao D (eds), Aerospace Materials Handbook. Advances in Materials Science and Engineering Series, CRC Press (2012), ISBN 9781439873298.

Kim H M, Miyaji F, Kokubo T, and Nakamura T, J Biomed Mater Res 32 (1996) 409.

Jemat A, Ghazali M J, Razali M, and Otsuka Y, Surface Modifications and Their Effects on Titanium Dental Implants, vol. 2015, Article ID 791725.

Yang B, Zhou X, Yu H, Wu Y, Bao C, Man Y, Cheng L, and Sun Y, West China J Stomatol 37 (2019) 124.

Diamanti M V, Codeluppi S, Cordioli A, and Pedeferri M P, J Exp Nanosci 4 (2009) 365.

Acknowledgements

The authors would like to acknowledge the financial support from the “Science and Technology Development Fund, Grant No. 5540.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-Hadad, S., Ghaith, M., Yassin, A. et al. Optimizing the Surface Treatment Processes to Enhance the Bioactivity of Ti–6Al–7Nb Alloy. Trans Indian Inst Met 73, 2727–2738 (2020). https://doi.org/10.1007/s12666-020-02076-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02076-7