Abstract

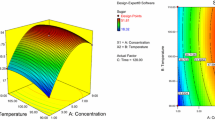

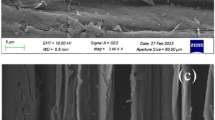

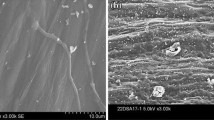

Ball milling of rice straw impregnated with sulfuric acid (RS-S), hydrochloric acid (RS-H), acetic acid (RS-A), or nitric acid (RS-N) were carried out in this study. Physicochemical analysis and subcritical water hydrolysis were performed to evaluate the effect of acid species on ball milling treatment of rice straw. Acetic acid and solo ball milling treatment showed little effect on solubility, thermal stability and crystalline structure of rice straw, while hydrochloric acid, acetic acid and nitric acid significantly improved the solubility and decreased the crystallinity index and thermal stability of rice straw. Sulfuric acid was found to be the most efficient acid to destroy the rice straw structure during ball milling followed by nitric acid and hydrochloric acid, attributed to its long retention on rice straw surface after drying. The effective cleavage of holocellulose-lignin chemical linkages in RS-S during pretreatment made the hydrolysis products of RS-S easier to be hydrolyzed to biochar at high reaction temperatures, resulting in the increased solid residue yield. The breakage of crystallites and holocellulose-lignin chemical linkages greatly improved the reactivity of RS-S, resulting in the lower temperature and activation energy required to initiate the hydrolysis reaction compared with those of rice straw and RS-A.

Graphical Abstract

Highlights

H2SO4 was the most efficient acid to destroy the RS structure during ball milling.

Acid-associated mechanical treatment can cleave the glycosidic bonds in RS.

The solubility of RS was greatly improved after acid impregnation and ball milling.

The destruction of hydrogen and glycosidic bonds made RS easier to be hydrolyzed.

Statement of novelty

Biomass is a promising platform for both bioenergy and feed stock chemicals. However, the rigid structure of biomass made it difficult to be hydrolyzed and converted to biofuels and value-added chemicals in subcritical water. Acid/alkaline pretreatment, a broadly employed biomass pretreatment method could efficiently cleave the chemical bonds in biomass. However, it suffers equipment corrosion and environmental pollution because of the high concentration of acid/alkaline used. In this study, diluted acids (H2SO4, HCl, CH3COOH and HNO3) were employed to impregnate rice straw, followed by ball milling, in order to improve the accessibility of rice straw during hydrolysis in subcritical water. H2SO4 was found to be the most efficient acid to destroy the rice straw structure during ball milling, which resulted in the lower activation energy needed to initiate the hydrolysis reaction in subcritical water, and higher contents of value-added chemicals in the hydrolysate.

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

Qu, T.J., Zhang, X.M., Gu, X.W., Han, L.J., Ji, G.Y., Chen, X.L., Xiao, W.H.: Ball milling for biomass fractionation and pretreatment with aqueous hydroxide solutions. ACS Sustain. Chem. Eng. 5, 7733–7742 (2017). https://doi.org/10.1021/acssuschemeng.7b01186

Okolie, J.A., Nanda, S., Dalai, A.K., Berruti, F., Kozinski, J.A.: A review on subcritical and supercritical water gasification of biogenic, polymeric and petroleum wastes to hydrogen-rich synthesis gas. Renew. Sust Energ. Rev. 119, 109546 (2020). https://doi.org/10.1016/j.rser.2019.109546

Zhang, J.X., Wen, C.T., Zhang, H.H., Duan, Y.Q., Ma, H.L.: Recent advances in the extraction of bioactive compounds with subcritical water: A review. Food Res. Int. 95, 183–195 (2020). https://doi.org/10.1016/j.tifs.2019.11.018

Mattonai, M., Nardella, F., Zaccaroni, L., Ribechini, E.: Effects of milling and UV pretreatment on the pyrolytic behavior and thermal stability of softwood and hardwood. Energy Fuels. 35, 11353–11365 (2021). https://doi.org/10.1021/acs.energyfuels.1c01048

Yang, W., Ma, Y.L., Zhang, X., Yang, F., Zhang, D., Wu, S.J., Peng, H.H., Chen, Z.Z., Che, L.: Effect of acid-associated mechanical pretreatment on the hydrolysis behavior of pine sawdust in subcritical water. Chin. J. Chem. Eng. 58, 195–204 (2023). https://doi.org/10.1016/j.cjche.2022.11.010

Akhtar, N., Gupta, K., Geyal, D., Goyal, A.: Recent advances in pretreatment technologies for efficient hydrolysis of lignocellulosic biomass. Environ. Prog Sustain. 35, 489–511 (2016). https://doi.org/10.1002/ep.12257

Kumar, B., Bhardwaj, N., Agrawal, K., Chaturvedi, V., Verma, P.: Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process. Technol. 199, 106244 (2020). https://doi.org/10.1016/j.fuproc.2019.106244

Sun, S.N., Sun, S.L., Cao, X.F., Sun, R.C.: The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour Technol. 199, 49–58 (2016). https://doi.org/10.1016/j.biortech.2015.08.061

Pang, J.F., Zheng, M.Y., Li, X.S., Sebastain, J., Jiang, Y., Zhao, Y., Wang, A.Q., Zhang, T.: Unlock the compact structure of lignocellulosic biomass by mild ball milling for ethylene glycol production. ACS Sustain. Chem. Eng. 7, 679–687 (2019). https://doi.org/10.1021/acssuschemeng.8b04262

Zhang, W., Zhang, X., Liang, M., Lu, C.: Mechanochemical preparation of surface-acetylated cellulose powder to enhance mechanical properties of cellulose-filler-reinforced NR vulcanizates. Compos. Sci. Technol. 68, 2479–2484 (2008). https://doi.org/10.1016/j.compscitech.2008.05.005

Dell’Omo, P.P., Spena, V.A.: Mechanical pretreatment of lignocellulosic biomass to improve biogas production: Comparison of results for giant reed and wheat straw. Energy. 203, 117798 (2020). https://doi.org/10.1016/j.energy.2020.117798

Nuruddin, M., Hosur, M., Uddin, M.J., Baah, D., Jeelani, S.: A novel approach for extracting cellulose nanofibers from lignocellulosic biomass by ball milling combined with chemical treatment. J. Appl. Polym. Sci. 9, 42990 (2016). https://doi.org/10.1002/app.42990

Liu, X.L., Dong, C.Y., Leu, S.Y., Fang, Z., Miao, Z.D.: Efficient saccharification of wheat straw pretreated by solid particle-assisted ball milling with waste washing liquor recycling. Bioresour Technol. 347, 126721 (2022). https://doi.org/10.1016/j.biortech.2022.126721

Sitotaw, Y.W., Habtu, N.G., Gebreyohannes, A.Y., Nunes, S.P., Gerven, T.V.: Ball milling as an important pretreatment technique in lignocellulose biorefneries: A review. Biomass Convers. Biorefin. 9, 8232–8237 (2021). https://doi.org/10.1007/s13399-021-01800-7

Shen, F., Xiong, X.N., Fu, J.Y., Yang, J.R., Qiu, M., Qi, X.H., Tsang, D.C.W.: Recent advances in mechanochemical production of chemicals and carbon materials from sustainable biomass resources. Renew. Sust Energ. Rev. 130, 109944 (2020). https://doi.org/10.1016/j.rser.2020.109944

Dornath, P., Cho, H.J., Paulsen, A., Dauenhauer, P., Fan, W.: Efficient mechano-catalytic depolymerization of crystalline cellulose by formation of branched glucan chains. Green. Chem. 17, 769–775 (2015). https://doi.org/10.1039/C4GC02187H

Shrotri, A., Lambert, L.K., Tanksale, A., Beltramini, J.: Mechanical depolymerisation of acidulated cellulose: Understanding the solubility of high molecular weight oligomers. Green. Chem. 15, 2761–2768 (2013). https://doi.org/10.1039/C3GC40945G

Carrasquillo-Flores, R., Kaldstrom, M., Schuth, F., Dumesic, J.A., Rindldi, R.: Mechanocatalytic depolymerization of dry (Ligno)cellulose as an entry process for high-yield production of furfurals. ACS Catal. 3, 993–997 (2013). https://doi.org/10.1021/cs4001333

Zhao, L.L., Chen, X.F., Liu, X.Y., Xu, G.Q., Guo, X.C., Yang, Y.: Highly efficient synthesis of C5/C6 sugar alcohols from bamboo enabled by mechanocatalytic depolymerization. ACS Sustain. Chem. Eng. 9, 6697–6706 (2021). https://doi.org/10.1021/acssuschemeng.1c00469

Hilgert, J., Meine, N., Rinaldi, R., Schuth, F.: Mechanocatalytic depolymerization of cellulose combined with hydrogenolysis as a highly efficient pathway to sugar alcohols. Energy Environ. Sci. 6, 92–96 (2013). https://doi.org/10.1039/c2ee23057g

Yang, Y., Hu, C.W., Abu-Omar, M.M.: Conversion of carbohydrates and lignocellulosic biomass into 5-hydroxymethylfurfural using AlCl3·6H2O catalyst in a biphasic solvent system. Green. Chem. 14, 509–513 (2012). https://doi.org/10.1039/C1GC15972K

Mandal, A., Chakrabarty, D.: Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr. Polym. 86, 1291–1299 (2011). https://doi.org/10.1016/j.carbpol.2011.06.030

Zhao, J.K., Yang, Y., Zhang, M., Wang, D.H.: Minimizing water consumption for sugar and lignin recovery via the integration of acid and alkali pretreated biomass and their mixed filtrate without post-washing. Bioresour Technol. 337, 125389 (2021). https://doi.org/10.1016/j.biortech.2021.125389

Liu, H., Chen, X.L., Ji, G.Y., Yu, H.T., Gao, C.F., Han, L.J., Xiao, W.H.: Mechanochemical deconstruction of lignocellulosic cell wall polymers with ball-milling. Bioresour Technol. 286, 121364–121371 (2019). https://doi.org/10.1016/j.biortech.2019.121364

Yao, W.Q., Weng, Y.Y., Catchmark, J.M.: Improved cellulose X-ray diffraction analysis using Fourier series modeling. Cellulose. 27, 5563–5579 (2020). https://doi.org/10.1007/s10570-020-03177-8

Ling, Z., Wang, T., Makarem, M., Cintron, M.S., Cheng, H.N., Kang, X., Bacher, M., Potthast, A., Rosenau, T., King, H., Delhom, C.D., Nam, S., Edwards, J.V., Kim, S.H., Xu, F., French, A.D.: Effects of ball milling on the structure of cotton cellulose. Cellulose. 26, 305–328 (2019). https://doi.org/10.1007/s10570-018-02230-x

Schuth, F., Rinaldi, R., Meine, N., Kaldstrom, M., Hilgert, J., Kaufman Rechulski, F.D.: Mechanocatalytic depolymerization of cellulose and raw biomass and downstream processing of the products. Catal. Tooday. 234, 24–30 (2014). https://doi.org/10.1016/j.cattod.2014.02.019

Xiao, Z.Q., Yang, Q.Q., Xu, X.Y., He, Y.F.: Ball milling promotes saccharification of agricultural biomassby heteropolyacid and enzyme: Unlock the lignin cage for sugars recovery. Biomass Conv Bioref. 12, 4105–4115 (2022). https://doi.org/10.1007/s13399-020-00950-4

Ersan, S., Guclu Ustundag, O., Carle, R., Schweiggert, R.M.: Subcritical water extraction of phenolic and antioxidant constituents from pistachio (Pistacia vera L.) hulls. Food Chem. 253, 46–54 (2018). https://doi.org/10.1016/j.foodchem.2018.01.116

Yang, W., Fang, M.N., Xu, H., Wang, H., Wu, S.J., Zhou, J., Zhu, S.X.: Interactions between holocellulose and lignin during hydrolysis of sawdust in subcritical water. ACS Sustain. Chem. Eng. 7, 10583–10594 (2019). https://doi.org/10.1021/acssuschemeng.9b01127

Fang, Z., Minowa, T., Smith, R.L., Ogi, T., Kozinski, J.A.: Liquefaction and gasification of cellulose with Na2CO3 and ni in subcritical water at 350°C. Ind. Eng. Chem. Res. 43, 2454–2463 (2004). https://doi.org/10.1021/ie034146t

Buhler, W., Dinjus, E., Ederer, H.J., Kruse, A., Mas, C.: Ionic reactions and pyrolysis of glycerol as competing reaction pathways in near- and supercritical water. J. Supercrit Fluids. 22, 37–53 (2002). https://doi.org/10.1016/S0896-8446(01)00105-X

Sasaki, M., Adschiri, T., Arai, K.: Kinetics of cellulose conversion at 25 MPa in sub- and supercritical water. AIChE J. 50, 192–202 (2004). https://doi.org/10.1002/aic.10018

Lawoko, M., Henriksson, G., Gellerstedt, G.: Characterisation of lignin-carbohydrate complexes (LCCs) of spruce wood (Picea abies L.) isolated with two methods. Holzforschung. 60, 156–161 (2006). https://doi.org/10.1515/HF.2006.025

Zhang, X.L., Yang, W.H., Blasiak, W.: Modeling study of woody biomass: Interactions of cellulose, hemicellulose, and lignin. Energy Fuels. 25, 4786–4795 (2011). https://doi.org/10.1021/ef201097d

Yang, W., Shimanouchi, T., Wu, S.J., Kimura, Y.: Investigation of the degradation kinetic parameters and structure changes of microcrystalline cellulose in subcritical water. Energy Fuels. 28, 6974–6980 (2014). https://doi.org/10.1021/ef501702q

Acknowledgements

Financial support from Huzhou Nature Science Foundation (2022YZ25) was acknowledged.

Funding

Prof. WeiYang, Huzhou Nature Science Foundation (2022YZ25).

Author information

Authors and Affiliations

Contributions

Investigation, paper writing; F.Y.: Sample preparation, paper writing, supervision; testing and analysis, format and data processing; S.W.: Conception, Supervision, Project management; L.C.: Project supervision, conception.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, W., Yang, F., Wu, S. et al. Characterization of Acid-Mechanical Milling Pretreated Rice Straw for Subcritical Water Hydrolysis. Waste Biomass Valor (2024). https://doi.org/10.1007/s12649-024-02493-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12649-024-02493-5