Abstract

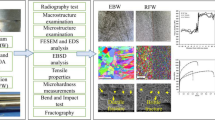

In the current work, rotary friction welding of electron beam melted (EBM) γ-TiAl alloy Ti–48Al–2Cr–2Nb (at%) was investigated. Welding experiments were conducted using cylindrical bars of 12 mm diameter and 70 mm height in as-fabricated and heat treated (1275 °C/2 h/furnace cooling) conditions. No cracking problems were encountered during friction welding of as-fabricated EBM samples. However, in as-welded condition, the joints did not perform well in tensile tests and failures were observed to invariably occur at the weld interface. Friction welded joints produced in heat treated EBM samples were also found to suffer from the same problem. In both the cases, the weld region showed fine, fully lamellar γ + α2 microstructure and relatively high hardness. In order to overcome the problem, a post-weld heat treatment (PWHT) was carried out at 1275 °C/2 h/furnace cooling. After the PWHT, the weld region showed a more desirable duplex microstructure consisting of equiaxed primary γ and relatively coarser lamellar γ + α2. The PWHTed joints showed satisfactory tensile properties, and no failures were observed at the weld interface.

Similar content being viewed by others

References

Djanarthany S, Viala J C, Bouix J, Mater Chem Phys 72 (2001) 301.

Srivastava D, Chang I T H, Loretto M H, Mater Des 21 (2000) 425.

Liu W, DuPont J N, Metall Mater Trans A 35a (2004) 1133.

Qu H P and Wang H M, Mater Sci Eng A 466 (2007) 187.

Sharman A R C, Hughes J I, Ridgway K, Intermetallics, 93 (2018) 89.

Löber L, Schimansky F P, Kühn U, Pyczak F, Eckert J, J Mater Process Techno 214 (2014) 1852.

Gussone J, Hagedorn Y C, Gherekhloo H, Kasperovich G, Merzouk T, Hausmann J, Intermetallics 66 (2015) 133.

Thomas M, Malot T, Aubry P, Colin C, Vilaro T, Bertrand P, Mater High Temp 33 (2016) 571.

Murr L E, Gaytan S M, Ceylan A, Martinez E, Martinez J L, Hernandez D H, Machado B I, Ramirez D A, Medina F, Collins S, Wicker R B Acta Mater 58 (2010) 1887.

Biamino S, Penna A, Ackelid U, Sabbadini S, Tassa O, Fino P, Pavese M, Gennaro P, Badini C, Intermetallics 19 (2011) 776.

Tang H P, Yang G Y, Jia W P, He W W, Lu S L, Qian M, Mater Sci Eng A 636 (2015) 103.

Baudana G, Biamino S, Klöden B, Kirchner A, Weißgärber T, Kieback B, Pavese M, Ugues D, Fino P, Badini C, Intermetallics 73 (2016) 43.

Mohammad A, Alahmari A M, Mohammed M K, Renganayagalu R K, Moiduddin K Materials 10 (2017) 211.

Todai M, Nakano T, Liu T, Yasuda H Y, Hagihara K, Cho K, Ueda M, Takeyama M, Addit Manuf 13 (2017) 61.

Gibson I, Stucker B, Rosen D W, Additive Manufacturing Technologies, Springer, New York (2010) p 136.

Hernandez J, Murr L E, Gaytan S M, Martinez E, Medina F, Wicker R B, Metallogr Microstruct Anal. 1 (2012)14.

Baeslack W A, McQuay P A, Lee D S, Fletcher E D, Mater Charact 31 (1993) 197.

Su M, Lang Z, Zheng L, Yan J, Guan K, Zhang H, J Mater Res. 15 (2012) 455.

Cao J, Qi J, Song X, Feng J, Materials, 7 (2014) 4930.

David S A, Horton J A, Goodwin G M, Phillips D H, Reed R W, Weld J Res Suppl (1990) 133s.

Baeslack W A, Joining of Gamma Titanium Aluminides (2003) report (# AFRL-ML-WP-TR-2003-4036).

Ventzke V, Bohm K H, Kocak M, Riekehr S, Horstmann M, Merhof P, Watzlaw M, J Mater Sci Technol 37 (2006) 649.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sankar, G.S., Karthik, G.M., Mohammad, A. et al. Friction Welding of Electron Beam Melted γ-TiAl Alloy Ti–48Al–2Cr–2Nb. Trans Indian Inst Met 72, 35–46 (2019). https://doi.org/10.1007/s12666-018-1458-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1458-x