Abstract

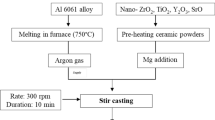

This study investigates the reciprocating wear behaviour of heat-treated ZrO2 reinforced Al7Si0.3Mg functionally graded composite under unlubricated conditions by varying the heat treatment conditions and applied load using Taguchi’s Design of Experiment methodology. The independent parameters chosen were ageing temperature (145, 165, 185 °C), ageing time (8, 10, 12 h), and applied load (20, 40, 60 N), whereas specific wear rate was the response parameter, as determined through Taguchi’s L27 Orthogonal Array. Wear performance was assessed using a pin-on-flat plate linear reciprocating tribometer. Statistical analysis and the percentage contribution of each process variable to the wear rate characteristics and their importance to the tribological behaviour was defined through ANOVA. Optimum wear rate was obtained at a parametric combination of 20 N load, 165 °C ageing temperature, and 10 h ageing time. The confirmation studies revealed an error percentage of 6 ± 2.5% for heat-treated composite when comparing the performance measures derived by optimal parameter values with experimental data. Analysis revealed that ageing temperature was the most influential factor, followed by applied load and ageing time. Atomic force microscopy and worn morphology analysis on the heat-treated composite revealed severe wear at extreme ageing and applied loads, and mild wear at optimum loading conditions. These composites are best suitable for pump parts and automotive piston-cylinder arrangements which involve reciprocating motion.

Similar content being viewed by others

Data Availability

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.

References

Mohamed MF, Yaknesh S, Radhakrishnan G, Mohankumar P (2020) Mater Today Proc 22:1203–1208. https://doi.org/10.1016/j.matpr.2019.12.122

Kumar TS, Shalini S, Priyadharshini GS (2021) Silicon 13:1051–1058. https://doi.org/10.1007/s12633-020-00492-4

Kumar H, Vashista M, Yusufzai MZK (2018) Trans Indian Inst Met 71(8):2025–2033. https://doi.org/10.1007/s12666-018-1335-7

Samal P, Vundavilli PR, Meher A, Mahapatra MM (2020) J Manuf Process 59:131–152. https://doi.org/10.1016/j.jmapro.2020.09.010

Jojith R, Radhika N (2019) Mater Res Express 6(11):1165c2. https://doi.org/10.1088/2053-1591/ab4dd7

Kumar TS, Nampoothiri J, Shalini S (2022) Silicon. https://doi.org/10.1007/s12633-021-01597-0

El-Galy IM, Saleh BI, Ahmed MH (2019) SN Appl Sci 1(11):1–23. https://doi.org/10.1007/s42452-019-1413-4

Pradeep AD, Rameshkumar T (2021) Mater Today Proc 45(2):729–734. https://doi.org/10.1016/j.matpr.2020.02.764

Radhika N, Raghu R (2015) Int J Mater Res 106(11):1174–1181. https://doi.org/10.3139/146.111293

Ambigai R, Prabhu S (2021) Silicon :1–12. https://doi.org/10.1007/s12633-021-01050-2

Saleh BI, Ahmed MH (2020) Met Mater Int 26(9):1430–1440. https://doi.org/10.1007/s12540-019-00391-3

Kumar B, Mer KKS, Prasad L (2019) Trends Mater Eng :1–11. https://doi.org/10.1007/978-981-13-9016-6_1

Savaş Ö (2020) Ind Lubr Tribol 72(10):1147–1152. https://doi.org/10.1108/ILT-12-2019-0538

Vijaya Kumar P, Jebakani D, Velmurugan C, Senthilkumar V (2022) Silicon 14(3):1247–1252. https://doi.org/10.1007/s12633-020-00933-0

Jojith R, Radhika N (2019) Mater Res Express 6(9):0965b8. https://doi.org/10.1088/2053-1591/ab1039

Roseline S, Paramasivam V (2019) J Alloys Compd 799:205–215. https://doi.org/10.1016/j.jallcom.2019.05.185

Harsha RN, Kulkarni MV, Babu BS (2020) Mater Today Proc 26(2):3100–3106. https://doi.org/10.1016/j.matpr.2020.02.641

Patil IS, Rao SS, Herbert MA, Goudar DM (2021) Adv Mater Process Technol :1–27. https://doi.org/10.1080/2374068X.2021.1927648

Savaş Ö (2020) Mater Today Commun 23:100920. https://doi.org/10.1016/j.mtcomm.2020.100920

Singh SP, Geethan KAV, Elilraja D, Prabhuram T, Durairaj JI (2020) Mater Today Proc 22:2824–2831. https://doi.org/10.1016/j.matpr.2020.03.414

Ekka KK, Chauhan SR (2015) Arab J Sci Eng 40(2):571–581. https://doi.org/10.1007/s13369-014-1528-2

Priyanka Muddamsetty LV, Radhika N (2016) Tribol Ind 38(1)

Rajeev VR, Dwivedi DK, Jain SC (2010) Tribol Int 43(8):1532–1541. https://doi.org/10.1016/j.triboint.2010.02.014

Rajeev VR, Dwivedi DK, Jain SC (2011) J Mater Eng Perform 20(3):368–376. https://doi.org/10.1007/s11665-010-9683-4

Yang X, Barekar NS, Ji S, Dhindaw BK, Fan Z (2020) J Mater Process Technol 279:116580. https://doi.org/10.1016/j.jmatprotec.2019.116580

Patil IS, Rao SS, Herbert MA, Kushwaha R (2021) Aust J Mech Eng :1–19. https://doi.org/10.1080/14484846.2021.1913872

Gomes JR, Ramalho A, Gaspar MC, Carvalho SF (2005) Wear 259:545–552. https://doi.org/10.1016/j.wear.2005.02.088

Gómez de Salazar JM, Barrena MI (2004) Wear 256:286–293. https://doi.org/10.1016/S0043-1648(03)00389-2

Mohandas A, Radhika N (2017) Tribol Ind 39(2)

Beroual S, Boumerzoug Z, Paillard P, Borjon-Piron Y (2019) J Alloys Compd 784:1026–1035. https://doi.org/10.1016/j.jallcom.2018.12.365

Sathyaseelan B, Manikandan E, Baskaran I, Senthilnathan K, Sivakumar K, Moodley MK, Ladchumananandasivam R, Maaza M (2017) J Alloys Compd 694:556–559. https://doi.org/10.1016/j.jallcom.2016.10.002

Askari E, Mehrali M, Metselaar IHSC, Kadri NA, Rahman MM (2012) J Mech Behav Biomed Mater 12:144–150. https://doi.org/10.1016/j.jmbbm.2012.02.029

Kumar PV, Jebakani D, Velmurugan C, Senthilkumar V (2021) Silicon :1–6. https://doi.org/10.1007/s12633-020-00933-0

Anilkumar V, Shankar KV, Balachandran M, Joseph J, Nived S, Jayanandan J, Jayagopan J, Balaji US (2021) Tribol Ind 43(4):590. https://doi.org/10.24874/ti.988.10.20.04

Radhika N, Jojith R, Thiagarajan NS, Ruthraprakash M (2020) Tribol Indu 42(3):513–527. https://doi.org/10.24874/ti.854.02.20.08

Vettivel SC, Selvakumar N, Narayanasamy R, Leema N (2013) Mater Des 50:977–996. https://doi.org/10.1016/j.matdes.2013.03.072

Baradeswaran A, ElayaPerumal A, Franklin Issac R (2013) Proced Eng 64:973–982. https://doi.org/10.1016/j.proeng.2013.09.174

Cruz KS, Meza ES, Fernandes FA, Quaresma JM, Casteletti LC, Garcia A (2010) Metall Mater Trans A 41(4):972–984. https://doi.org/10.1007/s11661-009-0161-2

Prasad CV, Rao KM (2018) Mater Today Proc 5(13):26843–26849. https://doi.org/10.1016/j.matpr.2018.08.166

Dey D, Bhowmik A, Biswas A (2020) Silicon 14:1–11. https://doi.org/10.1007/s12633-020-00757-y

Toptan F, Kerti I, Rocha LA (2012) Wear 290:74–85. https://doi.org/10.1016/j.wear.2012.05.007

Kumar GV, Rao CSP, Selvaraj N (2012) Compos Part B Eng 43(3):1185–1191. https://doi.org/10.1016/j.compositesb.2011.08.046

Lashgari HR, Zangeneh S, Shahmir H, Saghafi M, Emamy M (2010) Mater Des 31(9):4414–4422. https://doi.org/10.1016/j.matdes.2010.04.034

Menezes PL, Kailas SV (2009) Wear 266(1–2):103–109. https://doi.org/10.1016/j.wear.2008.05.008

Sam M, Radhika N (2021) Silicon 13(8):2671–2687. https://doi.org/10.1007/s12633-020-00623-x

Sharma S, Nanda T, Pandey OP (2019) Wear 426:27–36. https://doi.org/10.1016/j.wear.2018.12.065

Kumar CAV, Rajadurai JS (2016) Trans Nonferrous Met Soc China 26(1):63–73. https://doi.org/10.1016/S1003-6326(16)64089-X

Funding

This work was supported by Aeronautics Research and Development Board: [Grant Number ARDB/01/2031877/M/1].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Jojith R. The first draft of the manuscript was written by Jojith R, and Radhika N and M. Govindaraju commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no relevant financial or non-financial interests to disclose.

Ethics Approval

Not Applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jojith, R., Radhika, N. & Govindaraju, M. Reciprocating Wear Behavioural Analysis of Heat-treated Aluminium ZrO2/Al7Si0.3Mg Functionally Graded Composite Through Taguchi’s Optimization Method. Silicon 14, 11337–11354 (2022). https://doi.org/10.1007/s12633-022-01862-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-01862-w