Abstract

Fishbones contain significant amounts of plant nutrients. Fish residues may be preserved by acidification to pH < 4, which may affect the chemical extractability, and the plant availability of nutrients when applied as fertilisers. Grinded bone material from cod (Gadus morhua) heads was mixed with formic acid to investigate if this would increase the concentrations of ammonium lactate–acetate (AL)-extractable nutrients. Two degrees of fineness of fishbones (coarse 2–4 mm; fine < 0.71 mm) were compared at pH 3.0 and 4.0 plus a water control in a laboratory study over 55 days. Samples for measurement of AL-extractable P, Ca, Mg and K were taken on day 2, 15, 34 and 55. Whereas more formic acid and thereby lower pH clearly increased the concentrations of AL-extractable calcium (Ca-AL) and magnesium (Mg-AL), AL-extractable phosphorus (P-AL) was only significantly increased in finely grinded bones at pH 3. After 34 days at pH 3, 6% of the total content of P was extracted by AL in fine fishbones. In the water control, about 1% of the P was extracted, possibly from phospholipids. This P-AL concentration was well above P-AL extracted from acidified coarse fishbones (pH 3 and 4) and from fine fishbones acidified to pH 4. With acidification, about 30% of total Ca and 100% of total Mg were extracted by AL, and the Ca-AL and Mg-AL concentrations were closely correlated. A possible reason for lower P-AL in coarse fishbones at pH 3 and 4, and in fine fishbones at pH 4 than in water controls may be a precipitation of apatite from phospholipids and dissolved calcium.

Graphical Abstract

Similar content being viewed by others

Statement of Novelty

Fish and other sea-living animals have traditionally been applied as fertilisers. In modern fish industry, poorly utilised residual materials with high proportions of fishbones are often available. Such materials may be preserved by acids to below pH 4 to avoid putrefaction. Fishbones contain valuable plant nutrients, such as nitrogen, phosphorus, calcium, and magnesium. Would preservation with formic acid affect the availability of nutrients for crop plants when fishbones are applied as fertilisers? To assess this question, we measured the concentrations of extractable plant nutrients in fishbones after mixing them with formic acid. Whereas the addition of acid increased extractable calcium and magnesium, a significant increase in extractable phosphorus only occurred in fine fishbones at the lowest pH level. Potassium in fishbones was readily soluble in water.

Introduction

Large amounts of residual materials are produced in fisheries [1], and from lean fish like cod (Gadus morhua) and saithe (Pollachius virens), the utilisation of residual materials is sometimes poor. Fish residues such as heads, skin, viscera, and backbones, may be grinded (10 mm) and mixed with 85% formic acid to pH < 4.0, to avoid putrefaction. This preserved material may be stored in large tanks where it will be subject to a hydrolysis, where layers of oils and soluble proteins will form above a layer of sediment. Whereas oil and soluble proteins can be applied for feed in aquaculture, and hydrolysed proteins applied as fertiliser, the sediment layer is currently commonly disposed of as waste. Fish bones have a high content of minerals such as nitrogen (N), phosphorus (P) and calcium (Ca) [2], which are essential for the growth of crop plants. Phosphorus is a scarce resource [3], and waste disposal e.g., incineration commonly implies that P is lost from biological circulation. Application of the sediments in agriculture for fertilisation purpose could be a sustainable valorisation of a currently wasted material with valuable characteristics. Pot and field experiments conducted with fishbones comparable with the material tested in the present paper have shown that fishbones are an effective fertiliser for crop plants [4, 5] with a remarkably fast growth response, likely due to the high content of readily available N.

Plants may excrete organic acids from their root systems to extract nutrients from soil [6], and diluted organic acids are applied as extractants in chemical soil analysis to mimic this effect and measure “plant available” concentrations of essential nutrients in agricultural soil. In Norway and Sweden, the AL-method where a mixture of ammonium lactate and acetic acid at pH 3.75 is applied to extract P, Ca, potassium (K), magnesium (Mg) and sodium (Na) from agricultural soil is the standard method for assessing the need of application of fertilisers to the soil [7, 8]. Whereas K is a macronutrient of crop plants, the content of Na should not be high in soil or growing media. Formic acid has been tested and recommended as an appropriate extractant to assess the bioavailability of minerals e.g., in biochars [9], and extractions with ammonium citrate, 2% citric acid, and 2% formic acid are the most common methods to determine the bioavailability of P from rock phosphates [10]. Since formic acid will solubilise more phosphate from e.g., rock phosphates than water, we hypothesized that the preservation of grinded fish bones with formic acid could affect the plant availability of P and Ca, possibly also other nutrients, in this material.

Bone is a composite material composed of organic and inorganic components, primarily collagen and hydroxyapatite (Ca10(PO4)6(OH)2, also called bioapatite), as well as lipids and water [11]. Fishbones tend to exhibit more variability in the chemical composition than bones from mammals, and the collagen from fishbones is also chemically different. In most fish species except skates, sharks and rays, type I collagen is the structural organic element in the bones, being calcified to a variable extent dependent on fish species, type of organ and fish age. In general, for bones collagen constitutes about 20% of the bone mass and 35% by volume [11], and collagen comprises more than 90% of the bone organic matrix. Glycine is the major amino acid comprising about 30% of the total content of the collagen. The content of hydroxyproline is especially large in collagen and contributes to increase the stability and decrease the solubility of this protein. In the inorganic phase, elements like fluoride and chloride, and mineral carbonate, may also be present in the bioapatite. Lipids and proteins are present in fish bones even after enzymatic hydrolysis or boiling [12]. In most fish species, the bone structure is acellular [12]; among the commonly captured or raised species in Norway, only salmonids have cellular bones. Acellular fish bones have smaller crystals and a higher surface to volume ratio than cellular fish bones [12], which may affect degradation of such bone particles in soil.

Apatite is relatively insoluble at near-neutral pH [13]. With acidic conditions, such as in fish industry sediments preserved by formic acid, the hydroxyapatite crystals in fish bones will start to dissolve. In aqueous acidic media, the steady-state conditions of apatite dissolution include a series of simultaneous processes or steps [14]: (1) diffusion of chemical reagents (hydrogen ions, H+ and anions of acid, An−) from bulk solution to the solid/liquid interface; (2) adsorption of the chemicals onto the surface of apatite; (3) chemical transformations on the surface; (4) desorption of products (ions of calcium, potentially other cations and orthophosphate, PO43−) from the crystal surface; and (5) their diffusion into the bulk solution. If conditions (e.g., pH) allow for microbial activity, the organic compounds (collagen, lipids) will attract such activity, which may contribute to dissolution of apatite [13]. In bones, the apatite minerals are closely associated with the protein molecules, and the protein integrates into the crystalline structure [15]. Hence, even if collagen as such is readily soluble in weak acids [16], the close integration with minerals will protect the protein from being dissolved. For a complete dissolution of collagen from fishbones, bone fragments were powdered by blending while mixed with liquid nitrogen and decalcified by EDTA solution before dissolution of collagen in 0.5 M acetic acid [16].

When chemical extraction is applied to estimate the plant availability e.g., of P in soil, the ratio of liquid (L) to solid (S) phase is usually wide. The L:S ratio affects the solubility of phosphate. In a relevant study [17] when the amount of 2% citric acid (pH 2.0) applied per g of milled rock increased from 100 to 200 ml, the concentration of phosphate increased by almost 50%, from 5.5 to 10.7 mg l−1, on average for 10 types of apatite rock. A further increase to 300 ml increased the average concentration to 13.0 mg l−1, demonstrating that the effect of increasing L:S ratio levels off. A wide L:S ratio, and shaking during extraction, ensures that all material surface is exposed to chemical reactions, and favours diffusion of solubilised ions. When acids are applied for preservation purpose in fish industry, the consumption of acid is minimized to save costs and reduce risks related to health and environmental damage. A narrow L:S ratio may lead to precipitation and re-structuring of the chemical elements e.g., formation of calcium complexes such as calcium formate.

Formic acid is the simplest carboxylic acid, with the formula HCOOH and a negative log value of acid dissociation constant, pKa being 3.75. This pKa implies that by pH 3.75, 50% of the molecules will be dissociated to H+ and COOH-; at lower pH, a lower proportion will be dissociated. The low molecule weight (21.7 mol kg−1) implies that one weight unit of this acid may be a more reactive agent than one weight unit of organic acids with larger molecule weight [18]. For comparison, citric acid (CH2COOH-C(OH)COOH-CH2COOOH) has a molecule weight of 192.1 and a pKa1 of 3.15. 85% formic acid has a pH of 1.5.

In the fish industry, there is increasing interest to valorise poorly utilised materials, such as sediments with fish bones. To utilise such materials e.g., in a production of a commercial fertiliser, it is useful to understand how the application of formic acid to pH < 4 affects the bioavailability of P and other essential minerals for plant growth.

As demonstrated by the solubility of rock apatite in citric acid [17], we expected that the concentration of AL-extractable P in fishbones treated with formic acid would be higher than in fishbones not treated by acid. We also expected that increasing fineness of the particles, and decrease in pH, would increase the concentration of AL-extractable P in the fishbones. These assumptions were tested in a laboratory scale study which is presented here. The study was initiated by a measurement of volumes of formic acid required for targeted pH levels in slurries of fishbones and deionised water, whereas the main experimental part was to assess how the amendment of fishbones with targeted amounts of formic acid affected the concentrations of AL-extractable elements (P, Ca, Mg, K).

The purpose of the investigation was to study if the preservation of fishbones with formic acid, and increased fineness of bone particles, may increase the availability of nutrients in fishbones to be applied as fertilisers for crop plants? Using AL-extraction to assess this question, our hypothesis was that AL-soluble concentrations of P, Ca, Mg and K would increase with addition of formic acid, and more with higher acid concentrations, and that finer fishbone particles would release more AL-soluble nutrients than coarser particles due to a larger specific surface where chemical reactions can occur.

Materials and Methods

Fishbones and Overview of the Study

Fishbones to be applied in the present study were provided by SINTEF Ocean AS as an output from the project “Heads up I”, aiming at a better utilization of cod heads than drying them for export. Cod heads were subject to enzymatic hydrolysis in a pilot plant [19]. The remaining sediments were thoroughly washed to derive to a material containing only bone particles, and then frozen and stored at − 18 °C. The frozen bones were dried at 40 °C and grinded with a kitchen blender. The grinded material was sieved to produce a coarse fraction with particle diameter 2–4 mm, further called coarse fishbones (CFB) and a fine fraction passing a 0.71 mm sieve, further called fine fishbones (FFB).

The volume of formic acid required for achieving a certain pH value in CFB and FFB was assessed in an initial test. Thereafter, the main experiment was conducted over a period of 55 days, where a slurry of fishbones and formic acid, or deionised water, was regularly sampled and the samples subject to extraction by ammonium lactate–acetate (AL) solution. The AL-method [7] is the standard method in Norway to assess the plant availability of P, K, Ca, Mg and Na [8]. Dried samples of material are extracted by a mixture of 0.1 M ammonium lactate and 0.4 M acetic acid, pH 3.75, and the concentrations of phosphate and other ions in the extract are measured after filtration by Inductive Coupled Plasma Mass Spectroscopy (ICP-MS). pH and dry matter (DM) in the slurries were measured at each sampling date.

The chemical characteristics of applied fishbones was assessed at SINTEF Norlab Department Namsos (Table 1). One sample of CFB and one of FFB were analysed for pH, concentration of total carbon (C) and nitrogen (N), nitrate, ammonium and 22 mineral elements. pH was measured after application of deionised water (v:v 1:2.5). For total C, thermal decomposition at 1200–1500 °C to convert all carbon into CO2 was applied in a total organic carbon analyzer, including a step to measure CO2 by a detector, following NS-EN 15936: 2012. For total N, Kjeldahl-N was applied, where all nitrogen is converted to ammonium sulphate by application of concentrated sulfuric acid, converting ammonium to ammonia gas by application of sodium hydroxide and measuring the amount of ammonia by distillation into hydrochloric acid and measuring the amount of acid not reacting with ammonia. For determination of ammonium, the ammonium concentration was determined by a photometer after developing a blue coloured complex with thymol, following an internal method for extraction and NS-EN ISO 11732. For determination of nitrate and chlorine, the sample was extracted with deionised water for one hour, and concentrations measured by ionic chromatography. For iodine, nitric acid and alkalic stabilisation was applied for dissolution before measurement by ICP-SFMS/ICP-AES.

Multi-element determination of selected elements by ICP-MS (internal method based on NS-EN ISO 17294-2: 2016) consists of a chemical digestion of the sample by a nitric acid/hydrogen peroxide solution at 120 °C for 30 min to bring ions into aquatic solution, followed by a quantitative assessment of concentrations of elements by the measuring instrument, Agilent ICP-MS 7900.

Volumes of Formic Acid Required for Targeted pH Levels in Fishbones

Initially, we wanted to study AL-extractable nutrients in fishbones amended with formic acid at pH 5.0 and 3.0, to assess the effect of suboptimal and excess amounts of formic acid application when the industry aims for a pH < 4.0 to avoid putrefaction. In practice, the pH value is not easy to monitor precisely in large volumes of material with high and somewhat variable buffering capacity. To decide the correct amounts of formic acid, a separate test was required to study how addition of formic acid affected the pH in coarse and fine fishbones (CFB, FFB). Aliquots of 25 g of CFB or FFB were placed in 500 ml plastic flasks, and 100 ml of deionised water applied to each flask. Thereafter, diluted formic acid was added to the flasks, while measuring over a period of 59 days the amounts of acid which were required to derive a pH of about 5.0 or 3.0. The four treatments (CFB pH 3, CFB pH 5, FFB pH 3, FFB pH 5) were conducted with three replicate flasks, whereas control flasks comprising CFB and FFB with only deionised water were not replicated. Diluted formic acid was made by one part of concentrated formic acid (98–100%) to nine parts of deionised water. pH values on each date of measurement are shown in Tables 2 and 3. Control flasks were measured at somewhat other dates than acidified flasks because it was not expected that pH changes would occur as rapidly in the water flasks. In acidified flasks pH was measured before application of diluted formic acid, and thereafter the volume of acid required to achieve a stable pH of 5.0 or 3.0 was measured. Between the pH measurements, the flasks were kept closed by screw caps. Before each pH measurement, the flasks were thoroughly shaken. The pH values were measured directly in the flasks.

The initial buffering test revealed that a stable pH of 5.0 could not be achieved for CFB or FFB (Table 3). After 1 week in room temperature the content of the flasks gave a bad odour when opened, and from about 4 weeks to the end of the test, the comment “visible growth of microorganisms, bad odour” was noted for all replicate flasks. In the flasks maintained at pH 3.0, no such bad odour was observed, indicating no microbial activity. A yellow colour was also observed in flasks with a bad odour. Hence, we decided instead to target pH levels of approximately pH 3.0 and 4.0. The test further revealed that slightly more formic acid was required for fine fishbones than for coarse fishbones to achieve a pH of 3.0, and that the pH decrease proceeded faster in FFB (Table 3).

Since diluted formic acid had been applied in the initial test, some additional testing with fishbones amended with 85% formic acid was conducted over 3 days to assess required volumes of such acid for pH 3 and 4 in fishbone slurries. 1.5 ml of deionised water per g of fishbones was applicable to achieve a slurry mimicking industrial conditions with a minimum proportion of visible liquid, and to facilitate uniform sampling. For this slurry, 0.18 ml of 85% formic acid g−1 FFB and 0.14 ml g−1 CFB was required per g of fishbones to achieve pH 4.0. For pH 3, 0.46 ml of 85% of formic acid g−1 FFB and 0.38 ml g−1 CFB was required.

Extractable Elements in Fishbones Amended with Formic Acid

For the main experiment, 500 ml plastic flasks were used, and 40 g dry fishbones + 60 ml deionised water was added to each plastic flask (= 1.5 g water g−1 fishbones). For control treatments, no further amendments were made to the flasks after thorough shaking. In acidified treatments, the amounts of 85% formic acid which had been decided by initial testing were applied. Per flask these amounts comprised 7.2 ml to fine fishbones (FFB) to derive pH 4.0 and 18.4 ml to derive pH 3.0; and 5.6 ml to coarse fishbones (CFB) to achieve pH 4.0 and 15.2 to achieve pH 3.0. The bottles were well shaken, thereafter kept closed in room temperature with daylight. Each treatment (n = 6) had three replicate flasks, in total 18 flasks. The treatments are further abbreviated as FFB3 (fine fishbones, pH 3.0), FFB4 (fine fishbones, pH 4.0), FFBH2O (fine fishbones, deionised water), and CFB3, CFB4 and CFBH2O (coarse fishbones with pH 3, pH 4 or only deionised water). The experiment lasted from October 6 (day 0) to November 30, 2020 (day 55). Sampling occurred on day 2 (Oct 8), 15 (Oct 21), 34 (Nov 9) and 55. On each sampling date the slurry was stirred by a plastic rod, pH was measured in each flask and about 13 g of material was sampled with a plastic spoon. The samples were split in two aliquots, where one was used for determination of dry matter content, and the other was extracted by AL-solution as described above. All laboratory work including pH measurements was carried out at SINTEF Norlab Department Surnadal, Norway, whereas other chemical analyses were conducted at SINTEF Norlab Department Namsos. Filtrated extracts were kept frozen until determination of the concentrations of P, K, Ca, and Mg by ICP-MS measurement as described above. One sample of frozen extract, from treatment FFBH2O was broken on the way to the laboratory, leaving only two replicate samples for analysis of this treatment and sampling date.

Statistical Analysis

To test whether changes in characteristics between sampling dates for single treatments were statistically significant, we applied a paired t-test. To compare if the average characteristic on a certain date differed significantly between only two treatments, we applied a two-sample t-test. To compare if the average values were statistically significant between treatments on each sampling date, we applied one-way analysis of variance (GLM) with a Tukey t-test to analyse differences between means. The calculations were made by Minitab software. The statistically significant differences are referred to as ***p < 0.001, **p < 0.01, *p < 0.05 and nearly significant as (*) for 0.05 < p < 0.1.

Results

Chemical Characteristics of Applied Fish Bones

The chemical composition of fishbones was comparable in CFB and FFB. The pH was slightly alkalic (Table 1). A significant content of carbon and nitrogen indicates that the bones contain a high amount of structural protein (collagen). Among the six macronutrients required for satisfactory growth of crop plants, the fishbones had high concentrations of N, P, Ca, and some Mg and S. The concentration of K was quite low as compared with the needs of crop plants, who often have K contents comparable to N. For several elements, the concentration was below the limit of detection.

In a typical apatite, the ratio of molecular weight between P and Ca equals (6 × 30.97:10 × 40.08) = 0.46. In the materials studied here, the P:Ca ratio was 0.38 (Table 1). This indicates that in addition to apatite, some carbonate (CaCO3, MgCO3) is also present. If all P is present as apatite, it will take up 248 g of Ca per kg of fishbones containing on average 115 g P per kg DM (Table 1). The remaining about 50 g of Ca per kg DM may be present as carbonate. This represents about 6% of the total calcium content.

Change of pH in Initial Test Targeting pH 3 and 5

In the control flasks, the pH in slurry from fine fishbones (FFB) was initially slightly below the pH in coarse fishbones (CFB; Table 2). pH increased over time, and after about 3 weeks it was somewhat higher in CFB than FFB. Overall, the pH increased from about 7.4 to about 8.5 when no acid was applied. In treatments targeted towards pH 5.0, about 14 ml of diluted acid was applied to 25 g of CFB over 59 days and 20 ml to FFB, but this could not counteract a significant increase in pH to 7 or above (Table 3). The volumes if diluted acid correspond to 0.07 and 0.1 ml of 85% formic acid g−1. When the target pH was 3.0, a stable pH level was achieved after 3 days for FFB and 14 days for CFB, with volumes of acid corresponding to 0.7 and 0.8 ml 85% formic acid g−1 for CFB and FFB. These values are somewhat higher than applied in the main experiment (0.38 and 0.46 ml g−1 to achieve pH 3 in CFB and FFB; see Methods). Possibly, acid consumption was increased with higher proportion of water in the slurries.

In the main experiment, the pH was quite stable after acidification and hence the values for each date are not shown here. The final pH after 55 days was 2.93 for FFB3, 3.97 for FFB4, 3.20 for CFB3 and 4.00 in CFB4. In control treatments, pH decreased slightly from 6.7 on day 2 to 6.5 on day 15 for FFBH2O, then increased to a final pH of 7.9 on day 55. For CFBH2O, pH was 6.9 on day 2 and increased to pH 8.0 on day 55. These values were somewhat below the pH levels obtained in the initial test, 8.3–8.7 (Table 2).

Content of Dry Matter in the Fishbone Slurries

The average content of dry matter (DM) on each sampling date varied from 35 to 54% (Fig. 1). In the control treatments the values were slightly decreasing over time, from 40 to 37% in CFB and 39 to 35% in FFB. The decrease from day 2 to 55 in the control treatments was nearly statistically significant (p = 0.053) for FFBH2O, but not for CFBH2O (p = 0.16). A decreasing trend may be explained by decomposition of organic material by microbial activity, converting solid material to liquids and gas.

Dry matter (%) at days 2, 15, 34 and 55 after acidification of grinded fishbones with 85% formic acid to pH 3 or 4. Values are averages of 3 replicate samples per treatment; sampling days are indicated by increasingly grey colour. CFB coarse fishbones (2–4 mm), FFB fine fishbones (< 0.71 mm), H2O = control with only water, numbers 3 and 4 refer to pH

Since formic acid will decompose into carbon monoxide or carbon dioxide plus water vapour by drying at 105 °C, the addition of formic acid was not supposed to increase the dry matter content. However, if chemical reactions occur, e.g., formation of calcium formate, less acid may disappear during drying. The average values were quite stable between 40 and 46% in CFB3, CFB4 and FFB4 (Fig. 1). In FFB3, the content of dry matter seemed to increase over time, especially from day 15 to 34, and from day 34 to 55. However, the differences were not statistically significant from one sampling day to the next, or from day 2 to 55 (p = 0.125).

Extractable Calcium in Fishbones Treated with 85% Formic Acid

The dissolution of calcium was significant with application of formic acid and increased with increased acidification for both types of material (Fig. 2b). The average concentrations of extractable Ca (Ca-AL) across all sampling dates were 49.8 and 50.9 g Ca-AL kg−1 DM for CFB4 and FFB4, and about twice as high for CFB3 and FFB3, 89.2 and 98.56 g Ca-AL kg−1 DM. The concentrations at pH 3 comprise about 30% of the total content of calcium, which was about 300 g Ca kg−1 DM (Table 1).

AL-extractable calcium (Ca-AL) at days 2, 15, 34 and 55 after acidification of grinded fishbones with 85% formic acid to pH 3 or 4. Values are averages of 3 replicate samples per treatment; sampling days are indicated by increasingly grey colour. CFB coarse fishbones (2–4 mm), FFB fine fishbones (< 0.71 mm), H2O = control with only water, numbers 3 and 4 refer to pH. Left side, a control treatments, right side, b acidified treatments. Statistically significant changes between sampling dates are indicated by horizontal bars between dates and the level of significance by an asterisk located near such bars

In the control treatments (Fig. 2a) the difference between FFB and CFB was higher than for the acidified treatments; the average concentrations across sampling dates were 548 and 261 mg Ca-AL kg−1 DM. The changes from one sampling date to the next, or from the start to the end of the experiment, were not statistically significant for the control treatments. The average values of Ca-AL comprised 0.18% of the total Ca content for FFBH2O and 0.09% for CFBH2O. In acidified treatments, several increases in Ca-AL were near to, or statistically significant (Fig. 2b).

The decreases from day 34 to day 55 for CFB3 and FFB3 could possibly indicate that some Ca was chemically bound over time e.g., by formation of complexes such as calcium formate. However, these changes were not statistically significant (p = 0.206 for FFB3; p = 0.168 for CFB3).

For Ca-AL, the effect of grinding was not significant. After 55 days, the concentration of AL-extractable Ca differed significantly between the acidified treatments (p = 0.000; GLM), with CFB4 (5.8 g) being lower than CFB3, FFB3 and FFB4 (9.1, 9.0 and 7.0 g). When FFB and CFB were compared across pH levels in a two-sample t-test, FFB had significantly more Ca-AL than CFB (p = 0.041).

Extractable Magnesium in Fishbones Treated with 85% Formic Acid

For extractable Mg (Mg-AL), the pattern was quite similar to the pattern of variation in extractable Ca (Figs. 2, 3), and there was a close correlation between these two characteristics (p = 0.000; r2 = 0.8, Fig. 4). In the control treatments, concentrations increased from 62 to 128 mg Mg-AL kg−1 DM for CFB and from 71 to 253 for FFB. The concentrations were slightly higher for finely ground fishbones (Fig. 3), but the difference in Mg-AL between FFB and CFB amended with water was not statistically valid on any sampling date (Table 4). The concentrations of Mg extractable by AL-solution in the controls comprised 3% for coarse fishbones (0.128 g/4.10 g × 100, Table 1) and 4% for fine fishbones (0.253 g/5.7 g × 100).

AL-extractable magnesium (Mg-AL) at days 2, 15, 34 and 55 after acidification of grinded fishbones with 85% formic acid to pH 3 or 4. Values are averages of 3 replicate samples per treatment; sampling days are indicated by increasingly grey colour. CFB coarse fishbones (2–4 mm), FFB fine fishbones (< 0.71 mm), H2O = control with only water, numbers 3 and 4 refer to pH. Statistically significant changes between sampling dates are indicated by horizontal bars between dates and the level of significance by an asterisk located near such bars

In acidified treatments, the concentrations of AL-extractable Mg were much higher (Fig. 3). The average total concentration of Mg in the fishbones was 4.9 g Mg kg−1 of DM (Table 1). The average values across sampling dates of FFB3, FFB4, CFB3 and CFB4 were 4.8, 4.8, 4.6 and 3.8 g Mg-AL kg−1 DM, indicating that nearly 100% of the total Mg was solubilised by formic acid treatment and especially with finer grinding. With pH 4, the concentration increased over time in both CFB and FFB. With pH 3, the dissolution of Mg seemed to occur immediately in FFB and within day 15 in CFB. On each sampling date there was a significant difference between acidified and non-acidified treatments. Comparable to the results for Ca-AL, no clear effect was found of grinding on the concentration of AL-extractable Mg (Table 4), and the effect of pH level was also not clear, even if acidification as such increased Mg-AL significantly.

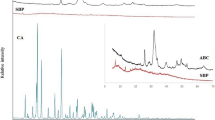

Extractable Phosphorus in Fishbones Treated with 85% Formic Acid

For phosphorus, the dissolution was much less than for calcium. Surprisingly, extractable P (P-AL) concentrations were much higher in fishbones amended with only water than in fishbones amended with 85% formic acid to pH 4 (Fig. 5). At pH 3, high P-AL concentrations, on average 6.8 g P-AL kg−1 DM, were achieved after 30 days in FFB. This comprised 6% of the total amount of P in the fishbones (on average 115 g kg−1 DM, Table 1). For CFB, the P-AL concentration at pH 3 was well below the P-AL concentration in water.

AL-extractable phosphorus (P-AL) at days 2, 15, 34 and 55 after acidification of grinded fishbones with 85% formic acid to pH 3 or 4. Values are averages of 3 replicate samples per treatment; sampling days are indicated by increasingly grey colour. CFB coarse fishbones (2–4 mm), FFB fine fishbones (< 0.71 mm), H2O = control with only water, numbers 3 and 4 refer to pH. Statistically significant changes between sampling dates are indicated by horizontal bars between dates and the level of significance by an asterisk located near such bars

In the control treatments, the maximum concentration of P-AL was 1.3 g P-AL kg−1 DM, which comprises 1.1% of the average total P content. For fine fishbones, there was a significant decrease over time from 1.3 to 0.6 g kg−1 DM (Fig. 3, FFBH2O). This may possibly be explained by microbial activity, changing extractable P to non-extractable organically bound P.

In acidified treatments, there was a small and nearly significant increase in P-AL from day 2 to 55 in CFB3. For FFB3 and 4, increases from day 2 to 55 were significant, but very small for FFB4. Only for FFB3, the increase was high, and occurred between day 15 and 34.

At each sampling date, the differences between treatments were statistically highly significant (p = 0.000; GLM; Table 5). The control treatments had significantly higher P-AL values than any acidified treatment on day 2 and 15. On days 34 and 55, a clear and positive effect was found of finely grinding of fishbones at pH 3. Hence, for P which is possibly the most important nutrient in fishbones from a crop fertilisation perspective, fishbones must be acidified to pH 3.0 for at least 30 days to increase the concentration of AL-extractable P significantly.

Extractable Potassium in Fishbones Treated with 85% Formic Acid

The average concentrations of extractable potassium (K) were somewhat higher in the control treatments than in acidified slurries and increased over time from 787 to 1023 mg K kg−1 DM for CFB and from 880 to 1023 mg for FFB (Fig. 6). These values are above the values of total K presented in Table 1 (0.75 g kg−1 DM in coarse and 0.62 g kg−1 DM in fine fishbones), indicating that the potassium in hydrolysed fishbones is highly soluble in both water and weak acids. In acidified treatments, the K-AL concentrations towards the end of the study were lower for FFB3 than for other treatments.

AL-extractable potassium (K-AL) at days 2, 15, 34 and 55 after acidification of grinded fishbones with 85% formic acid to pH 3 or 4. Values are averages of 3 replicate samples per treatment; sampling days are indicated by increasingly grey colour. CFB coarse fishbones (2–4 mm), FFB fine fishbones (< 0.71 mm), H2O = control with only water, numbers 3 and 4 refer to pH. Statistically significant changes between sampling dates are indicated by horizontal bars between dates and the level of significance by an asterisk located near such bars

Discussion

pH Increases in Control Treatments and with Target pH 5.0

The increase of pH in both control treatments, from about pH 7.0 to 8.0 in the slurry with less water (main experiment) and to about 8.5 in slurry with more water (initial test, Table 2), as well as the pH increase to 7 or above in the initial test targeting pH 5.0, may be explained by proteolysis where collagen or other protein is degraded to amines and ammonia (NH3). These compounds are common degradation products when fish is spoiled [20], and a higher liquid to solid ratio may have supported such spoiling. Since the gas could not emit from the closed flasks, it would increase the pH of the fishbone slurries.

Formic Acid Dissolved Ca and Mg

The fishbones contained much more Ca (about 30% of DM) than Mg (0.41–0.57% of DM, Table 1). The P:Ca ratio in the fishbones (Table 1) indicated that significant calcium carbonate minerals were present, in addition to apatite. For both Ca and Mg, acidification increased AL-extractable concentrations significantly. Similarly, adding CaCO3 to a substrate of rock P during extraction of P with 2% formic acid significantly affected the solubilisation of P [21]. The proportion of total Ca comprised of Ca-AL was about 30%, whereas for Mg, the total content was “recovered” as AL-extractable. This indicates that the fishbones likely contained a significant amount of calcite (CaCO3) in addition to some dolomite (CaMg(CO3)2) or possibly even magnesite (MgCO3). Several ratios of Ca to Mg may be found in carbonate minerals. As a geological rule of thumb, calcite dissolves more readily in acidic conditions than minerals containing magnesium [22], which could point to that the fishbone contained significant amounts of calcite. However, the simple analytical procedures applied in the present study are not appropriate for a description of the mineralogy of cod heads.

The dissolved calcium could also be derived from apatite. Carbonate accumulates in the bone cells of animals such as mice, rats and chicken with increasing age [23]. A cod fish may be several years old when being caught; FAO estimates that a typical cod may use about 5 years to reach a size of 30 inches (76 cm), where the fish may qualify as a cod and not a codling [24]. Calcium carbonate has been shown to be more readily dissolved at low pH than hydroxyapatite. In a study of calcium minerals for human intake [25], the solubility of various calcium minerals at various pH from 2.0 to 8.5 was reviewed. At pH 4.5, the observed solubility of calcium phosphate was 0.63 mg Ca ml−1, whereas the solubility of calcium carbonate at pH 4.5 was 46. This indicates that most of the calcium in carbonates would be dissolved before dissolving of apatite. As discussed in relation to Table 1, if all P in the fishbones was present as apatite, about 6% of the total Ca could be present in carbonates. When about 30% of the total Ca is dissolved (as Ca-AL), this indicates that the formic acid has dissolved apatite. As described in the Introduction, formic acid is relatively weak with a moderately low pKa. A stronger acid would likely have solubilised more minerals at pH 3, than was found here.

Dissolution of P Only in Fine Fishbones at pH 3

The experiment showed that fishbones had to be finely grinded, and acidified to pH 3.0 for at least 30 days, to increase the concentration of AL-extractable P significantly. If this increase was caused by dissolution of apatite, we should expect a comparable increase in AL-extractable Ca, but this was not the case.

High P-AL in Control Treatments

Microbial activity was observed in the control flasks, as evidenced by a yellow colour and strong odour. Microbial activity has been shown to release extractable P from apatite (e.g., Ref. [13]). However, in that study, the P release was explained by acidification. If microbial activity was the reason for the significantly higher concentration of extractable P in the water-amended fishbone slurries, especially at the start of the study, we could expect that the concentration would increase over time. Since, on the contrary, a decrease was observed in FFB and the concentration was maintained in CFB, and the concentration was quite high already after two days, the P-AL values seem to reflect that hydrolysed cod head bones contain about 1% AL-extractable P. This P may come from other chemical compounds than apatite. One possibility may be phospholipids, which comprise a significant part of the lipids in the bones of fat fish species. A significant fraction of the lipids in bones from lean fish (e.g., cod) has been proposed to be phospholipids [2].

We may ask why the concentration of P-AL was much lower in fishbones amended with formic acid to pH 4, than in the control treatments. For coarse fishbones at pH 3, the P-AL concentrations were also below the control levels. One possible explanation for this result is that already at the 1st sampling, significant concentrations of calcium had been dissolved (Fig. 2). It is possible that this calcium was precipitating phosphate ions derived from phospholipids to some form of calcium phosphate which was not extractable by AL solution.

Apatite Dissolution Conquered by Formation of Precipitation Minerals?

The narrow ratio of liquid to solid material in the slurries most likely supported the precipitation of secondary minerals. Phosphates of both calcium, magnesium and ammonium may have been precipitated, and as discussed above, phosphates from phospholipids may have been precipitated as phosphates not extractable by AL-solution in treatments CFB3, CFB4 and FFB4. If the reason for the significant increase in P-AL in FFB at pH 3 after more than 15 days was that with this pH, fineness of fishbones and storage period apatite was finally weathered, the P-AL increase should have been accompanied by a similar increase in Ca-AL, but that was not the case. Calcium may have become bound to formate anions in the slurries, but such formates are generally highly soluble in aquatic solutions such as the AL-solution. It may be that calcium ions dissolved from apatite after day 15 in FFB3 precipitated as calcium carbonate in a form less soluble in AL-solution. Even if the decreases in Ca-AL and Mg–AL from day 34 to 55 were not statistically significant in FFB3, the values indicate that less of these minerals were extractable towards the end of the study. This may possibly be due to some precipitation of sparely soluble CaCO3 or CaMg(CO3)2 after a rapid increase in dissolved Ca from apatite. Clarification of these processes would demand detailed studies of mineralogy.

More K-AL Than Total K

In the control treatments, and in FFB4, the concentrations of K-AL increased over time. This may be explained by dissolution of potassium salts, e.g. potassium chloride (KCl). In FFB3, the concentration decreased over time, and the acidified treatments generally had a somewhat lower concentration of K-AL than the controls. The decrease and the lower level in acidified treatments may possibly be explained by formation of some salts containing potassium in the slurries, even if potassium salts are generally highly soluble.

The total content of K varied from 620 to 750 mg K kg−1 DM (Table 1) and comprised on average 685 mg K. Several measurements of K-AL were well above this level, especially in the control treatments. Potassium as a monovalent cation is easily soluble. Hence it is not surprising that a very high proportion of the total K was extracted by AL solution in all treatments. It is more difficult to explain why the extractable K concentrations in the control treatments were well above the total K values. Potassium comprised a very small proportion of the total mineral content of the fishbones, and it may be that the analytical procedure underestimated this mineral.

Practical Application

For soils in need of maintaining a medium P concentration, e.g. in Norway set to 70 mg P-AL per kg of air-dried soil, a supply of 20 kg P per hectare and year is applicable [26]. To apply 20 kg of AL-available P from acidified fishbones, about 2900 kg per hectare of dry and grinded fishbones would be required. The total application of P would be about 330 kg, and the application would further apply about 145 kg N, 20 kg K, 870 kg Ca, 14 kg Mg, 5 kg sulphur (S) per hectare. The N has been shown to have an immediate effect [4], but some source of K would be required to ensure a balanced plant nutrition. For P, the residual effect will depend on factors like soil acidity and microbial activity and deserves further study. If not amended with acid, the availability of P in the fishbones will be much lower, but about 1% will be readily available. For preservation purpose, the pH must be 4 or below. One option for practical handling could be to acidify the sediments from 4 to 3 (or below) after the liquid phases of the hydrolysis have been removed. As demonstrated here, a thorough grinding of the bones is required, which may be challenging to conduct with acidified fishbones as the acid will cause corrosion. With the high content of calcium, there should be low risk of soil acidification from applying acidified fishbones to agricultural soil. However, the N availability for crop plants is very high [4, 5], which calls for careful timing of the date of application to avoid N loss.

Conclusions

This study revealed that a thorough grinding (to particles < 0.7 mm) and acidification by application of 85% formic acid to pH 3 over more than 15 days could dissolve about 6% of the total P in bones from cod heads, when assessed by an AL-extraction procedure. With less fine grinding, higher pH or lower duration of the acidification, AL-extractable P was decreased by acidification as compared with a water control. In fishbones amended with only water, about 1% of the total P was extracted by AL-solution. Since the total content of P in fishbones is high, about 11.5% of the dry matter, this is not a neglectable amount. It may be explained by presence of phospholipids.

The AL-soluble concentrations of calcium and magnesium increased significantly by acidification, but there was no large effect of decreasing the pH from 4 to 3. Most likely, other minerals than apatite were dissolved by formic acid and later by AL-solution.

Initially, we expected that the concentration of AL-extractable P in fishbones treated with formic acid would be higher than in fishbones not treated by acid. We also expected that the fineness of grinding, and decrease in pH, would increase the concentration of AL-extractable P in the fishbones. These assumptions were only partly confirmed. The reason for this is most likely that fishbones contain more minerals than rock phosphate, which affect the dissolution of P. Precipitation of secondary calcium phosphates may well have occurred with the high proportion of solid material in the slurries.

Further studies will be required to reveal the processes occurring with fishbone minerals during acidification. In practice, for application as fertiliser, residual effects of fishbone-derived P in on crop plants should be measured. Bonemeal from animal husbandry have been extensively studies as soil amendments, whereas much less studies have been carried out for P from fishbones.

Data Availability

The basic data will be made available upon request.

References

Ahuja, I., Dauksas, E., Remme, J.F., Richardsen, R., Løes, A.-K.: Fish and fish waste-based fertilizers in organic farming—with status in Norway: a review. Waste Manag. 115, 95–112 (2020). https://doi.org/10.1016/j.wasman.2020.07.025

Toppe, J., Albrektsen, S., Hope, B., Aksnes, A.: Chemical composition, mineral content and amino acid and lipid profiles in bones from various fish species. Comp. Biochem. Physiol. Part B 146(3), 395–401 (2007). https://doi.org/10.1016/j.cbpb.2006.11.020

Cordell, D., White, S.: Peak phosphorus: clarifying the key issues of a vigorous debate about long-term phosphorus security. Sustainability 3(10), 2027–2049 (2011). https://doi.org/10.3390/su3102027

Ahuja, I., Løes, A.-K.: Effect of fish bones and algae fibre as fertilisers for ryegrass. NORSØK report, vol. 4, no. 7, 2019, Norwegian Centre for Organic Agriculture, Tingvoll, Norway (2019). https://orgprints.org/id/eprint/36439

Løes, A.K., Ahuja, I., deBoer, A.: Harvesting our fertilisers from the sea—an approach to close the nutrient gaps in organic farming. Organic World Congress, Rennes, France September 8–10, 2021, Science Forum Topic 4 Innovation in Organic farming (2021)

Adeleke, R., Nwangburuka, C., Oboirien, B.: Origins, roles and fate of organic acids in soils: a review. S. Afr. J. Bot. 108, 393–406 (2017). https://doi.org/10.1016/j.sajb.2016.09.002

Égner, H., Riehm, H., Domingo, W.R.: Untersuchungen über die chemische Bodenanalyse als Grundlage für die Beurteilung des Nährtoffzustandes der Boden. II. Chemische Extraktionsmetoden zur Phosphor und Kaliumbestimmung. (Studies of chemical soil analysis to assess the nutrient content of soil. II Chemical extraction methods for measurement of phosphorus and potassium) Kungliga Lantbrukshögskolans Annaler 26, 199–215 (1960) (in German)

Krogstad, T.: Metoder for jordanalyser (Methods for soil analyses). NHL Institutt for jordfag. Rapport nr 6/92. Norwegian University of Life Sciences, Ås, Norway (1992) (in Norwegian)

Wang, T., Camps-Arbestain, M., Hedley, M., Bishop, P.: Predicting phosphorus bioavailability from high-ash biochars. Plant Soil 357, 173–187 (2012). https://doi.org/10.1007/s11104-012-1131-9

International Fertilizer Industry Association (IFA): Direct application of phosphate rock. https://fertilizer.org//images/Library_Downloads/2013_ifa_direct_application_pr.pdf. Accessed 23 June 2021

Szpak, P.: Fish bone chemistry and ultrastructure: implications for taphonomy and stable isotope analysis. J. Archaeol. Sci. 38, 3358–3372 (2011). https://doi.org/10.1016/j.jas.2011.07.022

Malde, M.K., Bügel, S., Kristensen, M., Malde, K., Graff, I.E., Pedersen, J.I.: Calcium from salmon and cod bone is well absorbed in young healthy men: a double-blinded randomised crossover design. Nutr. Metab. 7(61), 1–9 (2010)

Welch, S.A., Taunton, A.E., Banfield, J.F.: Effect of microorganisms and microbial metabolites on apatite dissolution. Geomicrobio J 19(3), 343–367 (2002). https://doi.org/10.1080/01490450290098414

Dorozkhin, S.V.: Dissolution mechanism of calcium apatites in acids: a review of literature. World J. Methodol. 2(1), 1–17 (2012)

Horvath, A.L.: Solubility of structurally complicated materials: II. Bone. J. Phys. Chem. Ref. Data 35(4), 1653–1668 (2006). https://doi.org/10.1063/1.2360606

Kittiphattanabawon, P., Benjakul, S., Visessanguan, W., Nagai, T., Tanaka, M.: Characterisation of acid-soluble collagen from skin and bone of bigeye snapper (Priacanthus tayenus). Food Chem. 89, 363–372 (2005). https://doi.org/10.1016/j.foodchem.2004.02.042

Porto, G.M., Neto, M.C.A., Finzer, J.R.D.: Solubility of phosphate rocks in citric acid. World Sci. Res. 5(1), 32–36 (2018)

Jenza, J.A.: Demystification of organic acid blends. Web post at eFeedLink.com, 5 October 2017. https://www.efeedlink.com/contents/10-05-2017/3a68e442-fbf1-428c-b515-7a77093da9e0-0101.html. Accessed 21 Oct 2021

Remme, J.F., Carvajal, A.K., Indergård, E., Toldnes, B., Slizyte, R., Grimsmo, L., Austnes, A.: Sluttrapport Heads Up I. Alternativ anvendelse av torskehoder. (Final report Heads Up I. Alternative applications of cod heads). SINTEF Report 2018: 00475 (2018). https://www.fhf.no/prosjekter/prosjektbasen/901308/ (in Norwegian)

Ghaly, A.E., Dave, D., Budge, S., Brooks, M.S.: Fish spoilage mechanisms and preservation techniques: review. Am. J. Appl. Sci. 7(7), 859–877 (2010). https://doi.org/10.3844/ajassp.2010.859.877

Braithwaite, A.C., Eaton, A.C., Groom, P.S.: Some factors associated with the use of the extractants 2% citric acid and 2% formic acid as estimators of available phosphorus in fertiliser products. Fertil. Res. 19, 175–181 (1989). https://doi.org/10.1007/BF01054459

King, H.M.: The “Acid Test” for carbonate minerals and carbonate rocks. https://geology.com/minerals/acid-test.shtml. Accessed 13 Oct 2021

Boskey, A.L., Coleman, R.: Aging and bone. J. Dental Res. 89, 1333–1348 (2010). https://doi.org/10.1177/0022034510377791

Food and Agriculture Organization of the United Nations (FAO). The Cod. http://www.fao.org/home/search/en/?q=The%20Cod#:~:text=www.fao.org-,%E2%80%BA%20...,-The%20cod%20is. Accessed 16 July 2021

Goss, S.L., Lemons, K.A., Kerstetter, J.E., Bogner, R.H.: Determination of calcium salt solubility with changes in pH and PCO2, simulating varying gastrointestinal environments. J. Pharm. Pharmacol. 59, 1485–1492 (2007). https://doi.org/10.1211/jpp.59.11.0004

Kristoffersen, A.: Gjødslingshåndbok (Handbook of fertiliser application). https://www.nibio.no/tema/jord/gjodslingshandbok?locationfilter=true. Accessed 13 Oct 2021 (in Norwegian)

Funding

Funding for this study was kindly provided by the County municipality of Møre and Romsdal, Norway for the project “Marine rest raw materials for fertilizers to organic agriculture” (RESTOR, 2017–2021).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study concept and design; and commented and approved the manuscript. Experimental work was conducted by JPA, SS and HW. AKL interpreted the data and was the responsible author. IA assisted with graphical presentations.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Løes, AK., Ahlin, J.P., Ahuja, I. et al. Effects of Formic Acid Preservation of Fishbones on the Extractability of Ammonium Lactate–Acetate Soluble Calcium, Phosphorus, Magnesium, and Potassium. Waste Biomass Valor 13, 3547–3559 (2022). https://doi.org/10.1007/s12649-022-01744-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01744-7