Abstract

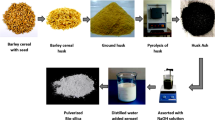

In this research stacked silicate nanoclay and red matta rice (Oryza longistaminata) husk ash (RHA) biosilica particles were used to make high toughness, impact damage resistance and biocompatible epoxy composites. The primary aim of this present research was to study the effect of adding silane treated stacked silicate nanoclay and red matta biosilica on mechanical, low-velocity impact damage and hydrophobic properties of ramie fibre-epoxy composites. As a concept of biomass conversion, the red matta-RHA based biosilica particle was synthesized using a thermo-chemical process and surface-treated with 3-Aminopropyltriethoxysilane (APTMS) via wet solution method. The ramie fibre-epoxy composites were made using hand layup method and cured at room temperature. The results concluded that the inclusion of nanoclay particles to the ramie fibre-epoxy composite increased the toughness and impact damage resistance. However, a large amount of biosilica addition leads marginal dip in the mechanical and drop load impact toughness. The hydrophobicity of silane-treated composites was closer to that of epoxy resin’s contact angle. For silane treated reinforcements, scanning electron microscope images revealed uniform dispersion and increased matrix adherence. These high toughness natural fibre composites using stacked nanoclay and red matta biosilica could be used as structural, automotive and defense applications since high load bearing properties are possible.

Similar content being viewed by others

Availability of Data and Material

No data available to deposit as private. There are no rights.

References

Raju P, Raja K, Lingadurai K, Maridurai T, and Prasanna SC. "Glass/Caryota urens hybridized fibre-reinforced nanoclay/SiC toughened epoxy hybrid composite: mechanical, drop load impact, hydrophobicity and fatigue behaviour." Biomass Conv Biorefinery (2021) 1–10

Vishnuvarthanan M, Al Shahidah MF, Gobika NR et al (2020) Effect of alumina silicate (MMT K10) Nanoclay on adhesion and barrier properties of cornstarch-based bioadhesive. Silicon. https://doi.org/10.1007/s12633-020-00732-7

Prolongo SG, Jiménez-Suárez A, Moriche R, Ureña A (2018) Influence of thickness and lateral size of graphene nanoplatelets on water uptake in epoxy/graphene nanocomposites. Appl Sci 8(9):1550

Ahn JH, Hong JS, Ahn KH (2021) Synergistic toughening effect of hybrid clay particles on poly (lactic acid)/natural rubber blend. Polym Compos 42(2):1021–1033

Arun Prakash VR, Xavier JF, Ramesh G et al (2020) Mechanical, thermal and fatigue behaviour of surface-treated novel Caryota urens fibre–reinforced epoxy composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-00938-0

Jayabalakrishnan D, Saravanan K, Ravi S, Prabhu P, Maridurai T, and Prakash VRA. "Fabrication and characterization of acrylonitrile butadiene rubber and stitched E-glass fibre tailored Nano-silica epoxy resin composite." Silicon (2020) 1–9

Prakash VRA, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos A: Appl Sci Manuf 118:317–326

Dinesh T, Kadirvel A, and Hariharan P. "Thermo-mechanical and wear behaviour of surface-treated pineapple woven fibre and nano-silica dispersed mahua oil toughened epoxy composite." Silicon (2020) 1–10

Kurien RA, Selvaraj DP, Koshy CP (2021) Worn surface morphological characterization of NaOH-treated chopped abaca fiber reinforced epoxy composites. J Bio Tribo-Corrosion 7(1):1–8

Arun Prakash VR, Jayaseelan V, Mothilal T, Kumar M, Depoures MV, Jayabalakrishnan D, and Ramesh G. "Effect of silicon coupling grafted ferric oxide and e-glass fibre in thermal stability, wear and tensile fatigue behaviour of epoxy hybrid composite." Silicon (2019) 1–12

Arun Prakash VR, Jaisingh SJ (2018) Mechanical strength behaviour of silane treated E-glass fibre/Al 6061 & SS-304 wire mesh reinforced epoxy resin hybrid composite. Silicon 10(5):2279–2286

Rajadurai A (2017) Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Defence Technol 13(1):40–46

Seghini MC, Touchard F, Sarasini F, Chocinski-Arnault L, Mellier D, Tirillò J (2018) Interfacial adhesion assessment in flax/epoxy and in flax/vinylester composites by single yarn fragmentation test: correlation with micro-CT analysis. Compos A: Appl Sci Manuf 113:66–75

Liu Y, Lv X, Bao J, Xie J, Xu T, Che J, Ma Y, Tong J (2019) Characterization of silane treated and untreated natural cellulosic fibre from corn stalk waste as potential reinforcement in polymer composites. Carbohydr Polym 218:179–187

Manikandan G, Jaiganesh V, Malarvannan RR, and Arun Prakash VR. "Mechanical and delamination studies on siliconized chitosan and morinda-citrifolia natural fiber-reinforced epoxy composite in drilling." Polymer Comp (2020)

Asim M, Jawaid M, Abdan K, Ishak MR (2018) The effect of silane treated fibre loading on mechanical properties of pineapple leaf/kenaf fibre filler phenolic composites. J Polym Environ 26(4):1520–1527

Karthigairajan M, Nagarajan PK, Raviraja Malarvannan R, Ramesh BR, Bapu D Jayabalakrishnan, Maridurai T, and Shanmuganathan VK. "Effect of silane-treated rice husk derived biosilica on visco-elastic, thermal conductivity and hydrophobicity behavior of epoxy biocomposite coating for air-duct application." Silicon (2020) 1–10

Anand, S. Hanish, N. Venkateshwaran, JV, Kumar SP, Kumar D, Ramesh Kumar C, and Maridurai T. "Optimization of Aging, Coating Temperature and Reinforcement Ratio on Biosilica Toughened in-situ Al-TiB2 Metal Matrix Composite: a Taguchi Grey Relational Approach." Silicon (2021) 1–11

Siregar JP, Zalinawati M, Cionita T, Rejab MRM, Mawarnie I, Jaafar J, Hamdan MHM (2021) Mechanical properties of hybrid sugar palm/ramie fibre reinforced epoxy composites. Mater Today: Proc 46:1729–1734

Krishnan G, Sai G, Shanmugasundar MV, Sivashanmugam N (2020) Mechanical properties of chemically treated Banana and ramie fibre reinforced polypropylene composites. In IOP Conf Ser: Mater Sci Eng 961(1):012013. IOP Publishing

Tyagita DA, Irawan A (2021) Strength and hardness of the engine mount prototype chopped composite fibre made from rubber compound and ramie fibre (Boehmeria nivea). In IOP Conf Series: Earth Environ Sci 672(1):012020. IOP Publishing

Santhi K, Aruna CS, Ajay Kumar R (2021) Experimental investigation of mechanical properties of jute-ramie fibres reinforced with epoxy hybrid composites. Mater Today: Proc 39:1309–1315

Steven S, Restiawaty E, Bindar Y (2021) Routes for energy and bio-silica production from rice husk: a comprehensive review and emerging prospect. Renew Sust Energ Rev 149:111329

Rajan B, Surya MA, Balaji S, Aslam M, Noorani AB (2019) Effect of silane surface treatment on the physico-mechanical properties of shell powder reinforced epoxy modified phenolic friction composite. Mater Res Express 6(6):065315

Miller A, Brown C, and Warner G. "Guidance on the use of existing ASTM polymer testing standards for ABS parts fabricated using FFF." Smart Sustain Manuf Syst 3(1) (2019)

Ben Samuel J, Julyes Jaisingh S, Sivakumar K et al (2021) Visco-elastic, thermal, antimicrobial and dielectric behaviour of Areca fibre-reinforced Nano-silica and Neem oil-toughened epoxy resin bio composite. Silicon 13:1703–1712. https://doi.org/10.1007/s12633-020-00569-0

Verma A, Negi P, Singh VK (2019) Experimental analysis on carbon residuum transformed epoxy resin: chicken feather fiber hybrid composite. Polym Compos 40(7):2690–2699

Thiyagu, TT, Sai Prasanna Kumar JV, Sathiyamoorthy V, and Arun Prakash VR. "Effect of cashew shell biomass synthesized cardanol oil green compatibilizer on flexibility, barrier, thermal, and wettability of PLA/PBAT biocomposite films." Biomass Conv Biorefinery (2021) 1–11

Rajeshkumar G, Arvindh Seshadri S, Ramakrishnan S, Sanjay MR, Siengchin S, and Nagaraja KC. "A comprehensive review on natural fiber/nano-clay reinforced hybrid polymeric composites: Materials and technologies." Polymer Comp (2021)

Mylsamy B, Palaniappan SK, Subramani SP, Pal SK, Aruchamy K (2019) Impact of nanoclay on mechanical and structural properties of treated Coccinia indica fibre reinforced epoxy composites. J Mater Res Technol 8(6):6021–6028

Raju P, Raja K, Lingadurai K, Maridurai T, Prasanna SC (2021) Mechanical, wear, and drop load impact behavior of glass/Caryota urens hybridized fiber-reinforced nanoclay/SiC toughened epoxy multihybrid composite. Polym Compos 42(3):1486–1496

Moyo M, Kanny K, Velmurugan R (2021) The efficacy of nanoclay loading in the medium velocity impact resistance of kenaf/PLA biocomposites. Appl Nanosci 11(2):441–453

Majid MS, Abdul M, Ridzuan JM, Lim KH (2020) Effect of nanoclay filler on mechanical and morphological properties of napier/epoxy composites. In interfaces in particle and fibre reinforced composites. Woodhead Publishing, Cambridge, pp 137–162

Devnani GL, Sinha S (2019) Effect of nanofillers on the properties of natural fiber reinforced polymer composites. Mater Today: Proc 18:647–654

Arun KK, Bala Theja M, Girisha L et al (2021) Time dependent behaviour of amino Silane-treated aramid fibre and waste latex rubber powder toughened epoxy composite. Silicon. https://doi.org/10.1007/s12633-021-01456-y

Wang A, Xian G, Li H (2019) Effects of fiber surface grafting with nano-clay on the hydrothermal ageing behaviors of flax fiber/epoxy composite plates. Polymers 11(8):1278

Acknowledgements

There is no funding body to acknowledge at this moment.

Funding

No funding received for this research work.

Author information

Authors and Affiliations

Contributions

All have done equal contribution.

Corresponding author

Ethics declarations

Yes this article compliance with ethical standards of journal.

Conflicts of Interest/Competing Interests

There is no conflict of interest by any form for this manuscript.

Consent to Participate

Yes. All permission granted.

Consent for Publication

Yes. All permission granted.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahalingam, S., Babu, A.S. Characterization of 3-Aminopropyltriethoxysilane Treated Stacked Silicate Nanoclay and Red Matta-RHA Biosilica Woven Ramie Fibre Epoxy Composite. Silicon 14, 8129–8139 (2022). https://doi.org/10.1007/s12633-021-01549-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01549-8