Abstract

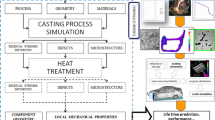

Metal casting is a multi-physics process involving many physical phenomena like fluid flow, phase transformation, heat transfer, microstructure evolution, defect formation and thermal stresses. Virtual casting based on process modeling and computer simulation of the above phenomena enables foundry engineers to reduce physical trials, and optimize various process parameters to achieve the desired quality and yield. A multi-disciplinary team of researchers from IIT Bombay and CSIR-NIIST combined their work in casting design and simulation, respectively, and teamed up with 3D Foundry Tech to create an integrated software package called AutoCAST FLOW+. Foundry engineers are able to visualize mold filling, temperature profiles during casting solidification and cooling curves; predict related defects like air blow hole, cold shut, shrinkage porosity and hard zones; and optimize the feeding and gating design. Two industrial case studies demonstrating its successful application for quality improvement are presented. The software has been implemented in several engineering institutes, raising the awareness and interest among students as well as teachers in metal casting field. These efforts are expected to lead to indigenous capability in casting simulation technology suitable for the local requirements.

Similar content being viewed by others

References

Lewis R W, and Ravichandran K, Int J Numer Methods Eng 47 (2000).

Bounds S, Moran G, Pericleous K, Cross M, and Croft T N, Metall Mater Trans 31 (2000).

Seetharamu K, ParaGasam R, Qadir G A, Zainal Z A, Prasad B S, and Sundararajan T, Sadhana 26 (2001).

Ou S, and Beckermann C, in Simulation of Dimensional Changes in Steel Casting. Chicago, Proceedings of the 57th SFSA Technical and Operating Conference (2003).

Hamilton R W, See D, Butler S and Lee P D, Mater Sci Eng A343 (2003).

Huat N C, Hassan S, Subudin S, and Ariffin S, Defect Analysis of Investment Casting Using Computer Simulation. Johor, International Conference on Information and Communication Technology (2005).

Kim K H, Hwang J H, Oh J S, Lee D H, Kim I H, and Yoon Y C, in Prediction of Shrinkage Defect in Steel Casting For Marine Engine Cylinder Cover by Numerical Analysis. Harrogate, Proceedings of 67th World Foundry Congress (2006).

Brooks B E, Beckermann C, and Richards V L, Int J Cast Metals Res 20 (2007).

Ravi B, and Joshi D, Indian Foundry J 53 (2007).

Kermanpur A, Mahmoudi S, and Hajipour A, J Mater Process Technol 206 (2008).

Hai-dong Z, Yan-fei B, Xiao-xian O, and Pu-yun D, Trans Nonferrous Metall Soc 20 (2010).

Zhanli G, Young-Hoon Y, Shuya K and Mook Y J, Simulation of Shrinkage Defect Formation in EXhaust Manifold. Korea, The 8th Pacific Rim International Conference on Modeling of Casting and Solidification (2010).

Sun Y, Luo J, Mi GF, and Lin X, Mater Design 32 (2011).

Sturm J and Busch G, in Cast Iron - A Predictable Material. Hangzhou, Proceedings of 69th World Foundry Congress (2011).

Stetina J, Klimes L, Mauder T and Kavicka F, Mater Technol 46 (2012).

Reilly C, Green N R, and Jolly M R, Appl Math Model 37 (2013).

Sistaninia M, Drezet J M, Phillion A B, and Rappaz M, J Miner Metals Mater Soc 65 (2013).

Tavakoli R, Int J Adv Manuf Technol 74 (2014).

Savithri S, Roschen S, Jacob E, Chourasia V, Sivakumar Y V M, and Lanka B, Indian Foundry J 60 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravi, B., Sivaraman, S., Sasikumar, R. et al. Indigenous Development and Industrial Application of Metal Casting Simulation Software. Trans Indian Inst Met 68, 1227–1233 (2015). https://doi.org/10.1007/s12666-015-0710-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0710-x