Abstract

Some villages and bridges are located on the ground surface of the working district no. 7 in the Wanglou Coal Mine. If longwall mining is adopted, the maximum deformation of the ground surface will exceed the safety value. Strip mining is employed for the working district no. 7 which is widely used to reduce surface subsidence and the consequent damage of buildings on the ground surface. To ensure the safety of coal pillars and improve the recovery coefficient, theoretical analysis and numerical simulation (FLAC 3D) were adopted to determine the coal pillar and mining widths and to discuss the coal pillar stress distribution and surface subsidence for different mining scenarios. The results revealed that the width of coal pillars should be larger than 162 m, and the optimized mining width varies from 150 to 260 m. As the coal seam is exploited, vertical stress is mainly applied on the coal pillar, inducing stress changes on its ribs. The coefficient of mining-induced stress varies from 2.02 to 2.62 for different mining scenarios. The maximum surface subsidence and horizontal movement increase as the mining width increases. However, when the mining width increases to a certain value, increasing the pillar width cannot significantly decrease the maximum subsidence. To ensure the surface subsidence less than 500 mm, the mining width should not be larger than 200 m. Considering the recovery coefficient and safety of the coal pillar, a pillar width of 165 m is suggested.

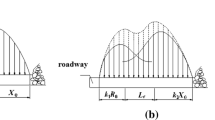

(Modified from Wilson and Ashwin 1972)

Similar content being viewed by others

References

Alejano LR, RamíRez-Oyanguren P, Taboada J (1999) FDM predictive methodology for subsidence due to flat and inclined coal seam mining. Int J Rock Mech Min Sci 36:475–491

Ambrožič T, Turk G (2003) Prediction of subsidence due to underground mining by artificial neural networks. Comput Geosci 29:627–637

Archibald JF (1999) Use of ground waste glass and normal portland cement mixtures for improving slurry and paste backfill support performance. CIM Bull 92:74–80

Aston TRC, Tammemagi HY, Poon AW (1987) A review and evaluation of empirical and analytical subsidence prediction techniques. Min Sci Technol 5:59–69

Bunting D (1991) Chamber pillars in deep anthracite mines. Trans Am Inst Min Eng 42:235–245

Chen SJ (2009) Basic experimental study on long-term stability of deep strip coal pillar. Dissertation, Shandong University of Science and Technology (in Chinese)

Chen SJ, Guo WJ, Zhou H, Shen B, Liu JB (2014) Field investigation of long-term bearing capacity of strip coal pillars. Int J Rock Mech Min Sci 70:109–114

Chen SJ, Yin D, Cao F, Liu Y, Ren K (2016) An overview of integrated surface subsidence-reducing technology in mining areas of China. Nat Hazards 81:1129–1145

Chugh YP, Pula O, Pytel WM (1990) Ultimate bearing capacity and settlement of coal pillar sub-strata. Int J Min Geol Eng 8:111–130

Gao W (2008) Elastic–plastic mechanics analysis on stability of coal pillar. Adv Mater Res 33–37:1123–1128

Gao W, Ge M (2016) Stability of a coal pillar for strip mining based on an elastic–plastic analysis. Int J Rock Mech Min Sci 87:23–28

Gao YF, Niu XR, Zhong YP et al (1999) Research for the technology of reducing the subsidence by grouting in multiple layer positions in overburden rock separating layers strips. Coal Mine Mod 5:23–25

Gao F, Stead D, Coggan J (2014) Evaluation of coal longwall caving characteristics using an innovative UDEC trigon approach. Comput Geotech 55:448–460

Guo WJ (2008) Mine special mining. China Coal Industry Publishing House, Beijing (in Chinese)

Guo GL, Wang YH, Ma ZG (2004) A new method for ground subsidence control in coal mining. J China Univ Min Technol 33(2):150–153 (in Chinese)

Guo WJ, Wang H, Liu Z (2015) Coal pillar stability and surface movement characteristics of deep wide strip pillar mining. J Min Safety Eng 32(3):369–375 (in Chinese)

Guo Q, Guo G, Lv X, Zhang W, Lin Y, Qin S (2016a) Strata movement and surface subsidence prediction model of dense solid backfilling mining. Environ Earth Sci 75:1426

Guo WJ, Wang H, Chen S (2016b) Coal pillar safety and surface deformation characteristics of wide strip pillar mining in deep mine. Arab J Geosci 9:1–9

Itasca Consulting Group Inc. (2007) FLAC3D Manual: fast Lagrangian analysis of continua in 3 dimensions, version 3.1. Itasca Consulting Group Inc., Minnesota, USA

Jawed M, Sinha RK, Sengupta S (2013) Chronological development in coal pillar design for bord and pillar workings: a critical appraisal. J Geol Min Res 5(1):1–11

Keilich W (2009) Numerical modelling of mining subsidence, upsidence and valley closure using UDEC. Dissertation, University of Wollongong

Li H, Guo G, Zhai SC (2016) Mining scheme design for super-high water backfill strip mining under buildings: a Chinese case study. Environ Earth Sci 75(12):1017

Likar J, Medved M, Lenart M, Mayer J, Malenković V, Jeromel G, Dervarič E (2012) Analysis of geomechanical changes in hanging wall caused by longwall multi top caving in coal mining. J Min Sci 48:135–145

Lin’Kov AM (2001) On the theory of pillar design. J Min Sci 37:10–27

Loui JP, Sheorey PR (2002) Estimation of non-effective width for different panel shapes in room and pillar extraction. Int J Rock Mech Min Sci 39:95–99

Mathey M (2016) Investigation into the mechanism of strength and failure in squat coal pillars in South Africa. Dissertation, University of Witwatersrand, Johannesburg

National Coal Board (1975) Subsidence engineers’ handbook. National Coal Board Mining Department, UK, pp 1–111

Ohnstad I (2003) Ultimate bearing capacity and settlement of coal pillar substrata. Int J Rock Mech Min Sci Geomech Abstr 28:235–241

Rezaei M, Hossaini MF, Majdi A (2015) Determination of longwall mining-induced stress using the strain energy method. Rock Mech Rock Eng 48(6):2421–2433

Salamon MDG (1970) Stability, instability and design of pillar workings. Int J Rock Mech Min Sci Geomech Abstr 7:613–631

Shabanimashcool M, Li CC (2013) A numerical study of stress changes in barrier pillars and a border area in a longwall coal mine. Int J Coal Geol 106(106):39–47

Shadbolt CH, Geddes JD (1978) Mining subsidence—historical review and state of the art. Large Ground Mov Struct 705:748

Sheorey PR, Das MN, Bordia SK et al (1986) Pillar strength approaches based on a new failure criterion for coal seams. Int J Min Geol Eng 4(4):273–290

Sun XK, Li XH (2008) New technology of waste-filling replacement mining on strip coal pillar. J China Coal Soc 33:259–263 (in Chinese)

Suorineni FT (2014) Reflections on empirical methods in geomechanics—the unmentionables and hidden risks. In: Australian ground control in mining conference. pp 143–156

Teng H, Xu J, Xuan D, Wang B (2016) Surface subsidence characteristics of grout injection into overburden: case study of Yuandian no. 2 coalmine, China. Environ Earth Sci 75:1–11

Waddington AA, Kay DR (1998) Development of the incremental profile method of predicting subsidence and its application in the Newcastle coalfield. In: MSTS 4th triennial conference on buildings and structures subject to ground movement. Mine Subsidence Technological Society, Newcastle, UK, pp 53–68

Wang A, Ma L, Wang Z, Zhang D, Li K, Zhang Y, Yi X (2016) Soil and water conservation in mining area based on ground surface subsidence control: development of a high-water swelling material and its application in backfilling mining. Environ Earth Sci 75:779

Wilson AH, Ashwin DP (1972) Research into the determination of pillar size. Min Eng 31:409–430

Xuan D, Xu J, Zhu W (2014) Dynamic disaster control under a massive igneous sill by grouting from surface boreholes. Int J Rock Mech Min Sci 71:176–187

Zhang XP, Wong LNY (2012) Cracking processes in rock-like material containing a single flaw under uniaxial compression: a numerical study based on parallel bonded-particle model approach. Rock Mech Rock Eng 45(5):711–737

Zhang XP, Wong LNY (2013) Crack initiation, propagation and coalescence in rock-like material containing two flaws: a numerical study based on bonded-particle model approach. Rock Mech Rock Eng 46:1001–1021

Zhang Q, Zhang XP (2017) A numerical study on cracking processes in limestone by the b value analysis of acoustic emissions. Comput Geotech 92:1–10

Zhang J, Zhang Q, Sun Q, Gao R, Germain D, Abro S (2015) Surface subsidence control theory and application to backfill coal mining technology. Environ Earth Sci 74:1439–1448

Zhang Q, Zhang JX, Han XL, Ju F, Tai Y, Li M (2016) Theoretical research on mass ratio in solid backfill coal mining. Environ Earth Sci 75:1–11

Zhang XP, Zhang Q, Wu S (2017) Acoustic emission characteristics of the rock-like material containing a single flaw under different compressive loading rates. Comput Geotech 83:83–97

Acknowledgements

The support provided by the National Basic Research Program of China (Grant nos. 2015CB058102 and 2015CB258500) is gratefully acknowledged. Thanks to Dr. Ruipeng Qian of the Taiyuan University of Technology for his help and advice on this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, W., Zhang, Q., Luan, Y. et al. A study of surface subsidence and coal pillar safety for strip mining in a deep mine. Environ Earth Sci 77, 627 (2018). https://doi.org/10.1007/s12665-018-7810-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-018-7810-y