Abstract

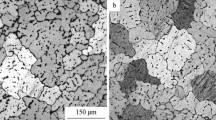

The effect of extrusion temperature and ratio on the microstructure, hardness, compression, and corrosion behavior of Mg−5Zn−1.5Y alloy were analyzed in this study. The microstructural observations revealed that the cast alloy consists of α-Mg grains, and Mg3Zn6Y and Mg3Zn3Y2 intermetallic compounds, mostly located on the α-Mg grain boundaries. Extruded alloy at higher temperatures showed coarser grain microstructures, whereas those extruded at higher ratios contained finer ones, although more dynamic recrystalized grains with lower intermetallics were measured at both conditions. Combined conditions of the lower temperature (340°C) and higher ratio (1:11.5) provided higher compressive strengths. However, no significant hardness improvement was achieved. The extrusion process could decrease the corrosion rate of the cast alloy in simulated body fluid for over 80% due to primarily the refined microstructure. The extrusion temperature showed a more pronounced effect on corrosion resistance compared to the extrusion ratio, and the higher the extrusion temperature, the higher the corrosion resistance.

Similar content being viewed by others

Change history

11 February 2022

An Erratum to this paper has been published: https://doi.org/10.1007/s12613-022-2433-4

References

M.Q. Wang and T.T. Tang, Surface treatment strategies to combat implant-related infection from the beginning, J. Orthop. Transl., 17(2019), p. 42.

A. O’Mahony and P. Spencer, Osseointegrated implant failures, J. Ir. Dent. Assoc., 45(1999), No. 2, p. 44.

H.X. Li, S.K. Qin, Y.Z. Ma, J. Wang, Y.J. Liu, and J.S. Zhang, Effects of Zn content on the microstructure and the mechanical and corrosion properties of as-cast low-alloyed Mg−Zn−Ca alloys, Int. J. Miner. Metall. Mater., 25(2018), No. 7, p. 800.

J.X. Chen, M. Gao, L.L. Tan, and K. Yang, Microstructure, mechanical and biodegradable properties of a Mg−2Zn−1Gd−0.5Zr alloy with different solution treatments, Rare Met., 38(2019), No. 6, p. 532.

E.L. Zhang, L.P. Xu, G.N. Yu, F. Pan, and K. Yang, In vivo evaluation of biodegradable magnesium alloy bone implant in the first 6 months implantation, J. Biomed. Mater. Res. A, 90(2009), No. 3, p. 882.

R. Bertolini, S. Bruschi, A. Ghiotti, L. Pezzato, and M. Dabalà, Large strain extrusion machining of magnesium alloys for biomedical applications, Procedia CIRP, 71(2018), p. 105.

Y.K. Kim, K.B. Lee, S.Y. Kim, K. Bode, Y.S. Jang, T.Y. Kwon, M.H. Jeon, and M.H. Lee, Gas formation and biological effects of biodegradable magnesium in a preclinical and clinical observation, Sci. Technol. Adv. Mater., 19(2018), No. 1, p. 324.

B. Chen, D.L. Lin, X.Q. Zeng, and C. Lu, Effects of yttrium and zinc addition on the microstructure and mechanical properties of Mg−Y−Zn alloys, J. Mater. Sci., 45(2010), No. 9, p. 2510.

H. Zengin, Y. Turen, H. Ahlatci, and Y. Sun, Microstructure, mechanical properties and corrosion resistance of as-cast and as-extruded Mg−4Zn−1La magnesium alloy, Rare Met., 39(2020), No. 8, p. 909.

M. Ali, M.A. Hussein, and N. Al-Aqeeli, Magnesium-based composites and alloys for medical applications: A review of mechanical and corrosion properties, J. Alloys Compd., 792(2019), p. 1162.

H. Jafari, F. Rahimi, Z. Sheikhsofla, and M. Khalilnezhad, Effect of minor yttrium on microstructure and mechanical properties of bioimplant Mg−5Zn alloy, J. Mater. Eng. Perform., 26(2017), No. 11, p. 5590.

X.G. Sun, M. Nouri, Y. Wang, and D.Y. Li, Corrosive wear resistance of Mg-Al-Zn alloys with alloyed yttrium, Wear, 302(2013), No. 1–2, p. 1624.

B.Q. Shi, R.S. Chen, and W. Ke, Effects of yttrium and zinc on the texture, microstructure and tensile properties of hot-rolled magnesium plates, Mater. Sci. Eng. A, 560(2013), p. 62.

D.K. Xu, W.N. Tang, L. Liu, Y.B. Xu, and E.H. Han, Effect of W-phase on the mechanical properties of as-cast Mg−Zn−Y−Zr alloys, J. Alloys Compd., 461(2008), No. 1–2, p. 248.

K.B. Nie, Z.H. Zhu, K.K. Deng, and J.G. Han, Influence of extrusion parameters on microstructure, texture and mechanical properties of a low Mn and high-Ca containing Mg−2.9Zn−1.1Ca−0.5 Mn magnesium alloy, J. Mater. Res. Technol., 9(2020), No. 3, p. 5264.

Y.Z. Ma, C.L. Yang, Y.J. Liu, F.S. Yuan, S.S. Liang, H.X. Li, and J.S. Zhang, Microstructure, mechanical, and corrosion properties of extruded low-alloyed Mg−xZn−0.2Ca alloys, J. Miner. Metall. Mater., 26(2019), No. 10, p. 1274.

F.D. Mohammadi and H. Jafari, Microstructure characterization and effect of extrusion temperature on biodegradation behavior of Mg−5Zn−1Y−xCa alloy, Trans. Nonferrous Met. Soc. China, 28(2018), No. 11, p. 2199.

C.J. Li, H.F. Sun, and W.B. Fang, Effect of extrusion temperatures on microstructures and mechanical properties of Mg−3Zn−0.2Ca−0.5Y alloy, Procedia Eng., 81(2014), p. 610.

H.Y. Niu, F.F. Cao, K.K. Deng, K.B. Nie, J.W. Kang, and H.W. Wang, Microstructure and corrosion behavior of the as-extruded Mg−4Zn−2Gd−0.5Ca alloy, Acta Metall. Sin. Engl. Lett., 33(2020), No. 3, p. 362.

X.F. Wu, C.X. Xu, J. Kuan, Z.W. Zhang, J.S. Zhang, and W.F. Yang, Effects of hot extrusion temperature on mechanical and corrosion properties of Mg−Y−Zn−Zr biological magnesium alloy containing W phase and I phase, Materials, 13(2020), No. 5, art. No. 1147.

M. Shiri and H. Jafari, Effect of extrusion temperature and extrusion ratio on microstructure and biodegradation behavior of Mg−4.5Zn binary alloy, JOM, 71(2019), No. 12, p. 4705.

X.B. Zhang, G.Y. Yuan, L. Mao, J.L. Niu, P.H. Fu, and W.J. Ding, Effects of extrusion and heat treatment on the mechanical properties and biocorrosion behaviors of a Mg−Nd−Zn−Zr alloy, J. Mech. Behav. Biomed. Mater., 7(2012), p. 77.

L.B. Tong, M.Y. Zheng, L.R. Cheng, S. Kamado, and H.J. Zhang, Effect of extrusion ratio on microstructure, texture and mechanical properties of indirectly extruded Mg−Zn−Ca alloy, Mater. Sci. Eng. A, 569(2013), p. 48.

X.B. Zhang, G.Y. Yuan, and Z.Z. Wang, Effects of extrusion ratio on microstructure, mechanical and corrosion properties of biodegradable Mg−Nd−Zn−Zr alloy, Mater. Sci. Technol., 29(2013), No. 1, p. 111.

Y. Lee, S.I. Lee, and J. Yoon, Effect of the extrusion ratio on the mechanical properties of as-forged Mg−8Al−0.5Zn alloy, Int. J. Precis. Eng. Manuf. Green Technol., 2(2015), No. 3, p. 275.

H. Jafari, F. Rahimi, and Z. Sheikhsofla, In vitro corrosion behavior of Mg−5Zn alloy containing low Y contents, Mater. Corros., 67(2016), No. 4, p. 396.

N. Tahreen and D.L. Chen, A critical review of Mg−Zn−Y series alloys containing I, W, and LPSO phases, Adv. Eng. Mater., 18(2016), No. 12, p. 1983.

S.Y. Wang, L. Gao, A.A. Luo, D.J. Li, and X.Q. Zeng, Hot deformation behavior and workability of pre-extruded ZK60A magnesium alloy, Trans. Nonferrous Met. Soc. China, 25(2015), No. 6, p. 1822.

S.H. Kim, S.W. Lee, B.G. Moon, H.S. Kim, Y.M. Kim, and S.H. Park, Influence of extrusion temperature on dynamic deformation behaviors and mechanical properties of Mg−8Al−0.5Zn−0.2Mn−0.3Ca−0.2Y alloy, J. Mater. Res. Technol., 8(2019), No. 6, p. 5254.

Y.X. Niu, Z.T. Song, Q.C. Le, J. Hou, and F.K. Ning, Excellent mechanical properties obtained by low temperature extrusion based on Mg−2Zn−1Al alloy, J. Alloys Compd., 801(2019), p. 415.

X. Liu, Z.Q. Zhang, W.Y. Hu, Q.C. Le, L. Bao, and J.Z. Cui, Effects of extrusion speed on the microstructure and mechanical properties of Mg−9Gd−3Y−1.5Zn−0.8Zr alloy, J. Mater. Sci. Technol., 32(2016), No. 4, p. 313.

J.F. Wang, Z.S. Wu, S. Gao, R.P. Lu, D.Z. Qin, W.X. Yang, and F.S. Pan, Optimization of mechanical and damping properties of Mg−0.6Zr alloy by different extrusion processing, J. Magnesium Alloys, 3(2015), No. 1, p. 79.

J.C. Sun, Y.L. Ma, H.W. Miao, K.J. Li, C.H. Li, and H. Huang, Effect of Ca concentration on microstructure and mechanical properties of as-cast and as-extruded quasicrystal-strengthened Mg−7.2Zn−2.4Gd alloy, Adv. Mater. Sci. Eng., 2018(2018), art. No. 9138753.

X. Zhao, S.C. Li, Y. Xue, and Z.M. Zhang, An investigation on microstructure, texture and mechanical properties of AZ80 Mg alloy processed by annular channel angular extrusion, Materials, 12(2019), No. 6, art. No. 1001.

Z.J. Yu, C. Xu, J. Meng, K. Liu, J.L. Fu, and S. Kamado, Effects of extrusion ratio and temperature on the mechanical properties and microstructure of as-extruded Mg−Gd−Y−(Nd/Zn)−Zr alloys, Mater. Sci. Eng. A, 762(2019), art. No. 138080.

H. Ma, Z.H. Huang, Y. Yao, H. Zhang, Z.M. Zhang, C.J. Xu, Y.H. Kang, S.C. Wang, M. Kuang, and J.C. Huang, Evolution of microstructures and mechanical properties of Mg−1.4Gd−1.2Y−0.4Zn−0.5Al sheets with different extrusion ratios, J. Alloys Compd., 817(2020), art. No. 152769.

H.F. Sun, C.J. Li, and W.B. Fang, Evolution of microstructure and mechanical properties of Mg−3.0Zn−0.2Ca−0.5Y alloy by extrusion at various temperatures, J. Mater. Process. Technol., 229(2016), p. 633.

Z.R. Zeng, N. Stanford, C.H.J. Davies, J.F. Nie, and N. Birbilis, Magnesium extrusion alloys: A review of developments and prospects, Int. Mater. Rev., 64(2019), No. 1, p. 27.

Z. Zhang, J.H. Zhang, J. Wang, Z.H. Li, J.S. Xie, S.J. Liu, K. Guan, and R.Z. Wu, Toward the development of Mg alloys with simultaneously improved strength and ductility by refining grain size via the deformation process, Int. J. Miner. Metall. Mater., 28(2021), No. 1, p. 30.

K. Sheng, L.W. Lu, Y. Xiang, M. Ma, and Z.C. Wang, Microstructure and mechanical properties of AZ31 Mg alloy fabricated by pre-compression and frustum shearing extrusion, Acta Metall. Sinica Engl. Lett., 32(2019), No. 2, p. 235.

J.Y. Yang and W.J. Kim, Effect of I(Mg3YZn6)-, W(Mg3Y2Zn3)-and LPSO(Mg12ZnY)-phases on tensile work-hardening and fracture behaviors of rolled Mg−Y−Zn alloys, J. Mater. Res. Technol., 8(2019), No. 2, p. 2316.

P. Hidalgo-Manrique, J.D. Robson, and M.T. Pérez-Prado, Precipitation strengthening and reversed yield stress asymmetry in Mg alloys containing rare-earth elements: A quantitative study, Acta Mater., 124(2017), p. 456.

G. Lou, S.M. Xu, X.Y. Teng, Z.J. Ye, P. Jia, H. Wu, J.F. Leng, and M. Zuo, Effects of extrusion on mechanical and corrosion resistance properties of biomedical Mg−Zn−Nd−xCa alloys, Materials, 12(2019), No. 7, art. No. 1049.

Y.Z. Du, Y.F. Ge, and B.L. Jiang, Dynamic precipitation behavior of a Mg−Zn−Ca−La alloy during deformation, JOM, 71(2019), No. 7, p. 2202.

Y.J. Zhang, C.W. Yan, F.H. Wang, and W.F. Li, Electrochemical behavior of anodized Mg alloy AZ91D in chloride containing aqueous solution, Corros. Sci., 47(2005), No. 11, p. 2816.

J.B. Jordon, V. Miller, V.V. Joshi, and N.R. Neelameggham, Magnesium Technology 2020, Springer, Cham, 2020.

J.G. Li, Y. Yang, H.J. Deng, M.M. Li, J.F. Su, F.P. Hu, X.M. Xiong, and X.D. Peng, Microstructure and corrosion behavior of as-extruded Mg−6.5Li−xY−yZn alloys, J. Alloys Compd., 823(2020), art. No. 153839.

Acknowledgement

The authors are very thankful to Shahid Rajaee Teacher Training University for supporting the experiments of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Jafari, H., Tehrani, A.H.M. & Heydari, M. Effect of extrusion process on microstructure and mechanical and corrosion properties of biodegradable Mg−5Zn−1.5Y magnesium alloy. Int J Miner Metall Mater 29, 490–502 (2022). https://doi.org/10.1007/s12613-021-2275-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2275-5