Abstract

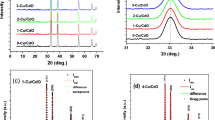

The effect of ageing on electrical properties of Fe-doped CuO thin films was investigated in this study. The pure and Fe (2, 4, 6; mol%)-doped CuO films were prepared by using spin coating technique and characterized by using X-ray diffractometer (XRD), field emission-scanning electron microscopy (FE-SEM), energy-dispersive X-ray spectroscopy (EDX), UV–Vis spectrophotometer and two-probe technique. The results showed that the pure and Fe-doped CuO thin films had a monoclinic phase and the monoclinic structure did not change with Fe doping. As the crystal size increased, the dislocation density and strain decreased. From the electron microscopy images, it is clearly observed that the pure and Fe-doped CuO thin films contain spherical structures. The energy band gaps of the thin films were estimated as 3.80, 3.89, 3.98 and 4.11 eV, respectively. The conductivity of the thin films increased with increasing temperature from 300 to 450 K. The activation energy of the films increased with Fe doping. These thin films are potential candidates for solar cell applications.

Similar content being viewed by others

Data availability

All data are contained within the manuscript or are available from the author on reasonable request.

References

M S Aguilar, I Zarazúa, R A Rodrìguez, T Lopez-Luke, and G Rosas J Solid State Chem. 305 122648 (2022)

S S Parui, N Kumar, P Tiwari, N Tiwari, and R N Chauhan Materials Today: Proceedings 41 233 (2020)

S Shen, J Jiang, P Guo, C X Kronawitter, S S Mao, and L Guo Nano Energy 1 732 (2012)

A A Qureshi, S Javed, H M A Javed, A Akram, M S Mustafa, U Ali, and M Z Nisar Mater. Sci. in Semicond. Process. 123 105545 (2021)

A Tripathi, T Dixit, J Agrawal, and V Singh Appl. Phys. Lett. 116 111102 (2020)

Q Zhang, K Zhang, D Xu, G Yang, H Huang, F Nie, C Liu, and S Yang Prog. Mater. Sci. 60 208 (2014)

X Yu, T J Marks, and A Facchetti Nat. Mater. 15 383 (2016)

C Yang, F Xiao, J Wang, and X Su J. Colloid Interface Sci. 435 34 (2014)

F Teng, W Yao, Y Zheng, Y Ma, Y Teng, T Xu, Z Liang, and Y Zhu Sensors and Actuators B: Chemical 134 761 (2008)

J S Shaikh, R C Pawar, R S Devan, Y R Ma, P P Salvi, S S Kolekar, and P S Patil Electrochimica Acta 56 2127 (2011)

K Velsankar, S Suganya, P Muthumari, S Mohandoss, and S Sudhabar J. Environ. Chem. Eng. 9 106299 (2021)

R Shabu, A M Ezhil, C Sanjeeviraja, and C Ravidhas Mater. Res. Bull. 68 1 (2015)

R Tan, Z Wei, J Liang, Z Lv, B Chen, J Qu, W Yan, and J Ma Mater. Res. Bull. 116 131 (2019)

S Upadhyay, D Sharma, V R Satsangi, R Shrivastav, U V Waghmare, and S Dass Matter. Chem. Phys. 160 32 (2015)

C Y Chiang, Y Shin, and S Ehrman Appl Energy 164 1039 (2016)

J Oh, H Ryu, W Lee, and J Bae Ceram Int 44 89 (2018)

J Oh, H Ryu and W Lee Compos. Part B 163 59 (2019)

M Iqbal, A A Thebo, A H Shah, A Iqbal, K H Thebo and S Phulpoto and A Mohsin Inorg. Chem. Commun 76 71 (2017)

X Xiong, C You, Z Liu, A M Asiri, and X Sun ACS sustain. Chem. Eng. 6 2883 (2018)

M Chaudhary, M Singh, A Kumar, Prachi, Y K Gautam, A K Malik, Y Kumar, and B P Singh Ceram Int 47 2094 (2021)

R V Vovk, N R Vovk, and O V Dobrovolskiy Adv. Condens. Matter. Phys. 2013 931726 (2013)

A Kuddus, J Hossain, and A B M Ismail J. Optoelectron Adv. Mater. 23 237 (2021)

R R Prabhu, A C Saritha, M R Shijeesh, and M K Jayaraj J. Mater. Sci. Eng. B 220 82 (2017)

H Absike, Z Essalhi, H Labrim, B Hartiti, N Baaalla, M Tahiri, B Jaber, and H Ez-zahraouy Opt. Mater. 118 111224 (2021)

M Faisal, S B Khan, M M Rahman, A Jamal, and A Umar Mater. Lett. 65 1400 (2011)

K Yao, S Liu, Y Dong, B Wang, J Bian, and M Ma JMADE 90 129 (2016)

J Wu, K S Hui, K N Hui, L Li, and H Chun, and Y R Cho J. Mater. Sci.: Mater. Electron 27 1719 (2016)

Y Wang, X Zhang, J Xu, Y Shen, C Wang, F Li, Z Zhang, J Chen, Y Ye, and R Shen Def. Technol. 17 1307 (2021)

N Lehraki, M S Aida, S Abed, N Attaf, A Attaf, and M Poulain Curr. Appl. Phys. 12 1283 (2012)

J Uddin, M Sharmin, M N Hasan, and J Podder Opt. Mater. 119 111388 (2021)

S Dolai, R Dey, S Das, S Hussain, R Bhar, and A K Pal J. Alloys Compd. 724 456 (2017)

A A Menazea and A M Mostafa J. Environ. Chem. Eng. 8 104104 (2020)

J Sultana, S Paul, A Karmakar, R Yi, G K Dalapati, and S Chattopadhyay Appl. Surf. Sci. 418 380 (2017)

S Paul, J Sultana, A Bhattacharyya, A Karmakar, and S Chattopadhyay Opt. 164 745 (2018)

K G Yang, P Hu, S X Wu, L Z Ren, M Yang, W Q Zhou, F M Yu, Y J Wang, M Meng, G L Wang, and S W Li Mater. Lett. 166 23 (2016)

M ul haq, M Iqbal, M A Z G Sial, S Shabbir, M Siddiq, and A Iqbal J. Photochem. Photobiol. A 335 112 (2017)

D M Chethana, T C Thanujaa, H M Mahesh, M S Kiruba, A S Jose, H Barshilia, and J Manjanna Ceram. Int. 47 10381 (2021)

D Jundale, S Pawar, M Chougule, P Godse, S Patil, B Raut, S Sen, and V Patil J. Sens. Technol. 1 36 (2011)

T Yi, C Guo, S Zhao, K Zhan, W Gao, L Yang, and G Du Eur. J. Wood Wood Prod. 78 471 (2020)

O Daoudi, Y Qachaou, A Raidou, K Nouneh, M Lharch, and M Fahoume Superlattices Microstruct. 127 93 (2019)

S Manna and S K De J. Magn. Magn. Mater. 322 2749 (2010)

K Kannaki, P S Ramesh, and D Geetha Materials Today: Proceedings 3 2329 (2016)

Z Pezeshki-nejad, S Alikhanzadeh-arani, and M A Kashi J. Magn. Magn. Mater. 482 301 (2019)

A M El Sayed and M Shaban Spectrochim. Acta. A Mol. Biomol. Spectrosc. 149 638 (2015)

S M Yakout, and A M El-Sayed Adv. Powder. Technol. 30 2841 (2019)

H Naatz, S Lin, R Li, W Jiang, Z Ji, C H Chang, J Köser, J Thöming, T Xia, A E Nel, L Mädler, and S Pokhrel ACS Nano. 11 501 (2018)

A Kaphle, T Reed, A Apblett, and P Hari J. Nanomater. 2019 7034620 (2019)

Y Yang, D Xu, Q Wu, and P Diao Sci. Rep. 6 35158 (2016)

M Nasir, G Kumar, P M Shirage, and S Sen J. Nanosci. Nanotechnol. 17 1345 (2017)

N M Basith, J J Vijaya, L J Kennedy, and M Bououdina Physica E 53 193 (2013)

J Koshy and K C George Int. J. Nanosci. Nanotechnol. 6 1 (2015)

N Bouazizi, R Bargougui, A Oueslati, and R Benslama Adv. Mater. Lett. 6 158 (2015)

M Yuksel, J R Pennings, F Bayansal, and J T W Yeow Physica B Condens. Matter. 599 412578 (2020)

A Rose, Wiley Interscience, New York, (1963)

Q Lin, A Armin, P L Burn, and P Meredith Nat. Photonics 9 687 (2015)

S Wu, Y Du, and S Sun Chem. Eng. J. 307 189 (2017)

T Dylla, F Finger, and R Carius Mat. Res. Soc. Symp. Proc. 762 81 (2003)

T Lim and H Park Int. J. Mater. Sci. Appl. 3 100 (2014)

R Bruggemann and N Souffi Non Cryst. Solids 352 1079 (2006)

D L Staebler and C R Wronski Appl. Phys. Lett. 31 292 (1977)

P Samarasekara, U Wijesingh, and E N Jayaweera GESJ: Phys. 1 13 (2015)

M Caglar, Y Caglar, S Aksoy, and S Ilican Appl. Surf. Sci. 256 4966 (2010)

Z Wang, L Zhang, T U Schülli, Y Bai, S A Monny, A Du, and L Wang Angew. Chem. 58 17604 (2019)

F Z Chafi, B Fares, A Hadri, C Nassiri, L Laaneb, N Hassanain, and A Mzerd IRSEC 1209 (2015)

D P Joseph and C Venkateswaran J. Korean Phys. Soc. 61 449 (2012)

M Gunes, E Turan, and G Yılmaz Phys. Status Solidi C 7 816 (2010)

Z M Saleh, G Nogay, E Ozkol, G Yilmaz, M Sagban, M Gunes, and R Turan J. Phys. 92 713 (2014)

A D Faisal and W Khalid J. Mater. Sci. Mater. Electron 28 18903 (2017)

Funding

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

SY carried out methodology, investigation, formal analysis, writing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The author has declared no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yildirimcan, S. Effect of ageing on electrical properties of Fe-doped CuO thin films deposited by spin coating technique. Indian J Phys 97, 1707–1716 (2023). https://doi.org/10.1007/s12648-022-02511-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-022-02511-z