Abstract

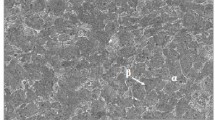

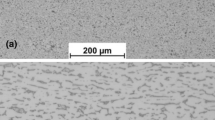

Electron beam welding combined with temperature field simulation has been carried out on the Ti70 titanium alloy, and the microstructural evolution and mechanical property of welded joint are systematically investigated. Results show that the simulated molten pool is well consistent with the experimental weld morphology. Microstructure analysis demonstrates that the upper part of fusion zone (FZ) consists of columnar crystals. The middle part of FZ is composed of equiaxed grains and β columnar crystals, and the fine martensite α′ presents the interlaced distribution within grains. The heat-affected zone is composed of transformed phase β structure (βt), martensite α′ and residual α phase. The microhardness in FZ is the highest. The maximum tensile strength of welded joint reaches 754.5 MPa, which is close to that of base metal. There are many equiaxed dimples on the joint fracture surface, and it dominantly presents the characteristic of ductile fracture.

Similar content being viewed by others

References

Yan S K, Song G L, Li Z X, Wang H N, Zheng D J, Cao F Y, Horynova M, Dargusch M S, and Zhou L, J Mater Sci Technol 34 (2018) 421.

Junaid M, Baig M N, Shamir M, Khan F N, Rehman K, and Haider J, J Mater Process Technol 242 (2017) 24.

Junaid M, Khan F N, Bakhsh N, Baig M N, and Rahman K, Mater Des 139 (2018) 198.

Wang S Q, Liu J H, and Chen D L, Mater Sci Eng A 584 (2018) 47.

Wang S Q, Li W Y, Jing K, Zhang X Y, and Chen D L, Mater Sci Eng A 697 (2017) 224.

Balasubramanian T S, Balakrishnan M, Balasubramanian V, and Muthu Manickam M A, Trans Nonferrous Met Soc China 21 (2011) 1253.

Gao F Y, Gao Q, Jiang P, and Liao Z Q, Int J Light Mater Manuf 1 (2018) 265.

Kar J, Chakrabarti D, Roy S K, and Roy G G, J Mater Process Technol 266 (2019) 165.

Wang S G, and Wu X Q, Mater Des 36 (2012) 663.

Adamus K, Kucharczyk Z, Wojsyk K, and Krzysztof K, Comput Mater Sci 77 (2013) 286.

Luo M, Hu R, Liu T, Wu B, and Pang S, Int J Heat Mass Transf 127 (2018) 1313.

Gao F Y, Gao Q, Jiang P, Liu Z Y, and Liao Z Q, Vacuum 146 (2017) 136.

Chowdhury S, Yadaiah N, Khan S M, Ozah R, Das B, and Muralidhar M, Mater Today Proc 5 (2018) 4811.

Chen Y, Wang S G, Wang Z Y, and Zhao L, Mater Res Express 5 (2018) 066537.

Rai R, Burgardt P, Milewski J O, Lienert T J, and DebRoy T, J Phys D Appl Phys 42 (2009) 1.

Ahmed T, and Rack H J, Mater Sci Eng A 243 (1998) 206.

Lin Prakash P S, Rajak B, Panda S K, Roy G G, Jha M N, and Mascarenhas M, Mater Today Proc 2 (2017) 908.

Malinov S, Sha W, Guo Z, Tang C C, and Long A E, Mater Charact 48 (2001) 279.

Hsieh C T, Shiue R K, Huang R T, and Tsay L W, Mater Sci Eng A 653 (2016) 139.

Liu H, Nakata K, Yamamoto N, and Liao J, Sci Technol Weld Join 16 (2011) 581.

Zeng L, and Bieler T R, Mater Sci Eng A 392 (2005) 403.

Karpagaraj A, Sivashanmugam N, and Sankaranarayanasamy K, Mater Sci Eng A 640 (2015) 180.

Wang G Q, Chen Z Y, Liu J W, Wang Q J, and Yang R, J Mater Sci Technol 34 (2018) 570.

Acknowledgements

This project is supported by the Foundation of College Innovation Center in NUAA (No. 2020CX00610) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), which are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, D., Wang, S. & Zhang, W. Numerical Simulation and Experimental Investigation on Ti70 Titanium Alloy Electron-Beam-Welded Joint. Trans Indian Inst Met 73, 2361–2369 (2020). https://doi.org/10.1007/s12666-020-02040-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02040-5