Abstract

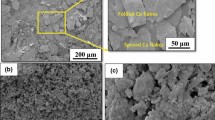

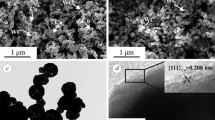

Spark plasma sintering (SPS) is a novel approach to fabricate Cu- SiC composites which have a relatively broad range of potential uses in space applications. The Cu- 4 wt% SiC composite with homogeneously dispersed SiC particles has been successfully synthesized at various SPS temperatures. In this study, the effect of SPS temperatures on the phase evaluation and mechanical characteristics of the Cu- 4 wt% SiC composite was investigated. From the results, it was confirmed that the optimum sintering temperature for Cu- 4 wt% SiC composite is 950°C. Raising the spark plasma sintering temperature from 850°C to 950°C led to a higher concentration of copper-liquid phase which accelerates the SiC particle rearrangement and fills the interstitial voids present in the interfaces of matrix and reinforcements which improves the mechanical properties of the Cu- 4 wt% SiC composite. However, increasing the SPS temperature by more than 950°C prone to the generation of the copper net and inhomogeneous SiC particle dispersion in the copper phases and declines the performance characteristics of the synthesized composite. The Cu- 4 wt% SiC composite sintered at 950°C exhibits superior mechanical characteristics than the composite sintered at 850°C, 900°C and 1000°C.

Similar content being viewed by others

Data Availability

All authors agreed that all relevant information from the Experiment is presented in this drafted manuscript.

References

Câmara NT, Raimundo RA, Lourenço CS et al (2021) Impact of the SiC addition on the morphological, structural and mechanical properties of cu-SiC composite powders prepared by high energy milling. Adv Powder Technol 32:2950–2961. https://doi.org/10.1016/j.apt.2021.06.006

Akbarpour MR, Mousa Mirabad H, Alipour S (2019) Microstructural and mechanical characteristics of hybrid SiC/cu composites with nano- and micro-sized SiC particles. Ceram Int 45:3276–3283. https://doi.org/10.1016/j.ceramint.2018.10.235

Altinsoy I, Celebi Efe FG, Aytaş D et al (2013) Some properties of cu-B4C composites manufactured by powder metallurgy. Period Eng Nat Sci 1:34–38. https://doi.org/10.21533/pen.v1i1.14

Zhan Y, Zhang G (2003) The effect of interfacial modifying on the mechanical and wear properties of SiCp/cu composites. Mater Lett 57:4583–4591. https://doi.org/10.1016/S0167-577X(03)00365-3

Wei H, Li M, Zou J, Gong Y (2023) Study on sintering process of Ti2SnC modified copper-graphite composites. Vacuum 209:111813. https://doi.org/10.1016/j.vacuum.2023.111813

Wang F, Li Y, Wang X et al (2016) In-situ fabrication and characterization of ultrafine structured cu-TiC composites with high strength and high conductivity by mechanical milling. J Alloys Compd 657:122–132. https://doi.org/10.1016/j.jallcom.2015.10.061

Zhou D, Geng H, Zeng W et al (2018) High temperature stabilization of a nanostructured cu-Y2O3 composite through microalloying with Ti. Mater Sci Eng A 712:80–87. https://doi.org/10.1016/j.msea.2017.11.105

Li J, Li F, Wu S et al (2019) Variation of microstructure and mechanical properties of hybrid particulates reinforced Al-alloy matrix composites with ultrasonic treatment. J Alloys Compd 789:630–638

Raimundo RA, Costa FA, Morales MA et al (2020) Effect of the high energy milling on the microstructure of cu-20%WC composite powders prepared with recycled WC. Int J Refract Met Hard Mater 90:105223. https://doi.org/10.1016/j.ijrmhm.2020.105223

Zhou D, Zeng W, Zhang D (2016) A feasible ultrafine grained cu matrix composite microstructure for achieving high strength and high electrical conductivity. J Alloys Compd 682:590–593. https://doi.org/10.1016/j.jallcom.2016.04.321

Ji R, Liu Y, Zhang Y, Wang F (2011) Machining performance of silicon carbide ceramic in end electric discharge milling. Int J Refract Met Hard Mater 29:117–122. https://doi.org/10.1016/j.ijrmhm.2010.09.001

Lim KY, Kim YW, Joo Kim K (2014) Electrical properties of SiC ceramics sintered with 0.5 wt% AlN-RE 2O3 (RE=Y, Nd, Lu). Ceram Int 40:8885–8890. https://doi.org/10.1016/j.ceramint.2013.12.157

Da Costa FA, Da Silva AGP, Umbelino Gomes U (2003) The influence of the dispersion technique on the characteristics of the W-cu powders and on the sintering behavior. Powder Technol 134:123–132. https://doi.org/10.1016/S0032-5910(03)00123-2

da Costa FA, da Silva AGP, Filho FA et al (2008) Synthesis of a nanocrystalline composite W-25 wt.%ag powder by high energy milling. Powder Technol 188:30–33. https://doi.org/10.1016/j.powtec.2008.03.009

Nikolopoulos P, Agatho Pou Los S, Angelopoulos GN et al (1992) Wettability and interfacial energies in SiC-liquid metal systems. J Mater Sci 27:139–145. https://doi.org/10.1007/BF02403656

Betke U, Sharma KSK, Rodak A et al (2016) Manufacturing of an electrically conducting cellular cu-SiC material by metal salt infiltration and chemical reduction (MESCAL). Mater Lett 185:201–203. https://doi.org/10.1016/j.matlet.2016.08.134

Zhu J, Liu L, Hu G et al (2004) Study on composite electroforming of cu/SiCp composites. Mater Lett 58:1634–1637. https://doi.org/10.1016/j.matlet.2003.08.040

Leszczyńska-Madej B, Garbiec D, Madej M (2019) Effect of sintering temperature on microstructure and selected properties of spark plasma sintered Al-SiC composites. Vacuum 164:250–255. https://doi.org/10.1016/j.vacuum.2019.03.033

Pandiyarajan R, Maran P, Marimuthu S, Prabakaran MP (2020) Investigation on mechanical properties of ZrO2, C and AA6061 metal matrix composites. Adv Mater Process Technol. https://doi.org/10.1080/2374068X.2020.1810946

Torabi H, Arghavanian R (2019) Investigations on the corrosion resistance and microhardness of cu–10Sn/SiC composite manufactured by powder metallurgy process. J Alloys Compd 806:99–105. https://doi.org/10.1016/j.jallcom.2019.07.245

Wang H, Zhang R, Hu X et al (2008) Characterization of a powder metallurgy SiC/cu-Al composite. J Mater Process Technol 197:43–48. https://doi.org/10.1016/j.jmatprotec.2007.06.002

Lin YC, Li HC, Liou SS, Shie MT (2004) Mechanism of plastic deformation of powder metallury metal matrix composites of cu-Sn/sic and 6061/SiC under compressive stress. Mater Sci Eng A 373:363–369. https://doi.org/10.1016/j.msea.2004.02.011

Surya MS, Kumar VN, Sridhar A (2022) To study the effect of varying sintering temperature and reinforcement on physical and mechanical characteristics of AA6061/SiC composites. Silicon. https://doi.org/10.1007/s12633-022-02233-1

Manikandan R, Arjunan TV, Akhil AR (2020) Studies on micro structural characteristics, mechanical and tribological behaviours of boron carbide and cow dung ash reinforced aluminium (Al 7075) hybrid metal matrix composite. Compos Part B Eng 183:107668. https://doi.org/10.1016/j.compositesb.2019.107668

Liu S, Wang Y, Muthuramalingam T, Anbuchezhiyan G (2019) Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos Part B Eng 176:107329. https://doi.org/10.1016/j.compositesb.2019.107329

Li X, Zhang M, Zhang G et al (2022) Effect of spark plasma sintering temperature on structure and performance characteristics of cu-20wt%W composite. J Alloys Compd 912:165246. https://doi.org/10.1016/j.jallcom.2022.165246

Venkatesh VSS, Deoghare AB (2022) Effect of sintering mechanisms on the mechanical behaviour of SiC and Kaoline reinforced hybrid Aluminium metal matrix composite fabricated through powder metallurgy technique. Silicon 14:5481–5493. https://doi.org/10.1007/s12633-021-01333-8

Venkatesh VSS, Deoghare AB (2020) Effect of controllable parameters on the tribological behavior of ceramic particulate reinforced aluminium metal matrix composites: a review. J Phys Conf Ser 1451. https://doi.org/10.1088/1742-6596/1451/1/012025

Venkatesh VSS, Deoghare AB (2022) Effect of microwave sintering on the mechanical characteristics of Al/kaoline/SiC hybrid composite fabricated through powder metallurgy techniques. Mater Chem Phys 287:126276. https://doi.org/10.1016/j.matchemphys.2022.126276

Mendoza-Duarte JM, Estrada-Guel I, Carreño-Gallardo C, Martínez-Sánchez R (2015) Study of Al composites prepared by high-energy ball milling; effect of processing conditions. J Alloys Compd 643:S172–S177. https://doi.org/10.1016/j.jallcom.2015.01.018

Venkatesh VSS, Rao RN (2023) Influence of microwave sintering temperatures on mechanical and microstructural behavior of Al/SiC/snail shell hybrid composite synthesized through powder metallurgy technique. Proc Inst Mech Eng Part C J Mech Eng Sci https://doi.org/10.1177/09544062231169120

Dědková K, Janíková B, Matějová K, et al (2015) Preparation, characterization and antibacterial properties of ZnO/kaoline nanocomposites. J Photochem Photobiol B Biol. https://doi.org/10.1016/j.jphotobiol.2015.03.034

Venkatesh VSS, Deoghare AB (2021) Modelling and optimisation of Wear parameters for spark plasma sintered Al – SiC – Kaoline hybrid composite modelling and optimisation of Wear parameters for spark plasma sintered Al – SiC – Kaoline hybrid composite. Adv Mater Process Technol 00:1–19. https://doi.org/10.1080/2374068X.2021.1939561

Liu A, Shi Z, Reddy RG (2020) Mechanism study of cu-Zn alloys electrodeposition in deep eutectic solvents. Ionics (Kiel) 26:3161–3172. https://doi.org/10.1007/s11581-019-03418-2

Wang X, Wei S, Xu L et al (2019) Effect of sintering temperature on fine-grained cu[sbnd]W composites with high copper. Mater Charact 153:121–127. https://doi.org/10.1016/j.matchar.2019.04.017

Tabassum N, Kotha M, Kaushik V et al (2018) On-demand CMOS-compatible fabrication of ultrathin self-aligned SiC nanowire arrays. Nanomaterials 8:1–14. https://doi.org/10.3390/nano8110906

Song X, Liu X, Zhang J (2006) Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J Am Ceram Soc 89:494–500. https://doi.org/10.1111/j.1551-2916.2005.00777.x

Venkatesh VSS, Prabhakara G, Patnaik L et al (2023) Processing and evaluation of nano SiC reinforced aluminium composite synthesized through ultrasonically assisted stir casting process. J Mater Res Technol 24:7394–7408. https://doi.org/10.1016/j.jmrt.2023.05.030

Venkatesh VSS, Deoghare AB (2021) Effect of sintering mechanisms on the mechanical behaviour of SiC and Kaoline reinforced hybrid Aluminium metal matrix composite fabricated through powder metallurgy technique. Silicon. https://doi.org/10.1007/s12633-021-01333-8

Manohar G, Pandey KM, Maity SR (2021) Effect of sintering mechanisms on mechanical properties of AA7075/B4C composite fabricated by powder metallurgy techniques. Ceram Int. https://doi.org/10.1016/j.ceramint.2021.02.073

Gu D, Shen Y (2008) Influence of cu-liquid content on densification and microstructure of direct laser sintered submicron W-cu/micron cu powder mixture. Mater Sci Eng A 489:169–177. https://doi.org/10.1016/j.msea.2007.12.008

Xiao Y, Lang L, Xu W, Zhang D (2022) Diffusion bonding of copper alloy and nickel-based superalloy via hot isostatic pressing. J Mater Res Technol 19:1789–1797. https://doi.org/10.1016/j.jmrt.2022.05.152

Jiang D, Long J, Cai M et al (2017) Femtosecond laser fabricated micro/nano interface structures toward enhanced bonding strength and heat transfer capability of W/cu joining. Mater Des 114:185–193. https://doi.org/10.1016/j.matdes.2016.11.094

Muthusamy P, Mohanraj M, Ramkumar T, Selvakumar M (2022) Effect of microwave sintering on the microstructure and tribological behavior of Ti-3Al-2.5 V-xWC composite. Tribol Int 174:107714. https://doi.org/10.1016/j.triboint.2022.107714

Zhang ZH, Wang FC, Lee SK et al (2009) Microstructure characteristic, mechanical properties and sintering mechanism of nanocrystalline copper obtained by SPS process. Mater Sci Eng A 523:134–138. https://doi.org/10.1016/j.msea.2009.07.016

Dong P, Wang Z, Wang W et al (2016) Understanding the spark plasma sintering from the view of materials joining. Scr Mater 123:118–121. https://doi.org/10.1016/j.scriptamat.2016.06.014

Ke S, Feng K, Zhou H, Shui Y (2019) Phase evolution of Mo-W-cu alloy rapid prepared by spark plasma sintering. J Alloys Compd 775:784–789. https://doi.org/10.1016/j.jallcom.2018.10.192

Acknowledgements

Authors like to thank Central Instrumentation Facility at National Institute of Technology Silchar for XRD analysis. The authors also would like to appreciate the Advance centre for Material Science at Indian Institute of Technology Kanpur for SEM and EDS analysis.

Author information

Authors and Affiliations

Contributions

V.S.S Venkatesh: Conceptualization, Experimentation, writing manuscript.

R.N.Rao: Data interpretation, data curation.

Lokeswar Patnaik: Experimentation, Editing the manuscript.

Corresponding author

Ethics declarations

The Authors declare that they don’t have known personal relationships or competing financial interest that could have appeared to influence the work reported in this manuscript.

Ethical Approval

No ethical issues arose throughout the course of writing the manuscript or conducting the experiments.

Consent to Participate

All of the Authors actively agreed to participate in this research.

Consent for Publication

This work has been approved for publication after receiving approval from all authors.

Research Involving Human Participants and/or Animals

Not applicable.

Informed Consent

Not applicable.

Competing Interests

The authors confirmed that they have no competing interests.

Disclosure of Potential Conflict of Interests

The authors declared that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Venkatesh, V.S.S., Rao, R.N. & Patnaik, L. Effect of Spark Plasma Sintering Temperature on Phase Evaluation and Mechanical Behaviour of cu- 4 Wt% SiC Composite. Silicon 15, 6439–6449 (2023). https://doi.org/10.1007/s12633-023-02530-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02530-3