Abstract

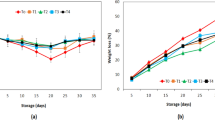

Waste-bottom fruits are spoiled and wasted due to their high moisture content. In order to contribute to reducing food waste and supply, waste fruits have a high potential to be turned into new products by drying. In this study, the effects of 3% citric acid and 3% ethyl oleate pretreatments on drying kinetics, color quality and energy analysis of fruit chips produced from waste Japanese apples were investigated. Within the scope of the study, it was determined that the drying rates of the drying processes varied between 0.0094 and 0.013 g moisture/g drying substance.minute values. It was determined that the effective diffusion values of the drying processes varied between 3.99 and 5.08 × 10–7 m2/s. It was found that the most suitable drying process in terms of color value was the citric acid pretreatment. The chroma and total color change values of the citric acid pre-treated chips were determined as 14.42 and 18.99, respectively. The average energy consumption values of the control, citric acid and ethyl oleate pretreated samples were determined as 0.620, 0.549 and 0.585 kWh, respectively. In citric acid pre-treatment drying, energy savings of 11.45% were achieved. According to the findings obtained in drying kinetics, color quality and energy analysis, it is recommended to prefer citric acid pretreatment.

Graphical Abstract

Similar content being viewed by others

Data Availability

Enquiries about data availability should be directed to the authors.

References

FAO: Global food losses and food waste—extent, causes and prevention. In: SAVE FOOD: an Initiative on Food Loss and Waste Reduction. Food and Agriculture Organization of United Nations, Rome (2011)

Dias, P.G.I., Sajiwanie, J.W.A., Rathnayaka, R.M.U.S.K.: Chemical composition, physicochemical and technological properties of selected fruit peels as a potential food source. Int. J. Fruıt Sci. 20(S2), 240-S251 (2020). https://doi.org/10.1080/15538362.2020.1717402

Galanakis, C.M.: Food waste recovery: Processing technologies and industrial techniques. Academic Press, Cambridge, UK (2015)

Royte, E.: How ‘Ugly’ Fruits and Vegetables Can Help Solve World Hunger. National Geographic (2016). http://www.nationalgeographic.com/magazine/2016/03/global-food-waste-statistics/

Maniyon, A., John, R., Mathew, A.: Evaluation of fruit peels for some selectednutritional and anti-nutritional factors. Emerg. Life Sci. Res. 1(2), 12–19 (2015)

Cepeda, E., Villaran, M.C.: Density and viscosity of Malus floribunda juice as a function of concentration and temperature. J. Food Eng. 41, 103–107 (1999)

Altuntaş, E.: Mass estimation of japanese crabapple based on physical properties with linear regression models. Gaziosmanpasa J. Sci. Res. 10(1), 153–161 (2021)

Du, L.J., Gao, Q.H., Ji, X.L., Ma, Y.J., Xu, F.Y., Wang, M.: Comparison of flavonoids, phenolic acids, and antioxidant activity of explosion-puffed and sun-dried jujubes (Ziziphus jujuba mill.). J. Agric. Food Chem. 61, 11840–11847 (2013)

Zou, K., Teng, J., Huang, L., Dai, X., Wei, B.: Effect of osmotic pretreatment on quality of mango chips by explosion puffing drying. LWT Food Sci. Technol. 51, 253–259 (2013)

Chaikham, P., Kreungngern, D., Apichartsrangkoon, A.: Combined microwave and hot air convective dehydration on physical and biochemical qualities of dried longan flesh. International Food Res. J. 20, 2145–2151 (2013)

Deng, L.Z., Xiong, C.H., Sutar, P.P., Mujumdar, A.S., Pei, Y.P., Yang, X.H., Ji, X.W., Zhang, Q., Xiao, H.W.: An emerging pretreatment technology for reducing postharvest loss of vegetables—a case study of red pepper (Capsicum annuum L.) drying. Drying Technol. 40(8), 1620–1628 (2022)

Xiao, H.W., Mujumdar, A.S.: Importance of drying in support of human welfare. Drying Technol. 38(12), 1542–1543 (2020)

Enerdata World Energy Consumption Statistics: (2020). https://yearbook.enerdata.net/total-energy/world-consumption-statistics.html

Motevali, A., Minaei, S., Banakar, A., Ghobadian, B., Darvishi, H.: Energy analyses and drying kinetics of chamomile leaves in microwave-convective dryer. J. Saudi Soc. Agric. Sci. 15(2), 179–187 (2012)

Llavata, B., García-Pérez, J.V., Simal, S., Cárcel, J.A.: Innovative pre-treatments to enhance food drying: a current review. Curr. Opin. Food Sci. 35, 20–26 (2020)

Yuan, Y., Zhao, Z., Wang, L., Xu, Y., Chen, H., Kong, L., Wang, D.: Process optimization of CO2 high-pressure and low-temperature explosion puffing drying for apple chips using response surface methodology. Drying Technol. 40(1), 100–115 (2022). https://doi.org/10.1080/07373937.2020.1771361

Ghinea, C., Prisacaru, A.E., Leahu, A.: Physico-chemical and sensory quality of oven-dried and dehydrator-dried apples of the starkrimson, golden delicious and florina cultivars. Appl. Sci. 12(5), 2350 (2022). https://doi.org/10.3390/app12052350

Xiao, M., Yi, J., Bi, J., Zhao, Y., Peng, J., Hou, C., Lyu, J., Zhou, M.: Modification of cell wall polysaccharides during drying process affects texture properties of apple chips. J. Food Qual. (2018). https://doi.org/10.1155/2018/4510242

Xiao, M., Bi, J., Yi, Y., Peng, J., Zhaou, L., Chen, Q.: Osmotic pretreatment for instant controlled pressure drop dried apple chips: Impact of the type of saccharides and treatment conditions. Drying Technol. 37(7), 896–905 (2019). https://doi.org/10.1080/07373937.2018.1473419

Kaveh, M., Sharabiani, V.R., Chayjan, R.A., Taghinezhad, E., Abbaspour-Gilandeh, Y., Golpour, I.: ANFIS and ANNs model for prediction of moisture diffusivity and specific energy consumption potato, garlic and cantaloupe drying under convective hot air dryer. Inf. Process. Agric. 5(3), 372–387 (2018)

Doymaz, İ, Tugrul, N., Pala, M.: Drying characteristics of dill and parsley leaves. J. Food Eng. 77, 559–565 (2006)

Joudi-Sarighayeh, F., Abbaspour-Gilandeh, Y., Kaveh, M., Hernandez-Hernandez, J.L.: The optimization of the physical–thermal and bioactive properties of pumpkin slices dried in a hybrid microwave–convective dryer using the response surface method. Agronomy 12(10), 2291 (2022). https://doi.org/10.3390/agronomy12102291

Maskan, M.: Microwave/air and microwave finish drying of banana. J. Food Eng. 44, 71–78 (2000)

Corzo, O., Bracho, N., Pereira, A., Vasquez, A.: Weibull distribution for modeling air drying of coroba slices. LWT Food Sci. Technol. 41(10), 2023–2028 (2008)

Ramallo, L.A., Mascheroni, R.H.: Quality evaluation of pineapple fruit during drying process. Food Bioprod. Process. 99, 275–283 (2012)

Alemrajabi, A.A., Rezaee, F., Mirhosseini, M., Esehaghbeygi, A.: Comparative evaluation of the effects of electrohydrodynamic, oven, and ambient air on carrot cylindrical slices during drying proces. Drying Technol. 30, 88–96 (2012)

Tan, M., Chua, K.J., Mujumdar, A.S., Chou, S.K.: Effect of osmotic pre-treatment and infrared radiation of drying rate and color changes during drying of potato and pineapple. Drying Technol. 19(9), 2193–2207 (2001)

Surendhar, A., Sivasubramanian, V., Vidhyeswari, D., Deepanraj, B.: Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J. Therm. Anal. Calorim. 136, 185–197 (2019)

Tepe, F.B.: Impact of pretreatments and hybrid microwave assisting on drying characteristics and bioactive properties of apple slices. J. Food Process. Preserv. 46, e17067 (2022). https://doi.org/10.1111/jfpp.17067

Kriaa, K., Nassar, A.F.: Comparative study of pretreatment on microwave drying of Gala apples (Malus pumila): effect of blanching, electric field and freezing. LWT (2022). https://doi.org/10.1016/j.lwt.2022.113693

Soydan, M., Doymaz, İ: An experimental study on thin-layer drying drying characteristics of apple slices. Lat. Am. Appl. Res. 51(2), 119–126 (2021)

Karaaslan, S., Ekinci, K.: Effect of pretreatments on solar dehydration of different varieties of apple (Malus domestica). Czech J. Food Sci. 40, 93–101 (2022). https://doi.org/10.17221/201/2021-CJFS

Jokić, S., Velić, D., Bilić, M., Lukinac, J., Planinić, M., Bucić-Kojić, A.: Influence of process parameters and pre-treatments on quality and drying kinetics of apple samples. Czech J. Food Sci. 27, 88–94 (2009). https://doi.org/10.17221/170/2008-CJFS

Wang, H.O., Fu, Q.Q., Chen, S.J., Hu, Z.C., Xie, H.X.: Effect of hot-water blanching pretreatment on drying characteristics and product qualities for the novel ıntegrated freeze-drying of apple slices. J. Food Qual. (2018). https://doi.org/10.1155/2018/1347513

Zarein, M., Samadi, S.H., Ghobadian, B.: Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J. Saudi Soc. Agric. Sci. 14(1), 41–47 (2015). https://doi.org/10.1016/j.jssas.2013.06.002

Rojariya, D., Shewale, S.R., Hebbar, H.U.: Refractance window drying of apple slices: mass transfer phenomena and quality parameters. Food Bioprocess. Technol. 12, 1646–1658 (2019)

Fernandes, F.A.N., Linhares, F.E., Rodrigues, S.: Ultrasound as pre-treatment for drying of pineapple. Ultrason. Sonochem. 15(6), 1049–1054 (2008)

Noshad, M., Mohebbi, M., Shahıdı, F., Mortazavı, S.A.: Kinetic modeling of rehydration in air-dried quinces pretreated wıth osmotic dehydration and ultrasonic. J. Food Process. Preserv. 36(5), 383–392 (2012). https://doi.org/10.1111/j.1745-4549.2011.00593.x

Nadian, M.H., Rafiee, S., Golzarian, M.R.: Real-time monitoring of color variations of apple slices and effects of pre-treatment and drying air temperature. Food Measure 10, 493–506 (2016)

Fijalkowska, A., Nowacka, M., Wiktor, A., Sledz, M., Witrowa-Rajchert, D.: Ultrasound as a pretreatment method to improve drying kinetics and sensory properties of dried apple. J. Food Process. Eng. 39(3), 256–265 (2016)

Bai, J.W., Zhang, L., Aheto, J.H., Cai, J.R., Wang, Y.C., Sun, L., Tian, X.Y.: Effects of different pretreatment methods on drying kinetics, three-dimensional deformation, quality characteristics and microstructure of dried apple slices. Innov. Food Sci. Emerg. Technol. (2023). https://doi.org/10.1016/j.ifset.2022.103216

Hernández, Y., Ramírez, C., Moreno, J., Núñez, H., Vega, O., Almonacid, S., Pinto, M., Fuentes, L., Simpson, R.: Effect of refractance window on dehydration of osmoticallypretreated apple slices: color and texture evaluation. J. Food Process. Eng. (2019). https://doi.org/10.1111/jfpe.13304

Fiippin, A.P., Filho, L.M., Fadel, V., Mauro, M.A.: Thermal intermittent drying of apples and its effects on energy consumption. Drying Technol. 36(14), 1662–1667 (2018). https://doi.org/10.1080/07373937.2017.1421549

Shewale, S.R., Rajoriya, D., Hebbar, H.U.: Low humidity air drying of apple slices: Effect of EMR pretreatment on mass transfer parameters, energy efficiency and quality. Innov. Food Sci. Emerg. Technol. 55, 1–10 (2019). https://doi.org/10.1016/j.ifset.2019.05.006

Dehghannya, J., Aghazade-Khoie, E., Heshmati, M.K., Ghanbarzadeh, B.: Influence of ultrasound ıntensification on the continuous and pulsed microwave during convective drying of apple. Int. J. Fruit Sci. 20(3), 1751–1764 (2020). https://doi.org/10.1080/15538362.2020.1830919

Acknowledgements

The use of data will be made available upon appropriate request.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

MT: Planning, laboratory work, data processing, article writing.

Corresponding author

Ethics declarations

Conflict of ınterest

The author in the study has no conflict of interest with any other author.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Taşova, M. Effect of Pretreatments on the Valorization as Chips of Japanese Apple (Malus floribunda L.) Waste: Drying Kinetics, Color Quality and Energy Consumption. Waste Biomass Valor (2023). https://doi.org/10.1007/s12649-023-02354-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12649-023-02354-7