Abstract

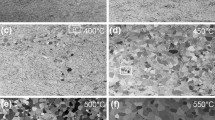

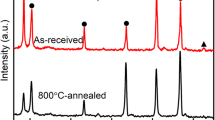

X-ray diffraction (XRD) was employed to analyze the texture evolution of commercial pure (CP) Ti during cold rolling and recrystallization annealing. The texture components were measured by electron backscattered diffraction (EBSD) after recrystallization annealing. The CP Ti tends to form a texture with the basal pole tilted 30°–40° away from the normal direction toward the transverse direction. The texture of the initial hot-rolled plate can be classified into three kinds, i.e., the pyramid texture \(\left( {\bar 1013} \right)\left[ {5\bar 2\bar 30} \right]\) and \(\left( {\bar 2021} \right)\left[ {10\bar 15} \right]\), the basal plane texture \(\left( {0001} \right)\left[ {2\bar 1\bar 10} \right]\), and the stronger prism texture \(\left( {11\bar 20} \right)\left[ {0001} \right]\). After cold rolling and annealing (700°C, 60 min), the main texture components are the cold-rolled texture \(\left( {11\bar 25} \right)\left[ {11\bar 23} \right]\) and the recrystallized texture \(\left( {\bar 1013} \right)\left[ {5\bar 2\bar 30} \right]\). The texture \(\left( {\bar 2021} \right)\left[ {10\bar 15} \right]\) is inherited from the texture of the initial hot-rolled plate with the decrease of orientation density gradually. The volume contents of the cold-rolled texture \(\left\{ {\bar 2115} \right\}\left\langle {01\bar 10} \right\rangle\) and the recrystallized texture \(\left\{ {10\bar 13} \right\}\left\langle {1\bar 210} \right\rangle\) are calculated by EBSD. After recrystallization annealing, the specimen is rich in the recrystallized texture and inherits some of texture components from the cold-rolled texture. When the annealing time is prolonged, the anisotropic value decreases.

Similar content being viewed by others

References

M.H. Yoo, Slip, twinning, and fracture in hexagonal close-packed metals, Metall. Trans. A, 12(1981), No.3, p.409

M.J. Philippe, M. Serghat, P. Van Houtte, and C. Esling, Modelling of texture evolution for materials of hexagonal symmetry: II. Application to zirconium and titanium α or near α alloys, Acta Metall. Mater., 43(1995), No.4, p.1619

Z.S. Zhu, J.L. Gu, N.P. Chen, and Z.S. Yang, Research on the relationship between texture and mechanical property anisotropy in commercially pure titanium sheets, Mater. Mech. Eng., 18(1994), No.2, p.23.

Z.S. Zhu, J.L. Gu, and N.P. Chen, The influence of cold rolling on the formation of recrystallization texture in titanium sheet, Mater. Sci. Technol., 3(1995), No.2, p.49.

Z.S. Zhu, M.G. Yan, J.L. Gu, and N.P. Chen, Investigation of phase transformation textures and their influence factors in titanium sheet, J. Aeronaut. Mater., 16(1996), No.1, p.19.

N. Bozzolo, N. Dewobroto, T. Grosdidier, and F. Wagner, Texture evolution during grain growth in recrystallized commercially pure titanium, Mater. Sci. Eng. A, 397(2005), No.1–2, p.346.

Z.P. Zeng, S. Jonsson, and H. J. Roven, The effects of deformation conditions on microstructure and texture of commercially pure Ti, Acta Mater., 57(2009), No.19, p.5822.

Z.P. Zeng, Y.S. Zhang, and S. Jonsson, Microstructure and texture evolution of commercial pure titanium deformed at elevated temperatures, Mater. Sci. Eng. A, 513–514(2009), p.83.

Y.B. Chun, S.H. Yu, S.L. Semiatin, and S.K. Hwang, Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium, Mater. Sci. Eng. A, 398(2005), No.1–2, p.209.

G. Proust, C.N. Tomé, and G.C. Kaschner, Modeling texture, twinning and hardening evolution during deformation of hexagonal materials, Acta Mater., 55(2007), No.6, p.2137.

Y.N. Wang and J.C. Huang, Texture analysis in hexagonal materials, Mater. Chem. Phys., 81(2003), No.1, p.11.

J.M. Liu, I.G. Chen, T.S. Chou, and S.S. Chou, On the deformation texture of square-shaped deep-drawing commercially pure Ti sheet, Mater. Chem. Phys., 77(2003), No.3, p.765.

T. Ungár, M.G. Glavicic, L. Balogh, K. Nyilas, A.A. Salem, G. Ribárik, and S.L. Semiatin, The use of X-ray diffraction to determine slip and twinning activity in commercial-purity (CP) titanium, Mater. Sci. Eng. A, 493(2008), No.1–2, p.79.

G.G.E. Seward, S. Celotto, D.J. Prior, J. Wheeler, and R.C. Pond, In situ SEM-EBSD observations of the hcp to bcc phase transformation in commercially pure titanium, Acta Mater., 52(2004), No.4, p.821.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Ht., Liu, Jx., Mi, Zl. et al. Texture evolution of commercial pure Ti during cold rolling and recrystallization annealing. Int J Miner Metall Mater 19, 530–535 (2012). https://doi.org/10.1007/s12613-012-0591-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0591-5