Abstract

The purpose of this article is to improve the understanding on sewage sludge (SS) pyrolysis behavior in a fluidized bed reactor between 700 and 890 °C. The experiments were carried out under a pure nitrogen atmosphere using sand and olivine as bed materials. The results gathered in this paper highlight the impact of temperature and bed materials on various performance criteria. It was observed that the use of olivine as a bed material affects the composition of the syngas, especially the fraction of the light hydrocarbons CH4 and C2HX. It was also noticed that increasing the pyrolysis temperature yielded more syngas and reduced the condensable species and char quantities. Furthermore, an increase in temperature led to an increase in the fraction of benzene in tars. Comparing different kinds of fuels revealed that SS pyrolysis yields less syngas than pinewood and more syngas than municipal green waste. SS pyrolysis led to significantly higher CH4 and C2HX yields than woody waste, as well as a higher tar quantity. It was also noticed that BTEX compounds account for 70% of the tars produced during the pyrolysis of each of the fuels that were studied at 850 °C. Findings show that the thermal decomposition of SS generates a syngas rich in H2 (25–37 mol%), CO (23–40%), CO2 (6–19%), CH4 (9–21%) and C2HX (4–17%). The syngas lower heating value is varying between 14,000 and 22,000 kJ/Nm3.

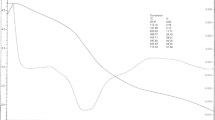

Graphic Abstract

Effect of temperature (700 and 850 °C) on sewage sludge (SS) pyrolysis products distribution in olivine fluidized bed reactor.

Similar content being viewed by others

Abbreviations

- d:

-

Pellets diameter (cm)

- d10, d50, d90 :

-

Fluidized media size distribution (µm)

- d3/2 :

-

Sauter mean diameter of fluidized media (µm)

- daf, B :

-

Dry ash free basis

- \({\text{F}}_{{{\text{daf}},{\text{B}}}}\) :

-

Mass flow rate of the fuel (daf, B) (kg/h)

- H2/CO:

-

Ratio between H2 and CO molar flow rates in the dry syngas (−)

- L:

-

Wood pellets length (cm)

- LHV:

-

Lower heating value of syngas (kJ/Nm3)

- MB :

-

Molar mass of the waste (daf, B) (kg−1 mol)

- Ni :

-

Molar flow rate of i constituent of syngas (mol/h)

- P:

-

Pressure (mbar)

- PG :

-

Syngas production yield (Nm3/kgdaf,B)

- PGi :

-

Production yield of i component (Nm3/kgdaf,B)

- T:

-

Bed temperature (°C)

- U:

-

Gas velocity in the reactor (m/s)

- Umf:

-

Minimum fluidization velocity (m/s)

- \(\dot{V}_{G} \left( t \right)\) :

-

Volumetric flow rate of the incondensable gases (Nm3/h)

- \(\dot{V}_{i} \left( t \right)\) :

-

Volume flow rate of different incondensable gaseous species (Nm3/h)

- \(V_{m}\) :

-

Molar volume in temperature and pressure at normal conditions (Nm3/mol)

- XcC :

-

Carbon conversion rate into char (−)

- XcG :

-

Carbon conversion rate into non-condensable gases (−)

- XcT :

-

Carbon conversion rate into tars (−)

- Yi :

-

Molar percentage of i component in syngas (−)

- ρs :

-

Skeletal density (kg/m3)

- \(\aleph_{\text{i}}^{\text{C}}\) :

-

Number of carbon atoms in i component (−)

References

Magdziarz, A., Werle, S.: Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manag. 34, 174–179 (2014). https://doi.org/10.1016/j.wasman.2013.10.033

Diblasi, C.: Modeling chemical and physical processes of wood and biomass pyrolysis. Prog. Energy Combust. Sci. 34, 47–90 (2008). https://doi.org/10.1016/j.pecs.2006.12.001

Hofbauer, H., Rauch, R., Foscolo, P., Matera, D.: Hydrogen rich gas from biomass steam gasification. 3 (n.d.)

Gomez-Barea, A., Nilsson, S., Vidal Barrero, F., Campoy, M.: Devolatilization of wood and wastes in fluidized bed. Fuel Process. Technol. 91, 1624–1633 (2010). https://doi.org/10.1016/j.fuproc.2010.06.011

Fonts, I., Gea, G., Azuara, M., Ábrego, J., Arauzo, J.: Sewage sludge pyrolysis for liquid production: a review. Renew. Sustain. Energy Rev. 16, 2781–2805 (2012). https://doi.org/10.1016/j.rser.2012.02.070

Patwardhan, P.R.: Understanding the product distribution from biomass fast pyrolysis. 162 (n.d.)

Link, S., Arvelakis, S., Paist, A., Martin, A., Liliedahl, T., Sjöström, K.: Atmospheric fluidized bed gasification of untreated and leached olive residue, and co-gasification of olive residue, reed, pine pellets and Douglas fir wood chips. Appl. Energy 94, 89–97 (2012). https://doi.org/10.1016/j.apenergy.2012.01.045

Morin, M., Nitsch, X., Pécate, S., Hémati, M.: Tar conversion over olivine and sand in a fluidized bed reactor using toluene as model compound. Fuel 209, 25–34 (2017). https://doi.org/10.1016/j.fuel.2017.07.084

Evans, R.J., Milne, T.A.: Molecular characterization of the pyrolysis of biomass. Energy Fuels 1, 123–137 (1987). https://doi.org/10.1021/ef00002a001

Déglise, X.: Les conversions thermochimiques du bois. Rev. For. Fr. (1982). https://doi.org/10.4267/2042/21577

Shafizadeh, F., Furneaux, R.H., Cochran, T.G., Scholl, J.P., Sakai, Y.: Production of levoglucosan and glucose from pyrolysis of cellulosic materials. J. Appl. Polym. Sci. 23, 3525–3539 (1979). https://doi.org/10.1002/app.1979.070231209

Dufour, A.: Optimisation de la production d’hydrogène par conversion du méthane dans les procédés de pyrolyse/gazéification de la biomasse

European Commision and the European Free Trade Association. Biomass gasification-tar and particles in products gases- sampling and analysis (2005)

Cypres, R.: Aromatic hydrocarbons formation during coal pyrolysis. Fuel Process. Technol. 15, 1–15 (1987). https://doi.org/10.1016/0378-3820(87)90030-0

Richter, H., Howard, J.: Formation of polycyclic aromatic hydrocarbons and their growth to soot—a review of chemical reaction pathways. Prog. Energy Combust. Sci. 26, 565–608 (2000). https://doi.org/10.1016/S0360-1285(00)00009-5

Mulholland, J.A., Lu, M., Kim, D.-H.: Pyrolytic growth of polycyclic aromatic hydrocarbons by cyclopentadienyl moieties. Proc. Combust. Inst. 28, 2593–2599 (2000). https://doi.org/10.1016/S0082-0784(00)80677-3

Thipkhunthod, P., Meeyoo, V., Rangsunvigit, P., Rirksomboon, T.: Describing sewage sludge pyrolysis kinetics by a combination of biomass fractions decomposition. J Anal Appl Pyrolysis 79, 78–85 (2007). https://doi.org/10.1016/j.jaap.2006.10.005

Wei, L., Wen, L., Yang, T., Zhang, N.: Nitrogen transformation during sewage sludge pyrolysis. Energy Fuels 29, 5088–5094 (2015). https://doi.org/10.1021/acs.energyfuels.5b00792

Schwab, A.W., Dykstra, G.J., Selke, E., Sorenson, S.C., Pryde, E.H.: Diesel fuel from thermal decomposition of soybean oil. J. Am. Oil Chem. Soc. 65, 1781–1786 (1988). https://doi.org/10.1007/BF02542382

Orsini, S., Parlanti, F., Bonaduce, I.: Analytical pyrolysis of proteins in samples from artistic and archaeological objects. J Anal Appl Pyrolysis 124, 643–657 (2017). https://doi.org/10.1016/j.jaap.2016.12.017

Zhang, Y., Kajitani, S., Ashizawa, M., Oki, Y.: Tar destruction and coke formation during rapid pyrolysis and gasification of biomass in a drop-tube furnace. Fuel 89, 302–309 (2010). https://doi.org/10.1016/j.fuel.2009.08.045

Dufour, A., Girods, P., Masson, E., Rogaume, Y., Zoulalian, A.: Synthesis gas production by biomass pyrolysis: effect of reactor temperature on product distribution. Int J Hydrog Energy 34, 1726–1734 (2009). https://doi.org/10.1016/j.ijhydene.2008.11.075

Dufour, A., Masson, E., Girods, P., Rogaume, Y., Zoulalian, A.: Evolution of aromatic tar composition in relation to methane and ethylene from biomass pyrolysis-gasification. Energy Fuels 25, 4182–4189 (2011). https://doi.org/10.1021/ef200846g

Shen, Y., Yoshikawa, K.: Recent progresses in catalytic tar elimination during biomass gasification or pyrolysis—a review. Renew. Sustain. Energy Rev. 21, 371–392 (2013). https://doi.org/10.1016/j.rser.2012.12.062

Li, C., Suzuki, K.: Tar property, analysis, reforming mechanism and model for biomass gasification—an overview. Renew. Sustain. Energy Rev. 13, 594–604 (2009). https://doi.org/10.1016/j.rser.2008.01.009

Fuentes-Cano, D., Gómez-Barea, A., Nilsson, S., Ollero, P.: The influence of temperature and steam on the yields of tar and light hydrocarbon compounds during devolatilization of dried sewage sludge in a fluidized bed. Fuel 108, 341–350 (2013). https://doi.org/10.1016/j.fuel.2013.01.022

RapagnaÂ, S., Jand, N., Kiennemann, A., Foscolo, P.U.: Steam-gasiÿcation of biomass in a uidised-bed of olivine particles. Biomass Bioenergy 11 (2000)

Abu El-Rub, Z., Bramer, E.A., Brem, G.: Review of catalysts for tar elimination in biomass gasification processes. Ind. Eng. Chem. Res. 43, 6911–6919 (2004). https://doi.org/10.1021/ie0498403

Detournay M. Vapogazéification de la biomasse en Lit Fluidisé Circulant : Élaboration des outils théoriques et expérimentaux (2011)

Abu El-Rub, Z., Bramer, E.A., Brem, G.: Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel 87, 2243–2252 (2008). https://doi.org/10.1016/j.fuel.2008.01.004

Fuentes-Cano, D., Gómez-Barea, A., Nilsson, S., Ollero, P.: Decomposition kinetics of model tar compounds over chars with different internal structure to model hot tar removal in biomass gasification. Chem. Eng. J. 228, 1223–1233 (2013). https://doi.org/10.1016/j.cej.2013.03.130

Nitsch, X., Commandré, J.-M., Valette, J., Volle, G., Martin, E.: Conversion of phenol-based tars over biomass char under H2 and H2O atmospheres. Energy Fuels 28, 6936–6940 (2014). https://doi.org/10.1021/ef500980g

Morin, M., Nitsch, X., Hémati, M.: Interactions between char and tar during the steam gasification in a fluidized bed reactor. Fuel 224, 600–609 (2018). https://doi.org/10.1016/j.fuel.2018.03.050

Di Blasi, C., Signorelli, G., Di Russo, C., Rea, G.: Product distribution from pyrolysis of wood and agricultural residues. Ind. Eng. Chem. Res. 38, 2216–2224 (1999). https://doi.org/10.1021/ie980711u

Pecate, S., Kessas, S.A., Morin, M., Hemati, M.: Beech wood gasification in a dense and fast internally circulating fluidized bed. Fuel 236, 554–573 (2019). https://doi.org/10.1016/j.fuel.2018.09.025

Piskorz, J., Scott, D.S., Westerberg, I.B.: Flash pyrolysis of sewage sludge. Ind. Eng. Chem. Process. Des. Dev. 25, 265–270 (1986). https://doi.org/10.1021/i200032a042

Stammbach, M.R., Kraaz, B., Hagenbucher, R., Richarz, W.: Pyrolysis of sewage sludge in a fluidized bed. Energy Fuels 3, 255–259 (1989). https://doi.org/10.1021/ef00014a022

Kaminsky, W., Kummer, A.B.: Fluidized bed pyrolysis of digested sewage sludge. J. Anal. Appl. Pyrolysis 16, 27–35 (1989). https://doi.org/10.1016/0165-2370(89)80033-6

Fonts, I., Juan, A., Gea, G., Murillo, M.B., Sánchez, J.L.: Sewage sludge pyrolysis in fluidized bed, 1: influence of operational conditions on the product distribution. Ind. Eng. Chem. Res. 47, 5376–5385 (2008). https://doi.org/10.1021/ie7017788

Park, E.-S., Kang, B.-S., Kim, J.-S.: Recovery of oils with high caloric value and low contaminant content by pyrolysis of digested and dried sewage sludge containing polymer flocculants. Energy Fuels 22, 1335–1340 (2008). https://doi.org/10.1021/ef700586d

Fonts, I., Azuara, M., Lázaro, L., Gea, G., Murillo, M.B.: Gas chromatography study of sewage sludge pyrolysis liquids obtained at different operational conditions in a fluidized bed. Ind. Eng. Chem. Res. 48, 5907–5915 (2009). https://doi.org/10.1021/ie900421a

Fonts, I., Azuara, M., Gea, G., Murillo, M.B.: Study of the pyrolysis liquids obtained from different sewage sludge. J. Anal. Appl. Pyrolysis 85, 184–191 (2009). https://doi.org/10.1016/j.jaap.2008.11.003

Park, H.J., Heo, H.S., Park, Y.-K., Yim, J.-H., Jeon, J.-K., Park, J., et al.: Clean bio-oil production from fast pyrolysis of sewage sludge: effects of reaction conditions and metal oxide catalysts. Bioresour. Technol. 101, S83–S85 (2010). https://doi.org/10.1016/j.biortech.2009.06.103

Nipattummakul, N., Ahmed, I.I., Kerdsuwan, S., Gupta, A.K.: Hydrogen and syngas production from sewage sludge via steam gasification. Int J Hydrog Energy 35, 11738–11745 (2010). https://doi.org/10.1016/j.ijhydene.2010.08.032

Jaramillo-Arango, A., Fonts, I., Chejne, F., Arauzo, J.: Product compositions from sewage sludge pyrolysis in a fluidized bed and correlations with temperature. J. Anal. Appl. Pyrolysis 121, 287–296 (2016). https://doi.org/10.1016/j.jaap.2016.08.008

Anca-Couce, A.: Reaction mechanisms and multi-scale modelling of lignocellulosic biomass pyrolysis. Prog. Energy Combust. Sci. 53, 41–79 (2016). https://doi.org/10.1016/j.pecs.2015.10.002

Kessas, S.A. Etude expérimentale de pyrolyse et de vapogazéification des boues de STEP en réacteurs à lit fluidisé entre 700 et 900 °C : comparaison avec les déchets boisés (2019)

Acknowledgements

The authors thank “L’Agence de l’Environnement et de la Maîtrise de l’Energie (Ademe)” for financial support of this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendices

Appendix 1

See Table 8.

Appendix 2

Inert nitrogen was chosen as the reference gas (tracer) for the analysis. It is introduced into the reactor with a known flow rate.

The gasification reactor performance is characterized by:

-

The composition of the incondensable gas (syngas) yi, determined by micro-GC,

-

The volumetric flow rate of the incondensable gases, considered at normal conditions, leaving the reactor, \(\dot{V}_{G} \left( t \right)\).

-

Knowing the nitrogen flow rate introduced into the reactor \(\dot{V}_{N2}\) and its molar (volume) fraction \(y_{N2} \left( t \right)\) determined by the chromatographic analysis, we can calculate this quantity:

-

The volume flow rate of different incondensable gaseous species. It is calculated by:

where \({\dot{\text{V}}}_{\text{G}} \left( {\text{t}} \right)\) and \({\text{y}}_{\text{i}} \left( {\text{t}} \right)\) are the volume flow rate of syngas and the molar fraction of the compound in syngas (excluding N2), respectively.

-

The production yield of each incondensable gaseous compound, PGi, defined as the volume of each gaseous constituent (considered at normal conditions) produced per kg of dry and ash free fuel (daf, B):

where PGi is production yield of i component (Nm3/kg daf,B), \({\dot{\text{V}}}_{\text{i}} \left( {\text{t}} \right)\) is the flow rate of noncondensable gas (Nm3/h) and \({\text{F}}_{{{\text{daf}},{\text{B}}}}\) is the mass flow rate of the fuel (daf, B) (kg/h);

-

The production yield of syngas, PG, is defined as the syngas volume produced per kg of fuel daf, B:

with PG the syngas production yield (Nm3/kgdaf,B), \({\dot{\text{V}}}_{\text{i}} \left( t \right)\) the volume flow rate of the incondensable gases (Nm3/h) and \({\text{F}}_{{{\text{daf}},{\text{B}}}}\) the mass flow rate of the fuel daf, B (kg/h)

In order to quantify the carbon distribution into different phases, we have defined the following quantities:

-

The carbon conversion rate into non-condensable gases, \({\text{X}}_{\text{cG}}\), in steady state is defined as the ratio between the carbon moles amount in the gaseous products and the carbon number of moles contained in the fuel:

-

Ni is the molar flow rate of i constituent of syngas: \(N_{i} = \frac{{{\dot{\text{V}}}_{\text{i}} \left( t \right) }}{{V_{m} }}\) and \({\dot{\text{V}}}_{\text{i}} \left( t \right)\) is the volume flow rate of incondensable gases (Nm3/h) and \(V_{m}\) is the molar volume in temperature and pressure at normal conditions (= 0.0224 Nm3/mol).

-

\(\aleph_{\text{i}}^{\text{C}}\) is the number of carbon atoms in i component (i = CO, CO2, CH4, C2H2, C2H4 and C2H6) and MB is the molar mass of the waste (daf, B) (kg/mol).

-

The carbon conversion rate into char \({\text{X}}_{\text{cC}}\), defined as the ratio between the number of moles of carbon in the solid residue (char) and the number of moles of carbon introduced as fuel. The char production yield obtained during the pyrolysis of fuels was determined by combustion after each experiment. One the fuel feeding is interrupted, the fluidizing gas is switched to air, and the evolution of the fumes composition versus time is recorded (CO, CO2, N2, O2). By integration,, we first calculate the number of moles of carbon remaining in the fluidized bed, we can then estimate the conversion rate of carbon into char:

From these results and by knowing the chemical formula of char, we calculate the mass of char produced (not converted) per kg of dry ash free fuel.

-

The carbon conversion rate into tars, \({\text{X}}_{\text{cT}}\), defined as the ratio between the number of moles of carbon in the tars and the number of carbon introduced in the reactor as fuel. It is estimated by difference:

-

The mass production yield of the pyrolysis products expressed in g/kg of fuel daf, B is calculated as follows: \({\text{P}}_{\text{Gi}} *\frac{{M_{i} }}{{V_{m} }}\) where \({\text{P}}_{\text{Gi}}\) is the production yield of i constituent (Nm3/kg daf,B), \(M_{i}\) is the molar mass of the i constituent and \(V_{m}\) is the molar volume (= 0,0224 Nm3/mol).

-

The low heating value is expressed as follows:

\(LHV_{i}\) represents the low heating value of i constituent in the syngas, and \(y_{i}^{syngas}\) is its molar fraction in steady state.

-

The production yield of tars and pyrolytic water, expressed in g/kgdaf,B, were determined as follows:

For a controlled flow rate and sampling time (1 h), the mass variation of the isopropanol solution (used in the tar protocol) is measured. This mass variation corresponds to the quantity of pyrolytic liquid (water and tars) captured. Knowing the flow rate of the incondensable gas, measured using a rotameter placed at the outlet of the vacuum pump, and the sampling time, we can calculate the production yield of the pyrolytic liquid in g/Nm3 of dry gas. The dry gas included nitrogen (tracer) and the syngas.

By measuring the mass fraction of the water in the sample (isopropanol + pyrolytic liquid), by Karl Fischer analysis, we can then calculate the water and tars contents in g/Nm3 of dry gas.

The measurement of the volume fraction of nitrogen in the dry gas allows us to express these condensable species quantities in g/Nm3 of dry syngas. Furthermore, they can also be represented in g/kg of fuel daf, B by multiplying by the value of syngas production yield (Nm3/kgdaf,B). Note that the water amount measured included the water produced by pyrolysis (pyrolytic water) and that introduced by the moisture in the fuel. By subtracting the fuel moisture, we can get the real value of the pyrolytic water yield.

Appendix 3

Appendix 4

See Table 9.

Rights and permissions

About this article

Cite this article

Kessas, S.A., Esteves, T. & Hemati, M. Products Distribution During Sewage Sludge Pyrolysis in a Sand and Olivine Fluidized Bed Reactor: Comparison with Woody Waste. Waste Biomass Valor 12, 3459–3484 (2021). https://doi.org/10.1007/s12649-020-01209-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01209-9