Abstract

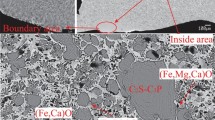

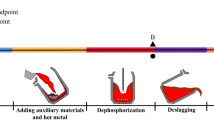

At low basicity and low temperature, the dephosphorization behavior and phosphorus distribution ratio (LP) between slag and molten steel in the double slag and remaining slag process were studied with a 180 t basic oxygen furnace industrial experiment. The dephosphorization slags with different basicities were quantitatively analyzed. At the lower basicity range of 0.9–2.59, both LP and dephosphorization ratio were increased as the basicity of dephosphorization slag increased. Dephosphorization slag consisted of dark gray P-rich, light gray liquid slag, and white Fe-rich phases. With increasing basicity, not only did the morphologies of different phases in the dephosphorization slag change greatly, but the area fractions and P2O5 content of the P-rich phase also increased. The transfer route of P during dephosphorization can be deduced as hot metal → liquid slag phase + Fe-rich phase → P-rich phase.

Similar content being viewed by others

References

Y. Ogawa, M. Yano, S.-Y. Kitamura, and H. Hirata, Development of the continuous dephosphorization and decarburization process using BOF, Steel Res. Int., 74(2003), No. 2, p. 70.

N. Sasaki, Y. Ogawa, S. Mukawa, and K.-I. Miyamoto, Improvement in hot-metal dephosphorization, Nippon Steel Tech. Rep., 104(2013), p. 26.

M. Kobayashi, K. Isobe, and M. Arai, Technical progress in steelmaking and casting for special bar and wire steel at muroran works, Nippon Steel Tech. Rep., 394(2012), p. 119.

X.H. Wang, G.S. Zhu, H.B. Li, and Y.C. Lü, Investigation on “slag-remaining + double-slag” BOF steelmaking technology, China Metall., 23(2013), No. 4, p. 40.

X. Yang, F.M. Sun, J.L. Yang, F. Liu, K.S. Cheng, and J. H. Wang, Optimization of low phosphorus steel production with double slag process in BOF, J. Iron Steel Res. Int., 20(2013), No. 8, p. 41.

Z.H. Tian, B.H. Li, X.M. Zhang, and Z.H. Jiang, Double slag operation dephosphorization in BOF for producing low phosphorus steel, J. Iron Steel Res. Int., 16(2009), No. 3, p. 6.

J.F. Lü, Z.N. Jin, H.Y. Yang, L.L. Tong, G.B. Chen, and F.X. Xiao, Effect of the CaO/SiO2 mass ratio and FeO content on the viscosity of CaO-SiO2-“FeO”-12wt%ZnO-3wt%Al2O3 slags, Int. J. Miner. Metall. Mater., 24(2017), No. 7, p. 756.

S. Kitamura, H. Shibata K. Shimauchi, and S. Saito, The importance of dicalcium-silicate on hot metal dephosphorization reaction, Revue De Métallurgie, 105(2008), No. 5, p. 263.

K. Ito, M. Yanagisawa, and N. Sano, Phosphorus distribution between solid 2CaO·SiO2 and molten CaO-SiO2-FeO-Fe2O3 slags, Tetsu-To-Hagané, 68(1982), No. 2, p. 342.

S. Kitamura, H. Shibata, and N. Maruoka, Kinetic model of hot metal dephosphorization by liquid and solid coexisting slags, Steel Res. Int., 79(2008), No. 8, p. 586.

L. Lin, Y.P. Bao, M. Wang, H.M. Zhou, and L.Q. Zhang, Influence of SiO2 modification on phosphorus enrichment in P bearing steelmaking slag, Ironmaking Steelmaking, 40(2013), No. 7, p. 521.

J.Y. Li, M. Zhang, M. Guo, and X.M. Yang, Enrichment mechanism of phosphate in CaO-SiO2-FeO-Fe2O3-P2O5 steelmaking slags, Metall. Mater. Trans. B, 45(2014), No. 5, p. 1666.

X. Gao, H. Matsuura, and F. Tsukihashi, Phase equilibrium for the CaO-SiO2-FeO-P2O5 system at 1673 K for dephosphorization with multi phase flux, J. Iron Steel Res. Int., 18(2011), Suppl. 2, p. 84.

X. Gao, H. Matsuura, I. Sohn, W.L. Wang, D.J. Min, and F. Tsukihashi, Phase relationship for the CaO-SiO2-FeO-5 mass% P2O5 system with oxygen partial pressure of 10-8 atm at 1673 and 1623 K, Mater. Trans., 54(2013), No. 4, p. 544.

S. Kitamura, S. Saito, K. Utagawa, H. Shibata, and D.G.C. Robertson, Mass transfer of P2O5 between liquid slag and solid solution of 2CaO·SiO2 and 3CaO·P2O5, ISIJ Int., 49(2009), No. 12, p. 1838.

S.L. Xie, W.L. Wang, Z.C. Luo, and D.Y. Huang, Mass transfer behavior of phosphorus from the liquid slag phase to solid 2CaO·SiO2 in the multiphase dephosphorization slag, Metall. Mater. Trans. B, 47(2016), No. 3, p. 1583.

R. Inoue and H. Suito, Phosphorous partition between 2CaO·SiO2 particles and CaO-SiO2-FetO slags, ISIJ Int., 46(2006), No. 2, p. 174.

K. Shimauchi, S. Kitamura, and H. Shibata, Distribution of P2O5 between solid dicalcium silicate and liquid phases in CaO-SiO2-Fe2O3 system, ISIJ Int., 49(2009), No. 4, p. 505.

X. Yang, H. Matsuura, and F. Tsukihashi, Reaction behavior of P2O5 at the interface between solid 2CaO·SiO2 and liquid CaO-SiO2-FeOx-P2O5 slags saturated with solid 5CaO·SiO2·P2O5 at 1573 K, ISIJ Int., 50(2010), No. 5, p. 702.

X. Yang, H. Matsuura, and F. Tsukihashi, Dissolution behavior of solid 5CaO·SiO2·P2O5 in CaO-SiO2-FeOx slag, Mater. Trans., 51(2010), No. 6, p. 1094.

X. Yang, H. Matsuura, and F. Tsukihashi, Condensation of P2O5 at the interface between 2CaO·SiO2 and CaO-SiO2-FeOx-P2O5 slag, ISIJ Int., 49(2009), No. 9, p. 1298.

C.M. Du, X. Gao, S. Ueda, and S. Kitamura, Distribution of P2O5 and Na2O between solid solution and liquid phase in the CaO-SiO2-Fe2O3-P2O5-Na2O slag system with high P2O5 content, Metall. Mater. Trans. B, 49(2018), No. 1, p. 181.

L. Lin, Y.P. Bao, C. Gu, W. Wu, and J.Q. Zeng, Distribution of P2O5 between P-rich phase and matrix phase in P-bearing steel-making slag, High Temp. Mater. Proc., 37(2018), No. 7, p. 655.

F. Pahlevani, S. Kitamura, H. Shibata, and N. Maruoka, Distribution of P2O5 between solid solution of 2CaO·SiO2-3CaO·P2O5 and liquid phase, ISIJ Int., 50(2010), No. 6, p. 822.

K. Ito and M. Terasawa, Utilization of multiphase fluxes for the dephosphorization of hot metal, Steel Res. Int., 80(2009), No. 10, p. 733.

T. Hamano, S. Fukagai, and F. Tsukihashi, Reaction mechanism between solid CaO and FeOx-CaO-SiO2-P2O5 slag at 1573 K, ISIJ Int., 46(2006), No. 4, p. 490.

X. Gao, H. Matsuura, I. Sohn, W.L Wang, D.J. Min, and F. Tsukihashi, Phase relationship of CaO-SiO2-FeO-5 mass pct P2O5 system with low oxygen partial pressure at 1673 K (1400°C), Metall. Mater. Trans. B, 43(2012), No. 4, p. 694.

S.L. Xie and W.L. Wang, Crystallization kinetics study of the (2CaO·SiO2-3CaO·P2O5) solid solution in the multiphase dephosphorization flux, Steel Res. Int., 87(2016), No. 3, p. 376.

G.W. Healy, New look at phosphorus distribution, J. Iron Steel Inst. (London), 208(1970), No. 7, p. 664.

H. Suito and R. Inoue, Phosphorus distribution between MgO-saturated CaO-FetO-SiO2-P2O5-MnO slags and liquid iron, Trans. Iron Steel Inst. Jpn., 24(1984), No. 1, p. 40.

K. Ide and R.J. Fruehan, Evaluation of phosphorus reaction equilibrium in steelmaking, Iron Steelmaker, 27(2000), No. 12, p. 65.

X.F. Zhang, I.D. Sommerville, and J.M. Toguri, Equation for the equilibrium distribution of phosphorus between basic slags and steel, Trans. Iron Steel Soc. AIME, 6(1985), p. 29.

H.M. Zhou, Y.P. Bao, and L. Lin, Effect of P2O5 on rich phosphorus phase of CaO-SiO2-FetO-P2O5 slag, China Metall., 23(2013), No. 1, p. 45.

S.L. Xie, W.L. Wang, D.Y. Huang, H.C. Li, and Y. Du, Clarification of the dissolution of solid CaO and the phosphorus-enrichment capability of calcium silicates in the multiphase slag based on the ion and molecule coexistence theory, Steel Res. Int., 89(2018), No. 2, art. No. 1700317.

Acknowledgement

This work was financially supported by the National Natural Science Foundation of China (No. U1960202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ye, Gf., Yang, J., Zhang, Rh. et al. Behavior of phosphorus enrichment in dephosphorization slag at low temperature and low basicity. Int J Miner Metall Mater 28, 66–75 (2021). https://doi.org/10.1007/s12613-020-2036-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2036-x