Abstract

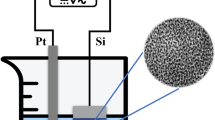

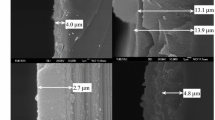

In this work, the capacity of porous silicon (PS) machined by laser photoetching was studied as an ethanol sensor, as well as the influences of the type and the conductivity of the crystalline silicon used to obtain sensors. The resistivities used were 1–10 and 0.0014–0.004 Ω∙cm, both wafers were n-type. The response of the device was determined at room temperature (27 °C). The results can be used to appropriately select the conductivity of semiconductor materials to be used as sensors. Infrared spectroscopy confirms the absorption of ethanol in the surface of the photoetched PS. Morphological analysis revealed a macroporous structure, with pore diameters of 2.6 and 0.39 μm for the wafers of 1–10 and 0.0014–0.004 Ω∙cm respectively. The macroporous structure demonstrates a high sensibility and exhibited excellent sensing characteristics during the detection of low concentrations of ethanol. The quantity of ethanol was registered with the changes in the voltage of operation. The performance of the sensor was characterized by curves of voltage vs. time. The minimum quantity of ethanol analyzed was 1 µl. The results demonstrate that photoetched PS has the potential to develop sensitive sensors.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Severiano F, García G, Castañeda L, Gracia-Jiménez JM, Gómez-Pozos H, Luna-López JA (2014) Electroluminescent devices based on junctions of indium doped zinc oxide and porous silicon. J Nanomater 14:1–7

Gör Bölen M, Karacali T (2020) A novel proton-exchange porous silicon membrane production method for µDMFCs. Turk J Chem 44(4):1216–1226

Vercauteren R, Leprince A, Mahillon J, Francis LA (2021) Porous silicon biosensor for the detection of bacteria through their lysate. Biosensors (Basel) 11(2):27

Kumeria T, McInnes SJP, Maher S, Santos A (2017) Porous silicon for drug delivery applications and theranostics: recent advances, critical review and perspectives. Expert Opin Drug Deliv 14(12):1407–1422

Liu D, Lipponen K, Quan P, Wan X, Zhang H, Mäkilä E, Salonen J, Kostiainen R, Hirvonen J, Kotiaho T, Santos HA (2018) Impact of pore size and surface chemistry of porous silicon particles and structure of phospholipids on their interactions. ACS Biomater Sci Eng 4(7):2308–2313

Riikonen J, Salomäki M, van Wonderen J, Kemell M, Xu W, Korhonen O, Ritala M, MacMillan F, Salonen J, Lehto V-P (2012) Surface chemistry, reactivity, and pore structure of porous silicon oxidized by various methods. Langmuir 28(28):10573–10583

Severiano F, López V, García-Salgado G, Delgado R, Ramírez NC (2021) Structural properties of porous silicon obtained with laser photoetching assisted by computerized numeric control. J Laser Appl 33:022001

Başak FK, Kayahan E (2022) White, blue and cyan luminescence from thermally oxidized porous silicon coated by green synthesized carbon nanostructures. Mater 124:111990

Kadlečíková M, Breza J, Vančo L, Mikolášek M, Hubeňák M, Racko J, Greguš J (2018) Raman spectroscopy of porous silicon substrates. Optik 174:347–353

Sun X, Sharma P, Parish G, Keating A (2021) Enabling high-porosity porous silicon as an electronic material. Micropor. Mesopor. Mater. 312:110808

Tipparat P, Lapanantnoppakhun S, Jakmunee J, Grudpan K (2001) Determination of ethanol in liquor by near-infrared spectrophotometry with flow injection. Talanta 53(6):1199–1204

Burikov S, Dolenko T, Patsaeva S, Starokurov Y, Yuzhakov V (2010) Raman and IR spectroscopy research on hydrogen bonding in water–ethanol systems. Mol Phys 108(18):2427–2436

Fine GF, Cavanagh LM, Afonja A, Binions R (2010) Metal oxide semi-conductor gas sensors in environmental monitoring. Sensors 10:5469–5502

Miller DR, Akbar SA, Morris PA (2014) Nanoscale metal oxide-based heterojunctions for gas sensing: a review. Sens Actuators B Chem 204:250–272

Acknowledgements

F. Severiano thanks CONACYT for its support through project 165 of cátedras CONAHCYT.

Funding

This research received no funding.

Author information

Authors and Affiliations

Contributions

Author Contributions F. Severiano prepared the experiments and wrote the main manuscript text. G. García Salgado, M. Salazar, J. Flores, O. Zaca, and M. Moreno helped with the analysis and written of the text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Ethics Approval

This paper fulfills the ethical standards of this journal.

Consent to Participate

All the authors agree with the revision of this paper in this journal.

Consent for Publication

All the authors agree with the publication of this paper.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Carrillo, F.S., Salgado, G.G., Villanueva, M.S. et al. Potential of Porous Silicon Machined by Laser Photoetching to be used as Sensor. Silicon (2024). https://doi.org/10.1007/s12633-024-02974-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12633-024-02974-1